Exploration drilling Serbian style - Atlas Copco

Exploration drilling Serbian style - Atlas Copco

Exploration drilling Serbian style - Atlas Copco

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

on show at intermat 2012 >>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>><br />

Heading for Paris<br />

Energy Efficient Solutions on Show at<br />

<strong>Atlas</strong> <strong>Copco</strong> has an impressive array of innovative products lined up for this<br />

year’s Intermat construction show in Paris with energy efficiency and sustainable<br />

productivity as a central theme.<br />

When Intermat 2012 opens its doors April<br />

14 at the Villepinte Center north of Paris,<br />

the <strong>Atlas</strong> <strong>Copco</strong> booth will clearly be one of<br />

the main attractions with energy efficiency<br />

and sustainable productivity as the central<br />

theme.<br />

The <strong>Atlas</strong> <strong>Copco</strong> showcase, covering<br />

everything from air compressors and drill<br />

rigs to equipment for demolition, crushing,<br />

soil compaction and road paving, will highlight<br />

the equipment needed to meet high<br />

productivity demands at the lowest possible<br />

cost of ownership. Here, M&C has selected<br />

four stars from the lineup and also examines<br />

what Stage 3B legislation means for compressor<br />

owners.<br />

Cutting the cost of diesel<br />

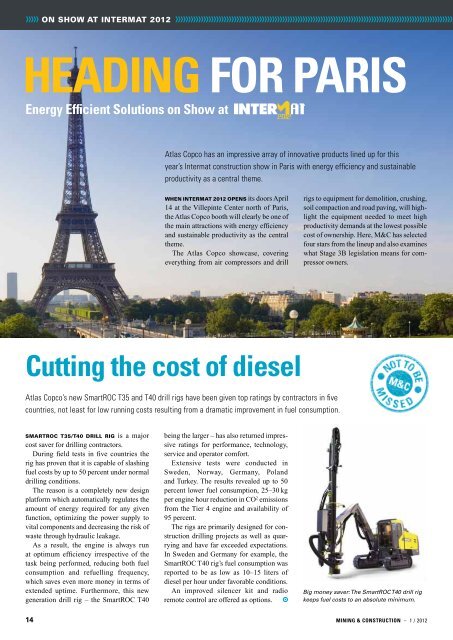

<strong>Atlas</strong> <strong>Copco</strong>’s new SmartROC T35 and T40 drill rigs have been given top ratings by contractors in five<br />

countries, not least for low running costs resulting from a dramatic improvement in fuel consumption.<br />

smartROC T35/T40 drill rig is a major<br />

cost saver for <strong>drilling</strong> contractors.<br />

During field tests in five countries the<br />

rig has proven that it is capable of slashing<br />

fuel costs by up to 50 percent under normal<br />

<strong>drilling</strong> conditions.<br />

The reason is a completely new design<br />

platform which automatically regulates the<br />

amount of energy required for any given<br />

function, optimizing the power supply to<br />

vital components and decreasing the risk of<br />

waste through hydraulic leakage.<br />

As a result, the engine is always run<br />

at optimum efficiency irrespective of the<br />

task being performed, reducing both fuel<br />

consumption and refuelling frequency,<br />

which saves even more money in terms of<br />

extended uptime. Furthermore, this new<br />

generation drill rig – the SmartROC T40<br />

being the larger – has also returned impressive<br />

ratings for performance, technology,<br />

service and operator comfort.<br />

Extensive tests were conducted in<br />

Sweden, Norway, Germany, Poland<br />

and Turkey. The results revealed up to 50<br />

percent lower fuel consumption, 25–30 kg<br />

per engine hour reduction in CO 2 emissions<br />

from the Tier 4 engine and availability of<br />

95 percent.<br />

The rigs are primarily designed for construction<br />

<strong>drilling</strong> projects as well as quarrying<br />

and have far exceeded expectations.<br />

In Sweden and Germany for example, the<br />

SmartROC T40 rig’s fuel consumption was<br />

reported to be as low as 10–15 liters of<br />

diesel per hour under favorable conditions.<br />

An improved silencer kit and radio<br />

remote control are offered as options.<br />

Big money saver: The SmartROC T40 drill rig<br />

keeps fuel costs to an absolute minimum.<br />

14 Mining & Construction – 1 / 2012