Instrumentation & Controls - Siemens

Instrumentation & Controls - Siemens

Instrumentation & Controls - Siemens

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

<strong>Instrumentation</strong> & <strong>Controls</strong><br />

<strong>Instrumentation</strong><br />

& <strong>Controls</strong><br />

<strong>Siemens</strong> Power Generation<br />

Control System Training Programs 2006<br />

Power Generation

Training Catalog

Table of Contents<br />

General Training Information 2<br />

Course Overview and Curriculum 4<br />

Registration 6<br />

Course Descriptions<br />

Hardware/Software Configuration<br />

and Maintenance 8<br />

PCS7 Hardware Configuration/Maintenance 9<br />

TXP Hardware Configuration/Maintenance 10<br />

TXP Control Logic Configuration 11<br />

TXP Graphics Configuration 15<br />

TXP Control Logic Maintenance 16<br />

TXP Graphics Maintenance 17<br />

TXP Advanced Logic Configuration 18<br />

TXP Archiving, Reporting, and Calculation 19<br />

TXP System Administration 20<br />

PCS7 Control Logic Configuration 21<br />

PCS7 Graphics Configuration 22<br />

TXP Governor Familiarity 23<br />

TXP Operator Training 24<br />

TXP Turbine and Boiler Protection 25<br />

TXP Static Frequency Converter /<br />

Static Excitation System 26<br />

PCS7 Operator Training 27<br />

PCS7 Maintenance Training 28<br />

SPPA-T3000 Process Control System<br />

System Overview 29<br />

SPPA-T3000 Process Control System<br />

System Basics 30<br />

SPPA-T3000 Process Control System<br />

Advanced Engineering 31<br />

SPPA-T3000 Process Control System<br />

Operation and Monitoring 32<br />

SPPA-T3000 Process Control System<br />

System Maintenance 33

Your I&C Training Partner<br />

As the only OEM in the controls business, <strong>Siemens</strong><br />

Power Generation offers unparalleled power industry<br />

experience and customer service, backed by our global<br />

network of more than 30,000 power generation employees.<br />

We are committed to meeting and exceeding customer expectations<br />

and requirements to maximize our customers’ operating<br />

plant service.<br />

This commitment includes product knowledge transfer for<br />

our <strong>Instrumentation</strong> & <strong>Controls</strong> (I&C) customers. Our comprehensive,<br />

hands-on I&C customer training program gives<br />

your personnel the knowledge to troubleshoot and maintain<br />

your plant's control system. This ability can translate into<br />

shorter outage times, increased In-Market Availability (IMA),<br />

and increased profitability for your plant.<br />

Our training program is a critical component of the <strong>Siemens</strong><br />

solutions suite. We've designed our training solutions around<br />

the needs of the learner, incorporating solid curricula and<br />

blended learning techniques that include instructor-led and<br />

hands-on training. Our top-notch trainers have years of power<br />

plant and classroom training experience to meet the demands<br />

of today's plant professionals. Students leave understanding<br />

how the TXP control system integrates with existing equipment<br />

and with the confidence to operate and maintain the<br />

control systems throughout your fleet.<br />

Thank you for giving us the opportunity to serve your<br />

training needs. We appreciate your business and strive to<br />

do all we can to ensure that your company receives personal<br />

and professional I&C training.<br />

We always enjoy hearing from our customers, so please feel<br />

free to email us if you have feedback regarding our training<br />

solutions at I&C.Training@swpc.siemens.com<br />

1

Training Catalog<br />

General information<br />

It is our opinion that customer training is<br />

considered one of the most important parts of<br />

any project and is heavily emphasized within<br />

<strong>Siemens</strong> Power Generation. In line with our Total<br />

Quality Management and training policies,<br />

<strong>Siemens</strong> is able to provide a complete customer<br />

training program, which ensures full knowledge<br />

transfer.<br />

Exact training requirements, however, can vary<br />

considerably from customer to customer. For this<br />

reason, <strong>Siemens</strong> offers both standard training<br />

courses and customer specific training programs.<br />

To help you decide which course is more suitable<br />

for you, we have assigned experienced technical<br />

support professionals to help you with your training<br />

requirements.<br />

All classes are offered in Alpharetta, GA, unless<br />

otherwise noted.<br />

2 www.sea.siemens.com/sitrain

Training Catalog<br />

Typical courses cover:<br />

• System concept overview<br />

• System operation<br />

• Operating and monitoring system<br />

• Automation system<br />

• Engineering system<br />

• Network<br />

• Function modules<br />

• System planning, assembly, configuration,<br />

operation and servicing<br />

• Alarm and fault diagnosis<br />

• Field devices<br />

• System simulation/demonstration<br />

• Diagnostics and maintenance<br />

Training program<br />

<strong>Siemens</strong> will provide training<br />

support, additional courses,<br />

course extensions, or repeat<br />

courses for the customer<br />

throughout the lifetime<br />

of the installed system.<br />

In the event of such training,<br />

<strong>Siemens</strong> will discuss the precise<br />

requirements with the<br />

customer in order to agree<br />

to the necessary terms and<br />

conditions.<br />

• Possibilities to connect third-party components<br />

The courses also include the following:<br />

• Preparation material<br />

• <strong>Siemens</strong> overview<br />

• Visit to our manufacturing locations<br />

• Visit to our test center<br />

www.sea.siemens.com/sitrain 3

Course Overview<br />

On-site training<br />

When five or more people require training, on-site<br />

training can be the best value. The on-site course<br />

will include all course material, rental, and freight<br />

of equipment, as well as travel expenses of the instructor.<br />

The price for our standard on-site course is given upon<br />

request.<br />

In addition to the standard course, <strong>Siemens</strong> offers<br />

customized training specific to your power plant<br />

requirements. These courses will consist of training on<br />

plant specific hardware and software.<br />

These prices do not include student travel expenses<br />

and lodging. They are based on a minimum of five and<br />

a maximum of ten students in class.<br />

Our training facility<br />

All training takes place at our <strong>Instrumentation</strong> and<br />

<strong>Controls</strong> headquarters in Alpharetta, Georgia, located<br />

40 miles north of Atlanta’s Hartsfield International<br />

Airport. Our facility provides the control technology<br />

for all new power generation equipment along with<br />

retrofit and IT services for operating plants.<br />

Classrooms are equipped with actual TXP systems.<br />

Directions from Hartsfield International Airport<br />

• Take I-85 North<br />

• I-85 merges with I-75 in Atlanta but continue to follow<br />

the signs for I-85 North<br />

-Take Exit 87 (GA 400 N)<br />

• You will have to pay a $0.50 toll<br />

• Take Exit 12-B (McFarland Road)<br />

• You will have to pay a $ 0.50 toll<br />

• Take exit 12 (McFarland Road)<br />

• After merging onto McFarland, turn left into the second<br />

office park, Ridgeland<br />

• The <strong>Siemens</strong> building sits in the back on the right<br />

• Enter the building through the doors under the <strong>Siemens</strong><br />

sign<br />

4<br />

www.sea.siemens.com/sitrain

TXP Engineer Curriculums<br />

All courses are designed to stand alone. There are<br />

certain courses, however, that are optimized when<br />

completed as part of a curriculum.<br />

Purchase of a complete curriculum will entitle the<br />

customer to a discounted price. Students will also<br />

receive a Curriculum Completion Certificate with<br />

the successful completion of all course work.<br />

Look for the color-coded boxes to determine<br />

which courses fall under which curriculum.<br />

TXP Software Engineer<br />

Responsible for tasks involving all aspects of<br />

TXP Software Engineering using the Engineering<br />

Workstation. These tasks include Conceptual<br />

Design; Equipment Arrangement; Connections to<br />

Foreign Systems; Hardware, Software and Graphics<br />

Implementation; Testing; Commissioning and<br />

Maintenance.<br />

TXP <strong>Controls</strong> Engineer<br />

Responsible for tasks involving all aspects of TXP<br />

Logic. These tasks include Hardware and Software<br />

Implementation; Testing; Commissioning and<br />

Maintenance.<br />

TXP Graphics Engineer<br />

Responsible for tasks involving all aspects of<br />

TXP Operator Graphics using the Engineering<br />

Workstation. These tasks include Graphic<br />

Implementation; Testing; Commissioning and<br />

Maintenance.<br />

TXP Advanced Engineer<br />

Responsible for tasks involving all aspects<br />

of the TXP System. This is the most complete<br />

TXP Curriculum.<br />

TXP System Engineer<br />

Responsible for tasks involving initial setup and<br />

maintenance of TXP equipment. These tasks include<br />

System Administration for the Automation System,<br />

the Operating and Monitoring System, Engineering<br />

Workstations, Diagnostic System, and the SIMATIC<br />

Industrial Ethernet.<br />

www.sea.siemens.com/sitrain<br />

5

Registration & Accommodations<br />

Four convenient<br />

ways to register<br />

Phone: (877) 442-8724<br />

Fax: (678) 256-1527<br />

Email: I&C.training@swpc.siemens.com<br />

Online: http://www.sea.siemens.com/sitrain<br />

Please provide<br />

the following<br />

information when<br />

you register<br />

• Course title, dates, and location<br />

• Your company name<br />

• Mailing address<br />

• Billing address<br />

• Telephone and fax number<br />

• Contact person<br />

• PO number<br />

A registration acknowledgement letter will be faxed to the<br />

student immediately after enrollment. A confirmation letter<br />

will be sent once payment has been received.<br />

Required<br />

prepayment<br />

The following payment methods are accepted:<br />

• Purchase order<br />

• Company check<br />

• Visa or MasterCard<br />

Payment must be received at least one week prior to the<br />

first day of class. Payments should be mailed to:<br />

<strong>Siemens</strong> Power Generation<br />

<strong>Instrumentation</strong> & <strong>Controls</strong><br />

Attn: Customer Training<br />

1345 Ridgeland Parkway, Suite 116<br />

Alpharetta, GA 30004<br />

Please include student name, course title, and course date<br />

with your payment.<br />

Cancellation<br />

and refunds<br />

Cancellation requests must be made at least one week prior to<br />

class start date for a full refund. Only 50% of tuition will be<br />

refunded for cancellations made less than one week prior to<br />

start of class. Students who do not attend a class without prior<br />

notification will be charged in full.<br />

6<br />

www.sea.siemens.com/sitrain

TXP Process Control System<br />

8<br />

TXP Process Control System<br />

On-Site Hardware/<br />

Software Configuration<br />

and Maintenance<br />

TXP-HW/SW<br />

3 weeks - price upon request<br />

Maximum of 10 students<br />

This course is usually scheduled on site.<br />

Prerequisites<br />

Electrical engineer, electronics<br />

technician, or competent individual<br />

with electronics background.<br />

Description<br />

This course will teach the<br />

participants the functions of an<br />

operating and monitoring system<br />

and how to operate it as a human<br />

machine interface (HMI). It will<br />

cover all tasks associated with<br />

process management and information.<br />

It will begin by covering<br />

the theory and operation of TXP<br />

hardware components and how<br />

they interact. Students will learn<br />

a practical approach to diagnosing<br />

and isolating faults to the card<br />

level using the various TXP<br />

tools, and will be required to<br />

troubleshoot actual hardware and<br />

software problems. Instruction on<br />

standard TXP hardware platforms<br />

will include hands-on labs covering<br />

their configuring and testing.<br />

This course will also emphasize<br />

the tasks performed by most<br />

instrument or computer technicians<br />

to isolate software problems<br />

and make system changes. This<br />

course will describe the general<br />

use and functions of the various<br />

components in the TXP system.<br />

Emphasis will be placed on the<br />

Engineering Station for the<br />

modification of logic diagrams,<br />

graphics for analog, and digital<br />

control. This course is based on<br />

TXP version 7 level software and<br />

hardware.<br />

Objectives<br />

Upon successful completion of this course, the student<br />

has been trained to:<br />

• Explain the operation of the TXP plant bus and<br />

terminal bus<br />

• Isolate card failures and configure a replacement<br />

card<br />

• Make all necessary settings to standard<br />

communications cards<br />

• Perform required preventive maintenance<br />

• Distinguish between hardware and software<br />

problems<br />

• Troubleshoot a TXP system using a logical approach<br />

• Create logic diagrams for an actual process model<br />

• Create graphics for same process model<br />

• Modify logic diagrams<br />

• Modify graphics<br />

• Compile and download configured software<br />

Course contents<br />

A. TXP overview<br />

1. TXP plant bus operation<br />

a. Theory of operation<br />

b. Protocol<br />

c. Communication processors<br />

2. TXP terminal bus operation<br />

a. TCP/IP basics<br />

b. Data exchange between nodes<br />

3. Automation system components<br />

a. System architecture and loading procedures<br />

b. Process I/O<br />

c. Digital I/O cards<br />

d. Analog I/O cards<br />

4. Operating and monitoring system components<br />

B. Troubleshooting<br />

1. Hardware problem solving<br />

2. Software problem solving<br />

C. Program development and modification<br />

1. Function plan editor<br />

2. Graphics editor<br />

3. Logic code compiling and downloading<br />

4. Graphics compiling and downloading<br />

D. Operator interaction<br />

1. Alarm acknowledgement<br />

2. Online configurable trends<br />

3. Window management<br />

4. Online dynamic tuning and troubleshooting<br />

5. Archiving and data logging

TXP Process Control System<br />

Prerequisites<br />

Electrical engineer, electronics technician, or competent<br />

individual with an electronics background. Prior experience<br />

with DCS control systems is desirable.<br />

Description<br />

This course will cover the theory and operation of PCS7<br />

hardware components and how they interact. Students<br />

will learn a practical approach to diagnosing and isolating<br />

faults to the card level using the various PCS7 tools,<br />

and will be required to troubleshoot actual hardware<br />

and software problems. Instruction on standard PCS7<br />

hardware platforms will include hands-on labs covering<br />

configuring, cleaning, and testing.<br />

Objectives<br />

Upon successful completion of this course, the student<br />

has been trained to:<br />

• Explain the operation of the PCS7 bus system<br />

• Isolate card failures and configure a replacement card<br />

• Make all necessary settings to standard communications<br />

cards<br />

• Perform required preventive maintenance<br />

• Distinguish between hardware and software problems<br />

• Troubleshoot a PCS7 system using a logical approach<br />

Course contents<br />

A. System architecture and loading procedures<br />

1. PCS7 bus system<br />

a. Theory of operation<br />

b. Protocol<br />

c. Communication processors<br />

2. Process I/O<br />

a. Digital I/O cards<br />

b. Analog I/O cards<br />

3. Hardware assembly<br />

a. Assembly of automation rack<br />

b. Initialization and code transfer<br />

B. Troubleshooting<br />

1. Module level<br />

2. Rack level<br />

Process Control System<br />

PCS7 Hardware Configuration/<br />

Maintenance<br />

PCS7 – HW<br />

(4.5 days) - $2,600.00<br />

June 5-9, 2006<br />

October 23-27, 2006<br />

Top five reasons to take a<br />

PCS7 training course<br />

1. Less down-time due to fast<br />

operator response and action<br />

2. Proper system maintenance<br />

ensures stable operation<br />

3. The courses provide system<br />

knowledge to help assist<br />

students in troubleshooting<br />

4. A well-trained operator<br />

will perform all functions<br />

efficiently<br />

5. Knowledge of the system<br />

ensures higher self-esteem<br />

and confidence in doing the<br />

job right<br />

www.sea.siemens.com/sitrain<br />

9

TXP Process Control System<br />

TXP Process Control System<br />

Hardware Configuration/<br />

Maintenance<br />

TXP-HW<br />

1 week - $2,650.00<br />

February 13-17, 2006<br />

July 10-14, 2006<br />

December 4-8, 2006<br />

Prerequisites<br />

Electrical engineer, electronics technician, or competent<br />

individual with an electronics background. Prior experience<br />

with DCS control systems is desirable.<br />

Description<br />

This course will cover the theory and operation of TXP<br />

hardware components and how they interact. Students<br />

will learn a practical approach to diagnosing and isolating<br />

faults to the card level using the various TXP tools, and<br />

will be required to troubleshoot actual hardware and<br />

software problems. Instruction on standard TXP hardware<br />

platforms will include hands-on labs covering their<br />

configuring, cleaning, and testing. This course is based<br />

on TXP version 7 level software and hardware.<br />

Objectives<br />

Upon successful completion of this course, the student<br />

has been trained to:<br />

• Explain the operation of the TXP plant bus and<br />

terminal bus<br />

• Isolate card failures and configure a replacement card<br />

• Make all necessary settings to standard communications<br />

cards<br />

• Perform required preventive maintenance<br />

• Distinguish between hardware and software<br />

problems<br />

• Troubleshoot a TXP system using a logical approach<br />

Course contents<br />

A. System architecture and loading procedures<br />

1. TXP plant bus and terminal Bus<br />

a. Theory of operation<br />

b. Protocol<br />

c. Communication processors<br />

d. TCP/IP basics<br />

2. Process I/O<br />

a. Digital I/O cards<br />

b. Analog I/O cards<br />

3. Hardware assembly<br />

a. Assembly of automation rack<br />

b. Initialization and code transfer<br />

B. Troubleshooting<br />

1. Module level<br />

2. Rack level<br />

10<br />

www.sea.siemens.com/sitrain

Registration & Accommodations<br />

<strong>Siemens</strong> reserves the right to change the schedule<br />

or discontinue or cancel courses if an insufficient<br />

number of students have enrolled. In the event<br />

that students are enrolled in courses that have<br />

been changed or canceled, <strong>Siemens</strong> will notify<br />

these students two weeks prior to the scheduled<br />

starting date. These students will be given first<br />

priority to enroll in the next scheduled class.<br />

Right to<br />

cancellation<br />

Hilton Garden Inn<br />

4025 Windward Plaza<br />

(770) 360-7766<br />

Local<br />

accommodations<br />

Marriott Alpharetta<br />

5750 Windward Parkway<br />

(770) 754-9600<br />

Marriott Courtyard<br />

12655 Deerfield Parkway<br />

(678) 366-3360<br />

AmeriSuites<br />

12505 Cingular Way<br />

(678) 339-0505<br />

AmeriSuites<br />

5595 Windward Parkway<br />

(770) 343-9566<br />

www.sea.siemens.com/sitrain<br />

7

TXP Process Control System<br />

Prerequisites<br />

A basic background in logic control and digital<br />

computer techniques. Prior completion of<br />

Hardware Configuration/Maintenance (TXP-HW)<br />

is recommended.<br />

Description<br />

This course emphasizes the tasks performed by<br />

most operators and instrumentation technicians.<br />

This course will describe the general use and<br />

functions of the various components in the<br />

TXP system. Emphasis will be placed on the<br />

engineering workstation for the creation of logic<br />

diagrams. The student will create a complete<br />

control system model using the function plan<br />

editor in the ES680 workstation.<br />

TXP Process Control System<br />

Control Logic Configuration<br />

TXP - CLC<br />

1 week - $2,650.00<br />

February 20-24, 2006<br />

July 17-21, 2006<br />

December 11-15, 2006<br />

Objectives<br />

Upon successful completion of this course, the<br />

student has been trained to:<br />

• Create logic diagrams for actual process model<br />

• Modify logic diagrams<br />

• Compile and download configured software to<br />

applicable TXP control system<br />

• Apply simulations<br />

Course contents<br />

A. TXP overview<br />

1. Communication bus operation<br />

2. Engineering workstation<br />

3. Automation system operation<br />

4. Operating and monitoring operation<br />

B. Program development and modification<br />

1. Functional logic<br />

2. Logic code compiling and downloading<br />

C. Engineering workstation user interface<br />

1. Window management<br />

2. Online dynamic simulation and<br />

troubleshooting<br />

www.sea.siemens.com/sitrain<br />

11

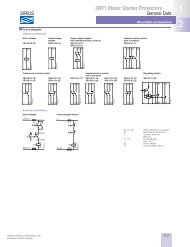

TXP Software Engineer<br />

TXP <strong>Controls</strong> Engineer<br />

TXP Graphics Engineer<br />

TXP Advanced Engineer<br />

TXP System Engineer<br />

Code Course Name JAN<br />

TXP-HW/SW<br />

TXP Hardware/Software<br />

Configuration & Maintenance<br />

PCS7-HW<br />

Hardware Configuration<br />

& Maintenance<br />

12<br />

TXP-HW TXP Hardware 1<br />

TXP-CLC TXP Control Logic 2<br />

Configuration<br />

TXP-GC<br />

TXP Graphics Configuration<br />

TXP-CLM<br />

TXP Control Logic Maintenance<br />

TXP-GM<br />

TXP Graphics Maintenance<br />

TXP-ALC<br />

TXP Advanced Logic<br />

Configuration<br />

TXP-ARC<br />

TXP Archiving, Reporting,<br />

and Calculation<br />

TXP-ADM<br />

TXP System Administration<br />

PCS7-CLC<br />

Control Logic Configuration<br />

PCS7-GC<br />

Graphics Configuration<br />

TXP-GOV<br />

TXP Governor Familiarity<br />

TXP-OP<br />

TXP Operator Training<br />

TXP-95F<br />

TXP Turbine and Boiler Protection<br />

SFC/SES<br />

Static Frequency Converter<br />

Static Excitation System<br />

PCS7-OP<br />

Operator Training<br />

PCS7-MAINT Maintenance Trainig<br />

T3K-OV<br />

SPPA-T3000 Process Control System<br />

T3K-BAS<br />

T3000 Process Control System<br />

T3K-ADV<br />

SPPA-T3000 Process Control System<br />

T3K-OP<br />

SPPA-T3000 Process Control System<br />

T3K-MNT<br />

SPPA-T3000 Process Control System

FEB MAR APR MAY JUN JUL AUG SEP OCT NOV DEC<br />

6-10 24-28<br />

3-17 10-14 4-8<br />

0-24 17-21 11-15<br />

27-3 24-28 18-22<br />

20-24<br />

22-26 11-15<br />

8-12<br />

10-21 25-6<br />

12-16 30-4<br />

19-23 6-10<br />

22-26 23-27<br />

26 9<br />

13 31 4<br />

20 7 11<br />

13

Let us come to you…<br />

Do you have a group of five or more employees<br />

taking the same course Take advantage of our<br />

on-site training. Benefits of on-site training include:<br />

• Convenience<br />

• Customized training<br />

• Save time and money<br />

• Team learning<br />

Email us: I&C.Training@swpc.siemens.com<br />

14 www.sea.siemens.com/sitrain

TXP Process Control System<br />

Prerequisites<br />

A basic background in modulating and logic<br />

control and in digital computer techniques.<br />

Prior completion of Control Logic Configuration<br />

(TXP-CLC) is recommended.<br />

Description<br />

This course emphasizes the tasks performed<br />

by most instrument or computer technicians to<br />

configure and modify a human machine interface<br />

(HMI) for operation of power plant equipment.<br />

This course describes the general use and functions<br />

of the various components in the TXP system.<br />

Emphasis will be placed on the engineering<br />

workstation for the creation of graphics. The<br />

student will create a complete graphics package<br />

model using the HMI graphics editor in the<br />

engineering workstation.<br />

TXP Process Control System<br />

Graphics Configuration<br />

TXP-GC<br />

1 week - $2,650.00<br />

February 27 - March 3, 2006<br />

July 24-28, 2006<br />

December 18-22, 2006<br />

Objectives<br />

Upon successful completion of this course,<br />

the student has been trained to:<br />

• Create and modify graphics<br />

• Compile and download configured graphics<br />

• Link graphics to logic function plans<br />

Course contents<br />

A. TXP overview<br />

B. Program development and modification<br />

1. Graphics editor (HMI)<br />

2. Configure plant displays, trends<br />

3. Set up graphical hierarchy<br />

4. Graphics compiling and downloading<br />

C. Operator interaction<br />

1. Alarm acknowledgement<br />

2. Online configurable trends<br />

3. Window management<br />

www.sea.siemens.com/sitrain<br />

15

TXP Process Control System<br />

TXP Process Control System<br />

Control Logic Maintenance<br />

TXP-CLM<br />

1 week - $2,650.00<br />

March 20-24, 2006<br />

Prerequisites<br />

A basic background in logic control and digital<br />

computer techniques. Prior completion of Control<br />

Logic Configuration (TXP-CLC) is recommended.<br />

Description<br />

This course for maintenance personnel describes<br />

the various components in the TXP system and<br />

maintaining plant equipment using the engineering<br />

workstation. Students will make changes to the<br />

input/output configuration adding new I/O points, and<br />

troubleshoot the logic and code. Students will learn to<br />

perform dynamic function changes as well as add and<br />

remove simulations.<br />

Objectives<br />

Upon successful completion of this course, the student<br />

has been trained to:<br />

• Troubleshoot TXP logic using the engineering<br />

workstation<br />

• Initialize standard settings on communication and<br />

I/O cards<br />

• Distinguish between hardware and software<br />

problems<br />

• Explain the difference between dynamic parameter<br />

changes and online and offline code transfers<br />

Course contents<br />

A. TXP overview<br />

B. Logic development and maintenance<br />

1. Adding hardware modules and I/O points<br />

2. Dynamic parameter changes, dynamic<br />

function plans<br />

3. Applying simulations<br />

4. Initialization of automation processor by<br />

programming an I/O flash card<br />

5. Communication processor card<br />

6. Code generation and transfer to applicable<br />

TXP computers<br />

C. Program and initialize an optical switch module<br />

D. Troubleshooting<br />

1. Hardware problem solving<br />

2. Software problem solving<br />

E. Use of SCO UNIX commands to verify status of CPU<br />

16<br />

www.sea.siemens.com/sitrain

TXP Process Control System<br />

Prerequisites<br />

A basic background in control system graphics<br />

and control logic, and prior experience with DCS<br />

control systems is desirable. Prior completion of<br />

Graphics Configuration (TXP-GC) is highly<br />

recommended.<br />

Description<br />

This course is designed for the technician<br />

responsible for graphics maintenance of the TXP<br />

system. Students will learn how to maintain TXP<br />

graphics with the human machine interface editor.<br />

They will also learn how to transfer new graphic<br />

displays into an existing project and work with<br />

configurable trends.<br />

TXP Process Control System<br />

Graphics Maintenance<br />

TXP-GM<br />

1 week - $2,650.00<br />

May 22-26, 2006<br />

September 11-15, 2006<br />

Objectives<br />

Upon successful completion of this course,<br />

the student has been trained to:<br />

• Make changes to graphics as required<br />

• Explain the process connection between function<br />

plan logic and human machine interface graphics<br />

• Navigate through operating and monitoring<br />

symbol library<br />

• Explain the code generation and transfer process<br />

Course contents<br />

A. TXP overview<br />

B. Graphic development and modification<br />

1. Create the graphics for an existing system<br />

2. Make process connections between the<br />

function plan editor and operating and<br />

human machine interface editor<br />

3. Create dynamic function plans<br />

4. Generate and transfer new or modified<br />

graphics<br />

C. Troubleshooting<br />

1. Code generation and transfer<br />

2. Process connections<br />

3. Software problem solving<br />

4. Recovery of deleted symbols from the<br />

graphics standard library<br />

www.sea.siemens.com/sitrain 17

TXP Process Control System<br />

TXP Process Control System<br />

Advanced Logic Configuration<br />

TXP-ALC<br />

1 week - $2,650.00<br />

May 8-12, 2006<br />

Prerequisites<br />

A basic background in logic control, TXP logic and<br />

digital computer techniques. Prior completion<br />

of Control Logic Configuration (TXP-CLC) is<br />

recommended.<br />

Description<br />

This course emphasizes the tasks performed by<br />

design and maintenance personnel. This course<br />

describes various advanced logical functions in the<br />

TXP system. Participants will work with the engineering<br />

workstation to design open- and closed-loop logic<br />

functions. The standard TXP manual will be used as a<br />

reference.<br />

Objectives<br />

Upon successful completion of this course, the student<br />

has been trained to:<br />

• Create and configure open-loop control functions<br />

• Create and configure closed-loop control functions<br />

• Troubleshoot TXP logic<br />

Course contents<br />

A. TXP overview<br />

B. Program development and modification<br />

1. Open-loop control logic functions<br />

2. Closed-loop control logic functions<br />

C. Code generation and transfer to applicable<br />

TXP computers<br />

D. Control logic troubleshooting<br />

18 www.sea.siemens.com/sitrain

TXP Process Control System<br />

Prerequisites<br />

A basic background in control systems and prior<br />

DCS knowledge is desirable. Prior completion of<br />

Control Logic Configuration (TXP-CLC) is highly<br />

recommended.<br />

Description<br />

This course emphasizes tasks performed by lead<br />

technicians and operators. This course will<br />

describe the various components of the TXP<br />

system. During the span of this course, the student<br />

will work with the engineering workstation,<br />

operating terminal, processing unit, and server<br />

unit to better understand archiving, reporting,<br />

and calculation, and the magnetic optical disk.<br />

The student will also learn about logs, alarm<br />

handling, switch cycle counters, and operating<br />

hours.<br />

TXP Process Control System<br />

Archiving, Reporting,<br />

and Calculation<br />

TXP-ARC<br />

1 week - $2,650.00<br />

This special course is<br />

scheduled as needed.<br />

Objectives<br />

Upon successful completion of this course,<br />

the student has been trained to:<br />

• Design and implement cycle counters, operating<br />

hour counters and other process information<br />

related calculations<br />

• Design and implement reports such as shift<br />

reports and event reports<br />

• Check and maintain the TXP alarm handling<br />

function blocks<br />

• Maintain and monitor the long-term archive<br />

and its storage media<br />

Course contents<br />

A. TXP overview<br />

B. Program development and modification<br />

1. Create logic for logs, alarm handler<br />

and counters<br />

2. Generate and transfer software code<br />

3. Load code into redundant processing<br />

unit, server unit, and operating terminal<br />

4. Monitor performance of TXP system<br />

C. Troubleshooting<br />

1. Magnetic optical disk resetting and<br />

restoring<br />

2. Alarm handling<br />

3. Analog and binary signals for<br />

processing unit logic counters<br />

www.sea.siemens.com/sitrain<br />

19

TXP Process Control System<br />

20<br />

TXP Process Control System<br />

System Administration<br />

TXP-ADM<br />

2 weeks - $5,300.00<br />

April 10-21, 2006<br />

September 25 - October 6, 2006<br />

Objectives<br />

Upon successful completion of this<br />

course, the student has been trained<br />

to:<br />

• Understand the basics of the UNIX<br />

operating system<br />

• Use the VI editor for file editing<br />

• Identify engineering station and<br />

operating and monitoring system<br />

hardware components<br />

• Understand the structure of engineering<br />

station and operating and<br />

monitoring system software<br />

• Query the project database using<br />

standard query language (SQL)<br />

• Identify operating and monitoring<br />

components and which object<br />

managers are running on each<br />

• Understand the structure of the<br />

operating and monitoring file<br />

system<br />

• Interpret the meaning of the internal<br />

identification numbers (IKZ’s)<br />

• Configure all necessary files for<br />

proper operating and monitoring<br />

operation<br />

• Understand the data transfer<br />

between the engineering station<br />

and operating and monitoring<br />

systems<br />

• Understand the automation system<br />

to operating and monitoring<br />

coupling<br />

• Install printers and troubleshoot<br />

printing problems<br />

• Use the various operating and<br />

monitoring tools<br />

• Schedule system back-ups<br />

Prerequisites<br />

A basic background in digital computer techniques and prior<br />

experience with DCS control systems is desirable. Prior completion<br />

of Hardware Configuration/Maintenance (TXP-HW) is highly<br />

recommended.<br />

Description<br />

This course is designed for the technician responsible for the<br />

computer network administration of a TXP system. This course<br />

emphasizes the tasks performed by most computer technicians<br />

to isolate system problems and basic network administration.<br />

This course will cover the basics of the UNIX operating system:<br />

the VI editor, the database system INGRES, printing, and all<br />

associated administrative tasks on the engineering system.<br />

Program components of the operating and monitoring system<br />

software, the file system structure, data transfer between the<br />

operating and monitoring system and engineering station,<br />

automation system to operating and monitoring coupling, and<br />

all administrative tasks on the operating and monitoring system<br />

will also be covered.<br />

Course contents<br />

A. Introduction to UNIX<br />

1. Operating system basics<br />

2. Most commonly used<br />

commands<br />

3. Use of variables<br />

B . Santa Cruz Operation (SCO) UNIX<br />

1. Style manager 3. Window manager<br />

2. File manager 4. Session manager<br />

C. Editors<br />

1. VI editor 2. SCO desktop editor<br />

D. Engineering station hardware<br />

E. Engineering station software<br />

F. Overview of project database and standard query language<br />

G. Program components of the operating and monitoring<br />

system software<br />

1. Object managers<br />

2. Operating and monitoring PC structures<br />

H. File system structure of operating and monitoring<br />

system PCs<br />

I. Meaning of the internal identification numbers (IKZ’s)<br />

J. Configuration data in the operating and monitoring system<br />

K. Data transfer between the engineering station and operating<br />

and monitoring system<br />

L. Automation system to operating and monitoring system<br />

coupling<br />

M. Operating and monitoring tools<br />

N. Diagnostics<br />

O. Back-ups<br />

P. Printing

TXP Process Control System<br />

Prerequisites<br />

A basic background in logic control and digital<br />

computer techniques. Prior completion of Hardware<br />

Configuration Maintenance (PCS7-HW) is recommended.<br />

Description<br />

This course emphasizes the tasks performed by<br />

most operators and instrumentation technicians.<br />

This course will describe the general use and<br />

functions of the various components in the PCS7<br />

system. Emphasis will be placed on the engineering<br />

workstation for the creation of logic diagrams. The<br />

student will create a complete control system model<br />

using the engineering workstation.<br />

Process Control System<br />

PCS7 Control Logic Configuration<br />

PCS7 – CLC<br />

(4.5 days) $2,600.00<br />

June 12-16, 2006<br />

October 30 – November 3, 2006<br />

Objectives<br />

Upon successful completion of this course, the<br />

student has been trained to:<br />

• Create logic diagrams for actual process model<br />

• Modify logic diagrams<br />

• Compile and download configured software to<br />

applicable PCS7 control system<br />

• Apply simulations<br />

Course contents<br />

A. PCS7 overview<br />

1. Communication bus operation<br />

2. Engineering workstation<br />

3. Automation system operation<br />

4. Operator station operation<br />

B. Program development and modification<br />

1. Functional logic<br />

2. Logic code compiling and downloading<br />

C. Engineering workstation user interface<br />

1. Window management<br />

2. Online dynamic simulation and<br />

troubleshooting<br />

www.sea.siemens.com/sitrain 21

TXP Process Control System<br />

Process Control System<br />

PCS7 Graphics Configuration<br />

PCS7 – GC<br />

(4.5 days) $2,600.00<br />

June 19-23, 2006<br />

November 6-10, 2006<br />

Prerequisites<br />

A basic background in logic control and digital computer<br />

techniques. Prior completion of Control Logic Configuration<br />

(PCS7-CLC) is recommended.<br />

Description<br />

This course emphasizes the tasks performed by most instrument<br />

or computer technicians to configure and modify a<br />

human machine interface (HMI) for operation of power<br />

plant equipment.<br />

This course describes the general use and functions of the<br />

various components in the PCS7 system. Emphasis will be<br />

placed on the engineering workstation for the creation of<br />

graphics. The student will create a complete graphics package<br />

model using the WinCC graphics editor on the engineering<br />

workstation.<br />

Objectives<br />

Upon successful completion of this course, the student has<br />

been trained to:<br />

• Create and modify graphics<br />

• Compile and download configured graphics<br />

• Link graphics to logic function plans<br />

Course contents<br />

A. PCS7 overview<br />

B. Program development and modification<br />

1. Graphics editor (WinCC)<br />

2. Configure plant displays and trends<br />

3. Set up graphical hierarchy<br />

4. Graphics compiling and downloading<br />

C. Operator interaction<br />

1. Alarm acknowledgement<br />

2. Online configurable trends<br />

3. Window management<br />

22<br />

www.sea.siemens.com/sitrain

TXP Process Control System<br />

Prerequisites<br />

A basic background in modulating and logic<br />

control and in digital computer techniques and<br />

prior experience with DCS control systems is<br />

desirable. Prior completion of Hardware<br />

Configuration/Maintenance (TXP-HW) and<br />

Control Logic Configuration (TXP-CLC) is highly<br />

recommended.<br />

Description<br />

This course is designed for the technician<br />

responsible for the software maintenance of a TXP<br />

system. It describes the general use and functions<br />

of the various components in the TXP governor<br />

system SIMADYN®. Emphasis will be placed on<br />

the governor system hardware layout, drawing<br />

conventions used, the STRUC G programming<br />

language, and troubleshooting techniques.<br />

Course contents<br />

A. Closed-loop control concepts<br />

B. Governor functional description<br />

1. Speed, load, and outlet temperature<br />

control (OTC) controllers<br />

C. Governor system hardware overview<br />

1. General cabinet layout for both gas<br />

turbines that are marketed by <strong>Siemens</strong><br />

2. Signal converter overview/description<br />

D. Program development and modification<br />

1. Hardware drawing overview/description<br />

2. Governor system software drawing<br />

overview/description<br />

3. Block diagram functional sheets<br />

4. STRUC G software<br />

E. Troubleshooting<br />

1. Hardware and software faults<br />

2. IBS program on commissioning<br />

and diagnostic tool PG740<br />

F. Plant bus communications with automation<br />

system<br />

1. NML software on commissioning and<br />

diagnostic tool PG740<br />

TXP Process Control System<br />

Governor Familiarity Course<br />

TXP-GOV<br />

1 week - $2,650.00<br />

May 22-26, 2006<br />

October 23-27, 2006<br />

Objectives<br />

Upon successful completion of this<br />

course, the student has been<br />

trained to:<br />

• Understand basic closed-loop<br />

control concepts<br />

• Understand the basics of speed<br />

control, load control, and OTC<br />

control concepts<br />

• Identify individual hardware<br />

components in the governor<br />

cabinet<br />

• Read and understand hardware<br />

drawings<br />

• Read and understand software<br />

drawings<br />

• Troubleshoot common hardware<br />

and software problems using a<br />

commissioning and diagnostic<br />

tool PG740 and the IBS software<br />

program<br />

• Understand communication<br />

tasks between the governor<br />

system and automation system<br />

www.sea.siemens.com/sitrain<br />

23

TXP Process Control System<br />

TXP Process Control<br />

System Operator Training<br />

TXP-OP<br />

4 days - $3,000.00<br />

This special course is<br />

scheduled as needed.<br />

Objectives<br />

Upon successful completion<br />

of this course, the student<br />

has been trained to:<br />

• Identify TXP system<br />

components<br />

• Identify types of graphics<br />

• Navigate graphics<br />

• Recognize graphic symbols<br />

• Control analog and digital<br />

devices<br />

• Analyze faults<br />

• Configure trends<br />

• Create and record logs<br />

• Dynamically force values<br />

• Dynamically tune control<br />

loops<br />

Prerequisites<br />

Power plant operator or competent individual with<br />

a background in operating power plants.<br />

Description<br />

This course will teach the participants the functions<br />

of an OM650 system and how to operate it using the<br />

human machine interface (HMI). It will cover all tasks<br />

associated with process operation and information. It<br />

will begin with an overview of TXP. Students will learn<br />

a practical approach to monitor and operate control<br />

devices using TXP. Instruction on standard TXP<br />

hardware platforms will include hands-on labs covering<br />

operation of controlled devices. This course will<br />

describe the general use and functions of the various<br />

components in the TXP system. Emphasis will be<br />

placed on the operator terminal for analog and<br />

digital control. Course is based on TXP version 7<br />

level software and hardware.<br />

Course contents<br />

A. TXP operations<br />

1. Distributed control system<br />

a. Component identification<br />

2. Automation system<br />

3. Operating and monitoring (OM650)<br />

components and operation<br />

a. System architecture<br />

b. Display types<br />

c. Navigation and hierarchy<br />

d. Plant displays and symbols<br />

e. Operation windows<br />

f. Notebook feature<br />

g. Alarm analysis<br />

h. Online configurable trends<br />

i. Archiving and data logging<br />

4. Plant bus and terminal bus<br />

5. Engineering station<br />

a. Dynamic logic<br />

b. Simulating values<br />

6. Diagnostic system<br />

24<br />

www.sea.siemens.com/sitrain

TXP Process Control System<br />

Prerequisites<br />

A basic background in modulating and logic control<br />

and in digital computer techniques and prior experience<br />

with DCS control systems is desirable. Prior<br />

completion of Hardware Configuration/Maintenance<br />

(TXP-HW) and Control Logic Configuration (TXP-CLC)<br />

is highly recommended.<br />

Description<br />

This course will provide general knowledge in the<br />

areas of SIMATIC STEP 5 and MC5 programming<br />

languages as they are used in the generation of<br />

software for the turbine and boiler fail-safe<br />

protection system AS 620F.<br />

Course contents<br />

MODULE 1 (STEP 5 and MC5 programming):<br />

A. STEP 5 commands and MC5 machine code<br />

B. Methods of representation<br />

C. Operation types and operation areas<br />

D. Structured programming<br />

E. Block types and logic operations<br />

F. Creating and handling projects and<br />

program files<br />

G. Editing blocks<br />

H. Force variables<br />

I. EPROM handling & management<br />

J. Diagnostics<br />

MODULE 2 (protection system AS620F):<br />

A. General concepts of redundancy<br />

B. Design, functions and connections S5-95F<br />

C. Configuration and error diagnosis and<br />

elimination software package COM 95F<br />

D. Guidelines for configuration, passivation and<br />

depassivation, error localization, software and<br />

hardware alarms, SINEC L1, SINEC L2 with<br />

CP541<br />

E. Communication processor CP541<br />

TXP Process Control System<br />

Turbine & Boiler<br />

Protection System<br />

(SIMATIC S5 & 95F)<br />

TXP-95F<br />

4 days - $3,300.00<br />

This special course is<br />

scheduled as needed.<br />

Objectives<br />

Upon successful completion of<br />

this course, the student has<br />

been trained to:<br />

• Understand the principles of<br />

the SIMATIC STEP 5<br />

Language<br />

• Identify MC5 machine code<br />

• Identify AS 620F system<br />

components<br />

• Identify common system<br />

errors<br />

• Analyze faults<br />

www.sea.siemens.com/sitrain 25

TXP Process Control System<br />

TXP Process Control System<br />

Static Frequency Converter<br />

Static Excitation System<br />

SFC/SES<br />

5 days - $3,300.00<br />

This special course is<br />

scheduled as needed.<br />

Prerequisites<br />

Power plant operator or competent individual with<br />

a background in operating power plants. Prior<br />

completion of Hardware Configuration/Maintenance<br />

(TXP-HW) is highly recommended.<br />

Description<br />

This course will cover the theory and operation of<br />

the SFC/SES control unit used for the start up of gas<br />

turbines and excitation of the generator. Students<br />

will learn about the operation and maintenance<br />

procedures with hands on labs using a Simadyn<br />

D control unit.<br />

Objectives<br />

Upon successful completion of this course, the<br />

student has been trained to:<br />

• Understand the equipment arrangement<br />

• Interpret the electrical schematic diagrams<br />

for the generator excitation<br />

• Identify the limits imposed by software<br />

• Understand the system functionality<br />

• Investigate the sequences involved in start up<br />

• Read the system schematic and software diagrams<br />

• Analyze hardware and software faults<br />

• Carry out routine system maintenance<br />

Course contents<br />

A. Introduction to plant set-up<br />

B. Power section SES<br />

C. Generator diagrams<br />

D. SFC functionality<br />

E. Modes of SFC operation<br />

F. Hardware description<br />

G. Interpreting schematic and software diagrams<br />

H. Fault detection<br />

I. Routine maintenance<br />

J. Use of OP1 interface module<br />

26<br />

www.sea.siemens.com/sitrain

TXP Process Control System<br />

Prerequisites<br />

Power plant operator or competent individual with a<br />

background in operating power plants.<br />

Description<br />

This course will teach the participants the functions of<br />

WinCC and how to operate it using the human machine<br />

interface (HMI). It will cover all tasks associated with<br />

process operation and information. It will begin with<br />

an overview of PCS7. Students will learn a practical<br />

approach to monitor and operate control devices using<br />

a plant specific simulation of the PCS7 system. The<br />

simulation will be used for hands-on labs covering<br />

startup, shutdown, over speed and valve testing. This<br />

course will describe the general use and functions of<br />

the various components in the PCS7 system. Emphasis<br />

will be placed on the operator station for analog and<br />

digital control.<br />

Process Control System<br />

PCS7 Operator Training<br />

PCS7 – OP<br />

(1 day) $1,350.00<br />

PCS7<br />

Course contents<br />

A. PCS7 operations<br />

1. Distributed control system<br />

a. Component identification<br />

2. Automation system<br />

3. Operator station (OS) components and operation<br />

a. System architecture<br />

b. Display types<br />

c. Navigation and hierarchy<br />

d. Plant displays and symbols<br />

e. Operation windows<br />

f. Alarm analysis<br />

g. Online configurable trends<br />

4. Bus system<br />

5. Engineering station<br />

a. Dynamic logic<br />

b. Simulating values<br />

6. Diagnostics<br />

www.sea.siemens.com/sitrain 27

TXP Process Control System<br />

Process Control System<br />

PCS7 Maintenance Training<br />

PCS7 – MAINT<br />

(3 days) $2,000.00<br />

Course contents<br />

A. PCS7 overview<br />

B. Engineering workstation<br />

overview<br />

1. Hardware modules and<br />

I/O points<br />

2. Parameter changes,<br />

dynamic function plans<br />

3.Startup and shutdown of<br />

Engineering components<br />

4.Replacement of the<br />

automation processor<br />

5.Replacement of the<br />

communication processor<br />

card<br />

6.Redundancy concepts<br />

C. Program and initialize and<br />

loading<br />

D. Configuration of the MP55<br />

Signal conditioning module<br />

E. Configuration of the axiomatic<br />

voltage to current converters<br />

F. System troubleshooting<br />

1. Dynamic value status<br />

monitoring mode<br />

2. Function code navigation<br />

3. Trip string evaluation<br />

Prerequisites<br />

A basic background in logic control and digital<br />

computer techniques. Prior completion of Control<br />

Logic Configuration (PCS7-CLC) is recommended.<br />

Description<br />

This course for maintenance personnel describes the<br />

various components in the PCS7 system and maintaining<br />

the system using the engineering workstation or<br />

project delivered tools. Students will navigate through<br />

their project to understand the HW and Logic configuration,<br />

configure the valve position feedback instrumentation,<br />

and understand the various protection<br />

devices.<br />

Objectives<br />

Upon successful completion of this course, the student<br />

has been trained to:<br />

• Troubleshoot PCS7 system logic using the<br />

engineering workstation<br />

• Initialize standard settings on communication and<br />

I/O cards<br />

• Distinguish between hardware and software<br />

problems<br />

• Configure the valve feedback instrumentation<br />

• Understand the turbine trip string<br />

28<br />

www.sea.siemens.com/sitrain

TXP Process Control System<br />

Prerequisites<br />

None<br />

Description<br />

This course will cover the overall concepts of SPPA-<br />

T3000 Process Control System. Students will be<br />

exposed to all the different components of the SPPA-<br />

T3000 system and a general understanding of how they<br />

interact. Instruction on standard SPPA-T3000 hardware<br />

platforms will include hands-on demonstrations.<br />

SPPA-T3000 Process<br />

Control System<br />

System Overview<br />

T3K-OV<br />

(1 day)<br />

June 26 - October 9, 2006<br />

Alpharetta training center or on site<br />

Objectives<br />

Upon successful completion of this course, the student<br />

will be able to:<br />

• Identify individual components in the SPPA-T3000<br />

Process Control System<br />

• Explain the tasks of the application and automation<br />

servers<br />

• Explain the functions of operation, engineering and<br />

diagnostic views<br />

• Explain the communications between all components<br />

• Understand the concepts of turbine control and<br />

third party connections<br />

Course contents<br />

• Introduction to the SPPA-T3000 control system<br />

• Highlights and advantages<br />

• System architecture<br />

• Peripherals<br />

• System documentation<br />

• Engineering view: function diagram, plant display,<br />

archive<br />

• Operation: faceplates, trends, alarms, reports, user<br />

specific plant displays<br />

• Diagnostic: force, change of parameters<br />

• Commissioning: point view<br />

• Concept: turbine control, (failsafe), modbus<br />

(Connect/90)<br />

• Online system demonstration<br />

www.sea.siemens.com/sitrain 29

TXP Process Control System<br />

T3000 Process<br />

Control System<br />

System Basics<br />

T3K-BAS<br />

(4 days) $2,600.00<br />

March 13 - July 31 - December 4, 2006<br />

Alpharetta training center or on site<br />

Prerequisites<br />

Electrical Engineer, electronics technician or competent<br />

individual with an electronics background and<br />

knowledge of PC operations using MS Windows. Prior<br />

experience with a DCS control system is desirable.<br />

Description<br />

The participant will learn the basic principles and<br />

views of I&C engineering, diagnostics and operation of<br />

the SPPA-T3000 system. Each student will implement a<br />

basic control system model, using the workbench to<br />

create both function diagrams and plant displays.<br />

Emphasis will be placed on sensor processing/coupling<br />

for analog and binary signals, along with motor/actuator<br />

control applications.<br />

Objectives<br />

Upon successful completion of this course, the student<br />

will be able to:<br />

Course contents<br />

• System hardware and software<br />

architecture, redundancy<br />

• Peripherals<br />

• System documentation<br />

• Engineering: function diagram,<br />

plant display, archive<br />

• Integrated engineering,<br />

using AF-blocks and prototypes,<br />

creating macros, creating trend<br />

displays<br />

• Operation: faceplates, trends,<br />

alarms, displays navigation<br />

• Diagnostic: change of parameters,<br />

dynamic function diagram,<br />

forcing ports<br />

• Commissioning: point view<br />

• Basic graphics, display hierarchy<br />

• Engineering examples: I/Os,<br />

logic, motor, graphics<br />

• SPPA-T3000 system summary<br />

• Implementation of basic<br />

functions (practical exercises):<br />

- hardware engineering using<br />

HW proxies<br />

- processing binary and analog<br />

values<br />

- motor control, actuator,<br />

protection<br />

- graphic layout of plant displays<br />

• Explain the operation of the control system<br />

and network<br />

• Identify the systems HW components<br />

• Navigate through the online documentation<br />

• Distinguish between hardware and software<br />

problems<br />

• Create logic and process diagrams for an<br />

actual plant model<br />

• Understand operation and configuration modes<br />

of operation<br />

• Use the diagnostic view to isolate faults in<br />

the system.<br />

30<br />

www.sea.siemens.com/sitrain

TXP Process Control System<br />

Prerequisites<br />

A basic background in logic control and in digital computer<br />

techniques. Prior completion of System Basics<br />

(T3000-BAS) course is recommended.<br />

Description<br />

Based on the basic class (T3000-BAS) the participants<br />

will gain knowledge about further engineering functions<br />

and system details. Each student will implement<br />

an advanced process model utilizing open and closed<br />

loop functions. The course is focussing on all users<br />

dealing with I&C engineering, commissioning and<br />

service.<br />

SPPA-T3000 Process<br />

Control System<br />

Advanced Engineering<br />

T3K-ADV<br />

(4 days) $2,600.00<br />

March 20 - August 7 - December 11, 2006<br />

Alpharetta training center or on site<br />

Objectives<br />

Upon successful completion of this course, the student<br />

will be able to:<br />

• Describe the advanced features of SPPA-T3000 Control<br />

System<br />

• Modify user properties and understand the effects of<br />

assigned access rights<br />

• Install new IO modules<br />

• Implement advanced logic and graphical functions<br />

• Understand the concept of third party connections<br />

• Troubleshoot SPPA-T3000 using a logical approach.<br />

Course contents<br />

• Project structure, inheritance<br />

• System and user properties : colors, login, logout,<br />

access rights<br />

• Advanced graphics<br />

• Controller, subgroup controller, device changeover,<br />

SOE<br />

• Copy & modify, import / export, spreadsheet<br />

engineering<br />

• Installation of new ET200M station (HW proxy,<br />

management proxy)<br />

• Concept: turbine control, failsafe, modbus,<br />

(connect/90)<br />

• Engineering examples: controller, device changeover,<br />

subgroup<br />

• Concept third party coupling<br />

• Implementation of advanced functions (practical<br />

exercises):<br />

- Closed loop controller, device change over<br />

- 3D Graphics, trend displays<br />

• Subgroup controller, step sequence<br />

• Trend display, navigation buttons<br />

www.sea.siemens.com/sitrain 31

TXP Process Control System<br />

T3000 Process<br />

Control System<br />

Operation and Monitoring<br />

T3K-OP<br />

(2 days) $1,200.00<br />

Alpharetta training center or on site<br />

Prerequisites<br />

A basic background in logic control and in digital<br />

computer techniques.<br />

Description<br />

The course is applicable for power plant operating personnel.<br />

The participant will learn the SPPA-T3000 operating<br />

functions and how to use the operating view for<br />

tasks associated with process management and information.<br />

Objectives<br />

Upon successful completion of this course, the student<br />

will be able to:<br />

• Explain the operation of the control system<br />

and network<br />

• Describe the available plant displays available in the<br />

system<br />

• Understand pictograms and faceplates<br />

• Navigate the online documentation<br />

• Use the trending, archiving and reporting features<br />

• Create a user-specific display<br />

• Understand the advanced features of the Alarm<br />

Sequence Display (ASD)<br />

• Troubleshoot alarms using dynamic function plans<br />

and diagnostic view.<br />

Course contents<br />

• Overview and introduction to SPPA-T3000<br />

• System documentation<br />

• Plant displays, user-specific plant displays<br />

• Pictograms and faceplates<br />

• Alarm sequence display, fault analysis<br />

• Archive, trends, reports<br />

• Multi screen operation<br />

• Dynamic function diagram<br />

• Diagnostic view<br />

• Trend displays, reports<br />

• Point view, diagnosis<br />

• Online help<br />

• Practical exercises on a simulated system, normal<br />

operation and handling of exceptional situations<br />

32<br />

www.sea.siemens.com/sitrain

TXP Process Control System<br />

Prerequisites<br />

A basic background in digital computer techniques and<br />

prior experience with DCS control systems is desirable.<br />

Prior completion of T3000-BAS and T3000-ADV is<br />

required.<br />

Description<br />

The participant is able to carry out all necessary activities<br />

to maintain the automation and operation level of<br />

SPPA-T3000.<br />

SPPA-T3000 Process<br />

Control System<br />

System Maintenance<br />

T3K-MNT<br />

(4 days) $2,600.00<br />

Alpharetta training center or on site<br />

Upon request<br />

Objectives<br />

Upon successful completion of this course, the student<br />

will be able to:<br />

• Distinguish between Hardware and Software<br />

problems<br />

• Backup the system and recover from various errors<br />

• Manage the long term Archive<br />

• Diagnose the network<br />

• Apply process simulations<br />

Course contents<br />

• Network diagnosis<br />

• Client diagnosis<br />

• Shutdown and reboot<br />

• Backup and restore<br />

• Archive management<br />

• I/O diagnosis and replacement and troubleshooting<br />

• Process value simulation and optimization<br />

• Using the system maintenance manual<br />

• Server HW components diagnosis and replacement<br />

• Practical exercises<br />

www.sea.siemens.com/sitrain 33

Looking for a way to rev up<br />

your profitability<br />

Look to <strong>Siemens</strong> to increase your control.<br />

<strong>Instrumentation</strong> & <strong>Controls</strong><br />

Smart drivers don’t run at ”full throttle”<br />

all the time. The rise and fall of consumer<br />

demands call for intelligent<br />

control in order to remain flexible,<br />

efficient and profitable. <strong>Siemens</strong><br />

<strong>Instrumentation</strong> & <strong>Controls</strong> provides<br />

integrated control systems capable<br />

of running a unit up to 1000 MW<br />

with a single operator; IT Power<br />

Solutions to drive your plant –<br />

or fleet of plants – with extreme<br />

efficiency; world-class service for<br />

maintaining in-market availability; and<br />

cutting-edge modernization programs<br />

designed to help you turn your older<br />

plant into a high-performing asset. All<br />

in record time. Let <strong>Siemens</strong> help you<br />

get a better handle on your power –<br />

and make it pay!<br />

Look us up:<br />

www.siemens.com/powergeneration<br />

Power Generation

<strong>Instrumentation</strong> & <strong>Controls</strong><br />

Published by and copyright © 2005:<br />

<strong>Siemens</strong> AG<br />

Power Generation<br />

Freyeslebenstrasse 1<br />

91058 Erlangen, Germany<br />

<strong>Siemens</strong> Power Generation, Inc.<br />

4400 Alafaya Trail<br />

Orlando, FL 32826-2399, USA<br />

www.siemens.com/powergeneration<br />

Order No.: A96001-W90- A833-X-4A00<br />

Printed in the USA.<br />

1343 110743M LP 1205.5<br />

All rights reserved.<br />

Subject to change without prior notice.<br />

Trademarks mentioned in this document are the property of <strong>Siemens</strong><br />

AG, its affiliates, or their respective owners.<br />

The information in this document contains general descriptions of the<br />

technical options available, which may not apply in<br />

all cases. The required technical options should therefore be specified<br />

in the contract.