Technical data Insulation fault location system for ... - Bender

Technical data Insulation fault location system for ... - Bender

Technical data Insulation fault location system for ... - Bender

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

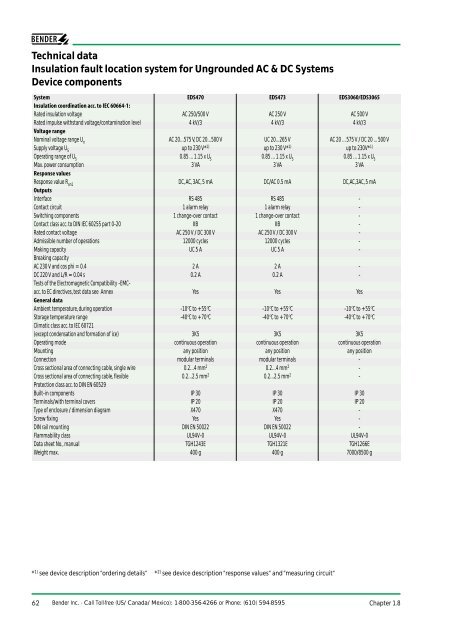

<strong>Technical</strong> <strong>data</strong><br />

<strong>Insulation</strong> <strong>fault</strong> <strong>location</strong> <strong>system</strong> <strong>for</strong> Ungrounded AC & DC Systems<br />

Device components<br />

System EDS470 EDS473 EDS3060/EDS3065<br />

<strong>Insulation</strong> coordination acc. to IEC 60664-1:<br />

Rated insulation voltage AC 250/500 V AC 250 V AC 500 V<br />

Rated impulse withstand voltage/contamination level 4 kV/3 4 kV/3 4 kV/3<br />

Voltage range<br />

Nominal voltage range U n<br />

AC 20...575 V, DC 20...500 V UC 20...265 V AC 20 ... 575 V / DC 20 ... 500 V<br />

Supply voltage U S<br />

up to 230 V* 1) up to 230 V* 1) up to 230V* 1)<br />

Operating range of U S<br />

0.85 ... 1.15 x U S<br />

0.85 ... 1.15 x U S<br />

0.85 ... 1.15 x U S<br />

Max. power consumption 3 VA 3 VA 3 VA<br />

Response values<br />

Response value R an1<br />

DC, AC, 3AC, 5 mA DC/AC 0.5 mA DC,AC,3AC, 5 mA<br />

Outputs<br />

Interface RS 485 RS 485 -<br />

Contact circuit 1 alarm relay 1 alarm relay -<br />

Switching components 1 change-over contact 1 change-over contact -<br />

Contact class acc. to DIN IEC 60255 part 0-20 IIB IIB -<br />

Rated contact voltage AC 250 V / DC 300 V AC 250 V / DC 300 V -<br />

Admissible number of operations 12000 cycles 12000 cycles -<br />

Making capacity UC 5 A UC 5 A -<br />

Breaking capacity<br />

AC 230 V and cos phi = 0.4 2 A 2 A -<br />

DC 220 V and L/R = 0.04 s 0.2 A 0.2 A -<br />

Tests of the Electromagnetic Compatibility -EMCacc.<br />

to EC directives, test <strong>data</strong> see Annex Yes Yes Yes<br />

General <strong>data</strong><br />

Ambient temperature, during operation -10°C to +55°C -10°C to +55°C -10°C to +55°C<br />

Storage temperature range -40°C to +70°C -40°C to +70°C -40°C to +70°C<br />

Climatic class acc. to IEC 60721<br />

(except condensation and <strong>for</strong>mation of ice) 3K5 3K5 3K5<br />

Operating mode continuous operation continuous operation continuous operation<br />

Mounting any position any position any position<br />

Connection modular terminals modular terminals -<br />

Cross sectional area of connecting cable, single wire 0.2...4 mm 2 0.2...4 mm 2 -<br />

Cross sectional area of connecting cable, flexible 0.2...2.5 mm 2 0.2...2.5 mm 2 -<br />

Protection class acc. to DIN EN 60529<br />

Built-in components IP 30 IP 30 IP 30<br />

Terminals/with terminal covers IP 20 IP 20 IP 20<br />

Type of enclosure / dimension diagram X470 X470 -<br />

Screw fixing Yes Yes -<br />

DIN rail mounting DIN EN 50022 DIN EN 50022 -<br />

Flammability class UL94V-0 UL94V-0 UL94V-0<br />

Data sheet No., manual TGH1243E TGH1321E TGH1266E<br />

Weight max. 400 g 400 g 7000/8500 g<br />

* 1) see device description “ordering details“ * 2) see device description “response values“ and “measuring circuit“<br />

62 <strong>Bender</strong> Inc. - Call Toll-free (US/Canada/Mexico): 1-800-356-4266 or Phone: (610) 594-8595 Chapter 1.8

Chapter 1.8<br />

Device type EDS3360/EDS3365 EDS165 EDS165-3<br />

<strong>Insulation</strong> coordination acc. to IEC 60664-1:<br />

Rated insulation voltage AC 250 V - -<br />

Rated impulse withstand voltage/contamination level 4 kV/3 - -<br />

Voltage range<br />

Nominal voltage range U n<br />

AC 20...265 V * 1) - -<br />

Supply voltage U S<br />

up to AC 230 V * 1) DC 6 V (battery) DC 6 V (battery)<br />

Operating range of U S<br />

0.85...1.15 x US DC 4.2...6.2 V DC 4.2 ... 6.2 V<br />

Max. power consumption 3 VA 0.6 W 0.6 W<br />

Response values<br />

Response value R an1<br />

DC/AC 0.5 mA - -<br />

Outputs<br />

Interface - RS 232 RS 232<br />

Contact circuit - - -<br />

Switching components - - -<br />

Contact class acc. to DIN IEC 60255 part 0-20 - - -<br />

Rated contact voltage - - -<br />

Admissible number of operations - - -<br />

Making capacity - - -<br />

Breaking capacity<br />

AC 230 V and cos phi = 0.4 - - -<br />

DC 220 V and L/R = 0.04 s - - -<br />

Tests of the Electromagnetic Compatibility -EMCacc.<br />

to EC directives, test <strong>data</strong> see Annex Yes Yes Yes<br />

General <strong>data</strong><br />

Ambient temperature, during operation -10°C to +55°C -10°C to +55°C -10°C to +55°C<br />

Storage temperature range -40°C to +70°C -40°C to +70°C -40°C to +70°C<br />

Climatic class acc. to IEC 60721<br />

(except condensation and <strong>for</strong>mation of ice) 3K5 - -<br />

Operating mode continuous operation - -<br />

Mounting any position - -<br />

Connection - - -<br />

Cross sectional area of connecting cable, single wire - - -<br />

Cross sectional area of connecting cable, flexible - - -<br />

Protection class acc. to DIN EN 60529<br />

Built-in components IP 30 IP 40 IP40<br />

Terminals/with terminal covers IP 20 IP 30 IP30<br />

Type of enclosure/dimension diagram - portable enclosure portable enclosure<br />

Screw fixing - - -<br />

DIN rail mounting - - -<br />

Flammability class UL94V-0 - -<br />

<strong>Technical</strong> manual TGH 1320E TGH 1266E TGH 1320E<br />

Weight max. 7000/8500 g 370 g 370 g<br />

1.8<br />

* 1) see device description “ordering details“ * 2) see device description “response values“ and “measuring circuit“<br />

Chapter 1.8<br />

Main catalogue part 1 / <strong>Insulation</strong> monitoring<br />

63

PGH471<br />

ON<br />

A3 A1<br />

SLAVE ADDRESS + 110<br />

START<br />

25mA A3 A2 A1 A0 SLAVE RS485 STOP<br />

1<br />

0<br />

10mA<br />

MASTER<br />

GENERATOR<br />

A3 A1<br />

6 0 V CAT I<br />

1 0 mA / 0,1 mA ~<br />

PSA3352<br />

EDS470 <strong>system</strong><br />

EDS473 <strong>system</strong><br />

<strong>Insulation</strong> <strong>fault</strong> <strong>location</strong> <strong>system</strong> <strong>for</strong><br />

Ungrounded (IT) AC and DC <strong>system</strong>s<br />

General description<br />

The EDS insulation <strong>fault</strong> <strong>location</strong> <strong>system</strong> is<br />

<strong>for</strong> ungrounded (IT) <strong>system</strong>s. This allows<br />

insulation <strong>fault</strong>s to be detected fast and<br />

reliably during operation.<br />

Advantages of the EDS <strong>system</strong><br />

• <strong>Insulation</strong> <strong>fault</strong> <strong>location</strong> during<br />

operation, no interruption to<br />

operation;<br />

• Reduction in costs because of<br />

reduced production stoppages<br />

• Reduced maintenance costs due<br />

to fast localization of insulation <strong>fault</strong>s<br />

• Improved preventive and scheduled<br />

maintenance<br />

• Higher availability of power supply<br />

thanks to diminished interruption to<br />

operation.<br />

Basic components<br />

An EDS470 <strong>system</strong> consists of:<br />

• control and indicating device PRC470,<br />

• test device PGH471,<br />

• 1 to 30 evaluators EDS470-12,<br />

• corresponding number of<br />

measuring current trans<strong>for</strong>mers<br />

of the W1-S35...W5-S210, WR<br />

or WS... series.<br />

System basic components<br />

A1 A2 11 14 L1 L2 L3<br />

A B GND IN1 IN2 IN3<br />

E<br />

Basic components<br />

An EDS473 <strong>system</strong> consists of:<br />

• control and indicating device PRC470,<br />

• test device PGH473/PGH474,<br />

• 1 to 30 evaluators EDS473-12,<br />

• corresponding number of<br />

measuring current trans<strong>for</strong>mers<br />

of the W1-35/8000, W08/8000,<br />

or WS50x80/8000 series.<br />

I∆s<br />

System characteristics<br />

• Universal <strong>system</strong> concept <strong>for</strong> all<br />

ungrounded (IT) <strong>system</strong>s<br />

I∆s<br />

ME SZANGE / CLAMP ON PROBE<br />

Datenbla t / Datash et : TGH1320<br />

Durchme ser / Diameter : 52 m<br />

Art.-Nr. / Art.-no. : B 980 695<br />

max. 1 A<br />

- EDS470, AC 20...575 V/DC 20...500 V<br />

(AC 20...790 V/DC 20...960 V<br />

with AGE470)<br />

- EDS473, AC/DC 20...265 V<br />

• Modular construction <strong>for</strong> individual<br />

adaptation to the electrical<br />

installation;<br />

• Measuring current trans<strong>for</strong>mers in<br />

various sizes and constructional<br />

designs;<br />

• Monitors and controls up to 360 CT<br />

circuits;<br />

• In<strong>for</strong>mation exchange between the<br />

individual devices via the RS485<br />

interface (two-wire);<br />

• Indication of the <strong>fault</strong>y circuit;<br />

• Indication of the test current flowing<br />

in each circuit.<br />

64 <strong>Bender</strong> Inc. - Call Toll-free (US/Canada/Mexico): 1-800-356-4266 or Phone: (610) 594-8595 Chapter 1.8

Function<br />

The EDS <strong>system</strong> works together with an insulation monitoring device that monitors the<br />

insulation resistance of the entire <strong>system</strong>. When an insulation <strong>fault</strong> is signalled by the<br />

insulation monitoring device, the EDS <strong>system</strong> starts <strong>fault</strong> <strong>location</strong> (automatically or<br />

manually) in order to determine the <strong>fault</strong>y circuit of the (IT) ungrounded <strong>system</strong>.<br />

When a first <strong>fault</strong> occurs in ungrounded <strong>system</strong>s, a <strong>fault</strong> current flows which is essentially<br />

determined by the <strong>system</strong> leakage capacitances and the insulation resistance. The basic<br />

concept in <strong>fault</strong> <strong>location</strong> is there<strong>for</strong>e to close the <strong>fault</strong> current circuit <strong>for</strong> a short period<br />

over a current-limiting resistance. As a result of this principle, the <strong>system</strong> voltage itself<br />

drives a test current which results in a signal that can be evaluated.<br />

The test current is generated periodically by the PGH471/473/474 test device. The test<br />

current is limited in amplitude and time. As this happens, the <strong>system</strong> conductors are<br />

connected alternately to ground (PE) via a current-limiting resistance. The test current pulse<br />

flows from the test device via the live conductors, taking the shortest path to the <strong>location</strong><br />

of the insulation <strong>fault</strong>. From there it flows via the insulation <strong>fault</strong> and the ground conductor<br />

back to the test device. This current pulse is then detected by the measuring current<br />

trans<strong>for</strong>mers located in the insulation <strong>fault</strong> path, and is evaluated by the connected<br />

insulation <strong>fault</strong> evaluator.<br />

Sophisticated evaluation method and filtering prevent false alarms <strong>for</strong> ground <strong>fault</strong> currents<br />

up to 10 A/(1 A). The measuring current trans<strong>for</strong>mers are used as ground <strong>fault</strong> current<br />

trans<strong>for</strong>mers, i.e. the ground (PE) conductor is not led through the current trans<strong>for</strong>mer.<br />

The response value is determined by the sensitivity of the insulation <strong>fault</strong> evaluators<br />

EDS470-12/EDS473-12 or EDS165/165-3. The response value is 5 mA as arithmetic mean<br />

value in DC as well as in AC and 3 AC <strong>system</strong>s (EDS470) respectively 0.5 mA (EDS473).<br />

1.8<br />

Chapter 1.8<br />

Main catalogue part 1 / <strong>Insulation</strong> monitoring<br />

65

Control and indicating device<br />

PRC470<br />

The control and indicating device PRC470<br />

per<strong>for</strong>ms the central control and<br />

monitoring function in EDS <strong>system</strong>s. The<br />

in<strong>for</strong>mation exchange between the<br />

individual components of the EDS470<br />

<strong>system</strong> takes place via the RS485 interface.<br />

Apart from the control functions and the<br />

extended scanning possibilities, the<br />

PRC470 is used to setup the EDS470<br />

<strong>system</strong> to different <strong>system</strong> parameters.<br />

The PRC470 also may be set to operation<br />

with <strong>system</strong> interferences, e.g. caused by<br />

frequency converters with low-frequency<br />

leakage currents or switch gear and<br />

controls producing transient leakage<br />

currents. Additional problems may arise<br />

through EMC suppression capacitors<br />

which are more and more used to comply<br />

with the EMC requirements.<br />

Essential func tions ar e<br />

• Control and synchronization of the<br />

test cycle of the PGH47. test device ;<br />

• Indication via LC display;<br />

• Display of the respective test current<br />

in each CT circuit;<br />

• Display of the connections between<br />

current trans<strong>for</strong>mer and insulation<br />

<strong>fault</strong> evaluator EDS470-12/EDS473-12;<br />

• Test function <strong>for</strong> testing all devices<br />

connected;<br />

• Setting of the operating principle <strong>for</strong><br />

each insulation <strong>fault</strong> evaluator;<br />

• Setting of the different measuring<br />

current trans<strong>for</strong>mer types used;<br />

• Setting via software menus;<br />

• Scanning of individual CT<br />

circuits.<br />

<strong>Insulation</strong> <strong>fault</strong> test device<br />

PGH471/473/474<br />

After detecting the insulation <strong>fault</strong> through<br />

the insulation monitoring device, insulation<br />

<strong>fault</strong> <strong>location</strong> is started via the<br />

control and indicating device PRC470.<br />

Once the insulation <strong>fault</strong> test device<br />

PGH471 is started, it produces a defined<br />

test current signal. The <strong>system</strong> voltage<br />

drives the test current. The value of the<br />

test current depends on insulation<br />

resistance, leakage capacitance and the<br />

<strong>system</strong> voltage. The test current is limited<br />

to max. 25 mA/(2.5 mA). The maximum<br />

test current can be limited to 10 mA/<br />

(1 mA) via a DIP switch. This limitation is<br />

recommended when using the <strong>system</strong> in<br />

control <strong>system</strong>s with sensitive relays or<br />

SPS.<br />

If the PGH471/473/474 is active, both<br />

cycle LEDs light up alternately during the<br />

respective cycle.<br />

<strong>Insulation</strong> <strong>fault</strong> evaluator<br />

EDS470-12, EDS473-12<br />

The insulation <strong>fault</strong> evaluator EDS470-12/<br />

EDS473-12 is controlled by means of a<br />

microcontroller. Together with the<br />

measuring current trans<strong>for</strong>mers it is used<br />

to evaluate test current signals generated<br />

by the insulation <strong>fault</strong> test device.<br />

The device subsequently evaluates the<br />

signals from all connected measuring<br />

current trans<strong>for</strong>mers. If the <strong>fault</strong> current<br />

detected by a measuring current<br />

trans<strong>for</strong>mer exceeds the response value,<br />

the respective alarm LED of the LED line<br />

and the alarm LED light up and the alarm<br />

relay switches. The alarm relay outputs a<br />

common alarm <strong>for</strong> all measuring<br />

channels.<br />

Up to 12 measuring current trans<strong>for</strong>mers<br />

can be connected to one insulation <strong>fault</strong><br />

evaluator EDS470-12/EDS473-12.<br />

Connection l of the measuring current<br />

trans<strong>for</strong>mers must be wired in a star<br />

connection to terminal l of the evaluator<br />

EDS470-12/EDS473-12.<br />

All settings within an EDS <strong>system</strong> are<br />

carried out at the control and indicating<br />

device PRC470.<br />

66 <strong>Bender</strong> Inc. - Call Toll-free (US/Canada/Mexico): 1-800-356-4266 or Phone: (610) 594-8595 Chapter 1.8

EDS470 <strong>system</strong><br />

EDS473 <strong>system</strong><br />

<strong>Insulation</strong> <strong>fault</strong> <strong>location</strong> <strong>system</strong> <strong>for</strong><br />

Ungrounded (IT) AC and DC <strong>system</strong>s<br />

Coupling device AGE470<br />

The EDS <strong>system</strong> is suitable <strong>for</strong> monitoring<br />

and scanning ungrounded (IT) <strong>system</strong>s of<br />

AC 45....65 Hz, 20...575 V and DC 20...500V.<br />

The voltage range of AC <strong>system</strong>s can be<br />

extended to AC 790 V, and that of DC<br />

<strong>system</strong>s to DC 960 V by means of the<br />

coupling device AGE470.<br />

Connection between the insulation <strong>fault</strong><br />

test device PGH471 and coupling device<br />

AGE470.<br />

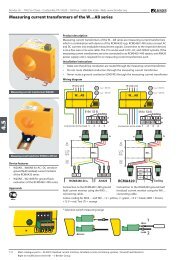

Measuring current trans<strong>for</strong>mers <strong>for</strong> EDS <strong>system</strong>s<br />

To meet the requirements of an electrical installation, different types of measuring<br />

current trans<strong>for</strong>mers are available <strong>for</strong> EDS insulation <strong>fault</strong> <strong>location</strong> <strong>system</strong>s. Measuring<br />

current trans<strong>for</strong>mers which are commercially available are not suitable <strong>for</strong> the EDS <strong>system</strong><br />

and must not be used.<br />

Suitable measuring current trans<strong>for</strong>mers are listed in the table below.<br />

All measuring current trans<strong>for</strong>mers listed in the table are highly sensitive and convert<br />

even very small residual currents into evaluable signals. Connection to the insulation <strong>fault</strong><br />

evaluator is carried out via two connecting leads. When installing please make sure that<br />

all current-carrying leads of the respective sub-circuit are passed through the current<br />

trans<strong>for</strong>mer. Te ground conductor must not be passed through the current trans<strong>for</strong>mer.<br />

Measuring current trans<strong>for</strong>mers <strong>for</strong> EDS <strong>system</strong>s<br />

Type Internal Design Setting Connection System<br />

diameter (mm)<br />

PRC470 menu<br />

W0-S15 15 circular standard 6.3 mm Faston EDS470<br />

W1-S35 35 circular standard screw terminals<br />

W2-S70 70 circular standard screw terminals<br />

W3-S105 105 circular standard screw terminals<br />

W4-S140 140 circular standard screw terminals<br />

W5-S210 210 circular standard screw terminals<br />

WR70x175S 70x175 rectangular standard screw terminals EDS470<br />

WR115x305S 115x305 rectangular standard screw terminals<br />

WR150x350S 150x350 rectangular standard screw terminals<br />

WS50x80S 50x80 split-core split-core screw terminals EDS470<br />

WS80x80S 80x80 split-core split-core screw terminals<br />

WS80x120S 80x120 split-core split-core screw terminals<br />

WS80x160S 80x160 split-core split-core screw terminals<br />

W1-35/8000 35 circular standard screw terminals EDS473<br />

W08/8000 8 circular standard 0.5 mm 2 x 2 m<br />

WS50x80/8000 50x80 split-core split-core screw terminals<br />

<strong>Technical</strong> <strong>data</strong> EDS470 EDS473<br />

Rated insulation voltage: AC 720 V AC 720 V<br />

Rated impulse withstand voltage: 3 kV 3 kV<br />

Contamination level: 3 3<br />

Dielectric test acc. to IEC 6044-1: AC 3 kV AC 3 kV<br />

Rated trans<strong>for</strong>mation ratio: 600:1 8000:1<br />

Rated burden: 180 Ω 24 kΩ<br />

Rated primary current: 10 A 1 A<br />

Continuous overload capacity: 100 A 6 A<br />

Rated short-time thermal current 1 (sec).: 14 kA/1s 0.75 kA/1s<br />

Nominal power: 50 mVA 0.375 mVA<br />

Accuracy class: 5 5<br />

Ambient temperature: -10°C ... + 55°C -10°C ... + 55°C<br />

Flammability class: UL94V-0 UL94V-0<br />

Length of the connecting leads<br />

Single wires 0.75 mm 2 up to 1 m up to 1 m<br />

Single wires 0.75 mm 2 , twisted up to 10 m up to 10 m<br />

Shielded cable 0.75 mm 2 (shield to terminal l) up to 25 m up to 25 m<br />

1.8<br />

Chapter 1.8<br />

Main catalogue part 1 / <strong>Insulation</strong> monitoring<br />

67

Measuring current trans<strong>for</strong>mer<br />

W0-S15<br />

Measuring current trans<strong>for</strong>mer<br />

W08/8000<br />

Measuring current trans<strong>for</strong>mer<br />

series W1-S35 ... W5-S210, W1-35/8000<br />

Split-core measuring current trans<strong>for</strong>mer<br />

series WS..., WS 50x80/8000<br />

Measuring current trans<strong>for</strong>mer<br />

series WR...<br />

Dimensions (in mm) and weights (in kg)<br />

Type A B C<br />

Type A B C D<br />

Type a b c d e<br />

W1-S35 100 79 26<br />

W1-35/8000 100 79 26<br />

W2-S70 130 110 32<br />

W3-S105 170 146 38<br />

W4-S140 220 196 48.5<br />

W5-S210 299 284 69<br />

Type D øE Weight<br />

W1-S35 48.5 35 0.25 kg<br />

W1-35/8000 48.5 35 0.25 kg<br />

W2-S70 66 70 0.38 kg<br />

W3-S105 94 105 0.70 kg<br />

W4-S140 123 140 1.50 kg<br />

W5-S210 161 210 2.50 kg<br />

WS 50x80S 50 80 78 114<br />

WS 50x80/8000 50 80 78 114<br />

WS 80x80S 80 80 108 144<br />

WS 80x120S 80 120 105 144<br />

WS 80 x 160S 80 160 108 144<br />

Type E Weight<br />

WS 50x80S 145 0.90 kg<br />

WS 50x80/8000 145 0.90 kg<br />

WS 80x80S 145 1.05 kg<br />

WS 80x120S 185 1.25 kg<br />

WS 80 x 160S 225 3.50 kg<br />

WR 70 x 175 S 70 175 225 85 22<br />

WR 115 x 305 S 115 305 360 116 25<br />

WR 150 x 350 S 150 350 415 140 28<br />

Type f g h i Weight<br />

WR 70 x 175 S 46 261 176 7.7 2.40 kg<br />

WR 115 x 305 S 55 402 240 8 5.45 kg<br />

WR 150 x 350 S 55 460 285 8 7.40 kg<br />

68 <strong>Bender</strong> Inc. - Call Toll-free (US/Canada/Mexico): 1-800-356-4266 or Phone: (610) 594-8595 Chapter 1.8

EDS470 / EDS473<br />

Construction of an EDS <strong>system</strong><br />

The example of an interconnection<br />

diagram below shows a central insulation<br />

monitoring device IRDH265 monitoring, a<br />

three-phase <strong>system</strong>. If the insulation<br />

value falls below the preset response<br />

value, the PGH471 will be activated by the<br />

insulation monitoring device via the relay<br />

contacts 21/24. The insulation <strong>fault</strong> test<br />

device PGH471 is connected to the<br />

insulation <strong>fault</strong> evaluator EDS470-12 and<br />

the control and indicating device PRC470<br />

via the RS485 interface (terminals A and B).<br />

After the PGH471 is activated from the<br />

PRC470 via the interface, the EDS470-12<br />

starts scanning the connected measuring<br />

current trans<strong>for</strong>mers. The diagram<br />

opposite shows three connected<br />

measuring current trans<strong>for</strong>mers. The<br />

RS485 serial interface has to be<br />

terminated at both ends with a resistor of<br />

120 Ω.<br />

The common connection I to the measuring<br />

current trans<strong>for</strong>mers must be

EDS470 <strong>system</strong><br />

Example of an interconnection diagram of an EDS <strong>system</strong> with SMO480-12, DI-1 and FTC1500<br />

Construction of an EDS <strong>system</strong> in combination with SMO480-12, DI-1 and FTC1500<br />

The interconnection diagram above<br />

illustrates an extended EDS <strong>system</strong>. The<br />

following components have been<br />

integrated into the classical EDS circuit:<br />

- SMO480-12<br />

(signal converter)<br />

- DI-1<br />

(RS485 repeater)<br />

- FTC1500<br />

(protocol converter)<br />

The SMO480-12 signal converter<br />

converts serial in<strong>for</strong>mation from <strong>Bender</strong><br />

evaluators into relay signals. There is one<br />

relay available <strong>for</strong> each of the measuring<br />

channels of the evaluators. The SMO480-<br />

12 signal converter allows <strong>fault</strong>y circuits of<br />

the <strong>system</strong> to be switched off in an<br />

insulation <strong>fault</strong> <strong>location</strong> <strong>system</strong>. In this<br />

way, a failure of the entire electrical<br />

<strong>system</strong> can be prevented. The RS485<br />

repeater DI-1 amplifies the signals of the<br />

RS485 interfaces. In EDS <strong>system</strong>s with a lot<br />

of circuits to be monitored, the maximum<br />

bus length of 1200 m often is not<br />

sufficient. Here the use of a DI-1 can<br />

extend the RS485 bus length to additional<br />

1200 m (4000 ft). As a side effect the<br />

number of the maximum possible bus<br />

nodes can be increased by 32.<br />

The EDS <strong>system</strong> (insulation <strong>fault</strong> <strong>location</strong><br />

<strong>system</strong>) communicates via the RS485<br />

interface using the BENDER BMS protocol.<br />

The protocol converter FTC1500 is a<br />

communication bridge between a RS485<br />

interface using the BENDER BMS protocol<br />

and an interface using the JBUS/MODBUS<br />

protocol, that allows the EDS <strong>system</strong> to be<br />

integrated into the JBUS/MODBUS<br />

environment.<br />

70 <strong>Bender</strong> Inc. - Call Toll-free (US/Canada/Mexico): 1-800-356-4266 or Phone: (610) 594-8595 Chapter 1.8

EDS473 <strong>system</strong><br />

Example of an interconnection diagram of an EDS473 <strong>system</strong><br />

1.8<br />

Chapter 1.8<br />

Main catalogue part 1 / <strong>Insulation</strong> monitoring<br />

71

EDS470 /EDS473<br />

<strong>Technical</strong> <strong>data</strong><br />

EDS470 <strong>system</strong><br />

EDS473 <strong>system</strong><br />

Components: PRC470, PGH471 PRC470, PGH473<br />

AGE470, EDS470-12<br />

EDS473-12<br />

SMO480-12, DI-1<br />

SMO480-12<br />

FTC-1500<br />

DI-1, FTC1500<br />

including E-version <strong>for</strong> 60 evaluators<br />

and 39 test devices<br />

Measuring current trans<strong>for</strong>mers W..., WR..., WS..., W1-35/8000; WS50 x 80/8000<br />

Portable <strong>system</strong>s EDS3065 and EDS3060 including EDS3360 and EDS3365 including<br />

PGH185; EDS165;PSA3020<br />

PGH183; EDS165-3, PSA3320<br />

PSA3052 and PSA3165<br />

and PSA3352<br />

Max. test current 25 / 10 mA 2.5 / 1 mA<br />

Response value 5 mA 0.5 mA<br />

<strong>Insulation</strong> resistance low response value higher response value (x10)<br />

Max. <strong>system</strong> leakage capacitance 20000 µFV (C e<br />

x U n<br />

) 300 µFV (C e<br />

x U n<br />

)<br />

EDS470 or EDS473 <br />

Selection EDS470 <strong>system</strong> EDS473 <strong>system</strong><br />

according to <strong>system</strong> voltage AC 20 -575 V AC 20 - 265 V<br />

DC 20 - 504 V<br />

DC 20 - 308 V<br />

including AGE470: AC 20...790 V/DC 20...960 V<br />

according to application<br />

extended ungrounded (IT) <strong>system</strong>s<br />

<strong>system</strong>s with variable-speed drives<br />

<strong>system</strong>s with electrical interferences<br />

auxiliary circuits<br />

diode-decoupled control circuits<br />

according to residual current max. 10A max. 1A<br />

72 <strong>Bender</strong> Inc. - Call Toll-free (US/Canada/Mexico): 1-800-356-4266 or Phone: (610) 594-8595<br />

Chapter 1.8

PGH183<br />

AC/DC<br />

System extensions, accessories<br />

The portable insulation <strong>fault</strong> evaluator<br />

EDS165-3 represents an ideal<br />

complement to the EDS <strong>system</strong> where<br />

EDS165 is suitable <strong>for</strong> EDS470 <strong>system</strong>s<br />

and EDS165-3 <strong>for</strong> EDS473 <strong>system</strong>s.<br />

The respective device can be used to track<br />

the <strong>fault</strong> <strong>location</strong> or to check additional<br />

subcircuits manually.<br />

The EDS165-3 is used in combination with<br />

current clamps.It detects the test current<br />

signal of the insulation <strong>fault</strong> test device<br />

PGH47. and works well with an existing<br />

EDS 47. <strong>system</strong>.<br />

The EDS165-3 is supplied via batteries. The<br />

operation and settings are carried out by<br />

means of the function keys and the LC<br />

display.<br />

Three current clamps are suitable <strong>for</strong> the<br />

EDS470 <strong>system</strong>. These are PSA3020 (with<br />

an internal diameter of 20 mm), PSA3052<br />

with an internal diameter of 52 mm and<br />

PSA3165 (with an internal diameter of<br />

100 mm).<br />

The current clamps PSA3320 with an<br />

internal diameter of 20 mm and PSA<br />

3352 with an internal diameter of 52<br />

mm are suitable <strong>for</strong> the EDS473 <strong>system</strong>.<br />

The clearly legible LC display indicates the<br />

actual test current flowing in the<br />

respective circuit and indicates if the<br />

alarm value has been exceeded.<br />

Furthermore it indicates which current<br />

clamp has been selected, the battery<br />

charge, the selected <strong>system</strong> frequency, and<br />

the mode of the buzzer.<br />

I∆s = 8 mA<br />

ALARM<br />

50Hz ( )<br />

The EDS165(-3) in combination with any<br />

current clamp can be used as a portable<br />

residual current monitor in grounded and<br />

high-resistance grounded. The operating<br />

mode can be changed by means of a<br />

selector.<br />

For detailed in<strong>for</strong>mation about portable<br />

insulation <strong>fault</strong> <strong>location</strong> refer to the<br />

technical manuals EDS3060 and EDS3065<br />

respectively EDS3360 and EDS3365.<br />

<strong>Insulation</strong> <strong>fault</strong> test device PGH185/PGH183<br />

The insulation <strong>fault</strong> test device PGH185/<br />

PGH183 is used to generate a defined test<br />

current<br />

which is generated there<strong>for</strong>e depends on<br />

the value of the insulation <strong>fault</strong> that is<br />

present, the leakage capacitance and on<br />

the <strong>system</strong> voltage. The test current is<br />

limited to a maximum of 25 mA/2.5 mA<br />

respectively max. 10 mA/ 1 mA depending<br />

on the switch position of the Imax switch.<br />

The test current flows from the <strong>system</strong> via<br />

the PGH185/PGH183 and then through<br />

the ground conductor (PE) and the<br />

insulation <strong>fault</strong>(s) back to the <strong>system</strong>. The<br />

test current signal is sensed by the current<br />

clamps or measuring current trans<strong>for</strong>mers<br />

located in the <strong>fault</strong> current circuit , and the<br />

<strong>fault</strong>y circuits are indicated by the<br />

insulation <strong>fault</strong> test device EDS165(-3)<br />

whenever the threshold of 5/0.5 mA is<br />

exceeded.<br />

1.8<br />

signal. It is applied in <strong>system</strong>s which do<br />

not include a permanently installed EDS<br />

<strong>system</strong>. <strong>Insulation</strong> <strong>fault</strong> <strong>location</strong> is carried<br />

out by means of the insulation <strong>fault</strong><br />

evaluators EDS165(-3) and the respective<br />

current clamps. The PGH185/PGH183 is a<br />

component of the EDS3065 respectively<br />

EDS3365.<br />

After switching on the PGH18. generates<br />

a defined test current signal. The voltage<br />

present in the <strong>system</strong> is used to drive the<br />

test current. The value of the test current<br />

100mA<br />

Us<br />

ON<br />

ON<br />

L1(+)<br />

2,5mA<br />

Imax<br />

1 mA<br />

L2(-)<br />

L3<br />

Chapter 1.8<br />

Main catalogue part 1 / <strong>Insulation</strong> monitoring<br />

73

System components at a glance<br />

The primary function of the EDS3.6. is that<br />

of an insulation <strong>fault</strong> <strong>location</strong> <strong>system</strong> in (IT)<br />

ungrounded <strong>system</strong>s. The components of<br />

the EDS3.6. are used in combination <strong>for</strong><br />

that purpose.<br />

<strong>Insulation</strong> <strong>fault</strong> test device PGH185/183<br />

Current clamp PSA3020<br />

Current clamp PSA3320<br />

Current clamp PSA3052<br />

Current clamp PSA3352<br />

<strong>Insulation</strong> <strong>fault</strong> evaluator EDS165(-3)<br />

Aluminium case with carrying belt<br />

Not illustrated:<br />

power supply cord (with plug <strong>for</strong> cold conditions) <strong>for</strong> the insulation <strong>fault</strong> test device PGH183;<br />

safety measuring leads 3 x black and 1x green/yellow;<br />

safety claw grip to connect the PGH18. with the <strong>system</strong> conductors and the equipment grounding conductor;<br />

BNC adapter unit/banana plug to connect measuring current trans<strong>for</strong>mers;<br />

banana plug;<br />

battery charging set <strong>for</strong> EDS165(-3).<br />

74 <strong>Bender</strong> Inc. - Call Toll-free (US/Canada/Mexico): 1-800-356-4266 or Phone: (610) 594-8595<br />

Chapter 1.8

Components and technical <strong>data</strong> of the EDS3.6. <strong>system</strong>s <strong>for</strong> ungrounded (IT) <strong>system</strong>s<br />

EDS3060 EDS3065 EDS3360 EDS3365<br />

Components Aluminium case Aluminium case Aluminium case Aluminium case<br />

EDS165 EDS165 EDS165-3 EDS165-3<br />

PSA3020 PSA3020 PSA3320 PSA3320<br />

PSA3052 PSA3052 PSA3352 PSA3352<br />

PSA3165 optional<br />

PSA3165 optional<br />

Accumulator charging set Accumulator charging set Accumulator charging set Accumulator charging set<br />

PGH185<br />

PGH183<br />

AGE185 optional<br />

Operating manual TGH1266 Operating manual TGH1266 Operating manual TGH1320 Operating manual TGH1320<br />

Max. test current 25/10 mA 25/10 mA 2.5/1 mA 2.5/1 mA<br />

Response value 5 mA 5 mA 0.5 mA 0.5 mA<br />

<strong>Insulation</strong> resistance low response value low response value higher response value (x10) higer response value (x10)<br />

Max. <strong>system</strong> leakage capacitance 20000 µFV (C e<br />

xU n<br />

) 20000 µFV (C e<br />

xU n<br />

) 500 µFV (C e<br />

xU n<br />

) 500 µFV (C e<br />

xU n<br />

)<br />

Selection EDS3060 EDS3065 EDS3360 EDS3365<br />

Nominal voltage range AC 20...575 V AC 20...575 V AC 20...265 V AC 20...265 V<br />

DC 20...504 V DC 20...504 V DC 20...308 V DC 20...308 V<br />

with AGE185:<br />

AC 500...790 V<br />

DC 400...960 V<br />

According to application extended IT <strong>system</strong>s, extended IT <strong>system</strong>s, auxiliary circuits, auxiliary circuits,<br />

IT <strong>system</strong>s with variable-speed IT <strong>system</strong>s with variable-speed auxiliary circuits with SPS, auxiliary circuits with SPS,<br />

drives and electrical drives and electrical diode-decoupled control circuits diode-decoupled control circuits<br />

interferences<br />

interferences<br />

According to residual current max. 10 A max. 10 A max. 1 A max. 1 A<br />

According to existing EDS <strong>system</strong> EDS470 already installed no EDS <strong>system</strong> installed EDS473 <strong>system</strong> already installed no EDS473 <strong>system</strong> installed<br />

Chapter 1.8<br />

Main catalogue part 1 / <strong>Insulation</strong> monitoring<br />

75

Ordering details<br />

Device components<br />

Type Supply Art. No.<br />

voltage U S<br />

EDS470-12 AC 230 V B 9501 2002 2)<br />

EDS470-1213 AC 90 - 132 V* B 9501 2005 2)<br />

EDS470-1221 DC 9.6 - 84 V* B 9501 2006 1)<br />

EDS473-12 AC 230 V B 9501 2019 2)<br />

EDS473-1213 AC 90 - 132 V* B 9501 2020 2)<br />

EDS473-1221 DC 10.5 - 80 V* B 9501 2021 1)<br />

PRC470 AC 230 V B 9501 2001 2)<br />

PRC470-13 AC 90 - 132 V* B 9501 2004 2)<br />

PRC470-21 DC 9.6 - 84 V* B 9501 2007 1)<br />

PGH471 AC 230 V B 9501 8004 2)<br />

PGH471-13 AC 90 - 132 V* B 9501 8005 2)<br />

PGH471-21 DC 9.6 - 84 V* B 9501 8006 1)<br />

PGH473 AC230 V B 9501 8009 2)<br />

PGH473-13 AC 90 - 132 V* B 9501 8010 2)<br />

PGH473-21 DC 10.5 - 80 V* B 9501 8011 1)<br />

PGH474 AC 230 V B 9501 8012 2)<br />

AGE470 - B 9801 8002 2)<br />

1)<br />

Only <strong>for</strong> use in the industrial sector.<br />

2)<br />

For use in the household as well as<br />

industrial sector.<br />

Other supply voltages on request<br />

* This in<strong>for</strong>mation represents absolute<br />

values <strong>for</strong> the supply voltage, to which the<br />

working range is not applicable.<br />

Measuring current trans<strong>for</strong>mers<br />

Type Internal diameter Art. No.<br />

in mm<br />

W0 - S15 15 B 911 753<br />

W1 - S35 35 B 911 731<br />

W2 - S70 70 B 911 732<br />

W3 - S105 105 B 911 733<br />

W4 - S140 140 B 911 734<br />

W5 - S210 210 B 911 735<br />

W08/8000 8 B 911 759<br />

W1-35/8000 35 B 911 756<br />

WS50x80/8000 50x80 B 911 757<br />

WR70 x 175S 70 x 175 B 911 738<br />

WR115 x 305S 115 x 305 B 911 739<br />

WR150 x 350S 150 x 350 B 911 740<br />

WS50 x 80S 50 x 80 B 911 741<br />

WS80 x 80S 80 x 80 B 911 742<br />

WS80 x 120S 80 x 120 B 911 743<br />

WS80 x 160S 80 x 160 B 911755<br />

Accessories, <strong>system</strong> extensions<br />

Type Supply voltage Art. No.<br />

EDS165 Akku 6 V B 91082001<br />

EDS3060 AC 230 V B 91082006<br />

EDS3065 AC 230 V B 91082004<br />

EDS3065-13 3) AC 90 - 132 V B 91082005<br />

EDS3360<br />

battery charger<br />

AC 230 V B 91082013<br />

EDS3365 AC 195 - 265 V* B 91082011<br />

EDS3365-13 3) 90 - 132 V* B 91082012<br />

AGE185<br />

AC 500 - 790 V<br />

DC 400 - 960 V B 980 305<br />

3)<br />

without charging set<br />

Standards<br />

DIN EN 61557-9 (VDE0413 part9),<br />

IEC 61557-9, EN 61557-9 specifie the<br />

requirements <strong>for</strong> insulation <strong>fault</strong> <strong>location</strong><br />

<strong>system</strong>s.<br />

All components of the EDS <strong>system</strong> are<br />

approved by the following authorities:<br />

76 <strong>Bender</strong> Inc. - Call Toll-free (US/Canada/Mexico): 1-800-356-4266 or Phone: (610) 594-8595<br />

Chapter 1.8