- Page 2 and 3: Diving Medicine for Scuba Divers 4t

- Page 4 and 5: ACKNOWLEDGMENTS ! For the 1 st and

- Page 6 and 7: Chapter 1 All chapters, full text,

- Page 8 and 9: The development of self-contained a

- Page 10 and 11: Chapter 2 All chapters, full text,

- Page 12 and 13: Water is much denser than air and 1

- Page 14 and 15: This law can easily be demonstrated

- Page 16 and 17: For example, if diver has a maximum

- Page 18 and 19: Stated in another way; if a gas is

- Page 20 and 21: Henry's Law This law describes the

- Page 22 and 23: O 2 supports combustion vigorously

- Page 24 and 25: BUOYANCY It is important for divers

- Page 26 and 27: the water temperature decreases wit

- Page 28 and 29: Chapter 3 All chapters, full text,

- Page 30 and 31: Below the larynx the air passes thr

- Page 32 and 33: Gas Uptake and Loss Air, which cont

- Page 34 and 35: In venous blood, the haemoglobin in

- Page 36 and 37: Circulation The blood flow from the

- Page 38 and 39: educes the safety margin in the eve

- Page 40 and 41: infections, hypothermia, panic and

- Page 42 and 43: BREAK POINT Fig 4.2 . . This diagra

- Page 44 and 45: MEDICAL CHECKLIST FOR SNORKELLERS H

- Page 46 and 47: Some face masks are fitted with a o

- Page 48 and 49: Snorkel The snorkel allows the dive

- Page 50 and 51: A poorly fitting wet suit can cause

- Page 54 and 55: 1. Air supply, cylinder, tank 2. On

- Page 56 and 57: Difficulties are still encountered

- Page 58 and 59: STANDARD DRESS or HARD HAT This tra

- Page 60 and 61: Closed and Semi-closed Circuit REBR

- Page 62 and 63: the B.C. to be inflated using air f

- Page 64 and 65: The scuba tank may be negatively bu

- Page 66 and 67: Diving Watch A reliable, accurate,

- Page 68 and 69: Surface detection aids include: •

- Page 70 and 71: The "Half Tank Rule". The best tech

- Page 72 and 73: It is important to return to the su

- Page 74 and 75: The problems centre on impaired vis

- Page 76 and 77: The lower surface pressure also mea

- Page 78 and 79: In general, successful military div

- Page 80 and 81: Factors which upset a diver's emoti

- Page 82 and 83: The above story illustrates some of

- Page 84 and 85: Women divers must be doing somethin

- Page 86 and 87: convenience, most women today prefe

- Page 88 and 89: Other Diving Diseases In a number o

- Page 90 and 91: ! Decompression sickness. As mentio

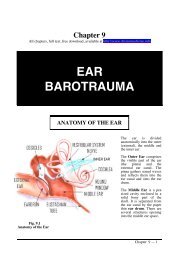

- Page 92 and 93: Chapter 9 All chapters, full text,

- Page 94 and 95: vibrate. These vibrations are trans

- Page 96 and 97: Fig. 9.5 If equalisation does not o

- Page 98 and 99: If the ear drum was perforated, com

- Page 100 and 101: The diver should then equalise ever

- Page 102 and 103:

If reasonable, avoid the use of hoo

- Page 104 and 105:

One or more of these must be presen

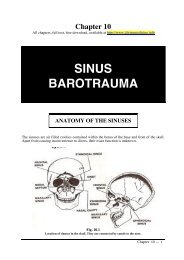

- Page 106 and 107:

There are four main groups of sinus

- Page 108 and 109:

TREATMENT Any case of suspected sin

- Page 110 and 111:

Chapter 11 All chapters, full text,

- Page 112 and 113:

Fig. 11.2 The various clinical mani

- Page 114 and 115:

Fig 11.3 The location of the medias

- Page 116 and 117:

Occasionally a valve effect allows

- Page 118 and 119:

The air bubbles obstruct or damage

- Page 120 and 121:

Predisposing Factors ! Breath-holdi

- Page 122 and 123:

In many navies free ascent training

- Page 124 and 125:

! Out of Air (OOA) and Low on Air (

- Page 126 and 127:

PULMONARY BAROTRAUMA OF DESCENT (LU

- Page 128 and 129:

This condition is easily prevented

- Page 130 and 131:

SUIT BAROTRAUMA OF ASCENT ("BLOW UP

- Page 132 and 133:

Chapter 13 All chapters, full text,

- Page 134 and 135:

SATURATION When tissues are subject

- Page 136 and 137:

DIVE PROFILES The type of dive has

- Page 138 and 139:

! Cold. Diving in cold conditions m

- Page 140 and 141:

A very short surface interval may a

- Page 142 and 143:

ased on modified Haldane principles

- Page 144 and 145:

DECOMPRESSION METERS and COMPUTERS

- Page 146 and 147:

! Safety suggestions (the DC Ten Co

- Page 148 and 149:

ONSET OF SYMPTOMS The clinical feat

- Page 150 and 151:

confined within the solid bone of t

- Page 152 and 153:

SKIN MANIFESTATIONS of DCS These ar

- Page 154 and 155:

The ABBREVIATED MENTAL TEST SCORE (

- Page 156 and 157:

Unfortunately 100% O 2 can be toxic

- Page 158 and 159:

Transportation in aircraft presents

- Page 160 and 161:

Other tables are available which in

- Page 162 and 163:

! Slow ascent rates. A slow ascent

- Page 164 and 165:

epeated minor trauma which is commo

- Page 166 and 167:

Prevention Avoidance of the known p

- Page 168 and 169:

CAUSES OF NITROGEN NARCOSIS The exa

- Page 170 and 171:

A diver who can "hold his liquor" i

- Page 172 and 173:

CLINICAL FEATURES The first sign is

- Page 174 and 175:

obstruction somewhere in the respir

- Page 176 and 177:

the lungs and body into the counter

- Page 178 and 179:

Chapter 21 All chapters, full text,

- Page 180 and 181:

CAUSES OF O 2 TOXICITY For resuscit

- Page 182 and 183:

Pulmonary Effects These effects wil

- Page 184 and 185:

Clinical Features A person hyperven

- Page 186 and 187:

CO 2 toxicity may increase the like

- Page 188 and 189:

CLINICAL FEATURES Symptoms are thos

- Page 190 and 191:

Chapter 24 All chapters, full text,

- Page 192 and 193:

If the compressor is operated in an

- Page 194 and 195:

Chapter 25 All chapters, full text,

- Page 196 and 197:

eaches the surface. If the diver is

- Page 198 and 199:

TREATMENT Rescue and recovery from

- Page 200 and 201:

PREVENTION It is paradoxical that d

- Page 202 and 203:

Chapter 26 All chapters, full text,

- Page 204 and 205:

Chapter 27 All chapters, full text,

- Page 206 and 207:

Fig. 27.3 Graph illustrating surviv

- Page 208 and 209:

PREVENTION Alcohol and other drugs

- Page 210 and 211:

Occasionally this disorder has been

- Page 212 and 213:

! Treatment. All coral cuts should

- Page 214 and 215:

! Vibrio and other Aquatic Organism

- Page 216 and 217:

SWIMMING POOL GRANULOMA Also called

- Page 218 and 219:

Until the risk is excluded it would

- Page 220 and 221:

MARINE Chapter 29 All chapters, ful

- Page 222 and 223:

! Stop the blood loss. This must be

- Page 224 and 225:

The venom has its most serious effe

- Page 226 and 227:

IRUKANDJI SYNDROME This disorder wa

- Page 228 and 229:

The first aid basic life support me

- Page 230 and 231:

hospital as soon as possible. Serio

- Page 232 and 233:

The spine may produce a puncture an

- Page 234 and 235:

Chapter 30 All chapters, full text,

- Page 236 and 237:

Middle Ear Disorders Disturbances o

- Page 238 and 239:

Chapter 31 All chapters, full text,

- Page 240 and 241:

CAUSES OF VERTIGO Problems arising

- Page 242 and 243:

Nitrogen narcosis may aggravate ver

- Page 244 and 245:

CRAMPS Cramp is a painful spasm of

- Page 246 and 247:

Air emboli and bubble development i

- Page 248 and 249:

Cold water entering an ear canal ca

- Page 250 and 251:

unconsciousness have been well reco

- Page 252 and 253:

SEASICKNESS This is a distressing a

- Page 254 and 255:

EXPLOSIONS - UNDERWATER BLAST This

- Page 256 and 257:

In addition to these the causes ass

- Page 258 and 259:

COLD OR HYPOTHERMIA (SEE CHAPTERS 3

- Page 260 and 261:

GENERAL MEDICAL CONDITIONS A variet

- Page 262 and 263:

Chapter 34 All chapters, full text,

- Page 264 and 265:

! Major Causes of Death identified

- Page 266 and 267:

unfortunately promoted by some inst

- Page 268 and 269:

Fig 34.3 But not always ! Buddy res

- Page 270 and 271:

Salt Water Aspiration This factor w

- Page 272 and 273:

Nitrogen Narcosis This was an effec

- Page 274 and 275:

Other Equipment Problems In 5% or l

- Page 276 and 277:

SUMMARY Diving fatalities generally

- Page 278 and 279:

Chapter 35 All chapters, full text,

- Page 280 and 281:

CONTRIBUTING CAUSES There are a num

- Page 282 and 283:

This reflex is present to some exte

- Page 284 and 285:

! Myocarditis. Some viral infection

- Page 286 and 287:

Flora Fisk Quiz for Recreational Di

- Page 288 and 289:

(50 ft) and admitted to being "bent

- Page 290 and 291:

is undertaken. Then a drug reaction

- Page 292 and 293:

Antihistamines These are usually ta

- Page 294 and 295:

PROPHYLACTIC (PREVENTION) DRUGS Sta

- Page 296 and 297:

Marijuana — Cannabis or "pot" Chr

- Page 298 and 299:

Chapter 38 All chapters, full text,

- Page 300 and 301:

Some antibiotics may have no direct

- Page 302 and 303:

The hearing function test (pure ton

- Page 304 and 305:

MEDICAL EXAMINATION FORMAT There is

- Page 306 and 307:

Chapter 38 — 9

- Page 308 and 309:

Chapter 38 — 11

- Page 310 and 311:

RESUSCITATION EQUIPMENT • Airways

- Page 312 and 313:

INFORMATION NEEDED about a DIVING A

- Page 314 and 315:

in medicine have 100% O 2 delivered

- Page 316 and 317:

compatible. Otherwise the diving il

- Page 318 and 319:

GENERAL INFORMATION Oxygen Toxicity

- Page 320 and 321:

Chapter 41 All chapters, full text,

- Page 322 and 323:

CHECK LIST FOR DIVING ACCIDENTS INF

- Page 324 and 325:

D and R - DANGER and RESPONSE DANGE

- Page 326 and 327:

If the rescuer has the equipment an

- Page 328 and 329:

Duration of CPR Continue CPR until:

- Page 330 and 331:

Chapter 43 All chapters, full text,

- Page 332 and 333:

THE TECHNICAL DIVE 1. DIVE PROTOCOL

- Page 334 and 335:

For the same depth/duration dive, t

- Page 336 and 337:

OXYGEN ENRICHED AIR or NITROX (EANx

- Page 338 and 339:

likely to oxidise and have a higher

- Page 340 and 341:

There is also a greater conductive

- Page 342 and 343:

The carbon dioxide absorbent must b

- Page 344 and 345:

• The oxygen rebreathers are clos

- Page 346 and 347:

CONCLUSION There are few problems i

- Page 348 and 349:

The actual incidence is unknown, bu

- Page 350 and 351:

Appendix A All chapters, full text,

- Page 352 and 353:

DIVING MEDICAL TEXTS • *Diving Me

- Page 354 and 355:

Appendix B All chapters, full text,

- Page 356 and 357:

Appendix C All chapters, full text,

- Page 358 and 359:

Appendix D All chapters, full text,