Electroplating machinery and equipment - Heimerle + Meule

Electroplating machinery and equipment - Heimerle + Meule

Electroplating machinery and equipment - Heimerle + Meule

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

<strong>Electroplating</strong> <strong>machinery</strong> <strong>and</strong> <strong>equipment</strong><br />

<strong>Heimerle</strong> + <strong>Meule</strong>’s <strong>equipment</strong><br />

manufacturing division<br />

offers a comprehensive <strong>and</strong><br />

individually designed range<br />

of electroplating units <strong>and</strong><br />

systems for one-off <strong>and</strong><br />

small-batch processing <strong>and</strong><br />

for series production.<br />

Our products are mainly<br />

used in industrial production,<br />

goldsmiths’ <strong>and</strong> watchmakers’<br />

workshops, schools,<br />

universities, institutes <strong>and</strong><br />

laboratories.<br />

JUNIOR 120<br />

Pen plating unit<br />

With this pen plating unit,<br />

gold, silver <strong>and</strong> rhodium can<br />

be deposited with ease.<br />

The technique is economical<br />

<strong>and</strong> stain-free. The apparatus<br />

is particularly suitable for<br />

jewellery with complex geometries<br />

such as settings,<br />

rings, brooches, necklaces<br />

<strong>and</strong> watches which would<br />

otherwise have to be masked<br />

– a time-consuming <strong>and</strong><br />

expensive procedure. Layers<br />

of approx. 0.1 – 0.2 μm can<br />

be deposited.<br />

JUNIOR 120 is very easy to<br />

operate: Using a pair of<br />

tweezers (cathode), attach<br />

the work to the pen plating<br />

unit. Dip the felt tip of the<br />

plating pen (anode) into the<br />

plating bath. Then apply the<br />

plating solution to the work,<br />

making sure that the tip only<br />

glides over the surface.<br />

When the plating is completed,<br />

rinse the plated part<br />

under running water <strong>and</strong><br />

dry it.<br />

Technical specifications<br />

JUNIOR<br />

Mains voltage<br />

230 ~/50 Hz<br />

Rectifier voltage<br />

1.5 – 15 V<br />

Output (electroplating)<br />

max. 0.4 A<br />

JUNIOR 120 8100 9 746<br />

complete with:<br />

1 pen plating unit JUNIOR 120<br />

1 plating pen with plug<br />

1 pair of tweezers with plug<br />

1 work plate<br />

10 felt tips, half size<br />

1 electrolyte jar<br />

Accessories<br />

1 plating pen with plug 8100 9 761<br />

1 pair of tweezers with plug 8100 9 759<br />

1 work plate 8100 9 748<br />

10 felt tips, half size 8614 7 019<br />

1 electrolyte jar 8614 7 025<br />

24

Titanium colouring<br />

Titanium in colour<br />

Titanium is a metal that<br />

forms a durable oxide layer<br />

with the ability to refract <strong>and</strong><br />

absorb light. By varying the<br />

thickness of the oxide layer,<br />

an array of very decorative<br />

colours can be achieved.<br />

Manufacturers of medical<br />

instruments, spectacle frames<br />

<strong>and</strong> writing implements have<br />

been benefiting from titanium’s<br />

properties for many<br />

years now. And jewellery<br />

designers, too, derive inspiration<br />

from colourful titanium.<br />

A multifunctional material –<br />

not only for high-tech<br />

applications<br />

Harder than steel; extremely<br />

resistant to heat, corrosion<br />

<strong>and</strong> acid; bio-compatible <strong>and</strong><br />

exceptionally lightweight:<br />

these properties make titanium<br />

<strong>and</strong> its alloys a material<br />

of choice for the aircraft<br />

<strong>and</strong> aerospace industries,<br />

deep-sea engineering<br />

(submarines), medicine<br />

(implants <strong>and</strong> prosthetics)<br />

<strong>and</strong> the chemical industry. All<br />

these beneficial properties –<br />

harder than steel, lightweight,<br />

hypoallergenic – are also<br />

remarkable features of titanium<br />

jewellery.<br />

The TFA 120/10 titanium<br />

anodiser: for durable <strong>and</strong><br />

beautiful titanium surfaces<br />

With this titanium colouring<br />

unit from <strong>Heimerle</strong> + <strong>Meule</strong>,<br />

existing passive layers can<br />

be reinforced by anodic oxidation.<br />

Increasing the voltage<br />

increases the thickness of<br />

the oxide layer. The various<br />

colours will appear at specific<br />

voltage levels.<br />

With a st<strong>and</strong>ard 20 litre process<br />

bath, a 120 V rectifier<br />

<strong>and</strong> a safety lid which locks<br />

automatically, the TFA 120/10<br />

titanium colouring unit is<br />

perfect for achieving a wide<br />

range of colours. Other<br />

variations are available on<br />

request. Using the titanium<br />

colouring solution developed<br />

Titanium colouring unit TFA 120/10 8687 1 800<br />

complete with:<br />

■ Polypropylene tank<br />

460 x 280 x 250 mm<br />

incl. automatically<br />

locking lid<br />

■ Anode <strong>and</strong> cathode rods<br />

■ Agitator<br />

■ Suction outlet<br />

■ Rectifier 120 V / 10 A<br />

Accessories<br />

■ Universal suspension rack<br />

with 40 titanium hooks<br />

■ Stainless steel anodes, set of 8<br />

Chemicals<br />

■ Titanium colouring solution<br />

■ Titanium pickle<br />

by <strong>Heimerle</strong> + <strong>Meule</strong> <strong>and</strong> the<br />

correct titanium pickle, the<br />

TFA 120/10 enables you to<br />

obtain immaculate shades of<br />

bronze, violet, bright blue<br />

steel, blue, yellow, pink <strong>and</strong><br />

green with the utmost of ease.<br />

8894 4 065<br />

8604 3 013<br />

8894 4 065<br />

8894 4 090<br />

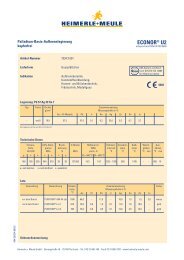

The following colours can be achieved with the TFA 120/10 titanium anodizer<br />

Bronze<br />

15 V<br />

Violet<br />

20 V<br />

Bright blue<br />

30 V<br />

Steel blue<br />

40 V<br />

Yellow<br />

60 V<br />

Pink<br />

80 V<br />

Green<br />

100 V<br />

25

<strong>Electroplating</strong> <strong>machinery</strong> <strong>and</strong> <strong>equipment</strong><br />

Benchtop plating units<br />

<strong>and</strong> systems<br />

These units are suitable for<br />

plating copper, nickel, silver,<br />

gold, rhodium <strong>and</strong> other<br />

metals with the exception<br />

of chrome. They are so easy<br />

to operate that even newcomers<br />

to electroplating can<br />

work with them.<br />

While the small plating units<br />

Type PGG 10 (1.5 <strong>and</strong> 3.0 litre)<br />

are generally used to plate<br />

small one-off parts, the<br />

systems Type PGG 20 <strong>and</strong><br />

PGG 60 are suitable for<br />

processing larger one-off<br />

items <strong>and</strong> small batches.<br />

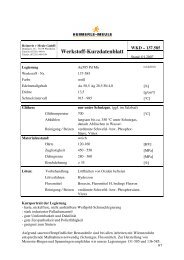

PGG 10 1.5 l PGG 10 3.0 l PGG 20 PGG 60<br />

Small size Small size Small size Small size<br />

electroplating unit electroplating unit electroplating system electroplating sytem<br />

type PGG 10 type PGG 10 type PGG 20 type PGG 60<br />

1.5 litre 3.0 litre<br />

Ref. No. 8101 0 492 8101 0 493 8101 0 494 8101 0 614<br />

Technical Nominal voltage/nominal frequency 220 V/50 Hz 220 V/50 Hz 220 V/50 Hz 220 V/50 Hz<br />

specifications Weight 14 kg 20 kg 45 kg 71 kg<br />

Housing Steel sheet with ● ● ● ●<br />

acid-resistant coating<br />

Dimensions 500 x 260 x 280 mm 580 x 300 x 320 mm 980 x 500 x 360 mm 980 x 800 x 510 mm<br />

(length x width x height)<br />

(including rinse tanks)<br />

Rectifier 10 V/10 A 48 % RW 10 V/10 A 48 % RW 10 V/20 A 48 % RW 10 V/60 A 48 % RW<br />

Stainless steel cathode ● ● ● ●<br />

<strong>and</strong> anode rods<br />

Agitator in tank 2 + 3 2 + 3 in the right-h<strong>and</strong> 2 + 3<br />

processing tank (6)<br />

Timer LCD-timer LCD-timer LCD-timer LCD-timer<br />

Thermostatic control unit 0 – 110 °C 0 – 110 °C 0 – 110 °C 0 – 110 °C<br />

Tanks In PPH – natural with lid ● ● ●<br />

Number 3 3 3 processing tanks 3 processing tanks<br />

1 running-water rinse tank 2 running-water rinse tanks<br />

2 rinsing tanks 8 rinsing tanks<br />

Capacity 1.5 l 3.0 l 8 l processing tanks 15 l processing tanks<br />

4 l rinsing tanks 7 l rinsing tanks<br />

Dimensions 150 x 100 x 150 mm 180 x 130 x 180 mm 210 x 210 x 210 mm 245 x 260 x 265 mm<br />

(length x width x height) processing tanks processing tanks<br />

210 x 105 x 210 mm 260 x 105 x 265 mm<br />

rinsing tanks<br />

rinsing tanks<br />

26

Small size electroplating system<br />

PGG 20, 8.0 litres<br />

Small size electroplating system<br />

PGG 60, 15.0 litres<br />

Small size electroplating unit<br />

PGG 10, 3.0 litres<br />

Small size electroplating unit<br />

PGG 10, 1.5 litres<br />

Accessories for benchtop electroplating units type PGG 10 1.5 litres <strong>and</strong> 3.0 litres<br />

Immersion heater 180 W 8607 0 020 Stainless steel anodes 150 x 50 x 0.5 mm 8609 3 004<br />

Stainless steel holder for heater 8607 0 013 Nickel anodes 100 x 50 x 2.0 mm 8609 2 004<br />

Bimetallic thermometer 8600 6 001 Fine silver anodes 100 x 50 x 2.0 mm 8609 4 004<br />

Stainless steel holder for thermometer 8600 6 005 Platinized titanium anodes 100 x 30 x 1.0 mm 8609 4 004<br />

Copper wire Ø 0.5 mm 8619 6 001 Copper anode 100 x 50 x 3.00 mm 8609 6 001<br />

Universal suspension rack for rings 8606 2 001 Anode holder in titanium 8609 5 002<br />

Universal suspension rack for chains 8606 2 022 Plating pen with terminal clamp 8614 7 011<br />

PPH tank 1.5 litres 8605 9 001 Pair of tweezers with terminal clamp 8614 7 009<br />

PPH tank lid for 1.5 litre tank 8605 8 001 Felt tips, half 8614 7 019<br />

PPH tank 3.0 litres 8605 9 022<br />

PPH tank lid for 3.0 litre tank 8605 8 009<br />

Accessories for benchtop electroplating system type PGG 20 (accessories for PGG 60 on request)<br />

Additional rectifier 10 V / 20 A 8602 0 013 PPH tank lid for 4.0 litre tank 8605 8 010<br />

Digital ammeter including installation 8601 4 011 PPH rinsing tank 4.0 litres 8605 9 003<br />

Shunt socket 8601 6 005 Copper wire Ø 0.5 mm 8619 6 001<br />

Additional agitators 8686 1 820 Universal suspension rack for rings, large 8606 2 005<br />

Thermostatic control 8615 4 013 Universal suspension rack for rings, small 8606 2 003<br />

Exhauster 2400 rpm 8603 0 003 Universal suspension rack for chains, large 8606 2 006<br />

Connection for filter pump 8615 4 008 Universal suspension rack for chains, small 8606 2 004<br />

Immersion heater 400 W 8607 0 021 Stainless steel anodes 8609 3 005<br />

200 x 50 x 0.8 mm<br />

Stainless steel holder for heater 8607 0 016 Nickel anodes 150 x 50 x 2.0 mm 8609 2 005<br />

Bimetallic thermometer 8600 6 002 Fine silver anodes 150 x 50 x 2.0 mm 8690 0 805<br />

Stainless steel holder 8600 6 005 Platinized titanium anodes 8690 4 005<br />

for thermometer<br />

150 x 30 x 1.0 mm<br />

PPH tank 8.0 litres 8605 9 004 Copper anode 150 x 50 x 3.0 mm 8609 6 002<br />

PPH tank lid for 8.0 litre tank 8605 8 011 Anode holder in titanium 8609 5 003<br />

PPH tank 4.0 litres 8605 9 002<br />

Pen electroplating<br />

with PGG 10 <strong>and</strong> PGG 20<br />

Both units can be used for<br />

pen plating. Tweezers <strong>and</strong><br />

electroplating pen (both<br />

with terminal clamps) are<br />

available as accessories.<br />

See also contact electroplating<br />

unit type JUNIOR 120,<br />

page 24.<br />

27

<strong>Electroplating</strong> <strong>machinery</strong> <strong>and</strong> <strong>equipment</strong><br />

Centrifugal dryers <strong>and</strong><br />

drying units<br />

Centrifugal hot-air dryers<br />

facilitate the speedy <strong>and</strong><br />

stainless drying of wet metal,<br />

glass or plastic parts.<br />

Centrifugal hot air dryer HT II<br />

Thanks to the fast-acting<br />

heater built into the lid,<br />

this unit dries even complex<br />

items without stains <strong>and</strong> in<br />

the shortest possible time.<br />

Ultrasonic cleaning units <strong>and</strong> systems<br />

Ultrasonic cleaning is now a st<strong>and</strong>ard<br />

method for the pre-treatment of items to<br />

be plated.<br />

With this process even heavily soiled or<br />

complex metal, glass <strong>and</strong> plastic parts can<br />

be quickly <strong>and</strong> thoroughly cleaned.<br />

With the<br />

Minison 120<br />

Minison 220<br />

Minison 320<br />

<strong>Heimerle</strong> + <strong>Meule</strong> offers you a range of<br />

ultrasonic cleaning units which meet every<br />

requirement in goldsmiths’ workshops,<br />

medical laboratories <strong>and</strong> in industry.<br />

Technical specifications<br />

Loading capacity<br />

Overall dimensions<br />

(length x width x height)<br />

Drive unit: electric motor<br />

Voltage<br />

Power consumption<br />

Workpiece basket (exchangeable)<br />

diameter<br />

height<br />

perforation<br />

Cycle<br />

Weight<br />

1 kg<br />

320 x 280 x 500 mm<br />

75 W, 3000 rpm<br />

220 V/50 Hz<br />

700 W<br />

130 mm<br />

105 mm<br />

5 mm<br />

max. 5 min<br />

20 kg<br />

Ref. No. 8688 1 200<br />

Accessories<br />

Perlon insert without bags 8607 9 003<br />

Perlon insert with bags 8607 9 004<br />

28

Ultrasonic cleaning units MINISON 120 MINISON 220 MINISON 320<br />

complete with heater with heater with heater <strong>and</strong> drain<br />

<strong>and</strong> accessories:<br />

workpiece basket in stainless steel,<br />

stainless steel lid, lid with holes for<br />

plastic beakers, 2 plastic beakers <strong>and</strong><br />

2 mesh baskets for plastic beakers<br />

Ref. No. 8100 9 296 8100 9 517 8100 9 518<br />

Ref. No. 8100 9 303<br />

with heater but without accessories<br />

Technical specifications<br />

Transducer 1 PZT broad-beam transducer 1 PZT large-area transducer 2 PZT large area transducers<br />

RF generator overload protected, continuous output overload protected, continuous output overload protected, continuous output<br />

Operation mode half wave full wave full wave<br />

Operating frequency 35 kHz automatic frequency control 35 kHz automatic frequency control 35 kHz automatic frequency control<br />

Continuous RF peak output max. 120 W/Per. 2 x 160 W/Per. 2 x 320 W/Per.<br />

Current consumption 0.5 A 1.0 A 2.0 A<br />

Power supply 230 V – 50/60 Hz or 230 V – 50/60 Hz or 230 V – 50/60 Hz or<br />

115 V – 50/60 Hz 115 V – 50/60 Hz 115 V – 50/60 Hz<br />

Power cable integrated, 2 m long, separate, 2 m long, separate, 2 m long,<br />

with European earthed plug with European earthed plug with European earthed plug<br />

External dimensions (l x w x h) 205 x 100 x 155 mm 260 x 160 x 250 mm 325 x 175 x 305 mm<br />

Weight 1.9 kg 3.6 kg 5.3 kg<br />

Oscillation tank<br />

Internal dimensions (l x w x d) 190 x 85 x 60 mm 240 x 140 x 100 mm 300 x 150 x 150 mm<br />

Capacity 0.9 l 3.0 l 5.7 l<br />

Features<br />

Heater 65 °C fixed setting, 30 – 80 °C thermostatic control, 30 – 80 °C thermostatic control,<br />

70 W 140 W 280 W<br />

Oscillation tank stainless steel stainless steel stainless steel<br />

Drain ball valve G 1/4<br />

Housing, splash-proof stainless steel stainless steel stainless steel<br />

Protection level IP 32 IP 32 IP 32<br />

H<strong>and</strong>les – – on the sides<br />

Timer 1 – 15 min <strong>and</strong> continuous use 1 – 15 min <strong>and</strong> continuous use 1 – 15 min <strong>and</strong> continuous use<br />

Accessories<br />

Stainless steel workpiece basket 8100 9 297<br />

Stainless steel lid 8100 9 298<br />

Lid with holes for plastic beakers 8100 9 299<br />

Plastic beaker 8100 9 300<br />

Mesh basket for plastic beakers 8199 9 301<br />

Plastic mesh basket, oval<br />

190 x 110 x 20 mm 8606 1 001 8606 1 001<br />

Plastic mesh basket, oval<br />

190 x 110 x 20 mm, with rests 8606 1 005<br />

Plastic mesh basket, oval<br />

275 x 110 x 25 mm, with rests 8606 1 006<br />

Stainless steel lid 8100 9 520 8100 9 519<br />

Ultrasonic cleaner Supplied as Concentration Treatment time Temperature Applications Special features<br />

Ultra Clean liquid 2 – 4 % 30 – 120 sec 40 – 70 °C removal of polish residues on gold, 100 % biodegradable,<br />

(concentrate) (concentrate) (25 – 50 m/l) silver, nonferrous metals <strong>and</strong> steel silicate-free<br />

Ultra 93 solid 3 – 4 % 60 – 120 sec 60 – 80 °C heavy soiling on precious metals powerful<br />

29<br />

(salt) (30 – 50 g/l) <strong>and</strong> steel cleaner<br />

Ultra 2000 solid 3 – 5 % 120 – 300 sec 50 – 90 °C removal of oil, polishing <strong>and</strong> grinding silicate-free,<br />

(powder) (30 – 50 g/l) residues on precious metals, wettable,<br />

nonferrous metals <strong>and</strong> aluminium ultra filterable<br />

29

<strong>Electroplating</strong> <strong>machinery</strong> <strong>and</strong> <strong>equipment</strong><br />

Electropolishers for gold<br />

<strong>and</strong> silver<br />

Electropolishing gold <strong>and</strong><br />

silver is an efficient <strong>and</strong> economical<br />

way to brighten<br />

jewellery, especially items<br />

with a complex geometry.<br />

This technique can be<br />

employed to brighten almost<br />

all silver <strong>and</strong> gold alloys<br />

(including centrifugal<br />

castings) with the exception<br />

of white gold/palladium.<br />

Polishing cycles last between<br />

5 – 30 seconds <strong>and</strong> even<br />

deeper <strong>and</strong> hidden surfaces<br />

can be successfully polished.<br />

You will find details of the<br />

required polishing salts on<br />

page 20.<br />

Electropolisher PEG 40<br />

This is a benchtop unit suitable<br />

for workshops. One item<br />

can be polished per cycle.<br />

The maximum surface of the<br />

workpiece should not exceed<br />

10 – 15 cm 2 .<br />

Technical specifications 8101 0 495<br />

Housing<br />

Housing dimensions<br />

(length x width x height)<br />

Rectifier<br />

Workpiece holder<br />

Cathode rods <strong>and</strong><br />

cathode metal sheets<br />

Heater<br />

Tanks with lids<br />

Number of tanks 2<br />

Tank dimensions<br />

(length x width x height)<br />

Capacity per tank<br />

Nominal voltage<br />

Weight<br />

Steel sheet with acid-resistant<br />

coating<br />

340 x 260 x 270 mm<br />

25 V/40 A with regulator knob<br />

Tweezers or hook<br />

Stainless steel<br />

150 x 50 x 0.5 mm<br />

Immersion heater, 180 W<br />

Temperature monitored by<br />

bimetallic needle-gauge thermometer<br />

Plastic<br />

150 x 100 x 150 mm<br />

1.5 litre<br />

220 V / 50 Hz<br />

16 kg<br />

Accessories<br />

Plastic tank 1.5 litres 8605 9 001<br />

Plastic tank lid 8605 8 001<br />

Immersion heater 8607 0 020<br />

Stainless steel holder 8607 0 013<br />

for heater<br />

Bimetallic thermometer 8600 6 001<br />

Stainless steel holder 8600 6 005<br />

for thermometer<br />

Polishing tweezers 8615 2 001<br />

Grip with platinum hook 8615 2 002<br />

30

Technical specifications 8685 2 300<br />

Dimensions<br />

(length x width x height)<br />

Rectifier<br />

Function of tank I<br />

Tank material<br />

Tank dimensions<br />

(length x width x height)<br />

Workpiece <strong>and</strong> cathode rods<br />

1130 x 910 x 870 mm<br />

25 V/300 A with regulator switch<br />

pulse control <strong>and</strong> timer<br />

from 1 – 1,000 seconds<br />

Polishing<br />

PPH<br />

460 x 280 x 250 mm,<br />

Capacity approx. 30 litres<br />

Copper, stainless steel<br />

Heater<br />

Emergency cut-out<br />

Cooling<br />

Drainage<br />

Function of tank II<br />

Tank material<br />

Dimensions<br />

(length x width x height)<br />

Water inlet <strong>and</strong> outlet<br />

Stainless-steel coil heater (1.4 kW),<br />

temperature regulated by<br />

non-contacting thermostat<br />

Yes<br />

Stainless steel pipes<br />

Discharge hose <strong>and</strong> stopper<br />

2 static rinses <strong>and</strong><br />

1 running rinse<br />

PPH<br />

460 x 280 x 400 mm<br />

(3, each 140 x 280 x 400 mm)<br />

Running rinse:<br />

water inlet <strong>and</strong> overflow st<strong>and</strong>pipe<br />

Static rinses:<br />

water discharge hose<br />

Nominal voltage 380 V/50 Hz (alternatively: 220 V)<br />

Output<br />

Weight<br />

Connection for<br />

water inlet <strong>and</strong> outlet<br />

Accessories<br />

approx. 9 kW/main switch<br />

approx. 210 kg<br />

Ø 1 / 2<br />

”/50 mm<br />

Polishing rack with 8606 2 009<br />

4 double hooks in platinum<br />

Polishing rack 8606 2 011<br />

with 8 double hooks<br />

<strong>and</strong> 4 single hooks in platinum<br />

Polishing rack 8606 2 010<br />

with 8 double hooks in platinum<br />

Chain holder 8606 2 012<br />

Electropolisher EP 300<br />

With this st<strong>and</strong>ard industrial<br />

system, a total surface area<br />

of 80 cm 2 can be polished<br />

during each cycle.<br />

The chassis is made of square<br />

stainless steel tubing clad<br />

with plastic panels. The<br />

worktop is made of easy-toclean<br />

plastic. The processing<br />

<strong>and</strong> rinsing tanks can easily<br />

be changed from the front.<br />

This can be done without<br />

removing the workpiece<br />

holders <strong>and</strong> cathode rods.<br />

To draw of the vapours from<br />

the bath, an extraction unit is<br />

mounted over the processing<br />

tank <strong>and</strong> two extractor ducts<br />

are located underneath the<br />

work surface. These are<br />

connected together by means<br />

of flexible pipes at the rear<br />

of the unit.<br />

The controls <strong>and</strong> displays for<br />

the rectifier <strong>and</strong> the thermostatically<br />

controlled heater<br />

are located on a console<br />

mounted at the rear of the<br />

machine. The rectifier is located<br />

on the right-h<strong>and</strong> side<br />

<strong>and</strong> is easily accessible from<br />

the front for servicing.<br />

An emergency cut-out is<br />

installed to monitor the bath<br />

level. If the solution drops<br />

below a preset level, the<br />

heater cuts out automatically.<br />

31