Click here for PDF - Society of Manufacturing Engineers

Click here for PDF - Society of Manufacturing Engineers

Click here for PDF - Society of Manufacturing Engineers

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

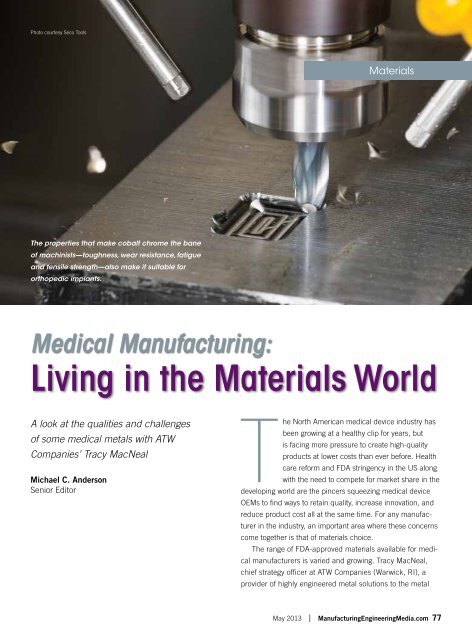

Photo courtesy Seco Tools<br />

Materials<br />

The properties that make cobalt chrome the bane<br />

<strong>of</strong> machinists—toughness, wear resistance, fatigue<br />

and tensile strength—also make it suitable <strong>for</strong><br />

orthopedic implants.<br />

Medical <strong>Manufacturing</strong>:<br />

Living in the Materials World<br />

A look at the qualities and challenges<br />

<strong>of</strong> some medical metals with ATW<br />

Companies’ Tracy MacNeal<br />

Michael C. Anderson<br />

Senior Editor<br />

The North American medical device industry has<br />

been growing at a healthy clip <strong>for</strong> years, but<br />

is facing more pressure to create high-quality<br />

products at lower costs than ever be<strong>for</strong>e. Health<br />

care re<strong>for</strong>m and FDA stringency in the US along<br />

with the need to compete <strong>for</strong> market share in the<br />

developing world are the pincers squeezing medical device<br />

OEMs to find ways to retain quality, increase innovation, and<br />

reduce product cost all at the same time. For any manufacturer<br />

in the industry, an important area w<strong>here</strong> these concerns<br />

come together is that <strong>of</strong> materials choice.<br />

The range <strong>of</strong> FDA-approved materials available <strong>for</strong> medical<br />

manufacturers is varied and growing. Tracy MacNeal,<br />

chief strategy <strong>of</strong>ficer at ATW Companies (Warwick, RI), a<br />

provider <strong>of</strong> highly engineered metal solutions to the metal<br />

May 2013 | <strong>Manufacturing</strong>EngineeringMedia.com 77

Materials<br />

component marketplace,<br />

expects growth in the medical<br />

industry, which currently<br />

accounts <strong>for</strong> 40% <strong>of</strong> its<br />

manufacturing.<br />

MacNeal’s entire career<br />

has been in FDA-regulated<br />

industries; she kindly walked<br />

ME Media through a virtual<br />

bazaar <strong>of</strong> medical materials<br />

Tracy MacNeal, chief strategy and discussed their strengths<br />

<strong>of</strong>ficer at ATW Companies. and challenges.<br />

Implants: Biocompatibility and Wear Issues<br />

Implants, orthopedic and otherwise, are all FDA Class<br />

Two and Class Three devices, with stringent requirements,<br />

the <strong>for</strong>emost <strong>of</strong> which is biocompatibility, MacNeal said. “Of<br />

the materials that are favored from a biocompatibility standpoint<br />

in metals, titanium would be the number one choice <strong>for</strong><br />

implants—it’s basically inert in the body. T<strong>here</strong> are also some<br />

alloys <strong>of</strong> stainless steel—people talk about ‘surgical stainless<br />

steel’ and those two would be the two big ones.”<br />

But as manufacturers in other industries know, titanium<br />

has its challenges: “Titanium is difficult to work with<br />

because it does catch fire. When you’re machining it, you<br />

really have to control your feeds and speeds. Its ratio <strong>of</strong><br />

hardness to brittleness is not great, and it doesn’t have<br />

good wear properties—it abrades. In an articulating joint<br />

like a knee or hip, you can’t have metal-on-metal t<strong>here</strong>, it’s<br />

much too s<strong>of</strong>t.”<br />

Cobalt chrome, another popular medical metal, has been<br />

used as a wear surface in orthopedic implants, but, as has<br />

been widely reported, it’s under fire right now: “People who<br />

have cobalt chrome metal-on-metal interfaces in their orthopedic<br />

joints get wear debris resulting in much higher than average<br />

levels <strong>of</strong> chromium ions in their body,” MacNeal noted.<br />

78 <strong>Manufacturing</strong>EngineeringMedia.com | May 2013

Materials<br />

“Those higher levels weren’t planned <strong>for</strong> and weren’t in<br />

the original filing data, so even though they haven’t been<br />

linked to any health problems, they’re an unexpected<br />

outcome, and the FDA is asking questions. So orthopedics<br />

companies are trying to get away from cobalt chrome <strong>for</strong><br />

such applications.<br />

“Instead <strong>of</strong> a metal-on-metal wear surface, companies typically<br />

will have a HDPE—high-density polyethylene wear surface,<br />

which simulates cartilage. In an actual<br />

hip joint, the bone is covered with cartilage,<br />

which when lubricated with synovial<br />

fluid is essentially friction-free. Inside<br />

the orthopedic joint, a biocompatible<br />

metal is coated with HDPE to mimic the<br />

cartilage role. But HDPE too can abrade,<br />

and in this case, the wear debris—inert<br />

polyethylene particles—builds up behind<br />

the metal, and as the body attempts<br />

to clean up these wear particles it can<br />

trigger an autoimmune reaction which<br />

causes resorption <strong>of</strong> bone tissue—a condition<br />

called osteolysis. The bone pulls<br />

away from the metal joint that had been<br />

screwed into it, and the joint can start to<br />

become loose. That’s usually why some<br />

patients need revision surgery—and<br />

why people who are, say, 65 years old<br />

may elect to put <strong>of</strong>f having replacement<br />

surgery, in order to not need to replace<br />

the joint at age 75.<br />

“Some hospitals are looking<br />

at reclaim and reuse, and<br />

considering investing<br />

in metal versions ...<br />

and reuse instead<br />

<strong>of</strong> disposables.”<br />

“So the hunt has been on <strong>for</strong> a<br />

better wear surface. Enter ceramics.<br />

Ceramics are super-hard and are great<br />

wear surfaces. They don’t abrade so you<br />

don’t have the wear debris issues. T<strong>here</strong><br />

have been two issues with ceramics,<br />

however. The first is that if the clearance<br />

isn’t completely and totally perfect, you<br />

end up with ceramic squeaking against<br />

80 <strong>Manufacturing</strong>EngineeringMedia.com | May 2013

Materials<br />

Photo courtesy Cordis Neurovascular<br />

ceramic: As people were taking steps, their joints were literally<br />

squeaking—loudly!—and these are permanent implants, so<br />

t<strong>here</strong>’s no easy way to minimize the sound. The other challenge<br />

with ceramics is that they’re comparatively brittle—if<br />

they receive the wrong impact, they break, creating a problem<br />

much worse than noisy joints.”<br />

While the squeaking is a quality <strong>of</strong> life problem, it is not<br />

much <strong>of</strong> a wear problem. Ceramics are essentially selflubricating.<br />

But t<strong>here</strong> are also serious machining issues with<br />

ceramics. They are extremely hard, so shaping them is a<br />

problem—especially when you need such a perfect fit.<br />

Nitinol: Thanks <strong>for</strong> the Memory<br />

A material that is growing in popularity <strong>for</strong> certain applications<br />

is the titanium/nickel alloy nitinol, which has shapememory<br />

capabilities that make it exceptional, MacNeal says,<br />

and t<strong>here</strong> are players in the industry that specialize in making<br />

devices that take advantage <strong>of</strong> that ability.<br />

“A common example would be nitinol stents,” she notes,<br />

“which can be manufactured in a shape needed to rebuild a<br />

blood vessel, then collapsed to a much narrower diameter <strong>for</strong><br />

easier insertion into the vessel, and finally allowed to resume<br />

its ‘remembered’ original shape as a scaffold to support the<br />

blood vessel.”<br />

Cordis Enterprise stent, a self-expanding shape-memory<br />

nitinol microstent.<br />

Shape-memory nitinol is also used <strong>for</strong> filters deployed<br />

in the aorta—if a blood clot gets through the aorta into the<br />

heart, it can mean instant death <strong>for</strong> the patient. MacNeal is<br />

impressed with the nitinol-based solution. “These filters are<br />

amazing—shape memory allows them to be inserted in a<br />

compact <strong>for</strong>m, but when they deploy, they look like fishing<br />

lures, with tiny prickers or barbs that extend out to catch clots<br />

be<strong>for</strong>e they can enter the heart.”<br />

Nitinol is also a metal popular in angioplasty applications:<br />

“The cardiac sector <strong>of</strong> the medical device industry is huge—<br />

Putting MIM in Gear at Parmatech<br />

ATW about an articulation gear part in an instrument<br />

subsidiary Parmatech Corp. (Petaluma, CA) was<br />

approached by a medical instrument manufacturer<br />

primarily used <strong>for</strong> minimally invasive surgical operations. The component<br />

was designed to be polymer injection molded, but during trials and<br />

development, the articulation gear would strip due to the <strong>for</strong>ces involved.<br />

Since it was already in late-stage development trials, the OEM had temporarily<br />

switched to an aluminum machined part to be able to continue<br />

production without delay. The machined part was then insert molded with<br />

plastic. Machined aluminum was sufficiently strong to prevent stripping<br />

<strong>of</strong> the gear teeth, but the subsequent cost to machine was a significant<br />

departure from planned costs.<br />

The OEM launched the product with the more expensive machined<br />

component, and then sought to convert the machined component to a<br />

MIM part. The part is insert molded, a process in which tolerances are<br />

typically accurate to within 0.0005" (0.0127 mm). Historically, plastic<br />

molders have been hesitant to use MIM parts <strong>for</strong> insert molding, because<br />

the tolerances are so tight that if the MIM part’s dimensions miss<br />

any tolerance, the insert molder’s tools could be destroyed.<br />

One <strong>of</strong> the most commonly used alloys, MIM-stainless steel 17-4,<br />

was chosen due its low material cost, robust operating parameters, and<br />

extensive operational history in terms <strong>of</strong> as-sintered tolerance capability.<br />

Parmatech made the 17-4 stainless steel articulation gear part with<br />

its proprietary MIM process, and then sent the part to the insert molding<br />

company, which put the part into the mold, sealed it and injected the<br />

insert molding. The two pieces, now joined together, were sent to the<br />

ultimate customer <strong>for</strong> assembly into the instrument.<br />

MIM process variation can induce a ±0.003" (0.076-mm) tolerance<br />

on a 1" (25.4-mm) dimension, so planning to put a MIM part into a hard<br />

tool steel mold, and have it properly shut <strong>of</strong>f to prevent flash or tool<br />

damage, is a challenging exercise. Parmatech worked closely with the<br />

insert mold tool builder to determine precisely how much room we had<br />

and tolerances required. The critical portion <strong>of</strong> Parmatech’s sintering is<br />

to make sure the part’s feet have a certain pocket or envelope that must<br />

fit exactly: missing just one part risked crashing the insert molder’s tool.<br />

At the end <strong>of</strong> the day, the customer received an insert-molded MIM<br />

part that met their functional and cost requirements. The success <strong>of</strong> the<br />

project demonstrates how MIM can be used to increase part strength<br />

without the high cost <strong>of</strong> machining, even when insert molding operations<br />

are involved. Cost savings were substantial over the machined<br />

part, with no individual part handling occurring after the initial stack at<br />

molding. In addition, t<strong>here</strong> is a much higher production rate capability<br />

with injection molding compared to machining. MIM material strength<br />

meets application requirements, and MIM material surface finish on the<br />

gear teeth was superior to that <strong>of</strong> machining. T<strong>here</strong> was very little material<br />

waste in fabricating the parts versus machining and no secondary<br />

operations involved with burr removal like those needed in machining.<br />

82 <strong>Manufacturing</strong>EngineeringMedia.com | May 2013

Materials<br />

second in size only to orthopedics.<br />

Cardiac applications call <strong>for</strong> companies<br />

that are good with wires; pulling wires<br />

and <strong>for</strong>ming wires ... nitinol use is at the<br />

<strong>for</strong>efront <strong>of</strong> much <strong>of</strong> that.”<br />

Photo courtesy Symmetry Medical<br />

Hip implants made from Ti-64.<br />

Competing in the Disposables Sector<br />

Plastics are playing an important role<br />

in the disposables market. For hospitals,<br />

one-use products such as syringes and<br />

IV bags are easier to deal with, in terms<br />

<strong>of</strong> quality and sterilization concerns,<br />

said MacNeal.<br />

“If it’s a single-use throwaway, you<br />

know that unless t<strong>here</strong> was a problem at<br />

the manufacturer’s sterilization facility,<br />

the product can be trusted. On the other<br />

hand, disposables are costly. And in<br />

particular, how are you going to enter the<br />

emerging markets w<strong>here</strong> a lot <strong>of</strong> industry growth is happening,<br />

when these products are so expensive While a single disposable<br />

product itself may be cheap, the number needed can<br />

make them an expensive choice.<br />

“Some hospitals are looking at reclaim and reuse, and<br />

considering investing in metal versions <strong>of</strong> the products and<br />

sterilization processes and reuse instead <strong>of</strong> disposables.<br />

“The cardiac sector <strong>of</strong> the medical<br />

device industry is huge—second<br />

in size only to orthopedics.”<br />

Our company is working with an OEM to develop a disposable<br />

metal suturing device. In this case metal is desirable <strong>for</strong><br />

its strength. T<strong>here</strong>’s a cantilevering action involved <strong>for</strong> which<br />

plastic just isn’t strong enough in the size the company is<br />

looking at. But machining the piece from metal would be<br />

prohibitively expensive, so they’re looking at manufacturing<br />

the device through the use <strong>of</strong> metal injection molding—MIM,<br />

one <strong>of</strong> our company’s primary technologies.<br />

MIM: Sinter <strong>of</strong> Excellence<br />

“With MIM, you start with powdered metal with a consistency<br />

similar to flour, and mix it with a binder—usually a<br />

polymer—and heat it so that the binder can flow but the metal<br />

84 <strong>Manufacturing</strong>EngineeringMedia.com | May 2013

itself hasn’t melted. The mixture is then injected into a mold,<br />

resulting in what we term a green part: the mixture has been<br />

shaped by the mold but the metal content is still solid—it’s<br />

just held in place by the binder.<br />

The green part is then put into a sintering<br />

furnace and the binder bakes <strong>of</strong>f,<br />

while the metal particles are heated just<br />

enough to touch and ad<strong>here</strong> directly to<br />

each other. If the furnace gets too hot,<br />

the metal would melt and the part would<br />

lose its shape, but with precise heating,<br />

the particles touch and sinter together<br />

to create a net-shape part.<br />

“T<strong>here</strong>’s a shrinkage factor because<br />

<strong>of</strong> the binder removal—the part will be<br />

15–25% smaller than when it went into<br />

the furnace. Maximizing the metal-tobinder<br />

ratio, controlling flow and finessing<br />

the amount <strong>of</strong> shrinkage are areas<br />

that call <strong>for</strong> expertise. The benefits over<br />

machining a part include saving time<br />

and saving raw material because you’re<br />

creating a net-shape part. In the sweetspot<br />

<strong>of</strong> using MIM, the process is 50%<br />

<strong>of</strong> the cost <strong>of</strong> creating the same part<br />

through machining raw metal.<br />

“MIM is playing a role in keeping<br />

some medical devices relevant in the<br />

current trend toward disposables. Our<br />

MIM technology is a runaway train right<br />

now, in terms <strong>of</strong> demand, because<br />

the whole industry is looking to MIM<br />

to try to wring cost out <strong>of</strong> the system.<br />

Both health care re<strong>for</strong>m in the US and<br />

Europe and the need to compete on<br />

cost in the developing world are <strong>for</strong>cing<br />

the OEMs to find ways to dramatically<br />

reduce costs. They know they’ve got to<br />

start looking at more innovative technologies,<br />

and MIM is on the list.”<br />

They’ve come a long way—I think they initially had strength<br />

issues—a laser-sintered part would be less strong than its<br />

machined counterpart—but I understand that they’ve come<br />

a long way. A process such as direct metal sintering could be<br />

The Advance <strong>of</strong> Additive<br />

“Additive manufacturing is another<br />

innovative technology that has been<br />

interesting to see being developed.<br />

May 2013 | <strong>Manufacturing</strong>EngineeringMedia.com 85

Materials<br />

Photo courtesy ATW Companies<br />

Stainless steel surgical scissors component made via metal injection molding—MIM—at Parmatech.<br />

considered a rival to MIM if it was being used <strong>for</strong> product runs<br />

<strong>of</strong> say 5000–15,000/year range.<br />

"I think they initially had strength issues—<br />

a laser-sintered part would be less strong<br />

than its machined counterpart—but I<br />

understand that they’ve come a long way."<br />

"I see additive right now as being used <strong>for</strong> lower-volume,<br />

mass-customization niches; it <strong>of</strong>fers the flexibility <strong>of</strong> making<br />

3000 <strong>of</strong> something this year and 2000 <strong>of</strong> something different<br />

the next year. Right now, we’re a high-volume player—we’re<br />

involved with major companies needing higher volumes.” ME<br />

More on Additive <strong>Manufacturing</strong><br />

See “Additive <strong>Manufacturing</strong>: A Custom Solution <strong>for</strong> the<br />

Medical Industry,” which appeared in the April issue,<br />

at www.MfgEngMedia.com.<br />

Want More In<strong>for</strong>mation<br />

ATW Companies<br />

Ph: 401-739-0740<br />

Web site: www.atwcompanies.com<br />

May 2013 | <strong>Manufacturing</strong>EngineeringMedia.com 87