62 - Polskie Stowarzyszenie BiomateriaÅów

62 - Polskie Stowarzyszenie BiomateriaÅów

62 - Polskie Stowarzyszenie BiomateriaÅów

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

4<br />

SCHEME 2. Chemical structure of poly(ester-ether-ester) terpolymer.<br />

In our work we focused on polyester–type condensation<br />

copolymers with poly(butylene terephthalate) as hard<br />

segment and two components of soft segments: dilinoleic<br />

acid (dimer) and poly(ethylene glycol) (SCHEME 2).<br />

The nanoreinforcement concept was realized through adding<br />

hydroxyapatite nanoparticles (FIG. 1) to produce highly<br />

elastomeric and strong materials.<br />

FIG. 1. TEM picture of nanosized hydroxyapa-<br />

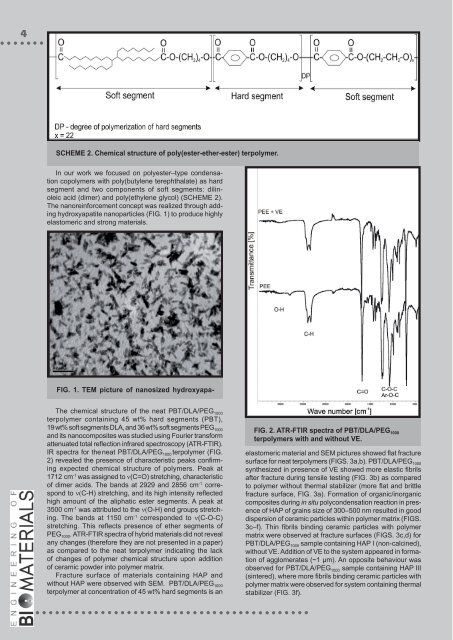

The chemical structure of the neat PBT/DLA/PEG 1000<br />

terpolymer containing 45 wt% hard segments (PBT),<br />

19 wt% soft segments DLA, and 36 wt% soft segments PEG 1000<br />

and its nanocomposites was studied using Fourier transform<br />

attenuated total reflection infrared spectroscopy (ATR-FTIR).<br />

IR spectra for the neat PBT/DLA/PEG 1000 terpolymer (FIG.<br />

2) revealed the presence of characteristic peaks confi rming<br />

expected chemical structure of polymers. Peak at<br />

1712 cm -1 was assigned to ν(C=O) stretching, characteristic<br />

of dimer acids. The bands at 2929 and 2856 cm -1 correspond<br />

to ν(C-H) stretching, and its high intensity reflected<br />

high amount of the aliphatic ester segments. A peak at<br />

3500 cm -1 was attributed to the ν(O-H) end groups stretching.<br />

The bands at 1150 cm -1 corresponded to ν(C-O-C)<br />

stretching. This refl ects presence of ether segments of<br />

PEG 1000 . ATR-FTIR spectra of hybrid materials did not reveal<br />

any changes (therefore they are not presented in a paper)<br />

as compared to the neat terpolymer indicating the lack<br />

of changes of polymer chemical structure upon addition<br />

of ceramic powder into polymer matrix.<br />

Fracture surface of materials containing HAP and<br />

without HAP were observed with SEM. PBT/DLA/PEG 1000<br />

terpolymer at concentration of 45 wt% hard segments is an<br />

FIG. 2. ATR-FTIR spectra of PBT/DLA/PEG 1000<br />

terpolymers with and without VE.<br />

elastomeric material and SEM pictures showed fl at fracture<br />

surface for neat terpolymers (FIGS. 3a,b). PBT/DLA/PEG 1000<br />

synthesized in presence of VE showed more elastic fi brils<br />

after fracture during tensile testing (FIG. 3b) as compared<br />

to polymer without thermal stabilizer (more fl at and brittle<br />

fracture surface, FIG. 3a). Formation of organic/inorganic<br />

composites during in situ polycondensation reaction in presence<br />

of HAP of grains size of 300–500 nm resulted in good<br />

dispersion of ceramic particles within polymer matrix (FIGS.<br />

3c–f). Thin fi brils binding ceramic particles with polymer<br />

matrix were observed at fracture surfaces (FIGS. 3c,d) for<br />

PBT/DLA/PEG 1000 sample containing HAP I (non-calcined),<br />

without VE. Addition of VE to the system appeared in formation<br />

of agglomerates (~1 μm). An opposite behaviour was<br />

observed for PBT/DLA/PEG 1000 sample containing HAP III<br />

(sintered), where more fi brils binding ceramic particles with<br />

polymer matrix were observed for system containing thermal<br />

stabilizer (FIG. 3f).