ENGR 121 Homework 7 Note: Problems 1 through 4 are individual ...

ENGR 121 Homework 7 Note: Problems 1 through 4 are individual ...

ENGR 121 Homework 7 Note: Problems 1 through 4 are individual ...

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

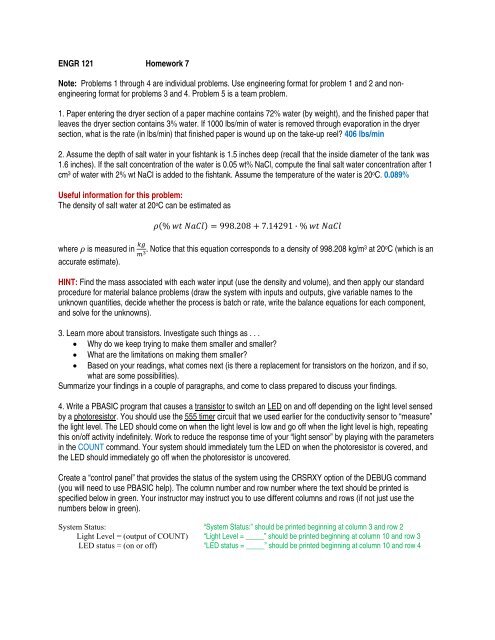

<strong>ENGR</strong> <strong>121</strong> <strong>Homework</strong> 7<strong>Note</strong>: <strong>Problems</strong> 1 <strong>through</strong> 4 <strong>are</strong> <strong>individual</strong> problems. Use engineering format for problem 1 and 2 and nonengineeringformat for problems 3 and 4. Problem 5 is a team problem.1. Paper entering the dryer section of a paper machine contains 72% water (by weight), and the finished paper thatleaves the dryer section contains 3% water. If 1000 lbs/min of water is removed <strong>through</strong> evaporation in the dryersection, what is the rate (in lbs/min) that finished paper is wound up on the take-up reel? 406 lbs/min2. Assume the depth of salt water in your fishtank is 1.5 inches deep (recall that the inside diameter of the tank was1.6 inches). If the salt concentration of the water is 0.05 wt% NaCl, compute the final salt water concentration after 1cm 3 of water with 2% wt NaCl is added to the fishtank. Assume the temperature of the water is 20 o C. 0.089%Useful information for this problem:The density of salt water at 20 o C can be estimated as% 998.208 7.14291 · % where is measured in . Notice that this equation corresponds to a density of 998.208 kg/m3 at 20 o C (which is anaccurate estimate).HINT: Find the mass associated with each water input (use the density and volume), and then apply our standardprocedure for material balance problems (draw the system with inputs and outputs, give variable names to theunknown quantities, decide whether the process is batch or rate, write the balance equations for each component,and solve for the unknowns).3. Learn more about transistors. Investigate such things as . . .• Why do we keep trying to make them smaller and smaller?• What <strong>are</strong> the limitations on making them smaller?• Based on your readings, what comes next (is there a replacement for transistors on the horizon, and if so,what <strong>are</strong> some possibilities).Summarize your findings in a couple of paragraphs, and come to class prep<strong>are</strong>d to discuss your findings.4. Write a PBASIC program that causes a transistor to switch an LED on and off depending on the light level sensedby a photoresistor. You should use the 555 timer circuit that we used earlier for the conductivity sensor to “measure”the light level. The LED should come on when the light level is low and go off when the light level is high, repeatingthis on/off activity indefinitely. Work to reduce the response time of your “light sensor” by playing with the parametersin the COUNT command. Your system should immediately turn the LED on when the photoresistor is covered, andthe LED should immediately go off when the photoresistor is uncovered.Create a “control panel” that provides the status of the system using the CRSRXY option of the DEBUG command(you will need to use PBASIC help). The column number and row number where the text should be printed isspecified below in green. Your instructor may instruct you to use different columns and rows (if not just use thenumbers below in green).System Status: “System Status:” should be printed beginning at column 3 and row 2Light Level = (output of COUNT) “Light Level = _____” should be printed beginning at column 10 and row 3LED status = (on or off) “LED status = _____” should be printed beginning at column 10 and row 4

Example Debug Terminal:Bring your Boe-Bot to class next time ready to demonstrate.5. Install your breadboard, solenoid valves, conductivity sensor, pump, overflow tank, salty and DI water tanks and alltubing on your fishtank platform as shown. You <strong>are</strong> free to move things around to suit your preferences. Rememberthat you will need to screw your “Board of Education” from the Boe-Bot onto the platform later, so save a place for it.You can use a large rubber band or a small tie-down strap to secure the pump and fishtank around the verticalmember of the fishtank platform (how you attach these things is up to you). Bring your completed system to classnext time.The other solenoid valve is on the opposite side (not in view).