conductivity - MEYER Industrie-Electronic GmbH

conductivity - MEYER Industrie-Electronic GmbH

conductivity - MEYER Industrie-Electronic GmbH

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Flow Sensors<br />

Analytical Sensors<br />

Flow Measurement<br />

Conductivity Measurement<br />

pH HMeasurement<br />

Meyer <strong>Industrie</strong>-<strong>Electronic</strong> <strong>GmbH</strong> – MEYLE<br />

Carl-Bosch-Straße 8<br />

49525 Lengerich/Germany<br />

Tel.: +49 54 81-93 85-0<br />

Fax: +49 54 81-93 85-12<br />

Internet: www.meyle.de<br />

E-Mail: sales@meyle.de<br />

1

. . . three<br />

companies,<br />

one service . . .<br />

INGENIEURBÜRO<br />

HERBERT <strong>MEYER</strong><br />

Systems for the Automation Industry<br />

System Integrator and Engineering<br />

company for applications and systems<br />

<strong>MEYER</strong> INDUSTRIE-<br />

ELECTRONIC GMBH<br />

Components for the Automation Industry<br />

Distribution of a wide range of components<br />

for the automation-, process-, machine<br />

building- and manufacturing industries<br />

INGENIEURGESELLSCHAFT<br />

SACHVERSTÄNDIGER<br />

REVISIONSINGENIEURE MBH<br />

Inspection Company for Quality<br />

Assurance<br />

Certified test laboratory for medical<br />

equipment and commercial building<br />

safety and quality tests

CONTENTS<br />

General overview<br />

Interconnection possibilities with insertion fittings 4<br />

Interconnection possibilities with inline fittings 5<br />

Flow Sensors · Batch Controllers · pH Sensors · Conductivity Sensors · Fittings<br />

Insertion flow sensor MyProc MFS 0242 6<br />

Digital flow transmitter My Proc MFT 0247 11<br />

Digital batch controller MyProc MFC 0247 19<br />

Inline flow sensor MyProc MFS 0252 26<br />

Digital flow transmitter My Proc MFT 0257 31<br />

Digital batch controller MyProc MFC 0257 37<br />

Electromagnetic flow transmitter MyProc MFT 0267 43<br />

Digital pH transmitter MyProc MPT 0427 49<br />

Digital pH controller MyProc MPC 0427 60<br />

Digital <strong>conductivity</strong> transmitter MyProc MCT 0447 71<br />

Digital inductive <strong>conductivity</strong> transmitter MyProc MCT 0448 80<br />

Accessories<br />

Insertion fittings for MyProc MAF 242 84<br />

Inline fittings for MyProc MAF 252 96<br />

Meyer <strong>Industrie</strong>-<strong>Electronic</strong> <strong>GmbH</strong> – MEYLE<br />

Carl-Bosch-Straße 8<br />

49525 Lengerich/Germany<br />

Tel.: +49 54 81-93 85-0<br />

Fax: +49 54 81-93 85-12<br />

Internet: www.meyle.de<br />

E-Mail: sales@meyle.de<br />

3

GENERAL OVERVIEW MyProc<br />

Interconnection possibilities with insertion fittings<br />

Remote electronics<br />

Type MFT 0247-MFC 0247<br />

Flow transmitter / batch controller<br />

Wall- or panel- mounted output:<br />

4–20 mA<br />

Relay<br />

Pulse<br />

Type MPT 0427-MPC 0427<br />

pH transmitter / controller<br />

Wall- or panel- mounted<br />

Type MCT 0447<br />

Conductivity transmitter<br />

Wall- or panel- mounted<br />

Compact electronics<br />

Type MCT 0247-MFC 0247<br />

Flow transmitter / batch controller<br />

output:<br />

4–20 mA<br />

Relay<br />

Pulse<br />

Type MPT 0427-MPC 0427<br />

pH transmitter / controller<br />

output<br />

4–20 mA<br />

Relay<br />

Type MCT 0448<br />

Inductive<br />

<strong>conductivity</strong><br />

transmitter<br />

output:<br />

4–20 mA<br />

Relay<br />

Type MCT 0447<br />

Resistive <strong>conductivity</strong><br />

transmitter<br />

output:<br />

4–20 mA<br />

Relay<br />

Type MFS 0242<br />

Flow sensor output:<br />

Pulse or Frequency<br />

Type MPT 0427<br />

pH sensor<br />

Sensor<br />

Type MCT 0447<br />

Resistive<br />

<strong>conductivity</strong><br />

sensor<br />

Insertion fitting<br />

Type MAF 242<br />

Metal or plastic<br />

Measuring chamber<br />

4<br />

Meyer <strong>Industrie</strong>-<strong>Electronic</strong> <strong>GmbH</strong> – MEYLE<br />

Carl-Bosch-Straße 8<br />

49525 Lengerich/Germany<br />

Tel.: +49 54 81-93 85-0<br />

Fax: +49 54 81-93 85-12<br />

Internet: www.meyle.de<br />

E-Mail: sales@meyle.de

GENERAL OVERVIEW MyProc<br />

Interconnection possibilities with inline fittings<br />

Remote electronics<br />

Type MFT 0247-MFC 0247<br />

Flow transmitter / batch controller<br />

Wall- or panel- mounted output:<br />

4–20 mA<br />

Relay<br />

Pulse<br />

Compact electronics<br />

Type MFT 0257-MFC 0257<br />

Flow transmitter / batch controller<br />

output:<br />

4–20 mA<br />

Relay<br />

Pulse<br />

Type MFS 0257<br />

Flow sensor<br />

output:<br />

Frequency<br />

Inline fitting<br />

Sensor<br />

Type MAF 252<br />

Metal or plastic<br />

Meyle flow sensors can be used in fluid media of<br />

a wide variety of types. Flow-rate measurements<br />

can be conducted in media ranging from highly<br />

pure to highly contaminated, including aggressive<br />

or viscous media and applications in hygienic<br />

areas. The fact that individual sensors operating<br />

on the basis of various measuring principles can<br />

be combined with various electronic evaluation<br />

systems allows a tailor-made solution for almost<br />

any application in accordance with the requirements.<br />

Meyle batch controllers can control very precise<br />

dosing and filling operations. Two switching relay<br />

outputs serve to actuate the valves for approx -<br />

imate and precise dosing or to trip an alarm. The<br />

dosing operations can be started manually or<br />

automatically.<br />

The design and materials allow use in virtually all<br />

types of fluids.<br />

Meyle offers a series of analysis sensors for<br />

detecting pH value and <strong>conductivity</strong>.<br />

The measuring instruments can be equipped with<br />

all necessary functions for measurements and<br />

control of these variables (4–20 mA current output,<br />

switching outputs and controller functions...).<br />

Design, materials and electrode selection enable<br />

use in virtually all types of fluids from ultra-pure<br />

water to effluent.<br />

Meyer <strong>Industrie</strong>-<strong>Electronic</strong> <strong>GmbH</strong> – MEYLE<br />

Carl-Bosch-Straße 8<br />

49525 Lengerich/Germany<br />

Tel.: +49 54 81-93 85-0<br />

Fax: +49 54 81-93 85-12<br />

Internet: www.meyle.de<br />

E-Mail: sales@meyle.de<br />

5

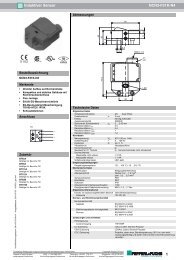

INSERTION FLOW SENSOR MyProc MFS 0242<br />

• Continuous flow measurement for use in neutral, slightly aggressive and solid free liquids<br />

• Paddle-wheel flow sensor<br />

• Simple installation into all pipes from PN 15 to 400<br />

• Frequency pulse signal, proportional to flow rate<br />

!<br />

MFT 0247<br />

General data:<br />

Compatibility<br />

with fittings MAF 242 (see corresp. data sheet)<br />

Materials<br />

Housing / Union nut<br />

PE / PC<br />

Cable plug<br />

PA<br />

Materials wetted parts Fitting<br />

Brass, stainless steel 1.4404/316L, PVC, PP, PVDF<br />

Finger, paddle-wheel<br />

PVDF<br />

Axis and bearing<br />

Ceramics<br />

Seal<br />

FKM (EPDM option)<br />

Electrical connections Cable plug EN 175301-803<br />

Connection cable<br />

Cross-section<br />

1.5 mm 2 max.<br />

Repeatibility ≤ 0.4 % of Reading 1)<br />

Recommended length<br />

max. 50 m, shielded<br />

Complete device data (fitting + sensor MFS 0242):<br />

Pipe diameter DN 15 to 400<br />

Measuring range<br />

0.3 to 10 m/s<br />

Fluid temperature with<br />

PVC fitting 0 up to 50 °C<br />

PP fitting 0 up to 80 °C<br />

St.st., brass, PVDF fitting -15 up to 80 °C<br />

Fluid pressure max.<br />

PN10<br />

Viscosity<br />

300 cSt. max.<br />

Accuracy<br />

Teach-In ≤ ± 0.5 % of F.S.* (at 10 m/s) 1)<br />

Standard K-factor ≤ ± (0.5 % of F.S.* + 2.5 % o. Reading) 1)<br />

Linearity ≤ ± 0.5 % of F.S.* (at 10 m/s) 1)<br />

Electrical data:<br />

Power supply<br />

Current consumption<br />

Pulse version<br />

Pulse “Low power” vers.<br />

Output: Frequency<br />

Pulse version<br />

Pulse “Low Power” vers.<br />

Reversed polarity of DC<br />

12–36 V DC<br />

with sensor<br />

≤ 50 mA<br />

≤ 0.8 mA<br />

Transistor NPN/PNP, open collector,<br />

max. 100 mA, frequency: 0...300 Hz;<br />

duty cycle 1/2<br />

Transistor NPN, open collector,<br />

max. 10 mA, frequency: 0...300 Hz;<br />

duty cycle 1/2<br />

Protected<br />

Flow transmitter<br />

MFC 0247<br />

Batch controller<br />

MAF 242<br />

Insertion fitting<br />

PLC<br />

Environment:<br />

Ambient temperature<br />

Relative humidity<br />

-15 up to +60 °C (operating and storage)<br />

≤ 80 %, non condensated<br />

Standards and approvals:<br />

Protection class<br />

IP65, with cable mounted and tigthened<br />

Standard<br />

EMC EN 61000-6-2, 61000-6-3<br />

Vibration EN 60068-2-6<br />

Shock EN 60068-2-27<br />

* FS. = Full scale (10 m/s)<br />

1) Under reference conditions i.e. measuring fluid = water, ambient and water temperature = 20 °C, applying the minimum inlet and outlet pipe straight, matched inside pipe dimensions.<br />

6<br />

Meyer <strong>Industrie</strong>-<strong>Electronic</strong> <strong>GmbH</strong> – MEYLE<br />

Carl-Bosch-Straße 8<br />

49525 Lengerich/Germany<br />

Tel.: +49 54 81-93 85-0<br />

Fax: +49 54 81-93 85-12<br />

Internet: www.meyle.de<br />

E-Mail: sales@meyle.de

INSERTION FLOW SENSOR MyProc MFS 0242<br />

Accuracy diagram:<br />

Design and principle:<br />

The flow sensor MFS 0242 consists of a transducer and a paddle-wheel with ceramic bearings. The ceramic rotating axis is set on<br />

the end of a PVDF INSERTION armature. The transducer is mounted inside the armature.<br />

In a 3-wire system, the signal can be displayed or processed directly. The output signal is provided via a cable plug according to<br />

EN 175301-803.<br />

When liquid flows through the pipe, the paddle-wheel with 4 inserted magnets is set in rotation, producing a measuring signal in the<br />

Hall transducer. The frequency modulated induced voltage is proportional to the flow velocity of the fluid.<br />

A conversion coefficient (K factor, available in the instruction manual of the fitting), specific to each pipe (size and material) enables<br />

the conversion of this frequency into flowrate.<br />

Two electronic module versions with frequency output are available:<br />

– with one pulse output (either NPN or PNP transistor output depending on wiring).<br />

An external power supply of 12–36 V DC is required. It is designed for connection to any system with open collector NPN or PNP frequency input.<br />

– with one pulse “Low Power” output (NPN transistor output).<br />

An external power supply of 12–36 V DC is required. Can only be connected to separate versions of flow transmitters Type MFT 0247.<br />

Pressure / temperature chart:<br />

A:<br />

Application<br />

range for<br />

complete device<br />

(fitting + sensor)<br />

Meyer <strong>Industrie</strong>-<strong>Electronic</strong> <strong>GmbH</strong> – MEYLE<br />

Carl-Bosch-Straße 8<br />

49525 Lengerich/Germany<br />

Tel.: +49 54 81-93 85-0<br />

Fax: +49 54 81-93 85-12<br />

Internet: www.meyle.de<br />

E-Mail: sales@meyle.de<br />

7

INSERTION FLOW SENSOR MyProc MFS 0242<br />

Installation:<br />

The MFS 0242 flow sensor can easily be installed into any insertion fitting system (Type MAF 242) by just fixing the main nut.<br />

Minimum straight upstream and downstream distances must be observed. According to the pipe’s design, necessary distances can<br />

be bigger or use a flow conditioner to obtain the best accuracy. For more information, please refer to EN ISO 5167-1.<br />

EN ISO 5167-1 prescribes the straight inlet and outlet distances that must be complied with when installing fittings in pipe lines in<br />

order to achieve calm flow conditions. The most important layouts that could lead to turbulence in the flow are shown below,<br />

together with the associated prescribed minimum inlet and outlet distances. These ensure calm, problem-free measurement<br />

conditions at the measurement point.<br />

DN = orifice Fluid direction --><br />

Regulating<br />

valve<br />

90°<br />

elbow joint<br />

or T-piece<br />

2 x 90°<br />

elbow joint<br />

3 dimensional<br />

Extension<br />

2 x 90°<br />

elbow joint<br />

Reduction<br />

The flow rate sensor can be installed in either horizontal or vertical pipes.<br />

Pressure and temperature ratings must be respected according to the selected fitting material.<br />

The suitable pipe size is selected using diagram Flow / Velocity / DN.<br />

The sensor is not designed for gas flow measurement.<br />

8<br />

Meyer <strong>Industrie</strong>-<strong>Electronic</strong> <strong>GmbH</strong> – MEYLE<br />

Carl-Bosch-Straße 8<br />

49525 Lengerich/Germany<br />

Tel.: +49 54 81-93 85-0<br />

Fax: +49 54 81-93 85-12<br />

Internet: www.meyle.de<br />

E-Mail: sales@meyle.de

INSERTION FLOW SENSOR MyProc<br />

MFS 0242<br />

Selection of fitting:<br />

Example:<br />

– Specification of nominal flow: 10 m 3 /h<br />

– Ideal flow velocity: 2...3 m/s<br />

– For these specifications, the diagram indicates a pipe size of DN40<br />

[or DN50 for (*) mentioned fittings]<br />

Dimensions:<br />

Type MFS 0242 standard<br />

(pulse or pulse “Low Power” version)<br />

Flow rate<br />

Note:<br />

The length of the sensor finger depends<br />

on the fitting used. See data sheet Type MAF 242.<br />

Flow velocity<br />

* for following fittings:<br />

– with external threads acc. to SMS 1145<br />

– with weld-ends acc. to SMS 3008, BS 4825 / ASME BPE or<br />

DIN 11850 Series 2<br />

– TriClamp ® acc. to SMS 3017 / ISO 2852, BS 4825 / ASME BPE or<br />

DIN 32676<br />

Tri-Clamp ® is a registered Trademark of Alfa Laval Inc.<br />

DN<br />

H [mm]<br />

[mm] T-Fitting Saddle Plastic St. St.<br />

spigot spigot<br />

15 156.0<br />

20 153.5<br />

25 153.5<br />

32 157.0<br />

40 161.0<br />

50 167.0 191.5 162.5<br />

65 167.0 190.5 172.5 167.0<br />

80 194.5 177.5 173.0<br />

100 199.5 184.0 183.5<br />

110 195.5<br />

125 202.5 194.5<br />

150 212.5 230.0 205.5<br />

180 236.5<br />

200 248.5 251.0 226.0<br />

250 269.0 286.0<br />

300 280.5 305.5<br />

350 294.0 317.5<br />

400 308.5<br />

Meyer <strong>Industrie</strong>-<strong>Electronic</strong> <strong>GmbH</strong> – MEYLE<br />

Carl-Bosch-Straße 8<br />

49525 Lengerich/Germany<br />

Tel.: +49 54 81-93 85-0<br />

Fax: +49 54 81-93 85-12<br />

Internet: www.meyle.de<br />

E-Mail: sales@meyle.de<br />

9

INSERTION FLOW SENSOR MyProc<br />

MFS 0242<br />

ORDERING CODE MFS 0242<br />

Complete system consists of:<br />

– a sensor module Type MFS 0242<br />

– an insertion fitting Type MAF 242 (DN15 – DN 400) (Refer to corresponding data sheet – has to be ordered separately)<br />

– a transmitter Type MFT 0247 or a batch contoller Type MFC 0247 – has to be ordered separately<br />

Specifications<br />

Supply voltage<br />

Output<br />

Sensor version<br />

Connector<br />

Item no.<br />

Pulse version sensor standard<br />

Pulse version sensor Low Power<br />

12–36 V DC<br />

from transmitter<br />

Frequency with pulse<br />

PNP or NPN<br />

Frequency with pulse<br />

NPN<br />

short<br />

long<br />

short<br />

long<br />

Cable plug EN 175301-803<br />

Cable plug EN 175301-803<br />

Cable plug EN 175301-803<br />

Cable plug EN 175301-803<br />

559 804<br />

559 805<br />

631 713<br />

631 715<br />

ORDERING CODE accessories (to be ordered separately)<br />

Specifications<br />

Set with 1 green FKM and 1 black EPDM gasket<br />

Ring<br />

Union nut<br />

Cable plug EN 175301-803 with cable gland (Type 4720)<br />

Cable plug EN 175301-803 with NPT1/2” reduction without cable gland (Type 4721)<br />

Item no.<br />

774 333<br />

831 427<br />

831 426<br />

650 033<br />

384 895<br />

10<br />

Meyer <strong>Industrie</strong>-<strong>Electronic</strong> <strong>GmbH</strong> – MEYLE<br />

Carl-Bosch-Straße 8<br />

49525 Lengerich/Germany<br />

Tel.: +49 54 81-93 85-0<br />

Fax: +49 54 81-93 85-12<br />

Internet: www.meyle.de<br />

E-Mail: sales@meyle.de

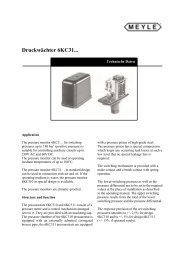

DIGITAL FLOW TRANSMITTER MyProc MFT 0247<br />

• Compact or remote version for DN 06 to 400, PN10<br />

• Shows both flow rate and volume (with two totalizers)<br />

• Automatic-calibration: TEACH-IN<br />

• Simulation: all output signals provided without the need for real flow<br />

!<br />

The flow transmitter is specially designed for use in neutral and slightly aggressive, solid-free liquids.<br />

The device is available in different models:<br />

• Compact transmitter with paddle-wheel sensor: standard signal output or battery powered indicator<br />

version.<br />

• Remote universal transmitter for panel or wall mounting for connection to a flow sensor from the<br />

market; sensors with open collector output, relay reed output, TTL, CMOS or coil can be operated by<br />

this transmitter.<br />

• Remote transmitter, for panel or wall mounting: standard signal output for connection to the<br />

MFS 0242/MFS 0252 sensor “Low Power“ version.<br />

Technical data (common to the various versions):<br />

General data<br />

Display<br />

15 x 60 mm, 8-digit LCD, alphanumeric,<br />

15 segments, 9 mm high<br />

Electrical connections<br />

shielded cable with 1.5 mm 2 max. cross-section<br />

MAF 242<br />

Insertion fitting<br />

Environment:<br />

Ambient temperature<br />

Relative humidity<br />

0 up to +60 °C (operation and storage)<br />

≤ 80 %, non condensated<br />

MFS 0242<br />

Insertion flow sensor<br />

Standards and approvals:<br />

Standard<br />

EMC EN 61000-6-2, EN 61000-6-3<br />

Security EN 61010-1<br />

Vibration EN 60068-2-6<br />

Shock EN 60068-2-27<br />

MFS 0252<br />

Inline flow sensor<br />

PLC<br />

Meyer <strong>Industrie</strong>-<strong>Electronic</strong> <strong>GmbH</strong> – MEYLE<br />

Carl-Bosch-Straße 8<br />

49525 Lengerich/Germany<br />

Tel.: +49 54 81-93 85-0<br />

Fax: +49 54 81-93 85-12<br />

Internet: www.meyle.de<br />

E-Mail: sales@meyle.de<br />

11

DIGITAL FLOW TRANSMITTER MyProc MFT 0247<br />

Versions:<br />

The compact version<br />

combines a paddle-wheel flow<br />

sensor and an electronic module<br />

with a display in an IP65<br />

enclosure.<br />

The output signals are provided<br />

via a cable plug EN175301-803<br />

or two cable glands.<br />

The panel-mounted version<br />

consists of an electronic<br />

module MFT 0247 integrated in<br />

a front-cover. The associated<br />

separate flow sensor is an<br />

MFS 0242, an MFS 0252 with<br />

pulse signal, or another flow sensor available<br />

from the market.<br />

The output signals are provided on a terminal<br />

strip.<br />

The wall-mounted version<br />

consists of an electronic<br />

module MFT 0247 in an IP65<br />

enclosure. The associated flow<br />

sensor is an MFS 0242, an<br />

MFS 0252 with pulse signal, or<br />

another flow sensor available from the market.<br />

The output signals are provided on a terminal<br />

strip via cable glands.<br />

Operation and display:<br />

The device can be calibrated by means of the K-factor, or via the TEACH-IN function.<br />

Customized adjustments, such as measuring range, engineering units, pulse output and filtering level are carried out on site.<br />

The operation is specified according to two or three levels, depending on the transmitter version:<br />

Flow transmitter (compact or remote)<br />

Indication in operating mode / Display<br />

– flow rate<br />

– output current<br />

– main totalizer<br />

– daily totalizer with reset function<br />

Parameter definition<br />

– language<br />

– engineering units<br />

– K-factor / TEACH-IN function<br />

– measuring range 4–20 mA<br />

– pulse output<br />

– relay (option)<br />

– filter<br />

– reset main totalizer<br />

Battery indicator / totalizer (compact)<br />

Indication in operating mode / Display<br />

– flow rate<br />

– main totalizer<br />

– daily totalizer with reset function<br />

Parameter definition<br />

– language<br />

– engineering units<br />

– K-factor / TEACH-IN function<br />

– filter<br />

– reset main totalizer<br />

Test<br />

– alteration of basic adjustment (offset, span)<br />

– frequency test of sensor<br />

– flow simulation (dry-run test operation)<br />

To scroll-up the menu or<br />

increase a value<br />

To scroll-down the menu<br />

or select a digit to be<br />

modified<br />

Confirm input and<br />

menu points<br />

Relay 2 LED*<br />

Relay 1 LED*<br />

*Not for Batteries version<br />

12<br />

Meyer <strong>Industrie</strong>-<strong>Electronic</strong> <strong>GmbH</strong> – MEYLE<br />

Carl-Bosch-Straße 8<br />

49525 Lengerich/Germany<br />

Tel.: +49 54 81-93 85-0<br />

Fax: +49 54 81-93 85-12<br />

Internet: www.meyle.de<br />

E-Mail: sales@meyle.de

DIGITAL FLOW TRANSMITTER MyProc MFT 0247<br />

Compact transmitter:<br />

Accuracy diagram:<br />

The compact transmitter<br />

is available in two versions:<br />

– standard signal<br />

(4–20 mA, frequency)<br />

– battery indicator/totalizer<br />

General data:<br />

Compatibility<br />

Materials<br />

Housing, cover, lid, nut<br />

Front panel foil<br />

Screws<br />

Cable plug / glands<br />

Wetted parts materials<br />

Fitting<br />

Sensor finger, paddle-wheel<br />

Axis and bearing / Seal<br />

Electrical connections<br />

with fittings MAF 242 (see corresp. data sheet)<br />

PC<br />

Polyester<br />

Stainless steel<br />

PA<br />

Brass, stainless steel 1.4404/316L, PVC, PP<br />

or PVDF<br />

PVDF<br />

Ceramics / FKM (EPDM option)<br />

Cable plug EN 175301-803 or cable glands<br />

M20 x 1.5 or none (for battery version).<br />

Design:<br />

When liquid flows<br />

through the pipe, the<br />

paddle-wheel with<br />

4 inserted magnets is<br />

set in rotation,<br />

producing a measuring<br />

signal in the sensor (coil<br />

or Hall transducer).<br />

The frequency modulated induced voltage is<br />

proportional to the flow velocity of the fluid.<br />

A conversion coefficient (K-factor, available in the<br />

instruction manual of the fitting), specific to each<br />

pipe (size and material) enables the conversion of<br />

this frequency into flow rate.<br />

The electronic component converts the measured<br />

signal into several outputs (according to the<br />

transmitter version) and displays the actual value.<br />

Complete device data (Fitting + <strong>Electronic</strong>s):<br />

Pipe diameter DN 15 to 400<br />

Measuring range<br />

0.5 to 10 m/s (Battery version - Coil transducer)<br />

0.3 to 10 m/s (Hall transducer version)<br />

Fluid temperature with fitting in<br />

PVC 0 up to 50 °C<br />

PP 0 up to 80 °C<br />

PVDF, brass or stainless steel -15 up to 80° C 1)<br />

Fluid pressure max.<br />

PN10 (see pressure/temperature diagram)<br />

Viscosity<br />

300 cSt. max.<br />

Accuracy<br />

Teach-In ≤ ± 0.5 % of F.S.* (at 10 m/s) 2)<br />

Standard K-factor ≤ ± (0.5 % of F.S.* + 2.5 % of Reading) 2)<br />

Linearity ≤ ± 0.5 % of F.S.* (at 10 m/s) 2)<br />

Repeatability ≤ 0.4 % of Reading 2)<br />

Electrical data:<br />

Power supply<br />

Standard signal version<br />

Battery indicator / totalizer version<br />

Reversed polarity of DC<br />

Current consumption with sensor<br />

(without consumption of pulse output)<br />

Output<br />

Standard signal version<br />

Signal current<br />

Pulse<br />

Relay<br />

Battery indicator / totalizer version<br />

12–30 V DC (V+) ± 10 %, filtered and regulated or<br />

115/230 V AC 50/60 Hz (see technical<br />

specifications 115/230 V AC)<br />

2 x 9 V DC batteries, autonomy min. 1 years<br />

at 20 °C<br />

protected<br />

≤ 70 mA – transmitter with relays<br />

≤ 20 mA – transmitter without relay<br />

4–20 mA (3-wire with relays; 2-wire without relay)<br />

max. loop impedance: 900 Ω at 30 V DC;<br />

600 Ω at 24 V DC; 50 Ω at 12 V DC;<br />

800 Ω with a 115/230 V AC voltage supply<br />

Polarized, potential free, 5...30 V DC; 100 mA,<br />

protected, line drop at 100 mA: 1.5 V DC<br />

2 relays, freely programmable, 3 A, 230 V AC<br />

None<br />

1) with Battery version = 100 °C<br />

2) Under reference conditions i. e. measuring fluid = water, ambient and<br />

water temperature = 20 °C, applying the minimum inlet and outlet pipe<br />

straights, matched inside pipe dimensions.<br />

* F.S.=Full scale (10 m/s)<br />

Technical specifications 115/230 V AC:<br />

Supply voltage<br />

Standard:<br />

Protection class<br />

27 V DC regulated,<br />

max. current: 125 mA<br />

integrated protection: fuse 125 mA temporised<br />

power: 3 VA<br />

IP65 with cable plug or gland mounted and<br />

tightened or with obturator locked if not used.<br />

Meyer <strong>Industrie</strong>-<strong>Electronic</strong> <strong>GmbH</strong> – MEYLE<br />

Carl-Bosch-Straße 8<br />

49525 Lengerich/Germany<br />

Tel.: +49 54 81-93 85-0<br />

Fax: +49 54 81-93 85-12<br />

Internet: www.meyle.de<br />

E-Mail: sales@meyle.de<br />

13

DIGITAL FLOW TRANSMITTER MyProc MFT 0247<br />

Installation:<br />

The MFT 0247 flow transmitter can easily be installed into any insertion fitting system (MAF 242) by just fixing the main nut.<br />

Minimum straight upstream and downstream distances must be observed. According to the pipe’s design, necessary distances can be bigger or use a flow<br />

conditioner to obtain the best accuracy. For more information, please refer to EN ISO 5167-1.<br />

EN ISO 5167-1 prescribes the straight inlet and outlet distances that must be complied with when installing fittings in pipe lines in order to achieve calm flow<br />

conditions. The most important layouts that could lead to turbulence in the flow are shown below, together with the associated prescribed minimum inlet and<br />

outlet distances. These ensure calm, problem-free measurement conditions at the measurement point.<br />

DN = orifice Fluid direction --><br />

Regulating<br />

valve<br />

90°<br />

elbow joint<br />

or T-piece<br />

2 x 90°<br />

elbow joint<br />

3 dimensional<br />

Extension<br />

2 x 90°<br />

elbow joint<br />

Reduction<br />

The flow rate transmitter can be installed into either horizontal or vertical pipes.<br />

Pressure and temperature ratings must be respected according to the selected fitting material.<br />

The suitable pipe size is selected using diagram Flow / Velocity / DN.<br />

The flow transmitter is not designed for gas flow measurement.<br />

Pressure/Temperature diagram:<br />

A:<br />

Application<br />

range for<br />

complete device<br />

(fitting +<br />

transmitter)<br />

14<br />

Meyer <strong>Industrie</strong>-<strong>Electronic</strong> <strong>GmbH</strong> – MEYLE<br />

Carl-Bosch-Straße 8<br />

49525 Lengerich/Germany<br />

Tel.: +49 54 81-93 85-0<br />

Fax: +49 54 81-93 85-12<br />

Internet: www.meyle.de<br />

E-Mail: sales@meyle.de

DIGITAL FLOW TRANSMITTER MyProc MFT 0247<br />

Selection of fitting/pipe size:<br />

Example:<br />

– Specification of nominal flow: 10 m3/h<br />

– Ideal flow velocity: 2...3 m/s<br />

– For these specifications, the diagram indicates a pipe size of DN40<br />

[or DN50 for (*) mentioned fittings]<br />

Dimensions:<br />

91<br />

(21)<br />

R 90<br />

Flow rate<br />

85.5<br />

(30)<br />

164.50<br />

203<br />

82<br />

136<br />

70<br />

88<br />

Note:<br />

The length of the sensor finger depends<br />

on the fitting used. See data sheet Type MAF 242.<br />

88<br />

Flow velocity<br />

* for following fittings:<br />

– with external threads acc. to SMS 1145<br />

– with weld-ends acc. to SMS 3008, BS 4825 / ASME BPE or<br />

DIN 11850 Series 2<br />

– TriClamp ® acc. to SMS 3017 / ISO 2852, BS 4825 / ASME BPE or<br />

DIN 32676<br />

Tri-Clamp ® is a registered Trademark of Alfa Laval Inc.<br />

DN<br />

H [mm]<br />

[mm] T-Fitting Saddle Plastic St. St.<br />

spigot spigot<br />

15 187<br />

20 185<br />

25 185<br />

32 188<br />

40 192<br />

50 198 223 193<br />

65 198 221 206 199<br />

80 226 212 204<br />

100 231 219 214<br />

110 227<br />

125 234 254 225<br />

150 244 261 236<br />

180 268<br />

200 280 282 257<br />

250 300 317<br />

300 312 336<br />

350 325 348<br />

400 340<br />

Meyer <strong>Industrie</strong>-<strong>Electronic</strong> <strong>GmbH</strong> – MEYLE<br />

Carl-Bosch-Straße 8<br />

49525 Lengerich/Germany<br />

Tel.: +49 54 81-93 85-0<br />

Fax: +49 54 81-93 85-12<br />

Internet: www.meyle.de<br />

E-Mail: sales@meyle.de<br />

15

DIGITAL FLOW TRANSMITTER MyProc MFT 0247<br />

Remote transmitter:<br />

Each transmitter is available in either:<br />

– MFT 0247 Universal transmitter for connection to MEYLE sensor or other sensor types<br />

– This flow transmitter can be associated with MEYLE flow sensor MFS 0242, MFS 0252 or another<br />

flow sensor, with pulse output signal.<br />

– MFT 0247 transmitter for connection to compact MEYLE sensors.<br />

– This flow transmitter can only be associated with MEYLE flow sensor MFS 0242, MFS 0252 with<br />

“Low Power“ pulse output signal.<br />

Wall-mounted<br />

Panel-mounted<br />

Dimensions:<br />

Panel-mounted version<br />

88<br />

38<br />

76 25<br />

88<br />

Wall-mounted version<br />

126<br />

31.50<br />

143<br />

90<br />

120<br />

23<br />

23<br />

16<br />

Meyer <strong>Industrie</strong>-<strong>Electronic</strong> <strong>GmbH</strong> – MEYLE<br />

Carl-Bosch-Straße 8<br />

49525 Lengerich/Germany<br />

Tel.: +49 54 81-93 85-0<br />

Fax: +49 54 81-93 85-12<br />

Internet: www.meyle.de<br />

E-Mail: sales@meyle.de

DIGITAL FLOW TRANSMITTER MyProc MFT 0247<br />

Technical data (remote version):<br />

MFT 0247 Universal transmitter<br />

MFT 0247 transmitter<br />

General data<br />

Compatibility MEYLE flow sensor with frequency output MEYLE flow sensor with frequency output<br />

MFS 0242, MFS 0252 and other sensors with MFS 0242, MFS 0252 (pulse “Low Power” .<br />

compatible electrical data.<br />

version).<br />

Materials<br />

Housing, cover<br />

PC (panel-mounted version); ABS (wall-mounted version)<br />

Front panel foil<br />

Polyester<br />

Screws<br />

Stainless steel<br />

Cable glands<br />

PA (wall-mounted version)<br />

Electrical connections<br />

Terminals (panel-mounted version) or terminals via gland (wall-mounted version)<br />

Electrical data<br />

Power supply<br />

Panel-mounted version 13–30 V DC (V+) ± 10 %, filtered and regulated 12–30 V DC (V+) ± 10 %, filtered and regulated<br />

Wall-mounted version 13–30 V DC (V+) ± 10 %, filtered and regulated or 12–30 V DC (V+) ± 10 %, filtered and regulated or<br />

115/230 V AC 50/60 Hz (see technical 115/230 V AC 50/60 Hz (see technical<br />

specifications 115/230 V AC)<br />

specifications 115/230 V AC)<br />

Reversal polarity of DC<br />

protected<br />

Current consumption without sensor ≤ 70 mA - transmitter with relays ≤ 70 mA - transmitter with relays<br />

(without consumption of pulse output) ≤ 30 mA - transmitter without relay ≤ 20 mA - transmitter without relay<br />

Sensor input<br />

Frequency range 0.5 Hz or 2.5 Hz up to 1400 Hz - 2.5 Hz up to 250 Hz<br />

max. voltage: 30 V DC<br />

Pulse “Low Power” (open collector NPN)<br />

Open collector NPN (with 470 Ω or 2.2 kΩ<br />

resistance) or PNP, Coil, TTL, CMOS<br />

(with 39 kΩ resistance)<br />

Sensor output<br />

Voltage supply 11...28 V DC (V+ - 2 V DC) or +12 V DC or 5 V DC 10–28 V DC (V+ - 2 V DC),<br />

(with a 13–30 V DC powered transmitter);<br />

+27 V DC or +12 V DC or 5 V DC (with a<br />

115/230 V AC powered transmitter)<br />

Current consumption max. current available from transmitter: max. current available from transmitter:<br />

100 mA 1 mA (internal limitation)<br />

Output Transmitter<br />

Signal current 4–20 mA, configurable in sourcing or sinking mode 4-20 mA (3-wire with relays; 2-wire without relay)<br />

max. loop impedance: 1200 Ω at 30 V DC;<br />

max. loop impedance: 900 Ω at 30 V DC;<br />

900 Ω at 24 V DC; 450 Ω at 15 V DC; 600 Ω at 24 V DC; 50 Ω at 12 V DC;<br />

300 Ω at 13 V DC; 800 Ω with a 115/230 V AC voltage supply<br />

1000 Ω with a 115/230 V AC voltage supply<br />

Pulse polarized, potential free, 5...30 V DC; 100 mA, polarized, potential free, 5...30 V DC; 100 mA,<br />

protected, line drop at 100 mA: 1.5 V DC<br />

protected, line drop at 100 mA: 1.5 V DC<br />

Relay 2 relays, programmable, 3A, 230 V AC 2 relays, programmable, 3A, 230 V AC<br />

Technical specifications<br />

115/230 V AC<br />

Wall-mounted version<br />

Supply voltage supply: 27 V DC regulated,<br />

Max. current: 250 mA<br />

Integrated protection: fuse 250 mA temporised<br />

Power: 6 VA<br />

Standards and approvals<br />

Protection class<br />

IP65 (panel-mounted and wall-mounted version)<br />

IP20 (panel-mounted version, inside the cabinet)<br />

Agreements CE CE<br />

Meyer <strong>Industrie</strong>-<strong>Electronic</strong> <strong>GmbH</strong> – MEYLE<br />

Carl-Bosch-Straße 8<br />

49525 Lengerich/Germany<br />

Tel.: +49 54 81-93 85-0<br />

Fax: +49 54 81-93 85-12<br />

Internet: www.meyle.de<br />

E-Mail: sales@meyle.de<br />

17

DIGITAL FLOW TRANSMITTER MyProc MFT 0247<br />

ORDERING CODE MFT 0247<br />

Compact flow transmitter or indicator / totalizer with integrated paddle-wheel sensor<br />

Complete system consists of:<br />

– an insertion flow transmitter Type MFT 0247<br />

– an insertion fitting Type MAF 242 (DN 15 – DN 400) (Refer to corresponding data sheet – has to be ordered separately)<br />

Specifications<br />

Standard output signal<br />

transmitter, 2 totalizers<br />

Indicator, 2 totalizers<br />

Supply voltage<br />

12–30 V DC<br />

115–230 V AC<br />

2 x 9 V DC<br />

Batteries<br />

Output<br />

4–20 mA (2 wires)<br />

+ pulse<br />

4–20 mA (3 wires)<br />

+ pulse<br />

4–20 mA (2 wires)<br />

+ pulse<br />

4–20 mA (3 wires)<br />

+ pulse<br />

Relays<br />

None<br />

2<br />

None<br />

2<br />

None<br />

Sensor version<br />

Hall, short<br />

Hall, long<br />

Hall, short<br />

Hall, long<br />

Hall, short<br />

Hall, long<br />

Hall, short<br />

Hall, long<br />

Coil, short<br />

Coil, long<br />

Note: FKM gasket in standard; 1 Kit including a black EPDM gasket for the sensor, an obturator for an M20 x 1.5 cable gland, a 2 x 6 mm multiway seal and a mounting instruction sheet is supplied with each transmitter.<br />

Electrical Connector<br />

EN 175301-803<br />

2 cable glands<br />

EN 175301-803<br />

2 cable glands<br />

2 cable glands<br />

2 cable glands<br />

2 cable glands<br />

2 cable glands<br />

2 cable glands<br />

2 cable glands<br />

None<br />

None<br />

Item no.<br />

559 806<br />

630 024<br />

630 985<br />

559 807<br />

630 990<br />

630 991<br />

559 812<br />

559 813<br />

630 653<br />

630 654<br />

630 625<br />

630 627<br />

Remote Universal transmitter (panel- or wall-mounted)<br />

Complete system consists of:<br />

– a remote universal transmitter Type MFT 0247 (wall-mounted or panel-mounted)<br />

– an insertion flow sensor type MFS 0242 or in line flow sensor MFS 0252 (Refer to corresponding data sheet – has to be ordered separately)<br />

– an insertion fitting MAF 242 (DN 15 – DN 400) or in line fitting MAF 252 (DN 6 – DN 65) (Refer to corresponding data sheet – has to be<br />

ordered separately)<br />

Specifications<br />

Supply voltage<br />

Output<br />

Relays<br />

Electrical Connector<br />

Item no.<br />

Universal transmitter,<br />

panel mounted<br />

2 totalizers<br />

13–30 V DC<br />

4–20 mA (3 wires)<br />

+ pulse<br />

None<br />

2<br />

Terminal strip<br />

Terminal strip<br />

559 810<br />

631 759<br />

Universal transmitter,<br />

wall-mounted<br />

2 totalizers<br />

13–30 V DC<br />

115–230 V AC<br />

4–20 mA (3 wires)<br />

+ pulse<br />

4–20 mA (3 wires)<br />

+ pulse<br />

4–20 mA (3 wires)<br />

+ pulse<br />

None<br />

2<br />

None<br />

2<br />

3 cable glands<br />

3 cable glands<br />

3 cable glands<br />

3 cable glands<br />

559 811<br />

631 762<br />

559 816<br />

631 765<br />

Remote transmitter (panel- or wall-mounting) for connection to MEYLE “Low Power“ sensors only<br />

Complete system consists of:<br />

– a remote transmitter Type MFT 0247 (wall-mounted or panel-mounted)<br />

– an insertion flow sensor type MFS 0242 or inline flow sensor MFS 0252 (pulse „Low Power“ version) (Refer to corresponding data sheet – has to be ordered<br />

separately)<br />

– an insertion fitting MAF 242 (DN 15 – DN 400) or inline fitting MAF 252 (DN 6 – DN 65) (Refer to corresponding data sheet – has to<br />

be ordered separately)<br />

Specifications<br />

Supply voltage<br />

Output<br />

Relays<br />

Electrical Connector<br />

Item no.<br />

Transmitter,<br />

panel-mounted<br />

2 totalizers<br />

Transmitter,<br />

panel-mounted<br />

2 totalizers<br />

Transmitter,<br />

wall-mounted<br />

2 totalizers<br />

12–30 V DC<br />

12–30 V DC<br />

12–30 V DC<br />

115–230 V AC<br />

4–20 mA (2 wires)<br />

+ pulse<br />

4–20 mA (3 wires)<br />

+ pulse<br />

4–20 mA (2 wires)<br />

+ pulse<br />

4–20 mA (2 wires)<br />

+ pulse<br />

None<br />

2<br />

None<br />

None<br />

Terminal strip<br />

Terminal strip<br />

3 cable glands<br />

3 cable glands<br />

630 114<br />

774 948<br />

630 519<br />

630 622<br />

ORDERING CODE accessories for transmitter Type MFT 0247 (has to be ordered separately)<br />

Specifications<br />

Set with 2 cable glands M20 x 1.5 + 2 neoprene flat seals for cable gland or plug + 2 screw-plugs M20 x 1.5 + 2 multiway seals 2 x 6 mm<br />

Set with 2 reductions M20 x 1.5 /NPT1/2” + 2 neoprene flat seals for cable gland or plug + 2 screw-plugs M20 x 1.5<br />

Set with 1 stopper for unused cable gland M20 x 1.5 + 1 multiway seal 2 x 6 mm for cable gland + 1 black EPDM gasket for the sensor<br />

+ 1 mounting instruction sheet<br />

Ring<br />

Union nut<br />

Set with 1 green FKM and 1 black EPDM gasket<br />

Cable plug EN 175301-803 with NPT1/2” reduction without cable gland (Type 4721)<br />

Item no.<br />

661 977<br />

773 904<br />

773 997<br />

831 427<br />

831 426<br />

774 333<br />

384 895<br />

18<br />

Meyer <strong>Industrie</strong>-<strong>Electronic</strong> <strong>GmbH</strong> – MEYLE<br />

Carl-Bosch-Straße 8<br />

49525 Lengerich/Germany<br />

Tel.: +49 54 81-93 85-0<br />

Fax: +49 54 81-93 85-12<br />

Internet: www.meyle.de<br />

E-Mail: sales@meyle.de

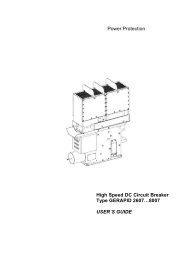

DIGITAL BATCH CONTROLLER MyProc MFC 0247<br />

• Compact or remote version for DN 06 to 400, PN10<br />

• Dosing<br />

• Automatic-calibration: TEACH-IN<br />

• Flow simulation possible on all output signals<br />

• Batched volume and totalizers displayed<br />

!<br />

The batch controller is specially designed for use in neutral and slightly aggressive, solid-free liquids.<br />

The device is available in different models:<br />

• Compact batch controller with integrated paddle-wheel sensor.<br />

• Remote batch controller for panel or wall mounting for connection to MFS 0242/MFS 0252 sensors or<br />

to a flow sensor from the market; sensors with open collector output, relay reed output or coil can be<br />

operated by this transmitter.<br />

Technical data (common to the various versions):<br />

General data<br />

Display<br />

15 x 60 mm, 8-digit LCD, alphanumeric,<br />

15 segments, 9 mm high<br />

Electrical connections<br />

shielded cable with 1.5 mm 2 max. cross-section<br />

and 50 m max. length<br />

Environment:<br />

Ambient temperature<br />

Relative humidity<br />

0 up to +60 °C (operation and storage)<br />

≤ 80 %, non condensated<br />

Standards and approvals:<br />

Standard<br />

EMC EN 61000-6-2, EN 61000-6-3<br />

Security EN 61010-1<br />

Vibration EN 60068-2-6<br />

Shock EN 60068-2-27<br />

MAF 242<br />

Insertion fitting<br />

MFS 0242<br />

Insertion flow sensor<br />

MFS 0252<br />

Inline flow sensor<br />

PLC<br />

Meyer <strong>Industrie</strong>-<strong>Electronic</strong> <strong>GmbH</strong> – MEYLE<br />

Carl-Bosch-Straße 8<br />

49525 Lengerich/Germany<br />

Tel.: +49 54 81-93 85-0<br />

Fax: +49 54 81-93 85-12<br />

Internet: www.meyle.de<br />

E-Mail: sales@meyle.de<br />

19

DIGITAL BATCH CONTROLLER MyProc MFC 0247<br />

Versions:<br />

The compact version<br />

combines a paddle-wheel flow<br />

sensor and an electronic module<br />

with a display in an IP65<br />

enclosure.<br />

The output signals are provided<br />

via two cable glands.<br />

The panel-mounted version<br />

consists of an electronic<br />

module MFC 0247 integrated<br />

in a front-cover. The associated<br />

separate flow sensor should<br />

have a pulse output signal, like<br />

Type MFS 0242, MFS 0252 or another flow<br />

sensor available from the market.<br />

The output signals are provided on a terminal<br />

strip.<br />

The wall-mounted version<br />

consists of an electronic<br />

module MFC 0247 in an IP65<br />

enclosure. The associated<br />

separate flow sensor should<br />

have a pulse output signal, like<br />

Type MFS 0242, MFS 0252 or another flow<br />

sensor available from the market.<br />

The output signals are provided on a terminal<br />

strip via cable glands.<br />

Operation and display:<br />

The device can be calibrated by means of the K-factor, or via the TEACH-IN function.<br />

Customized adjustments, such as measuring range, engineering units, pulse output are carried out on site.<br />

The operation is specified according to three levels:<br />

Indication in operating mode / Display<br />

– dosing amount<br />

– dosing mode<br />

– main totalizer<br />

– daily totalizer with reset function<br />

Parameter definition<br />

– language<br />

– engineering units<br />

– K-factor / TEACH-IN function<br />

– selection of dosing mode<br />

– over-run correction<br />

– alarm<br />

– function mode of relays<br />

– reset main totalizer<br />

Test<br />

– display of state of binary inputs<br />

– relay test<br />

– frequency test<br />

To scroll-up the menu or<br />

increase a value<br />

To scroll-down the menu<br />

or select a digit to be<br />

modified<br />

Confirm input and<br />

menu points<br />

Relay 2 LED*<br />

Relay 1 LED*<br />

*(option)<br />

20<br />

Meyer <strong>Industrie</strong>-<strong>Electronic</strong> <strong>GmbH</strong> – MEYLE<br />

Carl-Bosch-Straße 8<br />

49525 Lengerich/Germany<br />

Tel.: +49 54 81-93 85-0<br />

Fax: +49 54 81-93 85-12<br />

Internet: www.meyle.de<br />

E-Mail: sales@meyle.de

DIGITAL BATCH CONTROLLER MyProc<br />

MFC 0247<br />

Compact batch controller:<br />

Accuracy diagram:<br />

General data:<br />

Compatibility<br />

with fittings MAF 242 (see corresp. data sheet)<br />

Materials<br />

Housing, cover, lid, nut<br />

PC<br />

Front panel foil<br />

Polyester<br />

Screws<br />

Stainless steel<br />

Cable glands<br />

PA<br />

Wetted parts materials<br />

Fitting<br />

Brass, stainless steel 1.4404/316L, PVC, PP<br />

or PVDF<br />

Sensor finger, paddle-wheel<br />

PVDF<br />

Axis and bearing / Seal<br />

Ceramics / FKM (EPDM option)<br />

Electrical connections Cable glands M20 x 1.5<br />

Design:<br />

When liquid flows<br />

through the pipe, the<br />

paddle-wheel with 4 in -<br />

serted magnets is set in<br />

rotation, producing a<br />

measuring signal in the<br />

sensor (Hall sensor). The<br />

frequency modulated<br />

induced voltage is proportional to the flow velocity<br />

of the fluid. A conversion coefficient (K-factor,<br />

available in the instruction manual of the MAF 242<br />

fitting), specific to each pipe (size and material)<br />

enables the conversion of this frequency into<br />

volume. The electronic component converts the<br />

measured signal and displays the actual value of<br />

volume.<br />

The MFC 0247 batch controller is mounted in a<br />

pipe in series with the valve; the unit controls the<br />

opening of the valve and measures the quantity of<br />

the fluid which flows. The unit also closes the valve<br />

when the pre-programmed quantity has been<br />

delivered.<br />

The electronic component needs a voltage supply<br />

of 12-30 V DC or 115/230 V AC, and two output<br />

relays are used to activate the valves and to initiate<br />

alarms. The following dosing and filling operations<br />

are possible:<br />

– Local dosing:<br />

the user enters the quantity to be metered and<br />

initiates the dosage from the keypad.<br />

– Local dosing with pre-set quantity:<br />

the user selects a quantity which has been preset<br />

and initiates the dosage from the keypad.<br />

– Remote control dosing<br />

using a rotary knob (selecting a pre-set quantity)<br />

or binary data inputs.<br />

– Dosing controlled by a PLC unit<br />

using binary data inputs.<br />

– Automatic dosing controlled by variation of<br />

pulse duration.<br />

The quantity of the dose is directly proportional<br />

to the duration of a pulse.<br />

Complete device data (Fitting + <strong>Electronic</strong>s):<br />

Pipe diameter DN 15 to 400<br />

Measuring range<br />

0.3 to 10 m/s (Hall transducer version)<br />

Fluid temperature with fitting in<br />

PVC 0 up to 50 °C<br />

PP 0 up to 80 °C<br />

PVDF, brass or stainless steel<br />

-15 up to 80° C<br />

Fluid pressure max.<br />

PN10 (see pressure/temperature diagram)<br />

Viscosity<br />

300 cSt. max.<br />

Accuracy<br />

Teach-In ≤ ± 0.5 % of F.S.* (at 10 m/s) 1)<br />

Standard K-factor ≤ ± (0.5 % of F.S.* + 2.5 % of Reading) 1)<br />

Linearity ≤ ± 0.5 % of F.S.* (at 10 m/s) 1)<br />

Repeatability ≤ 0.4 % of Reading 1)<br />

Electrical data:<br />

Power supply<br />

Current consumption with sensor<br />

Input<br />

Output<br />

Batch status<br />

Relay<br />

Technical specifications 115/230 V AC:<br />

Supply voltage<br />

Standard and approvals:<br />

12–30 V DC, filtered and regulated or<br />

115/230 V AC 50/60 Hz (see technical<br />

specifications 115/230 V AC)<br />

≤ 70 mA – without consumption of inputs/outputs<br />

4 binary inputs, 5... 30 V DC; impedance 3.3 k Ω<br />

Functions: dosing quantity choice, start-stop<br />

dosing<br />

Polarized, potential free, 5...30 V DC; 100 mA,<br />

protected, line drop at 100 mA: 1.5 V DC – for<br />

status and alarm message<br />

2 relays, freely programmable, 3A, 230 V AC<br />

27 V DC regulated,<br />

max. current: 125 mA<br />

integrated protection: fuse 125 mA temporised<br />

power: 3 VA<br />

Protection class<br />

IP65 with cable gland tightened or with obturator<br />

locked if not used.<br />

1) Under reference conditions i.e. measuring fluid = water, ambient and water temperature = 20 °C, applying the minimum inlet and outlet pipe straights,<br />

matched inside pipe dimensions.<br />

* F.S.=Full scale (10 m/s)<br />

Meyer <strong>Industrie</strong>-<strong>Electronic</strong> <strong>GmbH</strong> – MEYLE<br />

Carl-Bosch-Straße 8<br />

49525 Lengerich/Germany<br />

Tel.: +49 54 81-93 85-0<br />

Fax: +49 54 81-93 85-12<br />

Internet: www.meyle.de<br />

E-Mail: sales@meyle.de<br />

21

DIGITAL BATCH CONTROLLER MyProc MFC 0247<br />

Installation:<br />

The MFC 0247 batch controller can easily be installed into any insertion fitting system (MAF 242) by just fixing the main nut.<br />

Minimum straight upstream and downstream distances must be observed. According to the pipe’s design, necessary distances can be bigger or use a flow<br />

conditioner to obtain the best accuracy. For more information, please refer to EN ISO 5167-1.<br />

EN ISO 5167-1 prescribes the straight inlet and outlet distances that must be complied with when installing fittings in pipe lines in order to achieve calm flow<br />

conditions. The most important layouts that could lead to turbulence in the flow are shown below, together with the associated prescribed minimum inlet and<br />

outlet distances. These ensure calm, problem-free measurement conditions at the measurement point.<br />

DN = orifice Fluid direction --><br />

Regulating<br />

valve<br />

90°<br />

elbow joint<br />

or T-piece<br />

2 x 90°<br />

elbow joint<br />

3 dimensional<br />

Extension<br />

2 x 90°<br />

elbow joint<br />

Reduction<br />

The batch controller sensor can be installed in either horizontal or vertical pipes.<br />

Pressure and temperature ratings must be respected according to the selected fitting material.<br />

The suitable pipe size is selected using diagram Flow / Velocity / DN.<br />

The batch controller is not designed for gas dosing.<br />

Pressure/Temperature diagram:<br />

A:<br />

Application<br />

range for<br />

complete device<br />

(fitting + controller)<br />

22<br />

Meyer <strong>Industrie</strong>-<strong>Electronic</strong> <strong>GmbH</strong> – MEYLE<br />

Carl-Bosch-Straße 8<br />

49525 Lengerich/Germany<br />

Tel.: +49 54 81-93 85-0<br />

Fax: +49 54 81-93 85-12<br />

Internet: www.meyle.de<br />

E-Mail: sales@meyle.de

DIGITAL BATCH CONTROLLER MyProc MFC 0247<br />

Selection of fitting/pipe size:<br />

Example:<br />

– Specification of nominal flow: 10 m 3 /h<br />

– Ideal flow velocity: 2...3 m/s<br />

– For these specifications, the diagram indicates a pipe size of DN40<br />

[or DN50 for (*) mentioned fittings]<br />

Dimensions:<br />

Flow rate<br />

Note:<br />

The length of the sensor finger depends<br />

on the fitting used. See data sheet Type MAF 242.<br />

Flow velocity<br />

* for following fittings:<br />

– with external threads acc. to SMS 1145<br />

– with weld-ends acc. to SMS 3008, BS 4825 / ASME BPE or<br />

DIN 11850 Series 2<br />

– TriClamp ® acc. to SMS 3017 / ISO 2852, BS 4825 / ASME BPE or<br />

DIN 32676<br />

Tri-Clamp ® is a registered Trademark of Alfa Laval Inc.<br />

DN<br />

H [mm]<br />

[mm] T-Fitting Saddle Plastic St. St.<br />

spigot spigot<br />

15 187<br />

20 185<br />

25 185<br />

32 188<br />

40 192<br />

50 198 223 193<br />

65 198 221 206 199<br />

80 226 212 204<br />

100 231 219 214<br />

110 227<br />

125 234 254 225<br />

150 244 261 236<br />

180 268<br />

200 280 282 257<br />

250 300 317<br />

300 312 336<br />

350 325 348<br />

400 340<br />

Meyer <strong>Industrie</strong>-<strong>Electronic</strong> <strong>GmbH</strong> – MEYLE<br />

Carl-Bosch-Straße 8<br />

49525 Lengerich/Germany<br />

Tel.: +49 54 81-93 85-0<br />

Fax: +49 54 81-93 85-12<br />

Internet: www.meyle.de<br />

E-Mail: sales@meyle.de<br />

23

DIGITAL BATCH CONTROLLER MyProc MFC 0247<br />

General data:<br />

Compatibility<br />

Materials<br />

Housing, cover<br />

Front panel foil<br />

Screws<br />

Cable glands<br />

Electrical connections<br />

Electrical data:<br />

Power supply<br />

Panel-mounted version<br />

Wall-mounted version<br />

Current consumption with sensor<br />

Sensor input<br />

Frequency range<br />

Sensor output<br />

Voltage supply<br />

Current consumption<br />

Input<br />

Output<br />

Batch status<br />

Relay<br />

Standards and approvals:<br />

Protection class<br />

Technical specifications 115/230 VAC:<br />

Supply voltage<br />

Flow sensor with frequency output MFS 0242, MFS 0252 or other sensors with compatible electrical data.<br />

PC (panel-mounted version); ABS (wall-mounted version)<br />

Polyester<br />

Stainless steel<br />

PA<br />

Terminals (panel-mounted version) or terminals via cable glands M16 x 1.5 (wall-mounted version)<br />

12–30 V DC (V+), filtered and regulated<br />

12–30 V DC, filtered and regulated or 115/230 V AC 50/60 Hz (see technical specifications 115/230 VAC)<br />

≤ 70 mA – without consumption of inputs/outputs<br />

2.5 Hz up to 700 Hz Open collector NPN, Coil, TTL, CMOS<br />

12...30 V DC (V+) or 0...18 V DC (V+ - 12 V DC) (with a 12-30 V DC powered controller);<br />

+15 V DC or + 27 V DC (with a 115/230 V AC powered controller)<br />

max. current available from controller: 25 mA (115/230 V AC version) 100 mA (12-30 V DC version)<br />

4 binary inputs, 5... 30 V DC; Functions: dosing quantity choice, start-stop dosing<br />

Polarized, potential free, 5...30 V DC; 100 mA, protected, line drop at 100 mA: 1.5 V DC – for status and<br />

alarm message<br />

2 relays, freely programmable, 3A, 230 V AC<br />

IP65 (panel-mounted and wall-mounted version), IP20 (panel-mounted version, inside the cabinet)<br />

27 V DC regulated, max. current: 250 mA integrated protection: fuse 250 mA temporised power: 6 VA<br />

Dimensions:<br />

Panel-mounted version<br />

Wall-mounted version<br />

24<br />

Meyer <strong>Industrie</strong>-<strong>Electronic</strong> <strong>GmbH</strong> – MEYLE<br />

Carl-Bosch-Straße 8<br />

49525 Lengerich/Germany<br />

Tel.: +49 54 81-93 85-0<br />

Fax: +49 54 81-93 85-12<br />

Internet: www.meyle.de<br />

E-Mail: sales@meyle.de

DIGITAL BATCH CONTROLLER MyProc MFC 0247<br />

ORDERING CODE MFC 0247<br />

Compact batch controller with integrated paddle-wheel sensor<br />

Complete system consists of:<br />

– an insertion batch controller Type MFC 0247<br />

– an insertion fitting Type MAF 242 (DN 15 – DN 400) (Refer to corresponding data sheet – has to be ordered separately)<br />

Specifications<br />

2 totalizers<br />

Supply voltage<br />

12–30 V DC<br />

115–230 V AC<br />

Relays<br />

2<br />

Sensor version<br />

Hall, short<br />

Hall, long<br />

Hall, short<br />

Hall, long<br />

Note: FKM gasket in standard; 1 Kit including a black EPDM gasket for the sensor, an obturator for an M20 x 1.5 cable gland, a 2 x 6 mm multiway seal and a mounting instruction sheet is supplied with each transmitter.<br />

2<br />

Electrical Connector<br />

2 cable glands<br />

2 cable glands<br />

2 cable glands<br />

2 cable glands<br />

Item no.<br />

559 808<br />

559 809<br />

559 814<br />

559 815<br />

Remote batch controller (panel- or wall-mounted)<br />

Complete system consists of:<br />

– a remote batch controller Type MFC 0247 (wall-mounted or panel-mounted)<br />

– a flow sensor MFS 0242, MFS 0252 (has to be ordered separately)<br />

Specifications<br />

Supply voltage<br />

Relays<br />

Sensor version<br />

Electrical Connector<br />

Item no.<br />

Panel mounted<br />

2 totalizers<br />

12–30 V DC<br />

2<br />

see note<br />

5 cable glands<br />

631 758<br />

Wall-mounted<br />

2 totalizers<br />

12–30 V DC<br />

115–230 V AC<br />

2<br />

2<br />

see note<br />

see note<br />

5 cable glands<br />

5 cable glands<br />

655 962<br />

655 963<br />

ORDERING CODE accessories for batch controller Type MFC 0247 (has to be ordered separately)<br />

Specifications<br />

Set with 2 cable glands M20 x 1.5 + 2 neoprene flat seals for cable gland or screw-plug + 2 screw-plugs M20 x 1.5 + 2 multiway seals<br />

2 x 6 mm<br />

Set with 2 reductions M20 x 1.5 /NPT1/2” + 2 neoprene flat seals for cable gland or screw-plug + 2 screw-plugs M20 x 1.5<br />

Set with 1 stopper for unused cable gland M20 x 1.5 +1 multiway seal 2 x 6 mm for cable gland + 1 black EPDM gasket for the sensor<br />

+ 1 mounting instruction sheet<br />

Ring<br />

PC-Nut<br />

Set with 1 green FKM and 1 black EPDM gasket<br />

Item no.<br />

661 977<br />

773 904<br />

773 997<br />

831 427<br />

831 426<br />

774 333<br />

Meyer <strong>Industrie</strong>-<strong>Electronic</strong> <strong>GmbH</strong> – MEYLE<br />

Carl-Bosch-Straße 8<br />

49525 Lengerich/Germany<br />

Tel.: +49 54 81-93 85-0<br />

Fax: +49 54 81-93 85-12<br />

Internet: www.meyle.de<br />

E-Mail: sales@meyle.de<br />

25

INLINE FLOW SENSOR MyProc MFS 0252<br />

• Continuous flow measurement for use in neutral, slightly aggressive and solid free liquids<br />

• Paddle-wheel flow sensor<br />

• Simple installation into all pipes from PN 15 to 400<br />

• Frequency pulse signal, proportional to flow rate<br />

!<br />

MFT 0247<br />

General data:<br />

Compatibility<br />

with fittings MAF 252 (see corresp. data sheet)<br />

Materials<br />

Housing, cover<br />

PC<br />

Cable plug<br />

PA<br />

Materials wetted parts<br />

Fitting, sensor armature<br />

Brass, stainless steel 1.4404/316L, PVC, PP, PVDF<br />

Paddle-wheel<br />

PVDF<br />

Axis and bearing<br />

Ceramics<br />

Seal<br />

FKM (EPDM option)<br />

Electrical connections Cable plug EN 175301-803<br />

Connection cable<br />

1.5 mm 2 max. cross-section;<br />

Repeatibility ≤ 0.4 % of Reading 1)<br />

max. 50 m length, shielded<br />

Complete device data (fitting + electronic module MFS 0252):<br />

Pipe diameter DN 06 to 65<br />

Measuring range<br />

0.3 to 10 m/s<br />

Fluid temperature with<br />

PVC fitting 0 up to 50 °C<br />

PP fitting 0 up to 80 °C<br />

St.st., brass, PVDF fitting -15 up to 100 °C<br />

Fluid pressure max.<br />

PN10 (with plastic fitting) PN16 (with metal fitting)<br />

(PN40 on request, see MAF 252 data sheet)<br />

Viscosity<br />

300 cSt. max.<br />

Accuracy<br />

Teach-In ≤ ± 0.5 % of F.S.* (at 10 m/s) 1)<br />

Standard K-factor ≤ ± (0.5 % of F.S.* + 2.5 % o. Reading) 1)<br />

Linearity ≤ ± 0.5 % of F.S.* (at 10 m/s) 1)<br />

Flow transmitter<br />

MFC 0247<br />

Batch controller<br />

MAF 252<br />

Inline fitting<br />

Electrical data:<br />

Power supply<br />

Current consumption<br />

Pulse version<br />

Pulse “Low power” vers.<br />

Output: Frequency<br />

Pulse version<br />

Pulse “Low Power” vers.<br />

Reversed polarity of DC<br />

Environment:<br />

Ambient temperature<br />

Relative humidity<br />

12–36 V DC<br />

with sensor<br />

≤ 30 mA<br />

≤ 0.8 mA<br />

Transistor NPN/PNP, open collector,<br />

max. 100 mA, frequency: 0...300 Hz;<br />

duty cycle 1/2<br />

Transistor NPN, open collector,<br />

max. 10 mA, frequency: 0...300 Hz;<br />

duty cycle 1/2<br />

Protected<br />

-15 up to +60 °C (operating and storage)<br />

≤ 80 %, non condensated<br />

PLC<br />

Standards and approvals:<br />

Protection class<br />

IP65, with connector plugged-in and tigthened<br />

Standard<br />

EMC EN 61000-6-2, 61000-6-3<br />

Vibration EN 60068-2-6<br />

Shock EN 60068-2-27<br />

* FS. = Full scale (10 m/s)<br />

1) Under reference conditions i.e. measuring fluid = water, ambient and water temperature = 20 °C, applying the minimum inlet and outlet pipe straight, matched inside pipe dimensions.<br />

26<br />

Meyer <strong>Industrie</strong>-<strong>Electronic</strong> <strong>GmbH</strong> – MEYLE<br />

Carl-Bosch-Straße 8<br />

49525 Lengerich/Germany<br />

Tel.: +49 54 81-93 85-0<br />

Fax: +49 54 81-93 85-12<br />

Internet: www.meyle.de<br />

E-Mail: sales@meyle.de

INLINE FLOW SENSOR MyProc MFS 0252<br />

Accuracy diagram:<br />

Design and principle of operation:<br />

The flow sensor is built up with an electronic module MFS 0252 associated to a fitting MPF 0252 with integrated measurement paddle-wheel. This connection<br />

is made by means of a Quarter-Turn.<br />

In a 3-wire system, the signal can be displayed or processed directly. The output signal is provided via cable plug according to EN 175301-803.<br />

When liquid flows through the pipe, the paddle-wheel is set in rotation, producing a measuring signal in the transducer. The frequency modulated induced<br />

voltage is proportional to the flow velocity of the fluid.<br />

A conversion coefficient (K-factor, available in the instruction manual of the fitting), specific to each pipe (size and material) enables the conversion of this<br />

frequency into flow rate.<br />

Two electronic module versions with frequency output are available:<br />

– with one pulse output (either NPN or PNP transistor output depending on wiring).<br />

An external power supply of 12–36 V DC is required. It is designed for connection to any system with open collector NPN or PNP frequency input.<br />

– with one pulse “Low Power” output (NPN transistor output).<br />

An external power supply of 12–36 V DC is required. Can only be connected to separate versions of flow transmitters Type MFT 0247.<br />

Pressure / temperature chart:<br />

A: Application range for<br />

complete device<br />

(fitting + sensor)<br />

Meyer <strong>Industrie</strong>-<strong>Electronic</strong> <strong>GmbH</strong> – MEYLE<br />

Carl-Bosch-Straße 8<br />

49525 Lengerich/Germany<br />

Tel.: +49 54 81-93 85-0<br />

Fax: +49 54 81-93 85-12<br />

Internet: www.meyle.de<br />

E-Mail: sales@meyle.de<br />

27

INLINE FLOW SENSOR MyProc MFS 0252<br />

Installation:<br />

The MFS 0252 flow sensor can easily be installed into any inline fitting system Type MAF 252, by means of a Quarter-Turn.<br />

Minimum straight upstream and downstream distances must be observed. According to the pipe’s design, necessary distances can<br />

be bigger or use a flow conditioner to obtain the best accuracy. For more information, please refer to EN ISO 5167-1.<br />

EN ISO 5167-1 prescribes the straight inlet and outlet distances that must be complied with when installing fittings in pipe lines in<br />

order to achieve calm flow conditions. The most important layouts that could lead to turbulence in the flow are shown below,<br />

together with the associated prescribed minimum inlet and outlet distances. These ensure calm, problem-free measurement<br />

conditions at the measurement point.<br />

DN = orifice Fluid direction --><br />

Regulating<br />

valve<br />

90°<br />

elbow joint<br />

or T-piece<br />

2 x 90°<br />

elbow joint<br />

3 dimensional<br />

Extension<br />

2 x 90°<br />

elbow joint<br />

Reduction<br />

The flow rate sensor can be installed in either horizontal or vertical pipes.<br />

Pressure and temperature ratings must be respected according to the selected fitting material.<br />

The suitable pipe size is selected using diagram Flow / Velocity / DN.<br />

The sensor is not designed for gas flow measurement.<br />

28<br />

Meyer <strong>Industrie</strong>-<strong>Electronic</strong> <strong>GmbH</strong> – MEYLE<br />

Carl-Bosch-Straße 8<br />

49525 Lengerich/Germany<br />

Tel.: +49 54 81-93 85-0<br />

Fax: +49 54 81-93 85-12<br />

Internet: www.meyle.de<br />

E-Mail: sales@meyle.de

INLINE FLOW SENSOR MyProc MFS 0252<br />

Selection of fitting/pipe size:<br />

Example:<br />

– Specification of nominal flow: 10 m 3 /h<br />

– Ideal flow velocity: 2...3 m/s<br />

– For these specifications, the diagram indicates a pipe size of DN40<br />

[or DN50 for (*) mentioned fittings]<br />

Dimensions:<br />

Flow rate<br />

Flow velocity<br />

DN [mm]<br />

H [mm]<br />

06 95.5<br />

08 95.5<br />

15 100.5<br />

20 98.0<br />

25 98.0<br />

32 102.0<br />

40 105.5<br />

50 112.0<br />

65 112.0<br />

* for following fittings:<br />

– with external threads acc. to SMS 1145<br />

– with weld-ends acc. to SMS 3008, BS 4825 / ASME BPE or<br />

DIN 11850 Series 2<br />

– TriClamp ® acc. to SMS 3017 / ISO 2852, BS 4825 / ASME BPE or<br />

DIN 32676<br />

Tri-Clamp ® is a registered Trademark of Alfa Laval Inc.<br />

Meyer <strong>Industrie</strong>-<strong>Electronic</strong> <strong>GmbH</strong> – MEYLE<br />

Carl-Bosch-Straße 8<br />

49525 Lengerich/Germany<br />

Tel.: +49 54 81-93 85-0<br />

Fax: +49 54 81-93 85-12<br />

Internet: www.meyle.de<br />

E-Mail: sales@meyle.de<br />

29

INLINE FLOW SENSOR MyProc MFS 0252<br />

ORDERING CODE MFS 0252<br />

Complete system consists of:<br />

– a sensor module Type MFS 0252<br />

– an inline fitting Type MAF 252 (DN 06 – DN 65) (Refer to corresponding data sheet – has to be ordered separately)<br />

– a transmitter Type MFT 0247 or a batch contoller Type MFC 0247 – has to be ordered separately<br />

Specifications<br />

Supply voltage<br />

Output<br />

Connector<br />

Item no.<br />

Pulse version sensor standard<br />

Pulse version sensor Low<br />

Power<br />

12–36 V DC<br />

from associated<br />

transmitter<br />

Frequency with pulse,<br />

PNP or NPN<br />

Frequency with pulse,<br />

NPN<br />

Cable plug EN 175301-803<br />

Cable plug EN 175301-803<br />

559 821<br />

645 136<br />

ORDERING CODE accessories (to be ordered separately)<br />

Specifications<br />

Cable plug EN 175301-803 with cable gland (Type 4720)<br />

Cable plug EN 175301-803 with NPT1/2“ reduction without cable gland (Type 4721)<br />

Item no.<br />

650 033<br />

384 895<br />

30<br />

Meyer <strong>Industrie</strong>-<strong>Electronic</strong> <strong>GmbH</strong> – MEYLE<br />

Carl-Bosch-Straße 8<br />

49525 Lengerich/Germany<br />

Tel.: +49 54 81-93 85-0<br />

Fax: +49 54 81-93 85-12<br />

Internet: www.meyle.de<br />

E-Mail: sales@meyle.de

DIGITAL FLOW TRANSMITTER MyProc MFT 0257<br />

• Compact version for DN 06 to 65. (Remote version see MFT 0247)<br />

• Shows both flow rate and volume (with two totalizers)<br />

• Automatic-calibration: TEACH-IN<br />

• Simulation: all output signals provided without the need for real flow<br />

!<br />

The paddle-wheel transmitter is especially designed for use in neutral, slightly aggressive, solid free<br />

liquids. The transmitter is made of a compact fitting (MAF 252) and an electronic module (MFT 0257)<br />

quickly and easily connected together by a Quarter-Turn.<br />

The fitting system ensures simple installation of the sensors into all pipes from DN 06 to 65. The<br />

compact inline flow transmitter is available in different versions:<br />

• Flow transmitter with standard output signal<br />

• Battery powered<br />

Technical data:<br />

General data<br />

MAF 252<br />

Compatibility<br />

with fittings MAF 252 (see corresp. data sheet)<br />

Inline fitting<br />

Materials<br />

Housing, cover, lid, nut<br />

PC<br />

Front panel foil / Screws<br />

Polyester / Stainless steel<br />

Cable plug / glands<br />

PA<br />

Wetted parts materials<br />

Fitting, sensor armature<br />

Brass, stainless steel 1.4404/316L, PVC, PP or<br />

PVDF<br />

Paddle-wheel<br />

PVDF<br />

PLC<br />

Repeatability ≤ 0.4 % of Reading 1)<br />

Axis and bearing / Seal<br />

Ceramics / FKM<br />

Display<br />

15 x 60 mm, 8-digit LCD, alphanumeric,<br />

15 segments, 9 mm high<br />

Electrical connections<br />

Cable plug EN 175301-803 or cable glands<br />

M20 x 1.5 or none (for battery version).<br />

Voltage supply cable<br />

max. 50 m, shielded, 1.5 mm 2 max. cross-section<br />

Complete device data (Fitting MAF 252 + <strong>Electronic</strong>s):<br />

Pipe diameter DN 06 to 65<br />

Measuring range<br />

0.5 to 10 m/s (Battery version – Coil transducer)<br />

0.3 to 10 m/s (Hall transducer version)<br />

Fluid temperature with fitting in<br />

PVC / PP 0 up to 50 °C / 0 up to 80 °C<br />

PVDF, brass or stainless steel -15 up to 100 °C<br />

Fluid pressure max.<br />

PN10 (with plastic fitting) – PN16 (with metal fitting)<br />

– (PN40 on request, see MAF 252 data sheet) –<br />

see pressure/temperature diagram<br />

Viscosity<br />

300 cSt. max.<br />

Accuracy<br />

Teach-In ≤ ± 0.5 % of F.S.* (at 10 m/s) 1)<br />

Standard K-factor ≤ ± (0.5 % of F.S.* + 2.5 % of Reading) 1)<br />

Linearity ≤ ± 0.5 % of F.S.* (at 10 m/s) 1)<br />

* FS. = Full scale (10 m/s)<br />

1) Under reference conditions i.e. measuring fluid = water, ambient and water temperature = 20 °C, applying the minimum inlet and outlet pipe straight, matched inside pipe dimensions.<br />

Meyer <strong>Industrie</strong>-<strong>Electronic</strong> <strong>GmbH</strong> – MEYLE<br />

Carl-Bosch-Straße 8<br />

49525 Lengerich/Germany<br />

Tel.: +49 54 81-93 85-0<br />

Fax: +49 54 81-93 85-12<br />

Internet: www.meyle.de<br />

E-Mail: sales@meyle.de<br />

31

DIGITAL FLOW TRANSMITTER MyProc MFT 0257<br />

Operation and display:<br />

The device can be calibrated by means of the K-factor, or via the TEACH-IN function.<br />

Customized adjustments, such as measuring range, engineering units, pulse output are carried out on site.<br />

The operation is specified according to two or three levels, depending on the transmitter version:<br />

Flow transmitter<br />

Indication in operating mode / Display<br />

– flow rate<br />

– output current<br />

– main totalizer<br />

– daily totalizer with reset function<br />

Parameter definition<br />

– language<br />

– engineering units<br />

– K-factor / TEACH-IN function<br />

– measuring range 4–20 mA<br />

– pulse output<br />

– relay (option)<br />

– filter<br />

– reset main totalizer<br />

Battery indicator / totalizer<br />

Indication in operating mode / Display<br />

– flow rate<br />

– main totalizer<br />

– daily totalizer with reset function<br />

Parameter definition<br />

– language<br />