EDS3365 Manual in PDF format - Bender

EDS3365 Manual in PDF format - Bender

EDS3365 Manual in PDF format - Bender

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

1 About the <strong>EDS3365</strong>What is <strong>EDS3365</strong>The <strong>EDS3365</strong> is a portable <strong>in</strong>sulation fault location system for IT systems (unearthedsystems). It enables <strong>in</strong>sulation faults to be located dur<strong>in</strong>g operation and withoutdisconnection from supply.The <strong>EDS3365</strong> consists of:• PGH183 <strong>in</strong>sulation fault test device• EDS165-3 <strong>in</strong>sulation fault evaluator• PSA3320 and PSA3352 current clamps• optional accessoriesFurthermore there is the EDS3360 version. This version does not conta<strong>in</strong> a PGH183but otherwise it is identical to <strong>EDS3365</strong>. The EDS3360 is suitable for:• residual current measurement <strong>in</strong> TT and TN systems• <strong>in</strong>sulation fault location <strong>in</strong> IT systems if there is a stationary <strong>in</strong>sulation faultlocation system with a PGH473 test device <strong>in</strong>stalledIn the past, classical <strong>in</strong>sulation fault location consisted of disconnect<strong>in</strong>g systemsections one after another and then carry<strong>in</strong>g out often laborious and protracted workto locate the faults. Modern fault location systems such as the <strong>EDS3365</strong>, PKA3001,EDS473 or EDS470 (as permanently <strong>in</strong>stalled systems) make the fault location a gooddeal easier and shorter, and contribute <strong>in</strong> this way to a better supply voltage.While <strong>in</strong>sulation fault location is be<strong>in</strong>g undertaken with the <strong>EDS3365</strong>, any <strong>in</strong>sulationmonitor<strong>in</strong>g device which may be present must be disconnected from the system forthe duration of the fault location. This must be done by effect<strong>in</strong>g an all-pole<strong>in</strong>terruption of the system coupl<strong>in</strong>g – it is not sufficient to switch off the supplyvoltage to the <strong>in</strong>sulation monitor<strong>in</strong>g device.The <strong>EDS3365</strong> or components of it can be used to accomplish the follow<strong>in</strong>gmeasur<strong>in</strong>g tasks:• <strong>in</strong>sulation fault location <strong>in</strong> IT systems, AC 20-265 V / DC 20-308 V• <strong>in</strong>sulation fault evaluation <strong>in</strong> IT systems, AC 20-265 V / DC 20-308 V <strong>in</strong>comb<strong>in</strong>ation with a permanently <strong>in</strong>stalled EDS473 <strong>in</strong>sulation fault locationsystem• residual current measurement <strong>in</strong> TT and TN systems (AC, earthed systems)Critical useDanger !For higher voltages we recommend to use our EDS3065 system.Before mak<strong>in</strong>g use of the <strong>EDS3365</strong> portable <strong>in</strong>sulation fault location system, the usermust have a very accurate knowledge of its possiblities, the special circumstancesrelat<strong>in</strong>g to its system, and of certa<strong>in</strong> hazards which are possible. Among the relevantpo<strong>in</strong>ts to be considered, particular attention must be paid to the maximum testcurrent. Depend<strong>in</strong>g on the switch position of the PGH183, this is a maximum of 2.5mA or 1 mA respectively.The test current flows between the system and earth, not as a load current. Underunfavourable comb<strong>in</strong>ations of circumstances (low impedance <strong>in</strong>sulation fault <strong>in</strong>connection with the test cycle of the test current), control errors cannot be ruled out<strong>in</strong> the case of sensitive system components (SPC, relays). Account must be taken ofthis possibility prior to use. If appropriate, a lower test current shoud be set, or thefault location system should not be used <strong>in</strong> this system.4TGH1320E/03.2000

About <strong>EDS3365</strong>The <strong>in</strong>sulationresistanceOne determ<strong>in</strong><strong>in</strong>g factor for the availability of an electrical system is the <strong>in</strong>sulationresistance. It appears at the head of the list of protection goals for electrical safety.This applies as a fundamental pr<strong>in</strong>ciple, regardless of the type of distributionsystem.Plann<strong>in</strong>g the <strong>in</strong>stallation of a safe, reliable power supply aim<strong>in</strong>g the highestavailability means:• Set-up of the power supply as an IT system. In comparison with a distributionsystem with <strong>in</strong>tentional earth connection of the active conductors, animproved reliability, improved fire protection, improved accident preventionas well as a higher permissible earth resistance are thereby achieved.• Use of the suitable monitor<strong>in</strong>g devices. The advantages named <strong>in</strong> theprevious paragraph stand or fall by the selection of the appropreate A-Isometer for the respective application. Unless there is a functionalmonitor<strong>in</strong>g, it is impossible to utilise the advantages of the IT system. Thedesired high level of <strong>in</strong>sulation resistance cannot be ma<strong>in</strong>ta<strong>in</strong>ed <strong>in</strong> the longterm without cont<strong>in</strong>uous monitor<strong>in</strong>g.• Reduction of ma<strong>in</strong>tenance costs and downtimes thanks to the use of an<strong>in</strong>sulation fault location system. Rapid location of an <strong>in</strong>sulation faultimmediately after it has occured is a long-cherished wish on the part of thema<strong>in</strong>tenance staff. The fault is reported and located without <strong>in</strong>terruption ofoperations, and without the need of possible night and weekend work. Theactual repair can be carried out at an appropriate time. The system operatormakes the decision as to whether the <strong>in</strong>sulation fault location system to beused should be a permanently <strong>in</strong>stalled or a portable system.• An alternative to supply voltage <strong>in</strong> the form of an IT system may be offeredby a TT or TN system which is equipped with residual current monitors andresidual current location systems. While this does not make it possible toavoid switch<strong>in</strong>g off when a first low-impedance fault occurs, it neverthelessguarantees a time advantage as far as <strong>in</strong><strong>format</strong>ion is concerned. As a result,deteriorations <strong>in</strong> the <strong>in</strong>sulation and creep<strong>in</strong>g <strong>in</strong>sulation faults are detected atan early stage and a considerable number of shutdowns are prevented <strong>in</strong> thisway.For the reliability of the power supply, it is decisive to ma<strong>in</strong>ta<strong>in</strong>e the good state of<strong>in</strong>sulation. This is only possible with the use of suitable monitor<strong>in</strong>g devices. Thesedevices cannot prevent the <strong>in</strong>sulation fault or the deterioration of the <strong>in</strong>sulation.However, early and rapid detection with <strong>in</strong><strong>format</strong>ion about the location of the faultwill simplify ma<strong>in</strong>tenance to an extraord<strong>in</strong>ary degree.Without suitable tools, fault location was (and cont<strong>in</strong>ues to be) time-consum<strong>in</strong>g andtroublesome. Weekend work was frequently necessary <strong>in</strong> order to localise the faultor faults while the system was switched off.Modern BENDER monitor<strong>in</strong>g devices such as the <strong>EDS3365</strong>, EDS3065, EDS470,EDS473 or RCMS470 solve these problems. Thanks to the automatic location of the<strong>in</strong>sulation fault, the necessary fault elim<strong>in</strong>ation is made very simple and the requiredhigh level of <strong>in</strong>sulation is ma<strong>in</strong>ta<strong>in</strong>ed. Localis<strong>in</strong>g takes place dur<strong>in</strong>g cont<strong>in</strong>uousoperation and it is not necessary to shut down the system.5TGH1320E/03.2000

About <strong>EDS3365</strong>Basic standardsIf a power supply system is set-up as an IT system, the relevant standards requirethat the first <strong>in</strong>sulation fault to occur must be elim<strong>in</strong>ated as quickly as possible:IEC 60364-4-41, Po<strong>in</strong>t 413.1.5.4 (Note),DIN VDE 0100 Part 410:1997-01, Po<strong>in</strong>t 413.1.5.4 (Note)It is recommended that the first fault should be elim<strong>in</strong>ated with the shortestpractical delay.Rapid <strong>in</strong>sulation fault location is made possible thanks to <strong>in</strong>sulation fault locat<strong>in</strong>gsystems such as the <strong>EDS3365</strong>, EDS3065, EDS473, EDS470 or RCMS470. In this way,the risk of the supply voltage be<strong>in</strong>g switched off because of a possible secondfault is considerably reduced.The standard IEC61557-9 deals with devices for <strong>in</strong>sulation fault location <strong>in</strong> IT ACsystems dur<strong>in</strong>g operation, IT AC systems with galvanically connected DC circuitsand IT DC systems. This <strong>in</strong>ternational standard lays down some specialrequirements for <strong>in</strong>sulation fault location systems <strong>in</strong> IT systems of up to AC 1000V and DC 1500 V.BENDER‘s <strong>in</strong>sulation fault location systems are based on this standard IEC61557-9.As far as possible, this operat<strong>in</strong>g manual attempts to use the term<strong>in</strong>ology of thedraft standard, <strong>in</strong>clud<strong>in</strong>g the term ‘<strong>in</strong>sulation fault location system´. This <strong>in</strong>dicatesnot only that <strong>in</strong>sulation faults with 0 Ω (earth faults) are found, but also resistivefaults.In addition, IEC 61010-1 is applicable. The title of this <strong>in</strong>ternational standard is”Safety requirements for electrical equipment for measurement, controland laboratory use”.Terms and def<strong>in</strong>itionsI ∆I ∆nI ∆s= fault current. The current that comes to flow through an <strong>in</strong>sulation fault.= rated residual operat<strong>in</strong>g current. The fault current at which the evaluatorunit responds under specified conditions.= measured value of the selective fault current of the evaluator unit.IMD = Insulation Monitor<strong>in</strong>g DeviceRCM = Residual Current MonitorRCD = Residual Current Protective Device6TGH1320E/03.2000

2 Safety <strong>in</strong>structionsIntended useThe <strong>in</strong>tended use of the <strong>EDS3365</strong> is to:• locate <strong>in</strong>sulation faults <strong>in</strong> IT systems, AC 50, 60 and 400 Hz, 20-265V and DC20-308 V.In addition to this, the EDS165-3 <strong>in</strong>sulation fault evaluator – which is a componentof the <strong>EDS3365</strong> – can be used to:• evaluate <strong>in</strong>sulation faults <strong>in</strong> comb<strong>in</strong>ation with a permanently <strong>in</strong>stalled EDS473<strong>in</strong>sulation fault location system (EDS mode)• measure residual currents <strong>in</strong> TN and TT systems (RCM mode)Any other use, or any use which goes beyond the forego<strong>in</strong>g, is deemed to beimproper. The BENDER companies shall not be liable for any loss and damagesaris<strong>in</strong>g therefrom.As a basic pr<strong>in</strong>ciple our ”General Conditions of Sale and Delivery” shall apply.These shall be available to the operator no earlier than the time when the contract isconcluded.Warranty and liabilityWarranty and liability claims <strong>in</strong> the event of <strong>in</strong>jury to persons or damage to propertyare excluded if they can be attributed to one or more of the follow<strong>in</strong>g causes:• Inproper use of the <strong>EDS3365</strong>.• Improper assembly/fitt<strong>in</strong>g, commission<strong>in</strong>g, operation and ma<strong>in</strong>tenance of the<strong>EDS3365</strong>.• Failure to take note of the <strong>in</strong><strong>format</strong>ion <strong>in</strong> the operat<strong>in</strong>g <strong>in</strong>structionsconcern<strong>in</strong>g transport, storage, assembly/fitt<strong>in</strong>g, commission<strong>in</strong>g, operation andma<strong>in</strong>tenance of the <strong>EDS3365</strong>.• Unauthorised structural modifications to the <strong>EDS3365</strong>.• Failure to take note of the technical data.• Improperly performed repairs and the use of spare parts or accessories whichare not recommended by the manufacturer• Cases of disaster brought about by the effect of foreign bodies and forcemajeure• The assembly and <strong>in</strong>stallation of non-recommended comb<strong>in</strong>ations of devices.In order to handle the <strong>EDS3365</strong> <strong>in</strong> accordance with safety requirements and toensure ist trouble-free operation, the fundamental prerequisite is a knowledge of thebasic safety <strong>in</strong><strong>format</strong>ion and the safety regulations.PersonnelEveryone who works with the <strong>EDS3365</strong> must take note of this operat<strong>in</strong>g manual,and <strong>in</strong> particular of the safety <strong>in</strong><strong>format</strong>ion.In addition to this, the rules and regulations concern<strong>in</strong>g accident prevention whichare valid for the operat<strong>in</strong>g location must be obeyed.Only suitably qualified staff may work with the <strong>EDS3365</strong>. The term ‘qualified´ meansthat such staff are familiar with the assembly, commission<strong>in</strong>g and operation of theproduct and that they have undergone tra<strong>in</strong><strong>in</strong>g which is appropriate to theiractivities.The staff must have read and understood the safety chapter and the warn<strong>in</strong>gs <strong>in</strong>these operat<strong>in</strong>g <strong>in</strong>structions.Risks when operat<strong>in</strong>gthe systemThe <strong>EDS3365</strong> is built accord<strong>in</strong>g to the state-of-the-art and the recognised safetyeng<strong>in</strong>eer<strong>in</strong>g rules. Dur<strong>in</strong>g use, it is nevertheless possible that dangers will arise tothe life and limb of the user or of third parties, or that the <strong>EDS3365</strong> system or otheritems of property may be impaired. The <strong>EDS3365</strong> must only be used:• for the purposes for which it is <strong>in</strong>tended• when it is <strong>in</strong> perfect condition as regards safety eng<strong>in</strong>eer<strong>in</strong>g aspects7TGH1320E/03.2000

Safety <strong>in</strong>structionsAny faults which might impair safety must be elim<strong>in</strong>ated immediately. Inadmissablemodifications, and the use of spare parts and additional devices which are not soldor recommended by the manufacturer of the devices may cause fires, electric shocksand <strong>in</strong>juries.Explanation of symbolsand notesThe follow<strong>in</strong>g designations and symbols for hazards and warn<strong>in</strong>gs are used <strong>in</strong>BENDER documentation:Danger !Warn<strong>in</strong>gThis symbol means an immediate threat of danger to human life and health.Failure to observe these warn<strong>in</strong>gs means that death, severe bodily <strong>in</strong>juries orsubstantial damage to property will occur if the correspond<strong>in</strong>g precautions are nottaken.This symbol means a possible threat of danger to human life and health.Failure to observe these warn<strong>in</strong>gs means that death, severe bodily <strong>in</strong>juries orsubstantial damage to property may occur if the correspond<strong>in</strong>g precautions are nottaken.This symbols means a possible hazardous situation.Failure to observe these warn<strong>in</strong>gs means that slight bodily <strong>in</strong>juries or damage toproperty may occur if the correspond<strong>in</strong>g precautions are not taken.AttentionThis symbol gives important <strong>in</strong><strong>format</strong>ion about the correct way to handle the<strong>EDS3365</strong>.Failure to comply with this <strong>in</strong><strong>format</strong>ion may result <strong>in</strong> faults on the <strong>EDS3365</strong> or <strong>in</strong> itsenvironment.This symbol guides you to application tips and particulary useful items of<strong>in</strong><strong>format</strong>ion.These will help you to make optimal use of all the functions on the <strong>EDS3365</strong>.8TGH1320E/03.2000

Safety <strong>in</strong>structionsInspection, transportand storageInspect the despatch and equipment packag<strong>in</strong>g for damage, and compare thecontents of the package with the delivery documents. In the event of transportdamage, please notify the BENDER company immediately.The components of the <strong>EDS3365</strong> must only be stored <strong>in</strong> rooms where they will beprotected aga<strong>in</strong>st dust, moisture, and sprayed or dripp<strong>in</strong>g water, and where the<strong>in</strong>dicated storage temperatures are ma<strong>in</strong>ta<strong>in</strong>ed.Warranty obligationsBENDER provides a warranty for fault-free execution and faultless material qualityon the <strong>EDS3365</strong> with all its components for a period of 12 months as from the dateof delivery, under normal operat<strong>in</strong>g conditions.This warranty does not extend to any ma<strong>in</strong>tenance work, regardless of its nature.The warranty is only valid for the <strong>in</strong>itial purchaser, and does not extend to productsor <strong>in</strong>dividual parts thereof which have not been correctly used to or whichmodifications have been made. Any warranty whatsoever shall lapse if the <strong>EDS3365</strong>system is operated under abnormal conditions.The warranty obligation is limited to the repair or exchange of a product which hasbeen sent <strong>in</strong> to BENDER with<strong>in</strong> the warranty period. It is also a qualify<strong>in</strong>g conditionof warranty that BENDER shall acknowledge that the product is faulty, and that thefault cannot be attributed to improper handl<strong>in</strong>g or modification of the device, or toabnormal operat<strong>in</strong>g conditions.Any warranty obligation whatsoever shall lapse if repairs to the <strong>EDS3365</strong> areundertaken by persons who are not authorised by BENDER.The forego<strong>in</strong>g warranty conditions shall apply exclusively, and <strong>in</strong> the place of allother contractual or legal warranty obligations, <strong>in</strong>clud<strong>in</strong>g (but not limited to) thelegal warranty of marketability, suitability for use and expediency for a specifiedpurpose of use.BENDER shall not assume any liability for direct and <strong>in</strong>direct concomitant orconsequential damage, regardless of whether these may be attributable to legal,illegal or other actions.About this manualGreat care has been taken <strong>in</strong> the preparation of this manual. However, faults anderrors can not be completely ruled out. BENDER shall not assume any liability forpersonal <strong>in</strong>jury or damage to property result<strong>in</strong>g from faults or errors <strong>in</strong> thisoperat<strong>in</strong>g manual.The copyright of this operat<strong>in</strong>g manual is left to the BENDER companies. Thisoperat<strong>in</strong>g manual is only meant for the operat<strong>in</strong>g authority and its staff.It conta<strong>in</strong>s rules and comments which shall be neither entirely nor partly duplicated,spread or published <strong>in</strong> any other way. Contraventions may entail crim<strong>in</strong>alprosecution.9TGH1320E/03.2000

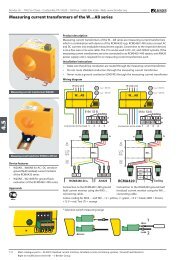

3 Op erat<strong>in</strong>g pr<strong>in</strong>ciple of the <strong>EDS3365</strong>Operat<strong>in</strong>g pr<strong>in</strong>ciple<strong>in</strong>sulation fault location(EDS-mode)AttentionWhen a first <strong>in</strong>sulation fault occurs <strong>in</strong> IT systems, a fault current flows which isessentially determ<strong>in</strong>ed by the system leakage capacitances. The basic concept <strong>in</strong>fault location is therefore to close the fault current circuit for a short period over adef<strong>in</strong>ed resistance. As a result of this pr<strong>in</strong>ciple, the system voltage itself drives a testcurrent which <strong>in</strong>cludes a signal that can be evaluated.The test current is generated periodically by the PGH183 (which is a component ofthe <strong>EDS3365</strong> system). The test current is limited <strong>in</strong> amplitude and time. As thishappens, the system conductors are connected alternately to earth over a def<strong>in</strong>edresistance. The fault current which is generated <strong>in</strong> this manner depends on the sizeof the present <strong>in</strong>sulation fault, and on the system voltage. It is limited to a maximumof 2.5 mA, and when I max= 1 mA is set, it is limited to 1 mA. For plann<strong>in</strong>g purposes,it should be noted that no system components are present <strong>in</strong> which this test currentcan br<strong>in</strong>g about a damag<strong>in</strong>g reaction, even <strong>in</strong> unfavourable cases.Voltage sourceL1(L+)IT systemConsumerL2(L-)Current clamp orcurrent transformerPGH183orPGH473test device132EDS165-3evaluatorInsulation faultRFPEThe test current pulse flows from the test device via the live conductors, tak<strong>in</strong>g theshortest path to the location of the <strong>in</strong>sulation fault. From there, it flows via the<strong>in</strong>sulation fault and the earth conductor (PE conductor) back to the test device. Thiscurrent pulse ist then detected by the current clamps or measur<strong>in</strong>g currenttransformers located <strong>in</strong> the <strong>in</strong>sulation fault path, and is reported by the connectedEDS165-3 evaluator.The current clamps and/or measur<strong>in</strong>g current transformers are used as residualcurrent transformers – that is to say, the PE conductor is not passed through thetransformer.Important: normal commercial current clamps or measur<strong>in</strong>g current transformersmust not be used.PositionPGH4731 3 2 3 12 sec 4 sec 2 sec 4 secThe test cycle of PGH183 <strong>in</strong> differentswitch positions (1, 2, 3) is shown <strong>in</strong> thediagram on the left.EDS start10TGH1320E/03.2000

Operat<strong>in</strong>g pr<strong>in</strong>ciple of the <strong>EDS3365</strong>Response valuesThe response value is determ<strong>in</strong>ed by the sensitivity of the EDS165-3 evaluator. InDC as well as AC systems, this is 0.5 mA as an arithmetic mean value .The accuracy is +/- 0.2 mA of the displayed measurement value. System<strong>in</strong>terferences and excessively high system leakage capacitances may have a negative<strong>in</strong>fluence on the accuracy.Term<strong>in</strong>ologyIn this operat<strong>in</strong>g manual, certa<strong>in</strong> measurement eng<strong>in</strong>eer<strong>in</strong>g terms will occurrepeatedly. The most important of these terms are demonstrated and expla<strong>in</strong>ed withthe help of the follow<strong>in</strong>g sketch.Voltage sourceIT systemMeasur<strong>in</strong>g current transformeror current clampConsumerI ∆EDS473-12EDS165-3PGH473PGH183C E-VR F-VCE-NR F-NPEI ∆Residual current through the measur<strong>in</strong>g current transformer:I ∆max1 A = FAULTC E-VUpstream capacitances, system leakage capacitances upstreamthe measur<strong>in</strong>g current transformerC E-NDownstream capacitances, system leakage capacitancesdownstream the measur<strong>in</strong>g transformerR F-VInsulation fault upstream the measur<strong>in</strong>g current transformerR F-NInsulation fault downstream the measur<strong>in</strong>g current transformerPGH183, PGH473 Insulation fault test deviceEDS165-3, EDS473-12 Insulation fault evaluatorsEarth fault loop of the test current I pr(I pr m<strong>in</strong>= 0.5 mA, I pr max= 2.5/1 mA)Residual currents I ∆The <strong>in</strong>sulation fault location system <strong>EDS3365</strong> detects <strong>in</strong>sulation faults downstreamof the measur<strong>in</strong>g current transformer (R F-N), subject to the condition that the testcurrent is more than 0.5 mA.The total residual current through the measur<strong>in</strong>g current transformer consists ofthe test current and the residual currents which result from the capacitances C E-V,C E-N, and/or <strong>in</strong>sulation faults R F-N. The total residual current through the measur<strong>in</strong>gcurrent transformer may be a maximum of 1 A. If higher residual currents occur,a FAULT message to this effect is given, and no evaluation is possible on thischannel. On this po<strong>in</strong>t, please refer to the FAULT curve on the next page as well.The upstream capacitances C E-Vmust be at least as large as the downstreamcapacitances C E-N(C E-V≥ C ). If this condition is not satisfied, false tripp<strong>in</strong>g signalsE-Nmay be given.Note: under certa<strong>in</strong> circumstances, balanced <strong>in</strong>sulation faults downstream of themeasur<strong>in</strong>g current transformer are not detected.11TGH1320E/03.2000

Operat<strong>in</strong>g pr<strong>in</strong>ciple of the <strong>EDS3365</strong>FAULT curveThe possible frequency range is shown by the curve (FAULT curve) which follows.This <strong>in</strong>dicates the range <strong>in</strong> which residual currents are displayed as a FAULT. Ingeneral, residual currents > 1 A are displayed accord<strong>in</strong>gly, and <strong>in</strong>dependently of thefrequency.Outside of the admissible range, FAULT messages may be given if residual currentsoccur. Likewise, excessively high leakage capacitances can lead to FAULT messages.These messages are displayed <strong>in</strong> the menu of the EDS165-3.FAULT FAULT-Kurve CurveIndication FAULT > 11000900Differenzstrom (mA)Residual current (mA)800700600500400300200100IndicationFAULTAdmissible Range08121822252735404448Frequency Frequenz (Hz) (Hz)54586580100120<strong>EDS3365</strong> electrical <strong>in</strong>terference. The curve <strong>in</strong>dicates the maximum residual current before aFAULT <strong>in</strong>dication is given.A sophisticated filter circuit and electronic system avoids malfunctions due toextraneous currents < 1 A.The follow<strong>in</strong>g FAULT conditions may be <strong>in</strong>dicated on the display of the EDS165-3:• Short circuited current clamp or current transformer connection. Display: no• Interrupted current transformer connection, or no current clamp or currenttransformer connected. Display: no• A residual current > 1 A through the current clamp or the current transformer.• The current transformer signal cannot be evaluated due to <strong>in</strong>terferences.• The leakage capacitances <strong>in</strong> the system, or <strong>in</strong> an output of the system, are toohigh.12TGH1320E/03.2000

Operat<strong>in</strong>g pr<strong>in</strong>ciple of the <strong>EDS3365</strong>Function <strong>in</strong> the RCMmodeIn the RCM mode (RCM=Residual Current Monitor), the <strong>EDS3365</strong> operates accord<strong>in</strong>gto the pr<strong>in</strong>ciple of residual current measurement. In this case, only the EDS165-3evaluator unit with the current clamp is used, and the PGH183 test device is notrequired.In accordance with Kirchhoff´s Law, the sum of the <strong>in</strong>flow<strong>in</strong>g currents at every<strong>in</strong>tersection <strong>in</strong> a system is equal to the sum of the outflow<strong>in</strong>g currents.I toI fromI∆=0PSA3352MESSZANGE / CLAMP ON PROBEDatenbla t / Datasheet : TGH1320Durchme ser / Diameter : 52 mmArt.-Nr. / Art.-no. : B 980 695max. 1 A600 V CAT I1000 mA / 0,1 mA ~The two currents I toand I fromare equal <strong>in</strong> quantity but have different directions, sothat the resultant sum is zero.The EDS165-3 recognises this and no message isgenerated.PEI toI fromI∆=0PSA3352MESSZANGE / CLAMP ON PROBEDatenblatt / Datasheet : TGH1320Durchme ser / Diameter : 52 mmArt.-Nr. / Art.-no. : B 980 695max. 1 A600 V CAT III1000 mA / 0,1 mA ~R FA portion of the current is flow<strong>in</strong>g away via an <strong>in</strong>sulation fault R F. The sum of thecurrents is no longer zero. If the residual current is equal to or greater than theresponse value, the EDS165-3 will generate a message.In the RCM mode, residual currents can be measured <strong>in</strong> one- and three-phase TT orTN systems (AC). If the system leakage capacitance upstream of the current clamp issufficiently high, the EDS165-3 can also be used for measurements <strong>in</strong> one-and threephaseIT systems (AC). Its suitability for this purpose must be checked <strong>in</strong> each<strong>in</strong>dividual case.PE13TGH1320E/03.2000

ONOperat<strong>in</strong>g pr<strong>in</strong>ciple of the <strong>EDS3365</strong>Direction of energyDirection of energyVoltage sourceConsumerPSA3352MESSZANGE / CLAMP ON PROBEDatenbla t / Datasheet : TGH1320Durchme ser / Diameter : 52 mmArt.-Nr. / Art.-no. : B 980 695max. 1 A600 V CAT I1000 mA / 0,1 mA ~Us2,5mAImax100mAON1 mAL1(+)AC/DCL2(-)L3PGH183Insulation fault upstreamof the current clampInsulation fault downstreamof the current clampWhen us<strong>in</strong>g the <strong>EDS3365</strong>, the direction of energy must always be taken <strong>in</strong>toaccount. This applies for the EDS mode (<strong>in</strong>sulation fault location).Insulation faults may arise up or downstream of the current clamp (or the measur<strong>in</strong>gcurrent transformer). The illustration above shows both those options. However, <strong>in</strong>the EDS mode faults can only be located DOWNSTREAM of the currentclamp.Please consider this fact when us<strong>in</strong>g <strong>EDS3365</strong>. For this reason it is advisable to startthe <strong>in</strong>sulation fault location near the voltage source <strong>in</strong> order to move towards theconsumer. This statement applies <strong>in</strong>cidentally to all <strong>in</strong>sulation fault location systems.14TGH1320E/03.2000

4 Produc t descriptionThe systemcomponents at a glanceThe primary function of the <strong>EDS3365</strong> is that of an <strong>in</strong>sulation fault location system <strong>in</strong>IT systems.The <strong>in</strong>dividual components of the <strong>EDS3365</strong> are used <strong>in</strong> comb<strong>in</strong>ation forthis purpose.Alum<strong>in</strong>ium case withcarry<strong>in</strong>g strapPSA3320PSA3320 currentclampPSA3352 currentclampPGH183 test devicePSA3352ONMESSZANGE / CLAMP ON PROBEDatenblatt / Datasheet : TGH1320Durchmesser / Diameter : 52 mmArt.-Nr. / Art.-no. : B 980 695max. 1 A600 V CAT I1000 mA / 0,1 mA ~Us2,5mAImax100mAON1 mAL1(+)AC/DCL2(-)L3PGH183EDS165-3 <strong>in</strong>sulation faultevaluatorNot illustrated:Power supply cable (europlug with connector for cold conditions) for PGH183<strong>in</strong>sulation fault test device.Safety measur<strong>in</strong>g leads, 3 x black and 1 x green/yellow.Safety claw grip with 2 A fuses to connect the PGH183 with the system conductorsand the PE.BNC adapter unit/banana plug to connect measur<strong>in</strong>g current transformers.Banana plugAccumulator charg<strong>in</strong>g set for EDS165.15TGH1320E/03.2000

Product descriptionParts listThe <strong>EDS3365</strong> <strong>in</strong>sulation fault location system comprises the follow<strong>in</strong>g components:1 pc. Alum<strong>in</strong>ium case with carry<strong>in</strong>g strap1 pc. PGH183 test device1 pc. EDS165-3 <strong>in</strong>sulation fault evaluator, accumulators <strong>in</strong>cluded1 pc. PSA3320 current clamp (diameter 20mm)1 pc. PSA3352 current clamp (diameter 52mm)1 pc. Power supply cable3 pcs. Safety measur<strong>in</strong>g lead, black1 pc. Safety measur<strong>in</strong>g lead, green/yellow4 pcs. Safety claw grip (3 x black, 1 x green/yellow) with 2A fuses1 pc. BNC Adaptor / banana plug -> transformer2 pcs. Banana plug1 pc. Accumulator charg<strong>in</strong>g set (not with the <strong>EDS3365</strong>-13 version)1 pc. TGH1320E operat<strong>in</strong>g manualBefore commission<strong>in</strong>g, please check that all the components listed above are<strong>in</strong>cluded. Do not undertake any work with an <strong>in</strong>complete system. If anycomponents are miss<strong>in</strong>g, please contact a technical adviser at BENDER.Supply voltageThere are two different <strong>EDS3365</strong> <strong>in</strong>sulation fault location systems available:• <strong>EDS3365</strong>• <strong>EDS3365</strong>-13The difference between them is the supply voltage for the PGH183:• PGH183 - supply voltage: AC 230 V• PGH183-13 - supply voltage: AC 90 …132 VAttentionOptionsPrior to commission<strong>in</strong>g, it is absolutely essential to check whether the supply voltageof the <strong>EDS3365</strong> system matches the voltage of the ma<strong>in</strong>s supply. Operation of the<strong>EDS3365</strong> with the wrong supply voltage can result <strong>in</strong> the destruction of the PGH183test device.When work<strong>in</strong>g with the <strong>EDS3365</strong>, only use those components which are suppliedwith the system. In particular, do not use other current clamps, measur<strong>in</strong>g leads ormeasur<strong>in</strong>g term<strong>in</strong>als.The <strong>EDS3365</strong> represents a complete system. In addition to the PSA3320 and PSA3352current clamps which are supplied with the system, measur<strong>in</strong>g current transformerscan be connected to the EDS165-3 <strong>in</strong>sulation fault evaluator. These may be BENDERmeasur<strong>in</strong>g current transformers which are already <strong>in</strong>stalled <strong>in</strong> the system.The follow<strong>in</strong>g types of transformers are suitable:Measur<strong>in</strong>g current transformer W1-35/8000 or W08/8000Split-core type measur<strong>in</strong>g transformer WS50x80/8000Important: normal commercial measur<strong>in</strong>g transformers must not be used!This also applies to additional current clamps or measur<strong>in</strong>g current transformersfrom the BENDER range.Attention: if transformers are not be<strong>in</strong>g used, they must not be left open <strong>in</strong> thesystem. In this case, the transformer term<strong>in</strong>als k u. 1 should be short-circuited.16TGH1320E/03.2000

Product descriptionAlum<strong>in</strong>ium caseAll the components of the <strong>EDS3365</strong> are accommodated <strong>in</strong> a stable alum<strong>in</strong>ium casewith foam <strong>in</strong>lays.462158167335360All dimensions <strong>in</strong> mmEDS165-3 <strong>in</strong>sulationfault evaluatorBNC socket fo clamps formesur<strong>in</strong>g currenttransformersOperat<strong>in</strong>g modeselector switchEDS165EDS165-3 V. 1.5RS232 <strong>in</strong>terfaceLC displayAlarm LEDsocket forpower packThe operat<strong>in</strong>g mode switch on the EDS165-3has three positions:Middle position: OFF – the device isswitched offPosition I ∆S: Function as evaluatorwith<strong>in</strong> an EDA3365or EDS473 system(EDS mode)Position I ∆N: Function as residualcurrent measur<strong>in</strong>g device(RCM mode)keys17TGH1320E/03.2000

Product descriptionTest device PGH183solid cas<strong>in</strong>g with gripeurosocket forcold conditionsON/OFF switchselector switch for max. testcurrent (2.5 / 1 mA)ONUs2,5mAImax100mAON1 mAL1(+)AC/DCL2(-)L3PGH183Fuse 100mAsocket for PEconnection3 sockets for coupl<strong>in</strong>g tothe electrical systemNot visible:magnetic adhesive stripon the rear side of thehous<strong>in</strong>g to fasten ontometal parts (e.g. switchcab<strong>in</strong>et)Display LEDs:ONPower on LED<strong>in</strong>dicates positive test cycle<strong>in</strong>dicates negative test cycleThe PGH183 is activated by us<strong>in</strong>g its ON/OFF switch, and it generates a def<strong>in</strong>ed testcurrent signal. The voltage present <strong>in</strong> the system is used to drive the test current.The value of the test current which is generated therefore depends on the value ofthe <strong>in</strong>sulation fault that is present, and on the system voltage. The test current islimited to a maximum of 2.5 mA or to 1 mA when the switch is under the 1mAposition.The test current flows from the system via the PGH183 and then through theprotective conductor (PE) and the <strong>in</strong>sulation fault (or faults) back to the system. Thetest current signal is detected by the current clamps or measur<strong>in</strong>g currenttransformers located <strong>in</strong> the fault current circuit, and the defective circuits are<strong>in</strong>dicated by the EDS165-3 <strong>in</strong>sulation fault evaluator whenever the response value of0.5 mA is exceeded.If the PGH183 is active, the cycle LEDs light up alternately <strong>in</strong> time with the testcycle. If the device is connected by term<strong>in</strong>als L1, L2, L3 (or L1, L2) to a system that islive for operational reasons the term<strong>in</strong>al must not be disconnected from theprotective conductor (PE).AttentionThe test current flows between the system and earth. If unfavourable comb<strong>in</strong>ationsof circumstances arise (low-impedance <strong>in</strong>sulation fault <strong>in</strong> comb<strong>in</strong>ation with the testcycle), control errors cannot be ruled out on very sensitive system components (SPC,m<strong>in</strong>iature relays). This possibility should be taken <strong>in</strong>to account prior to use. If thispossiblity exists, then sett<strong>in</strong>g I max= 1 mA should be selected.18TGH1320E/03.2000

Product descriptionPSA3320 current clampThe PSA3320 current clamp can be used to encircle leads of up to 20 mm <strong>in</strong>diameter. The connection to the EDS165-3 <strong>in</strong>sulation fault evaluator is made via aBNC connector and measur<strong>in</strong>g lead with a length of approximately 2m.PSA3320PSA3352 current clampPSA3352MESSZANGE / CLAMP ON PROBEDatenblatt / Datasheet : TGH1320Durchmesser / Diameter : 52 mmArt.-Nr. / Art.-no. : B 980 695max. 1 A600 V CAT III1000 mA / 0,1 mA ~The PSA3352 current clamp can be used to encircle leads of up to 52mm <strong>in</strong>diameter. The connection to the EDS165-3 <strong>in</strong>sulation fault evaluator is made via aBNC connector and measur<strong>in</strong>g lead with a length of approximately 2 m.19TGH1320E/03.2000

Product descriptionTechnical data<strong>EDS3365</strong><strong>EDS3365</strong> <strong>in</strong>sulation fault location systemInsulation coord<strong>in</strong>ation acc. to IEC 664-1:Type of operation:dependend on the current sensor usedcont<strong>in</strong>uous operationTechnical dataPGH183PGH183 <strong>in</strong>sulation fault test deviceRated <strong>in</strong>sulation voltage:AC 500 VRated impulse withstand voltage/contam<strong>in</strong>ation level 4 kV / 3Monitored systemOperat<strong>in</strong>g range of rated ma<strong>in</strong>s voltage, AC:20-265 VOperat<strong>in</strong>g range of rated ma<strong>in</strong>s voltage, DC:20-308 VSupply voltageSupply voltage, U S:AC 185-265 V for PGH183AC 90-132 V for PGH183-13Fuse protection for supply voltage:f<strong>in</strong>e-wire fuse, 100 mA, slow-act<strong>in</strong>gMeasur<strong>in</strong>g cycleMaximum test current:2.5 / 1 mATest cycle:2 sPause time:4 sType testsTest of electromagnectic compatibility (EMC):Immunity aga<strong>in</strong>st electromagnetic <strong>in</strong>terference acc. to prEN 50 082-2Emissions acc. to EN 50 081:Emissions acc. to EN 55 011/CISPR11: Class B *)Mechanical testsShock resistance, to IEC 68-2-27:15 g / 11 msBump<strong>in</strong>g acc. to IEC 68-2-29:40 g / 6 msVibration strength acc. to IEC 68-2-6:10 … 150 Hz / 0.15 mm – 2 gEnvironmental conditionsAmbient temperature dur<strong>in</strong>g operation : -10 … +55 °CAmbient temperature dur<strong>in</strong>g storage: -40 … +70 °CClimatic class acc. to IEC 721: 3K5, except condensation and <strong>format</strong>ion of iceGeneral dataOperat<strong>in</strong>g position:as desiredType of connection:flexible safety leads with safety term<strong>in</strong>alsSet up mode: upright, horizontal, or on metal parts with the use of magnetic stripsProtection class:IP20Weight:approximately 700 gDimensions:160x148x81 mm*) Class B devices are suitable for the use <strong>in</strong> <strong>in</strong>dustrial application as well as <strong>in</strong>households.20TGH1320E/03.2000

Product descriptionTechnical dataEDS165-3Insulation coord<strong>in</strong>ation acc. to DIN VDE 0110 T1:Type of operation:Monitored system:Rated <strong>in</strong>sulation voltage U n:System frequency <strong>in</strong> EDS mode:System frequency <strong>in</strong> RCM mode:depends on the current clamp usedcont<strong>in</strong>uous operationsee PGH183 and/or current clamps50,60,400 Hz (adjustable) or DC47 … 65 HzSupply voltageOperat<strong>in</strong>g range supply voltage U S:DC 4.2 … 6.2 VSupply: via 4 round cells, type LR6 AA – 1.5 V or 4 NC cells, 1.2 V, or via power unitFor supply via external power unit:DC 7.5 VI max:100 mAPolarity:+-Operat<strong>in</strong>g lifetime of the batteries:Power consumption:m<strong>in</strong>imum 8h0.6 WMeasurement <strong>in</strong>put for I Ds- function (EDS mode <strong>in</strong> comb<strong>in</strong>ation withEDS473 systems)Response value:0.5 mAAccuracy:+/- 0.2 mAMeasurement <strong>in</strong>put for I ∆n- function (RCM mode, residual currentmeasurement)Measur<strong>in</strong>g range with current clamps:AC 10 mA … 1.6 AMeasur<strong>in</strong>g range with measur<strong>in</strong>g current transformers:AC 10 mA … 1 AResponse range for alarm <strong>in</strong>dication:AC 10 mA … 1 AAccuracy: + 10 % / - 0 %Accuracy with measur<strong>in</strong>g current transformer WS50x80/8000: +/- 15%Weight:approximately 370 gTechnical datacurrent clampsCurrent clamps:Insulation coord<strong>in</strong>ation acc. to IEC 1010-2-032Nom<strong>in</strong>al <strong>in</strong>sulation voltage, PSA3320 and PSA3352:Protection class acc. to DIN 40 050Measurement outputDimensions, PSA3352Dimensions, PSA3320Permissible cable diameter, PSA3352 :Permissible cable diameter, PSA3320 :Weight, PSA3352 :Weight, PSA3320 :AC 600 V CAT IIIand AC 300 V CAT IVIP40BNC plug216x111x45 mm135x65x30 mm52 mm20 mmapproximately 550 gapproximately 200 g21TGH1320E/03.2000

5 Op eration and S ett<strong>in</strong>gFactory sett<strong>in</strong>gsThe components of the <strong>EDS3365</strong> are delivered with factory sett<strong>in</strong>gs, which aresuitable for many standard applications. The follow<strong>in</strong>g list shows the factory sett<strong>in</strong>gsfor the <strong>in</strong>dividual devices:PGH183 test deviceI max= 2.5 mAEDS165-3 <strong>in</strong>sulation fault evaluator (with the switch <strong>in</strong> position I ∆s)Fault memory: offBuzzer:onFrequency: 50 HzSensor:current clamp PSA3320Sett<strong>in</strong>gs on theEDS165-3 evaluatorExcept for the changeover of the maximum test current, all the sett<strong>in</strong>gs to the<strong>EDS3365</strong> systems are performed on the EDS165-3 <strong>in</strong>sulation fault evaluator.Switch<strong>in</strong>g on theEDS165-3The operat<strong>in</strong>g mode selector switch on the left hand side of the <strong>EDS3365</strong> hasthree positions:Middle position: OFF – the device is switched offRight-hand position: I ∆s- function as an <strong>in</strong>sulation fault evaluator with<strong>in</strong> the<strong>EDS3365</strong> or with<strong>in</strong> the EDS473 system (EDS mode)Left-hand position: I ∆n- function as a residual current measur<strong>in</strong>g device(RCM mode)EDS165operat<strong>in</strong>g modeselector switchI ∆nI ∆sEDS165-3 V. 1.5Three keys are used to operate the EDS165-3:UP DOWN ENTER22TGH1320E/03.2000

Operation and S ett<strong>in</strong>gThe EDS165-3displayHere is an example of a display on the EDS165-3 <strong>in</strong> the EDS mode:Test current(measur<strong>in</strong>g value)Response value exceededΙ∆s=0.8 mAALARM50HzCurrent clampis connectedIndication ofbattery charg<strong>in</strong>gAdjusted frequency ofthe electrical systemGo on with Buzzer is activated5 menusThe EDS165-3 provides 5 menus <strong>in</strong> order to parameterize:m1 (set sensor)For the sett<strong>in</strong>g of the connected current clamp or the connectedmeasur<strong>in</strong>g current transformer.m2 (reset)m3 (memory)m4 (buzzer)Resets all the displayed alarm messages.For the sett<strong>in</strong>g of the memory behaviour of the alarm messageand of the alarm LED.Activates and deactivates the <strong>in</strong>ternal buzzer.m5 (freq) In the EDS mode: adapt<strong>in</strong>g the <strong>EDS3365</strong> to therespective system frequency.In the RCM mode : sett<strong>in</strong>g the response value of theresidual current.23TGH1320E/03.2000

Operation and S ett<strong>in</strong>gThe EDS165-3 <strong>in</strong>the EDS modeThe EDS165-3 is operated and set us<strong>in</strong>g three control keys and the LCD display.When mak<strong>in</strong>g any of the sett<strong>in</strong>gs, you must press the relevant control keys for about1 second. The different sett<strong>in</strong>gs which are possible <strong>in</strong> the EDS mode (position I ∆s)are described below.If you move the operat<strong>in</strong>g mode selector switch to position I ∆sthe EDS 165-3 will be<strong>in</strong> the EDS mode. As soon as you have done this, you will see the display menu(see above).From the display menu, press the key to reach the sett<strong>in</strong>g menus. The key activates whichever sub-menu you have called up; use the keyto move to the next menu.Menu 1: set sensorm1: set sensorexit: , m2:Menu 1 (m1) allows you to set thesensor which is connected. Press: to reach the menu formodification, to move on to the next menu, m2or to return to the displaymode.sensor:ok:sensor: ,The sensor which is set at present is thePSA3320 current clamp. The possiblesett<strong>in</strong>gs are described below. Press: to accept the current sett<strong>in</strong>gand return to the display mode, to select the current clampor measur<strong>in</strong>g current transformers.The follow<strong>in</strong>g sett<strong>in</strong>gs are possible:PSA3320 current clampPSA3352 current clampSplit-core measur<strong>in</strong>g currenttransformers WS50x80/8000Standard measur<strong>in</strong>g current transformers:W1-35/8000W08/8000Menu 2: resetm2: resetm1: ,m3:The next menu (m2) is the reset menu.Press: to call up the reset program, to call up the next menu (m3) or to return to the previous menu(m1).reset: alarmno reset:Press the key to implementthe selected sett<strong>in</strong>g and return to thedisplay mode; use the key toselect reset or no reset.24TGH1320E/03.2000

Operation and S ett<strong>in</strong>gMenu 3: memorym3: memorym2: ,m4:The menu m3 is used to specify thememory behaviour for the alarmmessage and the alarm LED. Press: key to call up the subrout<strong>in</strong>e, to reach the next menu (m4) or to return to the previous menu(m1).Press the key to modify thepresent sett<strong>in</strong>g; press toconfirm the sett<strong>in</strong>g displayed <strong>in</strong> thetop l<strong>in</strong>e and to return to the displaymode.memory on:off:Menu 4: buzzerm4:on/offm3: ,m5:Menu 4 is used to activate or deactivatethe <strong>in</strong>ternal buzzer. Press: to reach the buzzer program, to go to the next menu (m5) or to return to the previous menu(m1).onoff:The top l<strong>in</strong>e shows the present statusof the buzzer – <strong>in</strong> this example, thebuzzer is activated (on). Press tochange the sett<strong>in</strong>g to off, or press to confirm the sett<strong>in</strong>g andthen to return to the display mode.Note: the buzzer sett<strong>in</strong>g will onlyrema<strong>in</strong> active until the next time theEDS165-3 is switched off!Menu 5: frequencym5: freq. (I∆s)m4: ,exit:Use menu (m5) to adapt the EDS165-3to the respective system frequency. Press to call up the systemfrequency adaptation menu, to return to the display mode or to return to the previous menu(m4).frequency: ok:50 HzThe top l<strong>in</strong>e displays the systemfrequency that is set at the moment,which is 50Hz <strong>in</strong> this case. Use the key to modify the frequency: thevalues available are 50, 60 and 400 Hz.Press to accept the set value and return to the display. You must alwaysset the frequency which is present <strong>in</strong> the respective system. In pure DC systemsonly, you must set the frequency of the system from which the DC isobta<strong>in</strong>ed.Note: after leav<strong>in</strong>g the <strong>in</strong>dividual menus (m1 … m5), you will always be returned tothe display mode.25TGH1320E/03.2000

Operation and S ett<strong>in</strong>gThe EDS165-3 <strong>in</strong> theRCM modeIf the operat<strong>in</strong>g mode selector switch is moved to position I ∆n, EDS165-3 operates <strong>in</strong>the RCM mode, and can be used as a portable residual current measur<strong>in</strong>g device <strong>in</strong>AC systems.Residual current (measur<strong>in</strong>g value)Response valueexceededRCM modeΙ∆=125 mAMALARMY=100mACurrent clampis connectedIndication ofbattery charg<strong>in</strong>gMemory = onBuzzer is activatedGo on with Preset response valueThe way the menus are set corresponds largely to the description already given forthe EDS mode. However, there is a difference <strong>in</strong> menu 5 (m5). In the RCM mode,the response value is set here <strong>in</strong> mA or A respectively.Use <strong>in</strong> order to start the program to set the response value, or press to return to the display mode.Menu 5: set Ym5: set Y (I∆n)m4: ,exit:Y= 20 mA ok:Y: ,The top l<strong>in</strong>e <strong>in</strong>dicates the current sett<strong>in</strong>g of the response value. Use the arrow keys(, ) to modify the response value between 10 mA and 1 A. Up to 500mA to 1 A, the modification is made <strong>in</strong> 10 mA steps; from 500 mA to 1 A, <strong>in</strong> stepsof 50 mA. Press to accept the set value and return to the display mode.Note: The sett<strong>in</strong>gs <strong>in</strong> menus m1, m2, m3 and m4 are always valid for the EDS modeand the RCM mode.26TGH1320E/03.2000

Operation and S ett<strong>in</strong>gThe EDS165-3 issues a fault message if no current clamps or measur<strong>in</strong>g currenttransformers are connected. The fault message is given acoustically and visually. TheBUZZER ON or BUZZER OFF sett<strong>in</strong>g does not <strong>in</strong>fluence the acoustic message if nocurrent clamp is present. The message is given <strong>in</strong> the EDS mode as well as the RCMmode.Attention: no fault message is given if an <strong>in</strong>correct current clamp or an <strong>in</strong>correctmeasur<strong>in</strong>g current transformer are connected. In this case the <strong>in</strong>dications of testcurrent and residual current can be quite different.noWhen the response value is exceeded <strong>in</strong> the RCM mode (I ∆n), this is shown on thedisplay by the ALARM message and <strong>in</strong>dication of the residual current.Ι∆=125 mA ALARMM Y=100mAIn the top l<strong>in</strong>e, I ∆nshows the currentlymeasured residual current; and <strong>in</strong> thelower l<strong>in</strong>e, Y shows the responsevalue that has been set.Ι∆s=1.5 mAM 50HzALARMIn the EDS mode (I ∆s), a selective testcurrent which is greater than 0.5 mAwill result <strong>in</strong> an alarm message.Ι∆ >1.0 AMFAULT50HzResidual currents that are greater than1 A lead to different messages. In theEDS mode, a FAULT message isgenerated:Ι∆ >1.0 AMALARMY=100 mAIn the RCM mode, an ALARMmessage is generated:If there is no current clamp connected to the system or if there is a short-circuit <strong>in</strong>the l<strong>in</strong>e of the current clamp, the display shows: noWhen <strong>in</strong>ternal faults or high EMC <strong>in</strong>terferences occur, it may be that no recognitionof the set mode is possible anymore. In this case a general fault message isdisplayed. This <strong>in</strong>dication may occur also <strong>in</strong> the case of an empty accumulator.No FunctionCall BENDER ServiceCall ++ - 6401 - 807 - 0 for technicalsupport.27TGH1320E/03.2000

Operation and S ett<strong>in</strong>gSerial <strong>in</strong>terfaceThe standard RS232 <strong>in</strong>terface makes it possible to connect system <strong>in</strong>dependentcomponents. These may be computer systems, stored-program controllers, or similaritems. With knowledge of the <strong>in</strong>terface protocol be<strong>in</strong>g used, it is possible for theuser to write his own programs and use them. The protocol for data transmissioncorresponds to the <strong>format</strong> for BENDER measur<strong>in</strong>g device <strong>in</strong>terfaces.Data transmission generally makes use of ASCII characters. The <strong>in</strong>terface data are:Baud rate:Transmission:Parity:Checksum:Address:9600 baud1 start bit, 7 data bits, 1 parity bit, 1 stop bit (1,7,E,1)even (P=0)sum of all transmitted bytes = 0 (without CR and LF)001 … 255 and 000 (=general address)Interface protocolProtocols:MasterSlave:;XXX:ABCDE 12345&XYZ::XXX:ABCDE 12345&XYZ:; recognition of start of master transmission:: recognition of start of slave transmissionXXXaddress: start byte for commandABCDEcommand, consist<strong>in</strong>g of a maximum of 5 ASCII characters(blank character) start byte for data12345 data, consist<strong>in</strong>g of a maximum of 5 ASCII characters,maximum size: 65 535&start byte for checksumXYZchecksum, consist<strong>in</strong>g of a maximum of 3 ASCII characters end of transmission (carriage return, l<strong>in</strong>e feed)The command and the data may be smaller than 5 bytes, or may be omittedaltogether. In every case, the end is recognised from the start byte to the nextcharacter type.28TGH1320E/03.2000

Quality SystemCertifiedOperation and S ett<strong>in</strong>gReplac<strong>in</strong>g theaccumulatorsThe charge status of the accumulators or the batteries is <strong>in</strong>dicated <strong>in</strong> the displaymenu. The illustration below shows an accumulator or a battery whose capacity ismore or less half used up.Ι∆=125 mAMALARMY=100mA↑The battery compartment is located on the rear side of the EDS165-3; it conta<strong>in</strong>sbatteries or rechargeable accumulators.ISO 9001BENDER EDS165-3ISOLATIONSFEHLERAUSWERTEGERÄTInsulation fault evaluatorSoftware Version: V 1.5Werk-Nr./Serial-no.: 9907049213Artikel-Nr./Art.-no.: B91082010Technische Daten /Technical DataRead Instructions before use!Ausführung für / design for: DC / AC 400, 60, 50 HzEmpf<strong>in</strong>dlichkeit / Sensitivity System: Is=DC 0,5 mAMeßbereich / Measur<strong>in</strong>g range: In=AC 10 mA ... 16 AVersorgungsspg. / Supply voltage: Us=DC 7,5 V or 4x1,2...1,5 V (LR6)Datenblatt / Data sheet: TGH1265-+1,5 V1,5 V+--1,5 V++ 1,5 V -In order to change the accumulators, the black cover flap on the rear side of theEDS165-3 has to be opened. To do this, carefully lift off the flap with the use of ascrewdriver (blade width: 3-5 mm).Then <strong>in</strong>sert the new accumulators accord<strong>in</strong>g to the impr<strong>in</strong>ted position<strong>in</strong>g diagram.Also note that the device parameters that have been set will rema<strong>in</strong> the same whenthe batteries are replaced.29TGH1320E/03.2000

6 Po<strong>in</strong>ts to be considered b efore useThe <strong>EDS3365</strong> makes it possible to search for <strong>in</strong>sulation faults <strong>in</strong> IT systems, AC 20-265 V and DC 20-308 V. This system is particularly well suited for use <strong>in</strong> controlvoltage systems where control errors may be caused as a result of high faultcurrents; this is due to the special features of the <strong>EDS3365</strong>, such as:• low test current => no control errors• high sensitivity• relatively <strong>in</strong>sensitive to system leakage capacitances and faults• long time measurement• data transmission with possibility of evaluationReduced measur<strong>in</strong>gcurrentEspecially <strong>in</strong> DC control voltage systems <strong>in</strong> the power station and supply companiesector, relays or SLCs may be <strong>in</strong>stalled which are already triggered by relatively lowcurrents.+DCK1-PGH183Imax: 2.5 bzw. 1 mAPEThe sketch above shows a DC system. Relay K1 can be caused to operate by an<strong>in</strong>sulation fault <strong>in</strong> comb<strong>in</strong>ation with the test cycle of the PGH183. In such a case, theI maxswitch on the PGH183 must be moved to the 1 mA position.AttentionAlso, when the <strong>EDS3365</strong> is be<strong>in</strong>g used with the activated test current limitation of 1mA, it is necessary to check whether any sensitive system components might becaused to operate un<strong>in</strong>tentionally.30TGH1320E/03.2000

Po<strong>in</strong>ts to be considered before useA sensible approachto fault locationThe sensitivity of the <strong>EDS3365</strong> is 0.5 mA. Hence the maximum <strong>in</strong>sulation resistancewhich can be deteced is dependent on the voltage wave form, the level of thevoltage and the system leakage capacitance that is present.In order to start <strong>in</strong>sulation faults location <strong>in</strong> a sensible manner, it is advisable toconsult the follow<strong>in</strong>g characteristic curves beforehand. These show:• the <strong>in</strong>sulation fault which can be found, <strong>in</strong> relation to the system voltage(curve 1)• the maximum permissible system leakage capacitance, <strong>in</strong> relation to thesystem voltage (curve 2)• the reduction <strong>in</strong> response sensitivity when system leakage capacitances arehigher (curve 3)An example:In a 110 V DC IT system, the <strong>in</strong>sulation monitor<strong>in</strong>g device which is already presentshows an <strong>in</strong>sulation fault of 500 kΩ. The system leakage capacitances are less than0.1 µF and are therefore negligible.A look at characteristic curve 1 shows that an <strong>in</strong>sulation fault of about 200 kΩ canbe found <strong>in</strong> a DC system with 110 V. Therefore it makes no sense <strong>in</strong> this case to start<strong>in</strong>sulation fault location with the <strong>EDS3365</strong>.Another example:In a 230 V AC IT system, the <strong>in</strong>sulation monitor<strong>in</strong>g device which is already presentshows an <strong>in</strong>sulaion fault of 100 kΩ. Characteristic curve 1 shows that <strong>in</strong> a 230 V DCsystem, an <strong>in</strong>sulaion fault can be found from about 200 kΩ upwards. Therefore <strong>in</strong>this case, it makes sense to start <strong>in</strong>sulation fault location, and the chances of f<strong>in</strong>d<strong>in</strong>gthe fault are very good.As a basic rule, it is necessary to take account of the possibility that the total<strong>in</strong>sulation resistance of a system is made up from the parallel connection of several<strong>in</strong>sulation faults. It is not known which <strong>in</strong>dividual faults contribute to this.If a fault is not found with the <strong>EDS3365</strong>, even though this ought to be the caseaccord<strong>in</strong>g to the characteristic curves, the cause may be the sum of a number of<strong>in</strong>dividual faults. In this <strong>in</strong>stance, none of the <strong>in</strong>dividual faults is of sufficiently lowimpedance that it can be detected by the <strong>EDS3365</strong>.Another reason why <strong>in</strong>sulation faults are not found may be an excessively highsystem leakage capacitance (on this po<strong>in</strong>t, see characteristic curves). Whenconsider<strong>in</strong>g the system leakage capacitances, a po<strong>in</strong>t to note is that the division tothe capacitances upstream and downstream of the current clamp is not arbitrary.The upstream capacitance of the entire system must account for at least 50% of thetotal capacitance. Otherwise a reduction <strong>in</strong> the response sensitivity must beexpected.31TGH1320E/03.2000

Po<strong>in</strong>ts to be considered before useCharacteristic curves700600DC: set the test currentto 2.5 mA or 1 mA500Rf (kΩ)400300ACDC20010000 50 100 150 200 250 300 350Un (V)AC: set the testcurrent to 2.5 mACurve 1:response value Rf <strong>in</strong> relation to the system voltage (AC 20-265 V andDC 20-308 V) with a maximum system leakage capacitance C easshown by curve 2.76AC: set the testcurrent to 2.5 mA5Ce (µF)43ACDC2DC: set the test currentto 2.5 mA or 1 mA100 100 200 300 400Un (V)Curve 2:maximum permissible system leakage capacitance <strong>in</strong> relation tothe nom<strong>in</strong>al voltage (AC 20-265 V, DC 20-308 V). Up to thissystem leakage capacitance, the <strong>EDS3365</strong> has the sensitivityshown <strong>in</strong> curve 1.32TGH1320E/03.2000

Po<strong>in</strong>ts to be considered before use12010080Re max60402000 0,5 1 1,5 2 2,5 3x Ce maxCurve 3:Reduction of response sensitivity when system leakage capacitances are greaterthan the maximum permissible value for C etaken from curve 2.When consider<strong>in</strong>g the curves, a po<strong>in</strong>t to be taken <strong>in</strong>to account is that the sum of thecapacitances upstream of the <strong>in</strong>dividual measur<strong>in</strong>g current transformer must amountto at least 50% of the total capacitance. Otherwise, a reduction <strong>in</strong> sensitivity must beexpected.The maximum system leakage capacitance is taken to be a value of 300 µFV. In a220 V system, therefore, this is 300 µFV/220 V = 1.4 µF. If the limit value isexceeded, there may be false tripp<strong>in</strong>gs.33TGH1320E/03.2000

Po<strong>in</strong>ts to be considered before useAll the charcteristic curves on the forego<strong>in</strong>g pages are valid for the <strong>in</strong>dicated testcurrents.Limitation of the test current to 1 mA is particulary <strong>in</strong>tended for the use of the<strong>EDS3365</strong> <strong>in</strong> DC control systems with consumers which may already operate at verylow currents. If the test current is activated <strong>in</strong> AC systems, the maximum test currentis then reduced to factor 0.5 <strong>in</strong> AC systems or 0.67 <strong>in</strong> 3AC systems respectively. Ofcourse, these factors are valid for a maximum test current of 2.5 mA as well.Recommendation: select 2.5 mA as the sett<strong>in</strong>g for the test current <strong>in</strong> AC systems.Limits of <strong>in</strong>sulationfault locationIt is a well-known fact that everyth<strong>in</strong>g <strong>in</strong> this world has its limits.This pr<strong>in</strong>ciple evenapplies to the measurement technique of the <strong>EDS3365</strong>. Modern suppply systemsnowadays conta<strong>in</strong> a large number of components which may lead to <strong>in</strong>fluences andfaults.Interferences for the EDS 3365 system are for example:• high system leakage capacitances• excessively high leakage currents• transient leakage currents• low-frequency leakage currentsThe limit conditions are cited <strong>in</strong> this operat<strong>in</strong>g manual. However, because of thelarge number of possibilities, we cannot make unambiguous statements about everytype of <strong>in</strong>terference compatibility, nor about functional limits. In case of doubt, youmust clarify the suitablility of the <strong>EDS3365</strong> for the application <strong>in</strong> question byconsult<strong>in</strong>g a BENDER adviser.The conditions, and the reactions of the <strong>EDS3365</strong> if the conditions are exceeded,should be expla<strong>in</strong>ed at this po<strong>in</strong>t:• Response sensitivity: for this purpose, curve 3 <strong>in</strong> this chapter should be taken<strong>in</strong>to account.• Influence of system leakage capacitances: curve 2 <strong>in</strong> this chapter shows theresponse sensitivity dependent on the leakage capacitance of the total system.If the leakage capacitance exceeds the permissible value <strong>in</strong> one subcircuitdownstream of the current clamp, <strong>in</strong>correct messages may appear on theEDS165-3 evaluator.• Maximum leakage currents: the maximum permissible system-dependentleakage current under which the evaluation will still function properly islimited to 1 A. If the leakage current exceeds 1 A, selective fault location canno longer be undertaken. Leakage currents > 1 A are shown by the <strong>in</strong>dication(I ∆> 1 A) <strong>in</strong> the display of the EDS165-3.• Transient leakage currents: switch<strong>in</strong>g and controll<strong>in</strong>g activities <strong>in</strong> the systemmay generate transient leakage currents which <strong>in</strong>fluence the evaluation of thetest signal. These transient leakage currents can only be filtered out to acerta<strong>in</strong> extent. It cannot be ruled out that periodic <strong>in</strong>terferences which happento have the same periodic duration, amplitude and signal frequency as the<strong>in</strong>ternal signal scann<strong>in</strong>g may result <strong>in</strong> faulty measurements and may thereforelead to false tripp<strong>in</strong>gs. However, the probability of this happen<strong>in</strong>g isextremely low. It is not possible to give a precise def<strong>in</strong>ition of these limitconditions because they depend on the nature of the system.• Low-frequency leakage currents: these may be brought about by the use offrequency converters. They may lead to false tripp<strong>in</strong>gs on the EDS165-3 iftheir frequency is equal to, or approximately equal to the test cycle frequencyof the test device (PGH473, PGH183).34TGH1320E/03.2000

AC/DC7 Practical useUse as a portable<strong>in</strong>sulation faultlocation systemIT systemPESupply voltage, see nameplate100mAPGH183UsONONL1(+)L2(-)2,5mAL3Imax1 mATo the consumersPSA3352ME SZANGE / CLAMP ON PROBEDatenbla t / Datash et : TGH1320Durchme ser / Diameter : 52 mmArt.-Nr. / Art.-no. : B 980 695max. 1 A600 V CAT I1000 mA / 0,1 mA ~The <strong>EDS3365</strong> is primarily used as a portable <strong>in</strong>sulation fault location system <strong>in</strong> ITsystems, AC 20 …265 V and DC 20 … 308 V.After conclud<strong>in</strong>g considerations as to whether it is possible and/or sensible to searchfor <strong>in</strong>sulation faults, and about the technical measurement limits of the system, theactual fault location can be started. The sequence of <strong>in</strong>sulation fault location isdescribed below, with the use of examples.• Test<strong>in</strong>g the nom<strong>in</strong>al system voltage: does this fall with<strong>in</strong> the permissible limitsfor the <strong>EDS3365</strong>?• Check whether the <strong>in</strong>sulation fault <strong>in</strong>dicated by the <strong>in</strong>sulation monitor<strong>in</strong>gdevice can be found. On this po<strong>in</strong>t, consult the chapter on POINTS TO BECONSIDERED BEFORE USE.Warn<strong>in</strong>g• Before mak<strong>in</strong>g a connection to the system which is to be checked, it isabsolutely essential to connect the green-yellow lead via the PE socket of thePGH183 <strong>in</strong>sulation fault test device with the PE of the system. It is advisableto connect the test device as near to the <strong>in</strong>com<strong>in</strong>g supply (transformer orbattery) as possible.• Connect the PGH183 <strong>in</strong>sulation fault test device to the system which is to bechecked, us<strong>in</strong>g the two connection leads supplied with the device. Whenyou do this, you must comply with the general guidel<strong>in</strong>es for livework<strong>in</strong>g.In a three-phase system: connect sockets L1, L2 and L3.In a s<strong>in</strong>gle-phase system, AC or DC: connect sockets L1 and L2.• Connect the <strong>in</strong>sulation fault test device to the supply voltage, us<strong>in</strong>g the powersupply cord supplied with the device. When you do this, note the level of thesupply voltage and compare it with the nameplate. Do not connect a supplyvoltage which is different from the one stated on the nameplate.• Disconnect the <strong>in</strong>sulation monitor<strong>in</strong>g device which is present <strong>in</strong> the ITsystem. When you do this, disconnect all poles of the system coupl<strong>in</strong>g. It isnot sufficient to switch off the supply voltage to the <strong>in</strong>sulation monitor<strong>in</strong>gdevice.35TGH1320E/03.2000

Practical use• Check the switch position I maxon the PGH183. The factory sett<strong>in</strong>g is 2.5 mA. If theIT system conta<strong>in</strong>s components which might already operate at low currents, then itmay be necessary to select the 1 mA switch position. Note: the maximum testcurrent flows between the system and earth, not as a load current. Undesiredoperation is therefore only possible if an <strong>in</strong>sulation fault is comb<strong>in</strong>ed with the testcycle. Note: <strong>in</strong> AC systems set 2.5 mA, <strong>in</strong> DC systems 2.5 or 1 mA.• Switch on the PGH183 <strong>in</strong>sulation fault test device. TheON LED must light up, the two test cycle LEDs mustlight up <strong>in</strong> time with the cycle and then go out aga<strong>in</strong>.The test cycle corresponds to the illustration opposite,with a 2-second positive cycle, a 4-second pauseperiod and a 2-second negative cycle.If the LEDs fail to show any activity whatsoever, thesupply voltage and the built-<strong>in</strong> 100 mA f<strong>in</strong>e-wire fuseshould be checked.0 2 4 6 8t(s)• Connect one of the current clamps to the EDS165-3 <strong>in</strong>sulation fault evaluator.Switch on the EDS165-3 and set the operat<strong>in</strong>g mode switch to position I ∆s. After thebasic menu has appeared on the display of the EDS165-3, test whether the correctnom<strong>in</strong>al system frequency has been set. The factory sett<strong>in</strong>g is 50 Hz/DC.• Check whether the correct current clamp and/or the correct measur<strong>in</strong>g currenttransformer are set <strong>in</strong> menu 1 (m1). The factory sett<strong>in</strong>g is current clamp PSA3320.• It is advisable to keep the contact surfaces of the current clamps clean.• First, encircle the green-yellow lead between the PGH183 and earth with thecurrent clamp. If the EDS165-3 <strong>in</strong>sulation fault evaluator does not react, the<strong>in</strong>sulation fault has too high an resistance and it cannot be found.• For fault location at a central position of the IT system, encircle all systemconductors , but not the PE conductor , with the current clamp. The currentclamp should not be used <strong>in</strong> the immediate vic<strong>in</strong>ity of devices which generatemagnetic fields, such as transformers or throttles, nor <strong>in</strong> the vic<strong>in</strong>ity of adjacentconductors with high operat<strong>in</strong>g currents.• When the current clamp is encircl<strong>in</strong>g live conductors, it must not bedisconnected from the EDS165-3. In an "open” operation of this sort, the currentclamp may be destroyed!• Inside the current clamp, you should aim for the maximum possible balanc<strong>in</strong>g ofthe conductors. Keep the current clamp steadily dur<strong>in</strong>g the measurement! Makesure that you do not exert any pressure on the current clamp arms.• An alarm message on the display of the EDS165-3 signals an <strong>in</strong>sulation faultdownstream of the current clamp. It is advisable to carry out the fault locationwith the buzzer activated.• Measure along the conductor with the EDS165-3 until the fault is found. Penetrateradially <strong>in</strong>to the sub-distributions as you do this.• The fault location is found when the fault current downstream of the currentclamp is at least 0.5 mA.36TGH1320E/03.2000

Practical useUs<strong>in</strong>g the EDS165-3with<strong>in</strong> an EDS473systemFor operat<strong>in</strong>g currents < 1 AC, measurement is also possible by encircl<strong>in</strong>g oneconductor only. Attention: for DC currents > 10 A, this may produce the effect thatthe current clamp can no longer be opened. This danger is particularly present <strong>in</strong>direct current sytems. If this behaviour occurs, under no circumstances use force,s<strong>in</strong>ce this would destroy the current clamp. Instead, you must switch off the relevantsystem. After this has been done, the current clamp can be opened without theapplication of force.The EDS165-3 <strong>in</strong>sulation fault evaluator can also be used without the PGH183 testdevice with<strong>in</strong> a system such as an EDS473, as a permanently <strong>in</strong>stalled system. In thiscase, it detects the test pulses from the PGH473 test device. Insulation faultevaluation is only possible <strong>in</strong> live IT systems.The practical use of the EDS165-3 with<strong>in</strong> a permanently <strong>in</strong>stalled EDS473 <strong>in</strong>sulationfault location system is described below:• The central <strong>in</strong>sulation monitor<strong>in</strong>g device has signalled an <strong>in</strong>sulation faultbelow its response value.• The <strong>in</strong>sulation monitor<strong>in</strong>g device has to be disconnected from the systemwith all poles.• The <strong>in</strong>sulation fault location system is activated by press<strong>in</strong>g the START key ofthe PGH473 and it starts fault location; the test device is clock<strong>in</strong>g. The<strong>in</strong>sulation fault evaluation cont<strong>in</strong>ues as long as the test device is clock<strong>in</strong>g.• Connect the current clamp (or the measur<strong>in</strong>g current transformer) via a BNCadapter.• Move the operat<strong>in</strong>g mode switch of the EDS165-3 to the I ∆sposition; waituntil the basic menu appears on the display.• Check whether the correct nom<strong>in</strong>al system frequency is set. The factorysett<strong>in</strong>g for the frequency is 50 Hz.• Check whether the correct current clamp and/or the correct measur<strong>in</strong>gcurrent transformer are set <strong>in</strong> menu 1 (m1 – set sensor). The factory sett<strong>in</strong>g iscurrent clamp PSA3320.• At subcircuits where no measur<strong>in</strong>g current transformer is <strong>in</strong>stalled, ordownstream of <strong>in</strong>stalled measur<strong>in</strong>g current transformers, fault location cannow be cont<strong>in</strong>ued with the EDS165-3.Attention: do not connect the core of the current clamp to system voltagesabove the nom<strong>in</strong>al <strong>in</strong>sulation voltage.• All system conductors, but not the PE , must be encircled by the currentclamp.Attention: do not encircle any shielded leads!• When the current clamp is encircl<strong>in</strong>g live conductors, it must not bedisconnected from the EDS165-3. In this type of ”open” operation, the currentclamp may be destroyed!• Dur<strong>in</strong>g the measurement, the current clamp must be held steadily. Theconductors should be encircled as symmetrically as possible. Make sure thatyou do not exert any pressure on the arms of the current clamp. An alarmmessage is given with<strong>in</strong> 30 seconds after clos<strong>in</strong>g of the current clamp.37TGH1320E/03.2000

PRC470ALARM RS485RS485ONSLAVE ADDRESS + 110START2.5mAA3 A2 A1 A0 SLAVE RS485 STOP101 mAMASTERGENERATORONK1 K2 K3 K4 K5 K6 K7 K8 K9 K10 K11 K12ALARM FAULTSLAVE ADDRESSA4 A3 A2 A1 A0onoffRS485TESTRESETMONITORPractical use• An alarm message signals an <strong>in</strong>sulation fault downstream of the sensor.• Measure along the lead with the EDS165-3 until you have found the faultlocation.• The fault location is found when the test current through the current clamp isat least 0.5 mA. On this po<strong>in</strong>t, see the chapter on SETTINGS ANDADAPTATIONS <strong>in</strong> the EDS473 operat<strong>in</strong>g manual.• For operat<strong>in</strong>g currents < 1 A, measurement is also possible by encircl<strong>in</strong>g oneconductor only. Attention: for currents > 10 A, this may produce the effectthat the current clamp can no longer be opened. This danger is particularlypresent <strong>in</strong> direct voltage systems. If this behaviour occurs, under nocircumstances use force, s<strong>in</strong>ce this would destroy the current clamp. Instead,you must switch off the relevant system. After this has been done, the currentclamp can be opened without the application of force.• For each measurement, wait for one cycle of the PGH473 test device(approximately 30 seconds).IT system (AC 20-265 V or DC 20-308 V)A1 A2 11 14 L1 L2 L3PGH473PGH473A B GND IN1 IN2 IN3EEDS startDisconnect the<strong>in</strong>sulation monitor<strong>in</strong>g devicedur<strong>in</strong>g the fault locationfrom the system!A1 A2 GND IN1 IN2 IN3 IN4 O1+ O1- O2+ O2-EDS-SystemA B 11 12 14 21 22 24EDS473-12A1 A2 K1 K2 K3 K4 K5 K6 K7 K8 K9I∆sA B R1 R2 l K12 K11 K10 11 12 14PRC470RS485 BusUse of an EDS165-3 <strong>in</strong> an IT system with a permanently <strong>in</strong>stalled EDS473 <strong>in</strong>sulationfault location system. In addition to the messages from PRC470 and EDS473-12, theportable EDS165-3 <strong>in</strong>sulation fault evaluator can be used to check <strong>in</strong>dividualsubcircuits and to display the test currents.38TGH1320E/03.2000