Alco Controls

Alco Controls

Alco Controls

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

<strong>Alco</strong> <strong>Controls</strong><br />

Electrical Control Valves<br />

Electrical Control Valve Technology<br />

Thermostatic expansion valves and mechanical<br />

regulator valves have been used in the refrigeration<br />

and air conditioning industry to control superheat<br />

and refrigerant mass flow since its very beginning. As<br />

today’s systems require improved energy efficiency,<br />

tighter temperature control, wider range of operating<br />

conditions and incorporate new features like remote<br />

monitoring and diagnostics, the application of<br />

electronically operated valves becomes mandatory.<br />

Only they offer the controls performance necessary<br />

to meet these needs.<br />

Electrical control valves are actuators only. For<br />

operation in a system they need sensors, valve drivers<br />

and controllers, see next chapter.<br />

EX2 is designed for pulse width modulation. It is<br />

applicable to all common HCFC and HFC refrigerants<br />

and for subcritical CO 2 applications and is used mainly<br />

for refrigeration applications such as display cases.<br />

The EX2 valve is a slide type solenoid valve with an<br />

orifice for expansion. It is either completely open or<br />

completely closed. One common valve body can be<br />

combined with 6 interchangeable orifices to cover 7<br />

capacity ranges.<br />

EX4/EX5/EX6/EX7/EX8 consist of two main internal<br />

assemblies, the valve and the stepper motor. The<br />

stepper motor is located next to the electrical<br />

plug and connected directly to the slide and cage<br />

assembly of the valve. Similar to the technology used<br />

in compressors, the motor is exposed to refrigerant<br />

and lubricant and the materials used are identical<br />

to the ones in compressor motors. The housing<br />

of the motor and valve assembly is made from<br />

stainless steel and fully hermetic, utilising exclusively<br />

brazing and welding technologies and eliminating<br />

all gaskets.<br />

This design offers several technical advantages such<br />

as proportional linear mass flow and a wide capacity<br />

range.<br />

A common feature of all ALCO electrical control valves<br />

is the positive shut-off function, which eliminates the<br />

need for additional solenoid valves.<br />

Valve Selection<br />

For EX2 the published table quotes capacities at 100%<br />

duty cycle. i.e. valve open continuously. However, it<br />

is recommended to operate the valve at partial load<br />

(50-80%) to allow for system load fluctuations.<br />

For EX4/EX5/EX6/EX7/EX8 and EXM/EXL all<br />

published capacities are maximum and there are no<br />

reserve capacities. Each valve should be selected for<br />

the highest possible capacity of the system. A wide<br />

range regulation (10 … 100%) with one slide orifice<br />

for each valve is achievable.<br />

To facilate valve dimensioning for other than the<br />

standard conditions ALCO offers an Excel based<br />

Selection Tool. This can be downloaded from<br />

www.emersonclimate.eu.<br />

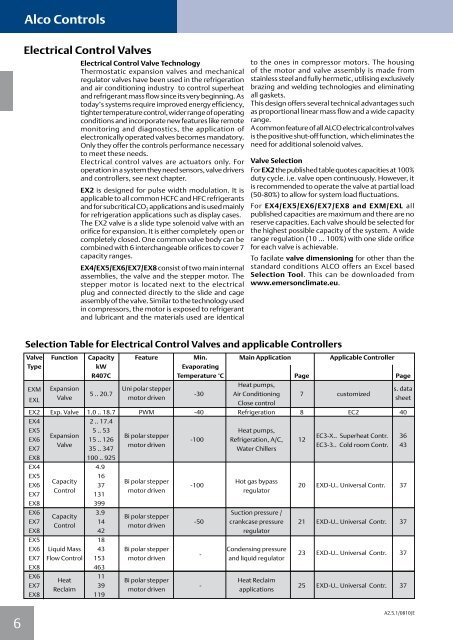

Selection Table for Electrical Control Valves and applicable Controllers<br />

Valve Function Capacity Feature Min. Main Application Applicable Controller<br />

Type kW Evaporating<br />

R407C Temperature °C Page Page<br />

Heat pumps,<br />

EXM Expansion<br />

Uni polar stepper<br />

s. data<br />

5 .. 20.7<br />

-30 Air Conditioning 7 customized<br />

EXL Valve<br />

motor driven<br />

sheet<br />

Close control<br />

EX2 Exp. Valve 1.0 .. 18.7 PWM -40 Refrigeration 8 EC2 40<br />

EX4 2 .. 17.4<br />

EX5 5 .. 53 Heat pumps,<br />

Expansion<br />

Bi polar stepper<br />

EC3-X.. Superheat Contr. 36<br />

EX6<br />

15 .. 126<br />

-100 Refrigeration, A/C, 12<br />

Valve<br />

motor driven<br />

EC3-3.. Cold room Contr. 43<br />

EX7<br />

35 .. 347<br />

Water Chillers<br />

EX8 100 .. 925<br />

EX4 4.9<br />

EX5 16<br />

Capacity<br />

Bi polar stepper<br />

Hot gas bypass<br />

EX6<br />

37<br />

-100<br />

Control<br />

motor driven<br />

regulator<br />

EX7<br />

131<br />

20 EXD-U.. Universal Contr. 37<br />

EX8 399<br />

EX6<br />

3.9<br />

Suction pressure /<br />

Capacity<br />

Bi polar stepper<br />

EX7<br />

14<br />

-50 crankcase pressure<br />

Control<br />

motor driven<br />

EX8 42 regulator<br />

21 EXD-U.. Universal Contr. 37<br />

EX5 18<br />

EX6 Liquid Mass 43 Bi polar stepper Condensing pressure<br />

-<br />

EX7 Flow Control 153 motor driven<br />

and liquid regulator<br />

23 EXD-U.. Universal Contr. 37<br />

EX8 463<br />

EX6<br />

11<br />

Heat<br />

Bi polar stepper Heat Reclaim<br />

EX7<br />

39<br />

-<br />

Reclaim<br />

motor driven<br />

applications<br />

EX8 119<br />

25 EXD-U.. Universal Contr. 37<br />

<br />

A2.5.1/0810/E