SPECTRUM MICRO MEDIA FILTER - Eco-Tec

SPECTRUM MICRO MEDIA FILTER - Eco-Tec

SPECTRUM MICRO MEDIA FILTER - Eco-Tec

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

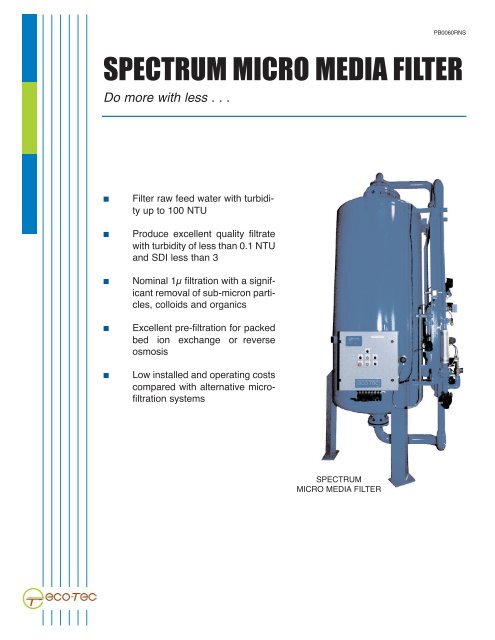

PB0060RNS<strong>SPECTRUM</strong> <strong>MICRO</strong> <strong>MEDIA</strong> <strong>FILTER</strong>Do more with less . . .■■■■■Filter raw feed water with turbidityup to 100 NTUProduce excellent quality filtratewith turbidity of less than 0.1 NTUand SDI less than 3Nominal 1µ filtration with a significantremoval of sub-micron particles,colloids and organicsExcellent pre-filtration for packedbed ion exchange or reverseosmosisLow installed and operating costscompared with alternative microfiltrationsystems<strong>SPECTRUM</strong><strong>MICRO</strong> <strong>MEDIA</strong> <strong>FILTER</strong>

How the Spectrum Micro Media Filter works ...The Spectrum Micro Media Filter isable to achieve its high level of performanceby using two backwashableparticulate media layers. An upper layerof coarse media allows for an extendedservice cycle by providing depth filtrationof large particles while a lower layer ofvery dense micromediaprovides surfacefiltration of smallcoagulated particles(Figure 1).Coarse upper layer:removal of large particles(depth filtration)The nominal diameter of the micromediain the lower layer is less than thediameter of the fine garnet media andless than 20% of the diameter of thecoarse sand commonly used in conventionalmulti-media filters (Figure2).The flow channels through the micromedia are extremely small. The tortuouspath of fine channels provides excellentretention of solids. During backwashing,the media expands to release solids.ACTIVATEDCARBONCOARSE SANDExtra-fine lower layer:removal of very smallparticles(surface filtration)Figure 1ANTHRACITE<strong>SPECTRUM</strong>UPPER LAYER<strong>SPECTRUM</strong>FINE <strong>MEDIA</strong>FINE SANDFigure 2Micrometers(Log Scale)Angstrom Units(Log Scale) 2 3 5 8√ ST Microscope √ Scanning Electron Microscope √ Optical Microscope √Visible to Naked EyeIonic Range Molecular Range Macro Molecular Range Micro Particle Range Macro Particle Range0.001 0.01 0.1 1.0 10 100 1000203050802003005008002000The Filtration Spectrum1 10 100 1000 10 4 10 5 10 6 10 73000500080002 3 5 82 3 5 8 2 3 5 8 2Approx. Molecular Wt.(Saccharide Type-No Scale)100 200 1000 10,000 20,000 100,000 500,000Albumin ProteinAqueous Salts Carbon Black Paint PigmentYeast CellsPinPointCourtesy of Osmonics Inc.RelativeSize ofCommonMaterialsProcess ForSeparationAtomicRadiusMetal IonSugarSyntheticDyePesticideHerbicideREVERSE OSMOSIS(Hyperfiltration)NANOFILTRATIONNote: 1 Micron (1x10 -6 Meters) ≈ 4x10 -5 Inches (0.00004 Inches)1 Angstrom Unit = 10 -10 Meters = 10 -4 Micrometers (Microns)Endotoxin/PyrogenVirusColloidal SilicaGelatinULTRAFILTRATIONThe Spectrum Micro Media Filterextends the range of particle filtration intothe range of microfiltrationTobacco SmokeAsbestosLatex/Emulsion<strong>MICRO</strong>FILTRATIONBacteriaBlue Indigo DyeA.C. Fine Test DustCryptosporidiumMilled FlourRedBloodCellsCoal DustGiardiaCystPollenHuman HairMistPARTICLE FILTRATIONBeach SandGranularActivated CarbonIon Ex.ResinBead© Copyright 1998, 1996, 1993, 1990, 1984 Osmonics, Inc., Minnetonka, Minnesota USA<strong>SPECTRUM</strong> <strong>MICRO</strong> <strong>MEDIA</strong> FILTRATIONwith coagulation

Simple operation . . .FEEDTO DRAINCOAGULANTAIRFILTRATESERVICEBACKWASH WATERBACKWASHThe Spectrum Micro Media Filter operates ona similar cycle to a conventional air-scourablemulti-media filter. Feed water is dosed withcoagulant and flows down through the filtermedia and out through the bottom of the vessel.Once a preset volume has been filtered or oncea pressure differential across the media reachesa preset value, backwash is automaticallyinitiated.Backwashing involves a number of stepsincluding air scouring of the media to ensureseparation of dirt from the media. Backwashflows upward through the scoured media andleaves through the top of the vessel.The filter media efficiently resettles into twodistinct layers ensuring continuous high qualityfiltration.Actual performance data from a1300 gpm Spectrum MicroMedia Filter system operating onraw surface water and feeding thereverse osmosis stage of an ultrapurewater treatment system. Feedturbidity ranges from 3 to 80 NTUwhile filtrate is typically less than0.05 NTU.TURBIDITY (NTU)1001010.10.0105:16.8 06:00.0 06:43.2 07:26.4 08:09.6 08:52.8 09:36.0 10:19.2FEEDFILTRATETIME (hours)

Particle Count /LFiltrate Turbidity (NTU)Filtrate Turbidity (NTU)1,000,000800,000600,000400,000200,0000.350.300.250.200.150.100.05Filtrate Turbidity < 0.1 NTUPurge10 ppm Feed25 ppm Feed0.000.0 1.0 2.0 3.0 401.00.90.80.70.60.50.40.30.20.1Column VolumeFiltrate Particle Size = 1 µm nominal10 ppm FeedFiltrate00 5 10 15Diameter (µm)Filtrate Turbidity<strong>SPECTRUM</strong>FEED: Suspended Solid = 10 ppmCoagulant Dose = 3 ppmConventional Dual Layer Media Filter(Anthracite/Fine Sand)0.00 5 10 15 20Onstream Volume (CV)Figure 3Figure 4Figure 5Performance ...High quality filtrate...All water sources contain fine particlesthat are typically in the form of colloidalsilt or microorganisms (e.g., algae, bacteria).If not addressed, these solids willfoul downstream reverse osmosis or ionexchange equipment, resulting in poorperformance and an increase in operatingcosts.The Spectrum Micro Media Filter isdesigned to remove these very fine particlesthat would otherwise pass throughother media filters. The filter effectivelyfilters turbid raw waters containing suspendedsolids concentrations of greaterthan 50 ppm to produce a filtrate of lessthan 0.1 NTU, with a particle size of lessthan 1 µm nominal (Figures 3 and 4)and a filtrate silt density index (SDI) ofless than 3.Minimal initial ripening...The Spectrum Micro Media Filter doesnot exhibit the ripening effect typicallyseen with other filters. A drawback ofrapid media filters is the poor qualitywater produced at the beginning of thefilter run. Fine matter passes throughthe filter during the initial period in substantialquantities and for an extendedperiod of time (Figure 5).In order to overcome this problem andprevent the improperly filtered waterfrom going downstream, it has been thepractice to send a large volume of theinitial filtrate to waste. This requirementresults in large amounts of waste waterand poor unit productivity. As shown inFigure 5, the Spectrum Micro MediaFilter produces a filtrate quality of lessthan 0.1 NTU after the purge of only asingle column volume. A conventionalmedia filter requires a purge of 10 columnvolumes or more in order to attainthe same filtrate quality.

Performance ...More robust...Surface waters are prone to seasonal andannual changes in the concentration of thesuspended matter. This is a concern forconventional media filters since breakthroughof solids will typically occur if thesolids holding capacity is exceeded(Figure6).There will not be any solids breakthroughif the solids holding capacity of themedia in the Spectrum Micro Media Filteris exceeded due an increase in the feedsuspended solids concentration. Thepressure drop across the filter will merelyincrease to the pre-determined value thatautomatically initiates the backwashsequence. This operational featureensures there will not be any contaminationof downstream storage volumes ortreatment equipment.Remove organics...Coagulation and fine filtration with theSpectrum Micro Media Filter is a provenmethod for removing naturally occurringorganics. Studies have shown a reductionin tannic acid concentration from around2.0 ppm to 0.35 ppm or less. This representsgreater than 80% reduction (Table1).The negatively charged organic moleculesattach themselves to the positivelycharged metal ions from the coagulantduring the agglomeration of the small particles(i.e., during floc formation). Theseorganics are then removed with theagglomerated solids in the filter. An organicpolymer can also be added to improvethe coagulation and filtration processes bypromoting the formation of a stronger flocthat will remain intact within the filter bed.This prevents floc fragmentation andbreakthrough into the filtrate stream.Onstream Turbidity (NTU)Figure 60.500.450.400.350.300.250.200.150.100.05CYCLE NO.Filtrate QualitySpectrum vs. Conventional Dual Layer Media Filter1.FEED: Suspended Solid = 10 ppmCoagulant Dose = 3 ppm1. <strong>SPECTRUM</strong>2. Conventional Dual Layer Media Filter(Anthracite/Fine Sand)0.000 50 100 150 200 250 300 350 400 450TABLE 1: TANNIC ACID REMOVAL EFFICIENCY12636872Onstream Volume (CV)FEED ‡TANNIC ACID(mg/L)1.81.82.01.92.0Naturally occurring organics, such astannic, humic or fulvic acids, enter thefeed water supply from decaying vegetationor agricultural runoff. Theseorganics tend to accumulate on the surfacesof reverse osmosis membranes oron anion resin in demineralizationequipment. This gradual fouling willlead to poor performance and increasedoperating costs.2.FILTRATETANNIC ACID(mg/L)0.130.120.330.260.20‡ Feed water contained 10 ppm of suspended solidsand dosed with 12 ppm coagulant%REMOVAL9393848690

Benefits ...Reduce cost & space...The superficial flowrate (i.e., flow per surfacearea) of the Spectrum Micro MediaFilter is two to three times that of a conventionalmulti-media filter. This increased unitproductivity results in a much smaller filtervessel diameter and an associated reductionin capital cost and required floorspace.In other media filters, the force of a highflowrate drives solids through the filter andinto the filtrate stream. The fine media layerat the bottom of the Spectrum Micro MediaFilter ensures solids will not breakthrough,even at the higher operational flowrate. Infact, the filtrate quality of the SpectrumMicro Media Filter at its high superficial flowis superior to the filtrate quality of a conventionaldual media filter at the lower flowrate(Figure 8).Compare with ultrafiltration ormicrofiltration . . .The Spectrum Micro Media Filter providesfiltered water quality that meets or exceedsthe requirements of R.O. membrane manufacturers.Along with goodoperating practice, thisensures long R.O. membranelife.While the use of membrane-basedprefiltration(ultrafiltration or micro-filtration)provides marginallyhigher filtered water quality,the incremental benefit toR.O. membrane life doesnot justify the significant additionalcost of membrane prefilters.% RemovalFigure 8Particle Removal EfficiencySpectrum vs. Conventional Dual Layer Media Filter1009998979695949392919089888786<strong>SPECTRUM</strong>FEED: Suspended Solid = 10 ppmCoagulant Dose = 3 ppmConventional Dual Layer Media Filter(Anthracite/Fine Sand)850 1 2 3 4 5 6 7 8 9 10Particle Diameter (µm)ECO-SERV Service Program...The Spectrum Micro Media Filter is fully coveredunder <strong>Eco</strong>-<strong>Tec</strong>'s ECO-SERV Customer ServiceProgram. The program begins with strict qualityassurance at every stage of the design and manufacturingprocesses, as demanded by ISO 9001.Samples of media from every shipment are tested inhouseto confirm particle size distributions. The filtervessels and carbon steel pipingsystems are constructed andtested in accordance withASME guidelines, and the PLCprogram is checked at the factoryto ensure the correct valvesequencing.An <strong>Eco</strong>-<strong>Tec</strong> ServiceRepresentative can provide onsitesupervision during start-upand offer operator training. AService Representative is available 24/7 to assist withany aspect of the system.ECO-TEC INC. ECO-TEC (Europe) Ltd.1145 Squires Beach Road, Pickering Unit 5C Ring Road, Zone 2, Burntwood Business ParkOntario,Canada L1W 3T9 Burntwood, Staffordshire, England WS7 3JQTelephone: 905-427-0077 Fax: 905-427-4477 Telephone: 44-15436-83086 Fax: 44-15436-74117email: ecotec@eco-tec.com email: ecoteceurope@aol.comwww.eco-tec.comThe information contained in this document is proprietary and is the sole property of <strong>Eco</strong>-<strong>Tec</strong> Inc., no part may be reproduced without the express consent of <strong>Eco</strong>-<strong>Tec</strong> Inc.