JurAssIC - KwIDF - Kuwait Oil Company

JurAssIC - KwIDF - Kuwait Oil Company

JurAssIC - KwIDF - Kuwait Oil Company

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

technical article i Hassan A. Rahim, Section Head, Production Support Gas and <strong>Oil</strong> Team<br />

The Origin of Digital Data<br />

Front and back view of a 24VDC, pole-mounted solar panel that provides power<br />

to RTU electronics, field instrumentation, solenoids and hydraulic pump, choke valve,<br />

and WIMAX CPE.<br />

The dream is a reality: Mr. Hassan A. Rahim, Section Head PSG & <strong>Oil</strong> Team, inspecting<br />

new wellhead instrumentation along with Ms. Lai Chan Chiu, Schlumberger <strong>KwIDF</strong> Project<br />

Manager, and Mr. Juan Carlos G. Bonilla, Schlumberger Change Management Consultant.<br />

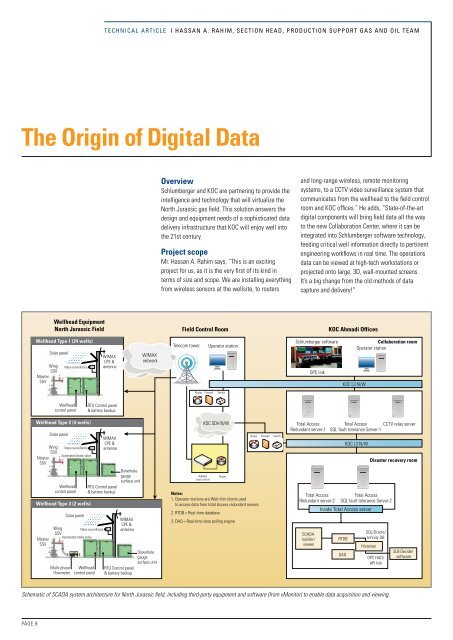

Wellhead Equipment<br />

North Jurassic Field<br />

Wellhead Type 1 (24 wells)<br />

Master<br />

SSV<br />

Solar panel<br />

Wing<br />

SSV<br />

H<br />

H<br />

M<br />

Video surveillance<br />

WIMAX<br />

CPE &<br />

antenna<br />

WIMAX<br />

network<br />

Overview<br />

Schlumberger and KOC are partnering to provide the<br />

intelligence and technology that will virtualize the<br />

North Jurassic gas field. This solution answers the<br />

design and equipment needs of a sophisticated data<br />

delivery infrastructure that KOC will enjoy well into<br />

the 21st century.<br />

Project scope<br />

Mr. Hassan A. Rahim says, “This is an exciting<br />

project for us, as it is the very first of its kind in<br />

terms of size and scope. We are installing everything<br />

from wireless sensors at the wellsite, to routers<br />

Field Control Room<br />

Telecom tower<br />

Operator station<br />

and long-range wireless, remote monitoring<br />

systems, to a CCTV video surveillance system that<br />

communicates from the wellhead to the field control<br />

room and KOC offices.” He adds, “State-of-the-art<br />

digital components will bring field data all the way<br />

to the new Collaboration Center, where it can be<br />

integrated into Schlumberger software technology,<br />

feeding critical well information directly to pertinent<br />

engineering workflows in real time. The operations<br />

data can be viewed at high-tech workstations or<br />

projected onto large, 3D, wall-mounted screens.<br />

It’s a big change from the old methods of data<br />

capture and delivery!”<br />

Schlumberger software<br />

OPC link<br />

KOC Ahmadi Offices<br />

KOC L3 N/W<br />

Collaboration room<br />

Operator station<br />

Project requirements<br />

Specifying the <strong>KwIDF</strong> Jurassic requirements and<br />

implementing the digital network solution was a<br />

joint effort accomplished by KOC’s IT department,<br />

Schlumberger Information Solutions (SIS), and<br />

vMonitor technical engineers. Mr. Rahim explains,<br />

“We were determined to create a scalable system<br />

to satisfy the company’s data acquisition needs<br />

today and in the future. Wireless connectivity and<br />

solar power are just two examples of the emerging<br />

technologies applied to the <strong>KwIDF</strong> Jurassic project.<br />

Down to the nuts and bolts of the control panels<br />

and battery backups, all items were chosen and<br />

configured to meet KOC’s desire for continuous<br />

remote, real-time data monitoring of this particularly<br />

hazardous location.”<br />

Field instrumentation and software<br />

Mr. Rahim informs, “With the new field<br />

instrumentation, it will be possible to collect and<br />

transmit real-time data by monitoring gas leaks,<br />

H 2<br />

S, and pressure at the wellhead, in addition to<br />

monitoring corrosion and temperature of the flowline<br />

24/7/365.” Other innovative features include the<br />

ability of the hydraulic control panel to support<br />

remote supplementary controls using solenoid valves<br />

and to optionally provide remote control of hydraulic<br />

pumps. Then, there is the new remote terminal unit<br />

(RTU) that will support multiple analog and digital<br />

inputs and outputs, multiple thread multi-tasking<br />

applications, IEC-61131 ISAGraf PLC programming<br />

languages, customized ESD logic, and data logging<br />

…to name a few.<br />

TotalAccess software from vMonitor will provide a<br />

user-friendly, onscreen console to view various types<br />

of data monitoring activities, including field<br />

measurement gauges, data polling graphs, and<br />

summary information of surface instrumentation data,<br />

such as pressure and flow rate, for a particular well.<br />

Digital, wireless connectivity<br />

According to Mr. Rahim, “The entire infrastructure<br />

is linked together via a WIMAX network connection<br />

to a telecommunications tower, which passes data to<br />

a field control room that houses the operator station<br />

with router, firewall, switch, etc. that connects to<br />

KOC’s Intranet using thin client technology.”<br />

Disaster recovery<br />

Included in the overall solution is a Disaster Recovery<br />

room, complete with a redundant server and SQL<br />

fault server, as well as a real-time database (RTDB),<br />

real-time data polling engine (DAQ), and a Historian<br />

database for archival purposes, making this a true<br />

end-to-end solution. n<br />

Router<br />

Firewall<br />

Switch<br />

Wellhead<br />

control panel<br />

RTU Control panel<br />

& battery backup<br />

Wellhead Type 2 (4 wells)<br />

Solar panel<br />

Wing<br />

SSV<br />

H<br />

Master<br />

SSV<br />

H<br />

Automated choke valve<br />

M<br />

Wellhead<br />

control panel<br />

Wellhead Type 3 (2 wells)<br />

Master<br />

SSV<br />

H<br />

Solar panel<br />

WIMAX<br />

CPE &<br />

antenna<br />

RTU Control panel<br />

& battery backup<br />

Wing<br />

Video surveillance<br />

SSV<br />

H Automated choke valve<br />

M<br />

Multi-phase<br />

flowmeter<br />

Video surveillance<br />

Wellhead<br />

control panel<br />

Downhole<br />

gauge<br />

surface unit<br />

WIMAX<br />

CPE &<br />

antenna<br />

RTU Control panel<br />

& battery backup<br />

Downhole<br />

gauge<br />

surface unit<br />

WIMAX<br />

base station<br />

KOC SDH N/W<br />

Router<br />

Notes:<br />

1. Operator stations are Web thin clients used<br />

to access data from total Access redundant servers.<br />

2. RTDB = Real-time database<br />

3. DAQ = Real-time data polling engine<br />

Router Firewall Switch<br />

Total Access<br />

Redundant server-1<br />

Total Access<br />

Redundant server-2<br />

SCADA<br />

builder/<br />

viewer<br />

Total Access CCTV relay server<br />

SQL fault tolerance Server-1<br />

Total Access<br />

SQL fault tolerance Server-2<br />

Inside Total Access server<br />

RTDB<br />

DAQ<br />

KOC L3 N/W<br />

Disaster recovery room<br />

SQL/Oracle/<br />

Infinity DB<br />

Historian<br />

OPC HAD/<br />

API link<br />

SLB Decide!<br />

software<br />

Schematic of SCADA system architecture for North Jurassic field, including third-party equipment and software (from vMonitor) to enable data acquisition and viewing.<br />

Stainless steel, enclosed remote terminal unit (RTU).<br />

Control room viewer displays current and trend values for instrumentation measurements in the field.<br />

PAGE 8<br />

PAGE 9