55291 NDT BROCHURE.indd - NDT Equipment

55291 NDT BROCHURE.indd - NDT Equipment

55291 NDT BROCHURE.indd - NDT Equipment

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

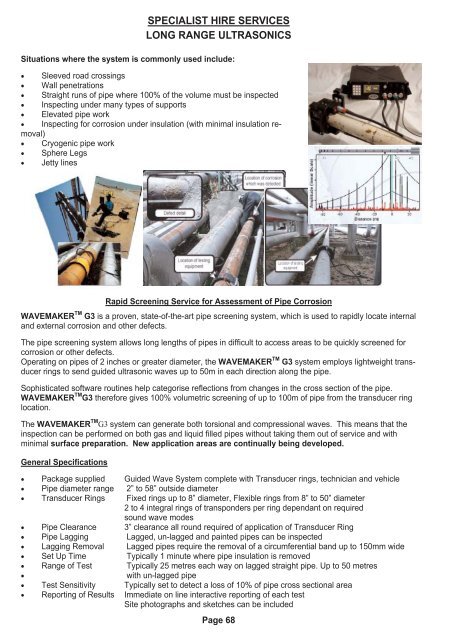

SPECIALIST HIRE SERVICES<br />

LONG RANGE ULTRASONICS<br />

Situations where the system is commonly used include:<br />

�� Sleeved road crossings<br />

�� Wall penetrations<br />

�� Straight runs of pipe where 100% of the volume must be inspected<br />

�� Inspecting under many types of supports<br />

�� Elevated pipe work<br />

�� Inspecting for corrosion under insulation (with minimal insulation removal)<br />

�� Cryogenic pipe work<br />

�� Sphere Legs<br />

�� Jetty lines<br />

Rapid Screening Service for Assessment of Pipe Corrosion<br />

WAVEMAKER TM G3 is a proven, state-of-the-art pipe screening system, which is used to rapidly locate internal<br />

and external corrosion and other defects.<br />

The pipe screening system allows long lengths of pipes in difficult to access areas to be quickly screened for<br />

corrosion or other defects.<br />

Operating on pipes of 2 inches or greater diameter, the WAVEMAKER TM G3 system employs lightweight transducer<br />

rings to send guided ultrasonic waves up to 50m in each direction along the pipe.<br />

Sophisticated software routines help categorise reflections from changes in the cross section of the pipe.<br />

WAVEMAKER TM G3 therefore gives 100% volumetric screening of up to 100m of pipe from the transducer ring<br />

location.<br />

The WAVEMAKER TM G3 system can generate both torsional and compressional waves. This means that the<br />

inspection can be performed on both gas and liquid filled pipes without taking them out of service and with<br />

minimal surface preparation. New application areas are continually being developed.<br />

General Specifications<br />

�� Package supplied Guided Wave System complete with Transducer rings, technician and vehicle<br />

�� Pipe diameter range 2” to 58” outside diameter<br />

�� Transducer Rings Fixed rings up to 8” diameter, Flexible rings from 8” to 50” diameter<br />

2 to 4 integral rings of transponders per ring dependant on required<br />

sound wave modes<br />

�� Pipe Clearance 3” clearance all round required of application of Transducer Ring<br />

�� Pipe Lagging Lagged, un-lagged and painted pipes can be inspected<br />

�� Lagging Removal Lagged pipes require the removal of a circumferential band up to 150mm wide<br />

�� Set Up Time Typically 1 minute where pipe insulation is removed<br />

�� Range of Test Typically 25 metres each way on lagged straight pipe. Up to 50 metres<br />

�� with un-lagged pipe<br />

�� Test Sensitivity Typically set to detect a loss of 10% of pipe cross sectional area<br />

�� Reporting of Results Immediate on line interactive reporting of each test<br />

Site photographs and sketches can be included<br />

Click here to return to contents page v<br />

Page 68