You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

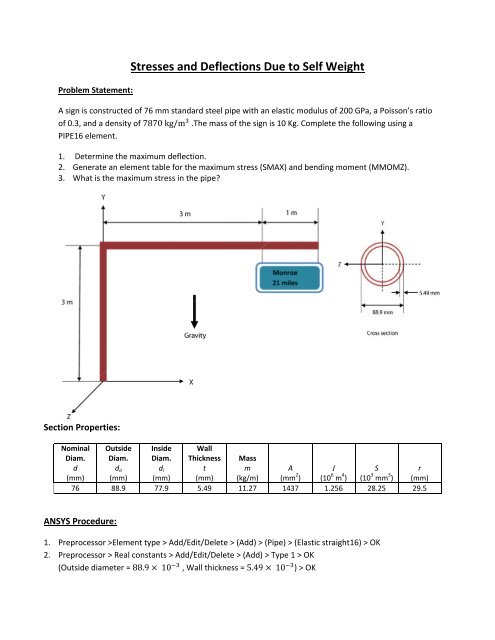

Problem Statement:Stresses and Deflections Due to Self WeightA sign is constructed of 76 mm standard steel pipe with an elastic modulus of 200 GPa, a Poisson’s ratioof 0.3, and a density of 7870 kg/m .The mass of the sign is 10 Kg. Complete the following using aPIPE16 element.1. Determine the maximum deflection.2. Generate an element table for the maximum stress (SMAX) and bending moment (MMOMZ).3. What is the maximum stress in the pipe?Section Properties:NominalDiam.d(mm)OutsideDiam.d o(mm)InsideDiam.d i(mm)WallThicknesst(mm)Massm(kg/m)A I S r(mm 2 ) (10 6 m 4 ) (10 3 mm 3 ) (mm)76 88.9 77.9 5.49 11.27 1437 1.256 28.25 29.5ANSYS Procedure:1. Preprocessor >Element type > Add/Edit/Delete > (Add) > (Pipe) > (Elastic straight16) > OK2. Preprocessor > Real constants > Add/Edit/Delete > (Add) > Type 1 > OK(Outside diameter = 88.9 10 , Wall thickness = 5.49 10 ) > OK

3. Preprocessor > Material properties > Material models > Structural > Linear > Elastic > Isotropic Enter EX= 200e9 and PRXY = 0.304. Preprocessor > Material properties > Material models > Density = 7870 > OK5. Preprocessor > Modeling > Create > Key points > In active CSKey point X coordinate Y coordinate Z coordinate1 0 0 02 0 3 03 3 3 04 4 3 06. Preprocessor > Modeling > Create > Lines >Lines > Straight lines (Click on the key points shown to makethe corresponding line)Key point Key point Line1 2 12 3 23 4 37. Preprocessor > Meshing > Mesh tool > Element attributes > Lines > Set > Choose lines > Pick all > OK8. Preprocessor > Meshing > Mesh tool > Size controls > Lines > Set > Pick all > Size = 0.1 > OK9. Preprocessor > Meshing > Mesh tool > Mesh > Lines > Pick all10. Utility menu: Plotctrls > Style > Size and shape > Select the radio button next to /ESHAPE > OK11. Utility menu: Plotctrls > Numbering (TurnKey point numbers on)12. Utility menu: Plot > Multi plots13. Utility menu: List > Elements > Nodes and attributes14. Utility menu: List > Nodes

Applying loads:15. Solution > Define loads > Apply >Structural > Displacement > Onkeypoints > (Pick keypoint 1 and fixall DOF)16. Solution > Define loads > Apply >Structural > Force /Moment > Onkeypoints > Pick keypoints 3 and 4 >OK > Fy = ‐49.05 >OKNote that this is half of 10 kg * 9.81m/s 2 .17. Solution > Define loads > Apply >Structural > Inertia > Gravity > Global >ACELY = 9.81 > OKNotice that this acceleration is positive sincean upward acceleration would produce adownward deflection (like gravity)18. Solution > solve > current LS

Post Processing:19. General Postproc > Plotresults > Deformed shape20. General Postproc > Plotresults > Contour Plot >Element Solution > Stress >X component of stress >OK21. General Postproc > Element table > Define table > Add > Name =SAXLi, by sequence number > LS= 17 >Apply > Name =SAXLj, by sequence number > LS= 49 > OK22. General Postproc > Element table > Define table > Add > Name =MMOMZi, by sequence number >SMISC=6 > Apply > Name =MMOMZj, by sequence number > SMISC= 12 > OKWe will discuss the table lookup numbers for the stresses and moments used above when we cover the use of thePIPE16 element in a later class. Here, the local x‐coordinate points in the global Y‐direction (along the length of thePIPE element). Since no orientation keypoint is defined for these elements, the local y‐coordinate of the elementmust lie in the global X‐Y plane, which means it points in the negative global X‐direction. Thus, the stresses on theright side of the bottom of the beam are determined by LS = 17 for node i and LS = 49 for node j.

Summary of Results:1. Maximum deflection : 0.83m.2. Element table of maximum stress and maximum bending moment at I and J nodesPRINT ELEMENT TABLE ITEMS PER ELEMENT***** POST1 ELEMENT TABLE LISTING *****STAT CURRENT CURRENT CURRENT CURRENTELEM SAXLI SAXLJ MMOMZI MMOMZJ1 -0.44188E+08-0.44180E+08 -1231.9 -1231.92 -0.44180E+08-0.44172E+08 -1231.9 -1231.93 -0.44172E+08-0.44164E+08 -1231.9 -1231.94 -0.44164E+08-0.44157E+08 -1231.9 -1231.95 -0.44157E+08-0.44149E+08 -1231.9 -1231.96 -0.44149E+08-0.44141E+08 -1231.9 -1231.97 -0.44141E+08-0.44134E+08 -1231.9 -1231.98 -0.44134E+08-0.44126E+08 -1231.9 -1231.99 -0.44126E+08-0.44118E+08 -1231.9 -1231.910 -0.44118E+08-0.44110E+08 -1231.9 -1231.911 -0.44110E+08-0.44103E+08 -1231.9 -1231.912 -0.44103E+08-0.44095E+08 -1231.9 -1231.913 -0.44095E+08-0.44087E+08 -1231.9 -1231.914 -0.44087E+08-0.44080E+08 -1231.9 -1231.915 -0.44080E+08-0.44072E+08 -1231.9 -1231.916 -0.44072E+08-0.44064E+08 -1231.9 -1231.917 -0.44064E+08-0.44056E+08 -1231.9 -1231.918 -0.44056E+08-0.44049E+08 -1231.9 -1231.919 -0.44049E+08-0.44041E+08 -1231.9 -1231.920 -0.44041E+08-0.44033E+08 -1231.9 -1231.921 -0.44033E+08-0.44026E+08 -1231.9 -1231.922 -0.44026E+08-0.44018E+08 -1231.9 -1231.923 -0.44018E+08-0.44010E+08 -1231.9 -1231.924 -0.44010E+08-0.44002E+08 -1231.9 -1231.925 -0.44002E+08-0.43995E+08 -1231.9 -1231.926 -0.43995E+08-0.43987E+08 -1231.9 -1231.927 -0.43987E+08-0.43979E+08 -1231.9 -1231.928 -0.43979E+08-0.43971E+08 -1231.9 -1231.929 -0.43971E+08-0.43964E+08 -1231.9 -1231.930 -0.43964E+08-0.43956E+08 -1231.9 -1231.931 -0.43579E+08-0.41680E+08 -1231.9 -1178.232 -0.41680E+08-0.39820E+08 -1178.2 -1125.633 -0.39820E+08-0.38000E+08 -1125.6 -1074.234 -0.38000E+08-0.36219E+08 -1074.2 -1023.835 -0.36219E+08-0.34477E+08 -1023.8 -974.5836 -0.34477E+08-0.32774E+08 -974.58 -926.4637 -0.32774E+08-0.31111E+08 -926.46 -879.4438 -0.31111E+08-0.29487E+08 -879.44 -833.5339 -0.29487E+08-0.27902E+08 -833.53 -788.7440 -0.27902E+08-0.26357E+08 -788.74 -745.0541 -0.26357E+08-0.24851E+08 -745.05 -702.4842 -0.24851E+08-0.23384E+08 -702.48 -661.0143 -0.23384E+08-0.21956E+08 -661.01 -620.6644 -0.21956E+08-0.20568E+08 -620.66 -581.4245 -0.20568E+08-0.19219E+08 -581.42 -543.2846 -0.19219E+08-0.17909E+08 -543.28 -506.2647 -0.17909E+08-0.16639E+08 -506.26 -470.3548 -0.16639E+08-0.15408E+08 -470.35 -435.5549 -0.15408E+08-0.14216E+08 -435.55 -401.8650 -0.14216E+08-0.13064E+08 -401.86 -369.2851 -0.13064E+08-0.11951E+08 -369.28 -337.8252 -0.11951E+08-0.10877E+08 -337.82 -307.4653 -0.10877E+08-0.98420E+07 -307.46 -278.2154 -0.98420E+07-0.88466E+07 -278.21 -250.0855 -0.88466E+07-0.78906E+07 -250.08 -223.0556 -0.78906E+07-0.69738E+07 -223.05 -197.1457 -0.69738E+07-0.60964E+07 -197.14 -172.33

***** POST1 ELEMENT TABLE LISTING *****STAT CURRENT CURRENT CURRENT CURRENTELEM SAXLI SAXLJ MMOMZI MMOMZJ58 -0.60964E+07-0.52582E+07 -172.33 -148.6459 -0.52582E+07-0.44593E+07 -148.64 -126.0660 -0.44593E+07-0.36997E+07 -126.06 -104.5861 -0.36997E+07-0.31530E+07 -104.58 -89.12762 -0.31530E+07-0.26455E+07 -89.127 -74.78163 -0.26455E+07-0.21773E+07 -74.781 -61.54664 -0.21773E+07-0.17483E+07 -61.546 -49.42265 -0.17483E+07-0.13587E+07 -49.422 -38.40866 -0.13587E+07-0.10084E+07 -38.408 -28.50567 -0.10084E+07-0.69737E+06 -28.505 -19.71368 -0.69737E+06-0.42562E+06 -19.713 -12.03169 -0.42562E+06-0.19316E+06 -12.031 -5.460370 -0.19316E+06 0.45671E-06 -5.4603 0.12910E-10MINIMUM VALUESELEM 1 1 31 30VALUE -0.44188E+08-0.44180E+08 -1231.9 -1231.9MAXIMUM VALUESELEM 70 70 70 70VALUE -0.19316E+06 0.45671E-06 -5.4603 0.12910E-103. Maximum stress = 44.2 MPa in compression. This is much lower than 210 GPa, which is arepresentative yield strength for structural steel. However, please realize that this is an idealizedsolution with no ice or wind loading and with no consideration of stress concentrations or fatiguefailure.This <strong>tutorial</strong> was developed by David Hall and Sai Ravi Kanth Tummala © 2008