Softener Data PB0103NS.qxd - Eco-Tec

Softener Data PB0103NS.qxd - Eco-Tec

Softener Data PB0103NS.qxd - Eco-Tec

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

<strong>PB0103NS</strong><br />

RECOFLO ® WATER SOFTENER<br />

Low Cost Softened Water<br />

T<br />

he Recoflo <strong>Softener</strong> outperforms<br />

other water softening systems with<br />

its high product quality and low operating<br />

cost. The distinctive design and<br />

operation of the Recoflo <strong>Softener</strong> allow<br />

for the production of water with less<br />

than 0.1 mg/L total hardness using less<br />

than half the brine required by other<br />

softeners.<br />

The Recoflo <strong>Softener</strong>'s shallow resin<br />

bed (6 inches/15 cm deep) is fully<br />

packed with fine mesh cation resin<br />

beads that are operated under low<br />

loading conditions and are regenerated<br />

counter-currently. These features allow<br />

for efficient usage of brine and water<br />

while using less than one half of the<br />

floorspace and headroom of other softeners.<br />

The shorter cycle time of the Recoflo<br />

<strong>Softener</strong> eliminates biological fouling in<br />

the resin bed and subsequent release of<br />

bacteria in the product water, making it<br />

ideal pretreatment to reverse osmosis<br />

systems.<br />

Low operating costs, high performance,<br />

and proven reliability have made the<br />

Recoflo <strong>Softener</strong> the choice of industry<br />

leading companies worldwide including<br />

Apotex Pharmaceuticals and Alberta<br />

Energy Corporation in Canada,<br />

Caterpiller and Blue Ridge Paper<br />

Products in the United States, Gloria S.A.<br />

Dairy in Peru and many others.<br />

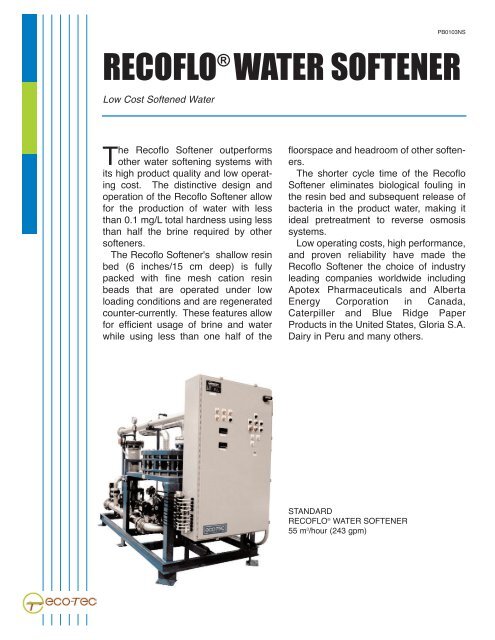

STANDARD<br />

RECOFLO ® WATER SOFTENER<br />

55 m 3 /hour (243 gpm)

Recoflo ® ion exchange features ...<br />

The Recoflo <strong>Softener</strong> is able to<br />

achieve a high level of efficiency and<br />

performance by employing several<br />

design and operational features.<br />

1. Short bed height/small resin volume<br />

- The resin bed in the Recoflo<br />

<strong>Softener</strong> is only 6 inches (15 cm) in<br />

depth and has approximately 10% of the<br />

CONVENTIONAL<br />

resin volume of<br />

other softeners<br />

(Figure 1). The use<br />

of the shallow bed<br />

is made possible by<br />

the rapid ion<br />

exchange kinetics<br />

RECOFLO ®<br />

that result from the<br />

use of fine mesh<br />

resins and low<br />

resin loading. This<br />

small resin inventory<br />

allows for the inexpensive, simple,<br />

and expeditious replacement of resin.<br />

Figure 1: Resin volume comparison<br />

2. Low resin loading - Unlike other softeners<br />

that load the resin to near exhaustion,<br />

the Recoflo <strong>Softener</strong> uses less than<br />

20% of the total exchange capacity of<br />

the resin. By using only the most accessible<br />

exchange sites at the surface of the<br />

resin beads, the exchange kinetics are<br />

improved and the brine usage is<br />

reduced since the sites that most readily<br />

accept an ion are those that are most<br />

easily regenerated. In addition, the low<br />

resin loading does not force the resin to<br />

undergo large changes in size that result<br />

in resin fragmentation in other softeners.<br />

3. Fine mesh cation resin - Since<br />

exchange kinetics and regeneration efficiency<br />

are improved by using only the<br />

exchange sites at surface of the resin<br />

beads, a fine mesh resin is used to<br />

increase the total surface area that is<br />

available for exchange. The size of<br />

these resin beads is approximately one<br />

quarter the size of the resin used in other<br />

softeners (Figure 2). The resin is uniformally<br />

sized to maximize the efficiency of<br />

rinsing and promote uniform distribution<br />

of flow through the bed.<br />

Figure 2: Resin bead size comparison<br />

CONVENTIONAL<br />

RECOFLO ®<br />

▲ ▲<br />

4. Counter-current regeneration - To<br />

maintain the cleanest resin at the bottom<br />

of the resin bed after regeneration, the<br />

brine regenerant is passed through the<br />

bed in the opposite direction of the feed<br />

flow (Figure 3). Counter-current regeneration<br />

minimizes brine usage and maximizes<br />

softened water quality.<br />

5. Compressed resin beds - The resin<br />

bed in the Recoflo <strong>Softener</strong> is fully<br />

packed such that no freeboard exists. In

Recoflo ® ion exchange features ...<br />

FEED WATER<br />

PRODUCT<br />

WATER<br />

Figure 3: Counter-current regeneration<br />

fact, the resin bed is compressed by adding an<br />

excess of resin prior to closing the vessel (Figure<br />

4). Compressed resin beds maximize regeneration<br />

efficiency by<br />

maintaining the<br />

exchange zone<br />

profile and ensuring<br />

proper flow distribution<br />

through<br />

the resin bed.<br />

Eliminating the<br />

freeboard reduces<br />

rinse requirements<br />

by minimizing<br />

intermixing and liquid<br />

dilution.<br />

WASTE<br />

REGENERANT<br />

Figure 4: Recoflo <strong>Softener</strong>s<br />

compressed resin bed<br />

7. Shorter cycle times - The combination of high<br />

flowrates, low resin loading, and small resin beds<br />

result in short cycle times, both in service and<br />

regeneration. Whereas other softeners are<br />

onstream for approximately 20 hours and require<br />

several hours to regenerate, the Recoflo <strong>Softener</strong><br />

is typically onstream for less than 30 minutes and<br />

is regenerated in less than 2 minutes.<br />

The shorter cycles allow for the continuous<br />

supply of the required flow with only one unit<br />

since during the short regeneration period, water<br />

can be drawn from the product storage tank.<br />

This buffer volume, and the softened water used<br />

for regeneration, can then be replaced during the<br />

subsequent onstream cycle. The shorter cycles<br />

allow for smaller waste piping and holding facilities<br />

since small amounts of waste are generated<br />

throughout the day rather than the large volume<br />

of waste generated daily by other softeners The<br />

shorter cycles also facilitate troubleshooting<br />

since many cycles can be witnessed in a single<br />

shift after the remedial action has been performed.<br />

6. Higher throughput rates - The rapid ion<br />

exchange kinetics and short resin bed allow for<br />

high throughput rates, typically two to three times<br />

higher than used in other softeners. The high<br />

flowrates result in a smaller resin bed diameter<br />

and hence up to a 50% reduction in the required<br />

amount of floorspace.

Benefits ...<br />

Reduce Operating Costs...<br />

The Recoflo <strong>Softener</strong> offers substantial<br />

savings in operating costs. The distinctive<br />

design and operational features of<br />

the Recoflo ion exchange process<br />

reduce the brine consumption to less<br />

than one half of the amount required by<br />

other softeners. The lower regenerant<br />

usage and highly effective rinsing of the<br />

resin result in the efficient usage of<br />

water and the subsequent minimization<br />

in waste generation. In addition, the<br />

Recoflo <strong>Softener</strong> is PLC controlled, fully<br />

automated and alarmed.<br />

Reduce Commissioning and<br />

Installation Costs...<br />

Prior to shipment, the Recoflo <strong>Softener</strong><br />

is completely assembled and wired, and<br />

the resin is loaded into the vessel. To<br />

reduce the time required for commissioning,<br />

the Recoflo unit is hydraulically<br />

tested and the proper execution of the<br />

PLC program with the correct valving<br />

sequence is confirmed. Once on site,<br />

the compact, skid-mounted design<br />

allows for easy placement and installation<br />

with no elaborate civil work. The<br />

Recoflo <strong>Softener</strong> is commissioned in<br />

only two days.<br />

Reduce Space...<br />

The throughput rate of the Recoflo<br />

<strong>Softener</strong> is two to three times that of<br />

other softeners. This increased productivity,<br />

and the shorter resin bed, result in<br />

a much smaller vessel diameter and low<br />

headroom requirements. In addition, the<br />

shorter cycle times reduce the size of<br />

the waste piping and holding facilities<br />

since small volumes of waste will be<br />

generated throughout the day rather<br />

than a large volume of waste being produced<br />

daily. The Recoflo <strong>Softener</strong><br />

requires approximately one half of the<br />

floorspace and headroom of other softeners.<br />

Eliminate Biological Fouling...<br />

The potential of biological fouling in<br />

deep-bed softeners has long been recognized.<br />

Biological growth is stimulated<br />

in the resin bed as large quantities of<br />

nutrients and organics are made available<br />

from the incoming feed water. The<br />

dense biological slimes that are allowed<br />

to form on the surface of the resin during<br />

the long onstream period are poorly<br />

removed during the brine regeneration<br />

step. This fouling results in a gradual<br />

reduction in softener capacity, efficiency,<br />

and performance. The sloughing off of<br />

the accumulated bacteria into the softened<br />

water may also accelerate biological<br />

fouling of downstream reverse<br />

osmosis membranes or process equipment.<br />

The shorter cycles of the Recoflo<br />

<strong>Softener</strong> maintain the resin bed in a disinfected<br />

state by contacting the resin<br />

with the brine regenerant every hour.<br />

Biological growth is further prevented by<br />

the high throughput velocity and small<br />

wetted perimeter that provides less surface<br />

area for bacterial attachment. Plate<br />

counts have confirmed the bacterial<br />

population in the product water from the<br />

Recoflo <strong>Softener</strong> to be an order of magnitude<br />

less than found in the water from<br />

deep-bed softeners.

Cycle steps ...<br />

1. ONSTREAM<br />

Pre-filtered water<br />

is pumped downward<br />

through the<br />

resin bed<br />

Feed<br />

To<br />

Product<br />

Tank<br />

3. RINSE<br />

Softened water from<br />

the storage tank is<br />

pumped upward<br />

through the resin bed<br />

to rinse out excess<br />

brine.<br />

To Waste<br />

2. REGENERATION<br />

Saturated brine is<br />

diluted with softened<br />

water in-line immediately<br />

below the resin<br />

bed. The diluted<br />

regenerant is then<br />

pumped upward<br />

through the resin bed.<br />

Dilution water is<br />

pumped from a small<br />

storage tank.<br />

Filter<br />

To Waste<br />

Saturated<br />

Brine<br />

4. TANK REFILL<br />

The softened<br />

water tank<br />

that stores the<br />

dilution and<br />

rinse water is<br />

refilled.<br />

Feed<br />

Regeneration<br />

Tank<br />

Service Program . . .<br />

The Recoflo <strong>Softener</strong> is fully covered under <strong>Eco</strong>-<strong>Tec</strong>'s ECO-SERV<br />

Customer Service Program. The program begins with strict quality<br />

assurance at every stage of the design and manufacturing processes,<br />

as demanded by ISO 9001. Samples of resin from every shipment<br />

are tested in-house to confirm that the particle size and characteristic<br />

distributions are acceptable. A Service Representative is<br />

available 24/7 to assist with any aspect of the system.<br />

ECO-TEC INC. ECO-TEC (Europe) Ltd.<br />

1145 Squires Beach Road, Pickering Unit 5C Ring Road, Zone 2, Burntwood Business Park<br />

Ontario,Canada L1W 3T9 Burntwood, Staffordshire, England WS7 3JQ<br />

Telephone: 905-427-0077 Fax: 905-427-4477 Telephone: 44-15436-83086 Fax: 44-15436-74117<br />

email: ecotec@eco-tec.com email: ecoteceurope@aol.com<br />

www.eco-tec.com<br />

The information contained in this document is proprietary and is the sole property of <strong>Eco</strong>-<strong>Tec</strong> Inc., no part may be reproduced without the express consent of <strong>Eco</strong>-<strong>Tec</strong> Inc.