Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

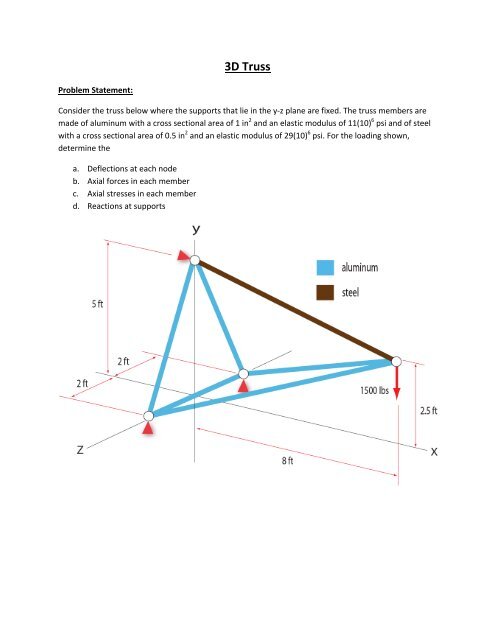

<strong>3D</strong> Truss<br />

Problem Statement:<br />

Consider the <strong>truss</strong> below where the supports that lie in the y‐z plane are fixed. The <strong>truss</strong> members are<br />

made of aluminum with a cross sectional area of 1 in 2 and an elastic modulus of 11(10) 6 psi and of steel<br />

with a cross sectional area of 0.5 in 2 and an elastic modulus of 29(10) 6 psi. For the loading shown,<br />

determine the<br />

a. Deflections at each node<br />

b. Axial forces in each member<br />

c. Axial stresses in each member<br />

d. Reactions at supports

ANSYS Procedure:<br />

1. Preprocessor > Element type > Add/Edit/Delete > (Add) > (Link) > (<strong>3D</strong> spar 8) > OK<br />

2. Preprocessor > Real constants > Add/Edit/Delete > (Add) > Type 1 > OK<br />

(Area = 1, Initial strain = 0) > OK<br />

Add/Edit/Delete > (Add) > Type 1 > OK<br />

(Area =0.5, Initial strain = 0) > OK<br />

3. Preprocessor > Material properties > Material models > Structural > Linear > Elastic > Isotropic<br />

Enter EX = 106 PRXY = 0.3 (Poission’s ratio is not really used for this element)<br />

4. From Material model window menu: Select new model > Define material id 2 > OK<br />

Material properties > Material models > Structural > Linear > Elastic > Isotropic<br />

Enter EX = 296 and PRXY = 0.3<br />

5. Preprocessor > Modeling > Create > Nodes > In active CS<br />

Node x‐coordinate y‐coordinate z‐coordinate<br />

1 0 0 24<br />

2 0 0 ‐24<br />

3 0 60 0<br />

4 96 30 0<br />

6. Utility Menu : Plot ctrls > Numbering > (turn NODE =on)<br />

7. Utility Menu : List > Nodes<br />

8. Utility Menu : Plot ctrls > Pan, Zoom, Rotate ,Click ISO

9. Preprocessor > Modeling > Create ><br />

Elements > Element attributes ( Make sure<br />

Material 1 and Real constant set 1 are<br />

active) for creating aluminum <strong>truss</strong><br />

members<br />

Preprocessor > Modeling > Create ><br />

Elements > Auto numbered > Thru nodes<br />

Element Node Node<br />

1 1 3 Apply<br />

2 3 2 Apply<br />

3 2 1 Apply<br />

4 1 4 Apply<br />

5 2 4 Apply<br />

10. Preprocessor > Modeling > Create ><br />

Elements > Element attributes ( Make sure<br />

Material 2 and Real constant set 2 are<br />

active) for creating the steel member<br />

Preprocessor > Modeling > Create ><br />

Elements > Auto numbered > Thru nodes<br />

Element Node Node<br />

6 3 4 Apply<br />

Applying loads:<br />

11. Solution > Define loads > Apply > Structural<br />

> Displacement > On nodes<br />

Select nodes 1, 2 and 3 > OK > Select “All<br />

DOF” > Constant value >Displacement value<br />

= 0 > OK<br />

12. Solution > Define loads > Apply > Structural<br />

> Force / Moment > On nodes<br />

(Pick node 4 > OK > FY > Constant value ><br />

‐1500 > OK<br />

13. Solution > Solve > Current LS > OK

Post processing:<br />

14. General Postproc > Plot results > Deformed<br />

Shape > (Def + Undef edge) > OK<br />

(notice that the maximum deflection is<br />

0.0637 inches)<br />

15. General Postproc > List results > Nodal<br />

solutions > Nodal solution > DOF solution ><br />

Displacement vector sum > OK<br />

16. General Postproc > Element table > Define table > Add<br />

(AVPRIN =1, lab = axial force > By sequence num > SMISC (enter “,1”) > OK)<br />

17. General Postproc > Element table > Define table > Add<br />

(AVPRIN =1, lab = ax stress > By sequence num > LS (enter “,1”) > OK)

18. General Postproc > Element table > List element table (Select the table you want to list) > OK<br />

19. General Postproc > Element table > Plot element table > Choose the item to plot > OK<br />

20. Utility Menu: List > Elements > Nodes > + Attributes + Real constants<br />

21. General Postproc > List results > Reaction<br />

solution > OK (for support reactions)

Summary of results<br />

1. Deflection at each node<br />

NODE U x (in) U y (in) U z (in) U sum (in)<br />

1 0.0000 0.0000 0.0000 0.0000<br />

2 0.0000 0.0000 0.0000 0.0000<br />

3 0.0000 0.0000 0.0000 0.0000<br />

4 0.67046e‐2 ‐0.63333e‐1 0.0000 0.63687e‐1<br />

2. Axial forces and stresses in each member<br />

Element Axial force (lbs) Axial stress (psi)<br />

1 0.0000 0.0000<br />

2 0.0000 0.0000<br />

3 0.0000 0.0000<br />

4 ‐1292.5 ‐1292.5<br />

5 ‐1292.5 ‐1292.5<br />

6 2514.5 5028.9<br />

3. Reactions at supports<br />

Node F x (lbs) F Y (lbs) F Z (lbs)<br />

1 1200 375 ‐300<br />

2 1200 375 300<br />

3 ‐2400 750 0<br />

This <strong>tutorial</strong> was developed by Sai Ravi Kanth Tummala and David Hall © 2008