Exploration drilling Serbian style - Atlas Copco

Exploration drilling Serbian style - Atlas Copco

Exploration drilling Serbian style - Atlas Copco

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

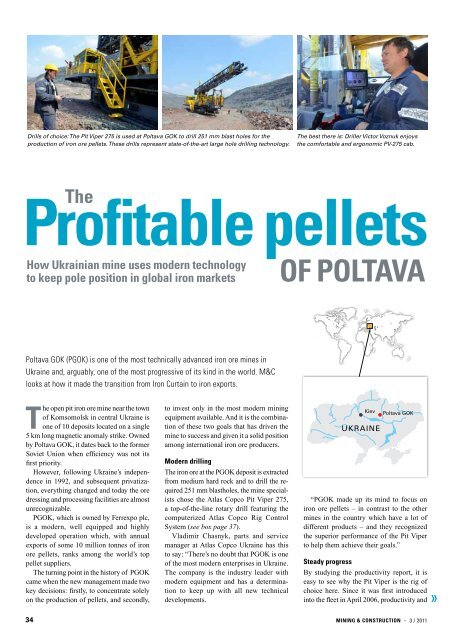

Drills of choice: The Pit Viper 275 is used at Poltava GOK to drill 251 mm blast holes for the<br />

production of iron ore pellets. These drills represent state-of-the-art large hole <strong>drilling</strong> technology.<br />

The best there is: Driller Victor Voznuk enjoys<br />

the comfortable and ergonomic PV-275 cab.<br />

The<br />

Profitable pellets<br />

How Ukrainian mine uses modern technology<br />

to keep pole position in global iron markets<br />

of Poltava<br />

Poltava GOK (PGOK) is one of the most technically advanced iron ore mines in<br />

Ukraine and, arguably, one of the most progressive of its kind in the world. M&C<br />

looks at how it made the transition from Iron Curtain to iron exports.<br />

The open pit iron ore mine near the town<br />

of Komsomolsk in central Ukraine is<br />

one of 10 deposits located on a single<br />

5 km long magnetic anomaly strike. Owned<br />

by Poltava GOK, it dates back to the former<br />

Soviet Union when efficiency was not its<br />

first priority.<br />

However, following Ukraine’s independence<br />

in 1992, and subsequent privatization,<br />

everything changed and today the ore<br />

dressing and processing facilities are almost<br />

unrecognizable.<br />

PGOK, which is owned by Ferrexpo plc,<br />

is a modern, well equipped and highly<br />

developed operation which, with annual<br />

exports of some 10 million tonnes of iron<br />

ore pellets, ranks among the world’s top<br />

pellet suppliers.<br />

The turning point in the history of PGOK<br />

came when the new management made two<br />

key decisions: firstly, to concentrate solely<br />

on the production of pellets, and secondly,<br />

to invest only in the most modern mining<br />

equipment available. And it is the combination<br />

of these two goals that has driven the<br />

mine to success and given it a solid position<br />

among international iron ore producers.<br />

Modern <strong>drilling</strong><br />

The iron ore at the PGOK deposit is extracte d<br />

from medium hard rock and to drill the required<br />

251 mm blastholes, the mine specialists<br />

chose the <strong>Atlas</strong> <strong>Copco</strong> Pit Viper 275,<br />

a top-of-the-line rotary drill featuring the<br />

computerized <strong>Atlas</strong> <strong>Copco</strong> Rig Control<br />

Syste m (see box page 37).<br />

Vladimir Chasnyk, parts and service<br />

manager at <strong>Atlas</strong> <strong>Copco</strong> Ukraine has this<br />

to say: “There’s no doubt that PGOK is one<br />

of the most modern enterprises in Ukraine.<br />

The company is the industry leader with<br />

modern equipment and has a determination<br />

to keep up with all new technical<br />

developments.<br />

Kiev<br />

UKRAINE<br />

Poltava GOK<br />

“PGOK made up its mind to focus on<br />

iron ore pellets – in contrast to the other<br />

mines in the country which have a lot of<br />

different products – and they recognized<br />

the superior performance of the Pit Viper<br />

to help them achieve their goals.”<br />

Steady progress<br />

By studying the productivity report, it is<br />

easy to see why the Pit Viper is the rig of<br />

choice here. Since it was first introduced<br />

into the fleet in April 2006, productivity and<br />

34 Mining & Construction – 3 / 2011