JurAssIC - KwIDF - Kuwait Oil Company

JurAssIC - KwIDF - Kuwait Oil Company

JurAssIC - KwIDF - Kuwait Oil Company

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

BY bader nasser al-qaoud, team leader production support gas group<br />

BY QASEM DASHTI, TEAM LEADER, FIELD DEVELOPMENT GAS GROUP<br />

Unique Challenges of the Complex<br />

Jurassic Gas Field<br />

Applying Digital Processes and<br />

Technology to Exploitation Strategy<br />

“HPHT gas fields that contain near critical fluids add<br />

a dimension of complexity to the overall exploitation<br />

strategy in terms of resource management,” says<br />

Mr. Al-Qaoud. He adds, “High drawdown pressures<br />

will inevitably lead to condensate drop-out in the<br />

reservoir structure, itself, with consequences of<br />

lower ultimate recovery, depletion of reservoir<br />

energy, and reduced gas flow potential.”<br />

In the <strong>KwIDF</strong> Jurassic project, “the complex geology<br />

is evidenced by areas with a tight rock matrix<br />

associated with a dense network of connected<br />

fractures. While this leads to good production,”<br />

Mr. Al-Qaoud cautions, “there is also a high<br />

probability of liquid loading. Further complexity is<br />

found in other areas of the same structure, which<br />

have very poor reservoir properties with a sparse<br />

fracture network.”<br />

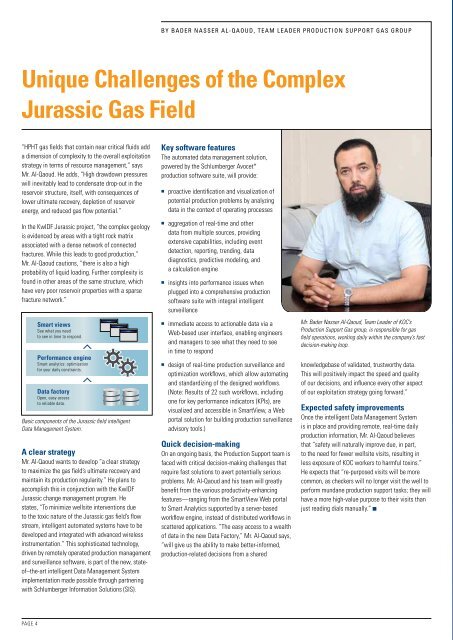

Smart views<br />

See what you need<br />

to see in time to respond.<br />

Performance engine<br />

Smart analytics: optimization<br />

for your daily constraints.<br />

Data factory<br />

Open, easy access<br />

to reliable data.<br />

Basic components of the Jurassic field intelligent<br />

Data Management System.<br />

A clear strategy<br />

Mr. Al-Qaoud wants to develop “a clear strategy<br />

to maximize the gas field’s ultimate recovery and<br />

maintain its production regularity.” He plans to<br />

accomplish this in conjunction with the <strong>KwIDF</strong><br />

Jurassic change management program. He<br />

states, “To minimize wellsite interventions due<br />

to the toxic nature of the Jurassic gas field’s flow<br />

stream, intelligent automated systems have to be<br />

developed and integrated with advanced wireless<br />

instrumentation.” This sophisticated technology,<br />

driven by remotely operated production management<br />

and surveillance software, is part of the new, stateof–the-art<br />

intelligent Data Management System<br />

implementation made possible through partnering<br />

with Schlumberger Information Solutions (SIS).<br />

Key software features<br />

The automated data management solution,<br />

powered by the Schlumberger Avocet*<br />

production software suite, will provide:<br />

■■<br />

■■<br />

■■<br />

■■<br />

■■<br />

proactive identification and visualization of<br />

potential production problems by analyzing<br />

data in the context of operating processes<br />

aggregation of real-time and other<br />

data from multiple sources, providing<br />

extensive capabilities, including event<br />

detection, reporting, trending, data<br />

diagnostics, predictive modeling, and<br />

a calculation engine<br />

insights into performance issues when<br />

plugged into a comprehensive production<br />

software suite with integral intelligent<br />

surveillance<br />

immediate access to actionable data via a<br />

Web-based user interface, enabling engineers<br />

and managers to see what they need to see<br />

in time to respond<br />

design of real-time production surveillance and<br />

optimization workflows, which allow automating<br />

and standardizing of the designed workflows.<br />

(Note: Results of 22 such workflows, including<br />

one for key performance indicators (KPIs), are<br />

visualized and accessible in SmartView, a Web<br />

portal solution for building production surveillance<br />

advisory tools.)<br />

Quick decision-making<br />

On an ongoing basis, the Production Support team is<br />

faced with critical decision-making challenges that<br />

require fast solutions to avert potentially serious<br />

problems. Mr. Al-Qaoud and his team will greatly<br />

benefit from the various productivity-enhancing<br />

features—ranging from the SmartView Web portal<br />

to Smart Analytics supported by a server-based<br />

workflow engine, instead of distributed workflows in<br />

scattered applications. “The easy access to a wealth<br />

of data in the new Data Factory,” Mr. Al-Qaoud says,<br />

“will give us the ability to make better-informed,<br />

production-related decisions from a shared<br />

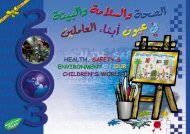

Mr. Bader Nasser Al-Qaoud, Team Leader of KOC’s<br />

Production Support Gas group, is responsible for gas<br />

field operations, working daily within the company’s fast<br />

decision-making loop.<br />

knowledgebase of validated, trustworthy data.<br />

This will positively impact the speed and quality<br />

of our decisions, and influence every other aspect<br />

of our exploitation strategy going forward.”<br />

Expected safety improvements<br />

Once the intelligent Data Management System<br />

is in place and providing remote, real-time daily<br />

production information, Mr. Al-Qaoud believes<br />

that “safety will naturally improve due, in part,<br />

to the need for fewer wellsite visits, resulting in<br />

less exposure of KOC workers to harmful toxins.”<br />

He expects that “re-purposed visits will be more<br />

common, as checkers will no longer visit the well to<br />

perform mundane production support tasks; they will<br />

have a more high-value purpose to their visits than<br />

just reading dials manually.” n<br />

Mr. Dashti contends, “Many production data<br />

management systems and practices in use today<br />

were not designed for real-time compliance, often<br />

creating a mistrust of data due to poor quality<br />

and unavailability at the time of need.” Mr. Dashti<br />

believes that “the absence of appropriate<br />

workflow tools can lead to missed opportunities<br />

for optimizing production.”<br />

According to Mr. Dashti, “Only a step change in<br />

production workflows and collaboration can ensure<br />

that data, human resources, and software application<br />

requirements are relevant to actual needs.”<br />

Intelligent automation<br />

“The greenfield nature of Jurassic gas field makes<br />

it an ideal candidate for digital field processes and<br />

technologies,” says Mr. Dashti. “However, this high<br />

pressure, high temperature (HPHT) gas field is<br />

geologically complex. It has fluids in near-critical<br />

condition with elevated concentrations of H 2<br />

S and<br />

CO 2<br />

. ”Mr. Dashti’s goal is to “maximize ultimate<br />

recovery, maintain production regularity, and<br />

minimize wellsite interventions due to the toxic<br />

nature of the flow stream.” He claims that<br />

”intelligent automation at the wellhead combined<br />

with advanced instrumentation will minimize<br />

HSE exposure of field personnel.”<br />

Interventions at the wellsite will be supported<br />

by handheld PDAs embedded with work orders.<br />

His Field Development Gas group will also use<br />

new digital field work processes supported by<br />

state-of-the-art collaboration rooms. These facilities<br />

enable proactive, real-time decisions to be made in<br />

accordance with the field’s exploitation strategy. Mr.<br />

Dashti asserts, “It is now possible to quickly<br />

leverage multidiscipline competencies that can<br />

easily contribute in real time to production<br />

operations, instead of conducting long-term studies<br />

and reviews.”<br />

Exploitation strategy—<br />

goals and implementation<br />

Mr. Dashti describes the field’s exploitation strategy<br />

as “concurrently maximizing the production of<br />

individual wells while minimizing the liquid<br />

drop-out in the reservoir. This will maximize<br />

reserves recovery, leading to a new paradigm<br />

in resource management.”<br />

“An ‘intelligent’ Data Management System,”<br />

says Mr. Dashti, “will eliminate the risk of<br />

non-validated data and inefficiencies of data<br />

retrieval and utilization. We want to achieve<br />

production regularity, aided by our highly<br />

instrumented wells that not only address the<br />

acquisition of well and reservoir data,<br />

but also capture additional information—<br />

such as sour and flammable gas detection<br />

and video images—that directly feeds into<br />

work routines governing loss prevention<br />

activities.” This is a big step toward improved<br />

safety conditions.<br />

Mr. Dashti says, “Using the new collaboration<br />

rooms for multi-disciplinary decision-making<br />

will help align individuals with pre-defined<br />

rules of the exploitation strategy. The active<br />

participation of team members also ensures<br />

that rules are modified, as needed, during<br />

field maturity.”<br />

The implementation of SIS smart tools is “helping to<br />

achieve production regularity via an integrated<br />

network model enabling production technologists to<br />

generate what-if scenarios and set the rules for<br />

routines to control automatic chokes. This prevents<br />

weak wells in tight areas of the reservoir from being<br />

overwhelmed by the wells in densely fractured<br />

areas.” Furthermore, features like alarms embedded<br />

in the Avocet Production Surveillance system allow<br />

problems to be flagged and mitigated proactively.<br />

The intelligent Data Management System supports<br />

Mr. Dashti’s goals by democratizing data, so that<br />

raw data is transformed into the right information<br />

and pushed to the target audience in a reliable and<br />

efficient manner.<br />

“Trustworthiness is a key requirement for real-time<br />

production optimization. It is absolutely necessary<br />

to have validated and conditioned data, as it will<br />

ensure cross-discipline collaboration is functioning<br />

at a high level. Viewing reliable data simultaneously—<br />

whether or not the decision makers are in a single<br />

collaboration room—is a KOC initiative destined to go<br />

beyond just this one gas field. n<br />

Mr. Qasem Dashti, Team Leader of KOC’s Field<br />

Development Gas group, is mainly involved in production<br />

optimization and well performance issues, working daily<br />

within the company’s medium decision loop.<br />

PAGE 4<br />

PAGE 5