INSTRUCTION MANUAL FOR SEWING MACHINE - Singer - This Wiki

INSTRUCTION MANUAL FOR SEWING MACHINE - Singer - This Wiki

INSTRUCTION MANUAL FOR SEWING MACHINE - Singer - This Wiki

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

i<br />

H<br />

<strong>SEWING</strong> <strong>MACHINE</strong><br />

<strong>INSTRUCTION</strong> <strong>MANUAL</strong><br />

H<br />

/<br />

<strong>FOR</strong><br />

WHITE<br />

www.whftesewing.com<br />

800-331-3164<br />

Call Toll Free<br />

fli

followed, including the following:<br />

appliance from the electric outlet immediately after using and before cleaning.<br />

When using an electrical appliance, basic safety precautions should always be<br />

IMPORTANT SAFETY <strong>INSTRUCTION</strong>S<br />

Always unplug before relamping, Replace bulb with same type rated 15 watts.<br />

is used by or near children.<br />

2. Use this appliance only for its rntended use as described in this manual. Use only<br />

electric shock, or injury to persons:<br />

Read all instructions before using<br />

1. Do not allow to be used as a toy. Close attention is necessary when this appliance<br />

3. Never operate this appliance if it has a damaged cord or plug, if it is riot working<br />

4. Never operate the appliance with any air openings blocked, Keep ventilation open<br />

An appliance should never be left unattended when plugged in. Always unplug this<br />

5. Never drop or insert any object into any opening.<br />

6. Do not use outdoors.<br />

10. Keep fingers away from all moving parts. Special care is required around the sewing<br />

7. Do not operate where aerosol (spray) products are being used or where oxygen is<br />

8. To disconnect, turn all controls to the off (“0”) position, then remove plug from<br />

ii. Always use the proper needle plate. The wrong plate can cause the needle to break.<br />

12. Do not use bent needles.<br />

9. Do not unplug by pulling on cord. To unplug, grasp the plug, not the cord.<br />

attachments recommended by the manufacturer as contained in this manual.<br />

ii Do not pull or push fabric while stitching. It may deflect the needle causing it to<br />

14. Unplug the sewing machine when making any adjustments in the needle area,<br />

property, if it has been dropped or damaged, or dropped into water, Return the<br />

appliance to the nearest authorized dealer or service center for examination, repair<br />

15. Always unplug sewing machine from the electrical outlet when removing covers,<br />

electrical or mechanical ad!ustment.<br />

DANGER To reduce the risk of electric shock:<br />

dust, and loose cloth.<br />

ings of the sewing machine and foot controller free from the accumulation of lint,<br />

being administered.<br />

outlet.<br />

machine needle.<br />

WARNING To reduce the risk of burns, fire,<br />

break.<br />

such as threading needle, changing needle, threading bobbin, or changing<br />

presser foot, etc.<br />

lubricating, or when making any other user servicing adjustments mentioned in the<br />

instruction manual.<br />

SAVE THESE <strong>INSTRUCTION</strong>S<br />

(this sewing machine)

CONTENTS<br />

Names of Parts.......................................................... I & 2<br />

Accessories 3<br />

Before sewing (Power suoply and Sewing Lamp) $<br />

Take Out extension tabte, free arm sewing 5<br />

Winding the bobbin 6<br />

Removing bobbin case and boboin 7<br />

Inserting bobbin into bobbin case 7<br />

Inserting bobbin case Into shuttle race 3<br />

Threading ucper thread & Twin needle threaoing 9<br />

Drawing up boobin thread 10<br />

Changing sewing directions 10<br />

Control dial & Adjusting thread tension (1 & 12<br />

Regulating the presser toot pressure (3<br />

Drop feed 13<br />

Changing needle 14<br />

Fabric. Thread. Needle table (5<br />

To start sewing 16<br />

Toñnishseam 17<br />

Straight stitch 18<br />

Zigzag sewing<br />

Button sewing 19<br />

Zipper sewing 20<br />

Hemming 21<br />

Twin Needle 22<br />

Embroidery 22<br />

Quilter & Seam guide 23<br />

Buttonhole sewing 24<br />

Maintenance (Cleaning and oiling) 25<br />

Checking Performance Prootems WHAT TO DO 26<br />

/

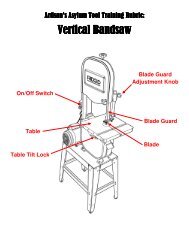

NAME OF PARTS (FRONT VIEW)<br />

Sub-spool pin<br />

Top cover<br />

Presure Regulator<br />

Take up lever<br />

Thread tension dial<br />

Needle position knob<br />

Reverse button<br />

Stitch lengtfl aiai<br />

Presser foot<br />

Shuttle<br />

Extension table<br />

read guide for upper threading<br />

—1—

Hand wheel<br />

Motion knob<br />

Stop clamp<br />

Bobbin winder stopper<br />

(REAR VtEW)<br />

/<br />

—2—<br />

/ /<br />

Presser foot lever<br />

Needle clamp screw<br />

Upper ±i read guide<br />

Bobbin winder spindle

ACCESSORIES<br />

0<br />

Bobbin<br />

Spool pin felt<br />

Zigzag foot<br />

(On machine)<br />

Buttonhole foot<br />

Button attaching loot<br />

Macgine Qjj<br />

Zipper foot<br />

Buttonhole cutter<br />

Screw driver<br />

Needle<br />

#11 414<br />

—3-—<br />

/

BE<strong>FOR</strong>E <strong>SEWING</strong><br />

1. Fit plug into the macnine.<br />

2. Plug the macnine tc<br />

supply<br />

he<br />

power<br />

3. Sewing speed can be varied by<br />

the toot control.<br />

Sewing lamp<br />

REMOVE ORHNSTALL BULB<br />

1. Qoen face cover in direction of<br />

arrow.<br />

emove<br />

2.<br />

bulb by unscrew<br />

ing it counter-clockwise.<br />

3. install a new bulb screwing it<br />

in clockwise.<br />

y<br />

4. Use a screw type bulb with<br />

5W(Max).<br />

120/1<br />

lMPOTANT : When leaving the sewing macnine unattended, the<br />

plug must be removed from the socket outlet.<br />

When servicing the sewing machine, or wnen removing covers or<br />

changing amps, the macnine must ce disconnected from the supply<br />

by removing the plug from the socket outlet.<br />

—4—<br />

I

as shown at side.<br />

etc., more easily.<br />

converts to free arm macnine by<br />

arrow.<br />

1 Hold the left end of table<br />

FREE-ARM SEWiNG<br />

REMOVING EXTENSION TABLE<br />

—5—<br />

2. Especially useful for sewing<br />

1. <strong>This</strong> sewing machine can be used<br />

3. To sew tubular ust sliø the sleeve<br />

as a fiat bed machine out easily<br />

removing the extension table.<br />

sleeves, pal-it legs, tubular faDr:cs<br />

or leg of pants on to the free arm<br />

and pull out in dIrection or

I<br />

WINDING ThE BOBBIN<br />

1 .elease stop motion knob.<br />

2.Thread as shown.<br />

3.When bobbin s filled,<br />

tighten stop motion knob.<br />

5cm thread<br />

7’ThcbbIn N<br />

winder<br />

spindle -.<br />

Push bobbin winder spindle in<br />

direction of arrow.<br />

When bobbin winding is com<br />

pleted return spindle to<br />

original position.<br />

x<br />

;:j><br />

x<br />

When bobbin winding is in<br />

correct, release the screw of<br />

upper thread guide and ad<br />

Just U or down until bobbin<br />

winding is balanced.<br />

—6—

—.7—<br />

spnng<br />

slot.<br />

SLOT<br />

Hinged latch<br />

REMOVING BOBBIN CASE AND BOBBiN<br />

1 .Ralse needle to Its highest<br />

INSERTING BOBBIN INTO BOBBIN CASE<br />

1.Pull off 5cm of thread from<br />

position and open the<br />

shuttle race cover.<br />

bobbin and insert it into<br />

bobbin case as shown.<br />

3.elease the latch and bob<br />

3.Pull into slot and under<br />

bin will fail out easily.<br />

tension spring and draw<br />

out about 10cm of thread.<br />

2. Open hinged latch of bobbin<br />

2.Guide the end of thread into<br />

case and pull bobbin case<br />

out of machine.

—8—<br />

latch<br />

onto centre pin in shuttle and release<br />

2.Hoiding latch open, place bobbin case<br />

latch of bobbin case and hold it.<br />

pulling thread to the front, open the<br />

1 ,Rase needle to its highest position,<br />

INSERTiNG BOBBIN CASE INTO SHUTTLE RACE

THREADING UPPER THREAD<br />

Twin need’e tt,reading<br />

—9—<br />

/<br />

/

needle qoes down and<br />

slcwiy towards you until the<br />

I<br />

—10--<br />

as desired.<br />

needle to change direction<br />

pivot the fabric around the<br />

I Lower needle oown into<br />

fabric and raise presser foot.<br />

CHANGLNG SEWiNG DIRECTiONS<br />

4<br />

DRAWING UP BOBBIN ThREAD<br />

2. Lower presser foot and start<br />

to sew.<br />

(see page 16)<br />

4. Start to sow<br />

presser foot.<br />

foot from the front, lower<br />

3. Place fabric under presser<br />

machine.<br />

presser foot to the rear of<br />

place them together under<br />

2. Pull out both threads and<br />

up in a loop.<br />

lower thread will be brought<br />

the upper thread and the<br />

position. lightly araw up<br />

takeup lever is at its hignest<br />

hand wheel when the<br />

comes up. Then stop the<br />

hand, turn the hana wneel<br />

1. Hold upper thread with left

CONTROL DIAL<br />

1 Reverse button<br />

2 Zig-zaq wOth dia’<br />

3 Thread tensOfl daI<br />

4 Needle posiUofl knoo<br />

SutCh length dal<br />

—11—<br />

/

ADJUSTING THREAD TENSION<br />

Corec<br />

Weak<br />

Strong<br />

Upper thread<br />

Uoper thread tension<br />

may be aciusted by<br />

turning the thread<br />

tension dial.<br />

Bobbin thread<br />

ncorrect<br />

insice of fabric<br />

thread<br />

Upoer<br />

LOWER THREAD TENSION<br />

Lower thread tension can<br />

be adlusted by turning<br />

screw on bobbin case siight•<br />

ly to the right (clock-wise)<br />

to increase tension. Turn<br />

the screw (courter-clockwise)<br />

to the left to decrease ten<br />

sion.<br />

—12—

self.<br />

fabrics)<br />

A<br />

//<br />

REGULATING THE PRESSER FOOT PRESSURE<br />

There are a few times when you want to control me feeding of fabric by your<br />

for button sewing application — 13 —<br />

DROP FEED Note: Darning date can be purchased seoarateiy. N<br />

4 No pressure adjustment is required wnen darnrig<br />

or sewing embroidery.<br />

skipped stitcries, or difficulty in guiding the faoric.<br />

2. Push down outer ring to release pressure. (Heavy<br />

3. Insufficient pressure may cause poor feeding.<br />

(Light to medium fabrics)<br />

1 Push oown rifler pin (A)<br />

over needle plate aflgning two pins of darning plate with holes of needle piate<br />

Raise needle bar to its highest position and raise presser toot, place darning plate<br />

You may then deermine the movement of the fanric by yourself See daqe 19<br />

to increase pressure.

Needle clamp screw<br />

CHANGiNG NEEDLE<br />

2.Loosen needle camc screw and remove ore needle.<br />

3. With the lar sice of the needle facing away from you.<br />

4 Tighten the needle dame screw securely.<br />

aise needle oar to its nighest position.<br />

insert needle as tar up as 1 will go.<br />

—14—<br />

\Loosen<br />

Flat face slde<br />

away from you.<br />

Tigtteri

15 —<br />

Medium 60-80<br />

Jersey 50 S. Fiberl 11.14<br />

Tweed 150Sk 11.14<br />

0.5 —<br />

\<br />

\<br />

I .<br />

o.<br />

Ging nam Cotton<br />

1 4<br />

—<br />

a<br />

3O.5<br />

—4<br />

Heavy Denim so cotton 14.16<br />

IGaoardtne 60 lk<br />

\ Jerse’60 S. :ber<br />

1 1<br />

—<br />

1 ( )<br />

-<br />

\<br />

i- \<br />

Wool silk<br />

Fber<br />

SE\<br />

Sik 50 sk 1 3<br />

Trcot 160 S. oeri 9<br />

Lgnt Nylon lao Cotton<br />

regulation dIa’<br />

\<br />

Z tension<br />

\<br />

Fabric Thread Needle oresser foot<br />

\ Ptiissure Srtcn ength<br />

\ Pressure of ttns Incica<br />

Lencttr<br />

Please note that me foIl owing list is a guide when sewing different fabrics.<br />

FABRIC THREAD NEEDLE TABLE

— !i5 —<br />

after stopping sewing.<br />

TO START <strong>SEWING</strong><br />

3. Sufficient fabric should be placed under needle before owering<br />

Attention<br />

Imoortant Hints<br />

4. Depress foot and start to se’i’<br />

1. Raise the take-up ever to its highest position before starttnQ na<br />

5. Test the machine stitches n a scrap of faric you clan to use,<br />

1. When turning the balaj,ce wneel manually, always turn t<br />

2.Guide the cloth gently with your hand.<br />

3. To Oreverit breaking needle always raise the needle out of the<br />

toward you.<br />

to your fabric.<br />

aalusttng the machine tar the length of stitch and tension suitaole<br />

presser foot.<br />

two or three stitches.<br />

2. Hold born threads about 10 cms tc the rear of machine to tne first<br />

fabric when you stop sewing.

macnine.<br />

about 3-4 orns.<br />

I .Sew to the eoge of seam.<br />

TO FiNISH SEAM<br />

2Push the reverse button and sew in reverse for<br />

3.Raise needle to its highest posItion<br />

— 17—<br />

5.Cut threads as shown on the threab cutter.<br />

4.Ltt presser foot ano pull ou the faonc to rear of

2 The zig-zag presser foot can be used for both straight arc zig-zag<br />

sewing.<br />

I <strong>This</strong> type of siticning is the one useO most treuentIy.<br />

—<br />

Satin stitching can be used for sewing initiats. patterns, appllque, etc.<br />

1L<br />

E<br />

zIQzaa width t3oStlon<br />

ZIGZAG <strong>SEWING</strong><br />

3.For sewing light fabric, use smaller stitch size. (Refer to cage 15 for diat<br />

setting).<br />

STRAIGHT STITCH

1 .Lower drop teed.<br />

BUTTON <strong>SEWING</strong><br />

4.Manually turn hand whee towards you ensuring that tne needle enters<br />

3.Ptace button between presser foot and fabric and lower resser foot.<br />

2. Place button attaching presser toot n position.<br />

5.Sew about 7 stitches.<br />

6.PuiI both threads to the underside arid tie together.<br />

(Increase or decreise width setting).<br />

into both ho’es of button without obstruction.<br />

— 19—

Select stralgnt stItch.<br />

ZIPPER <strong>SEWING</strong><br />

/<br />

— 20<br />

—<br />

sew as illustrated.<br />

of the needle.<br />

set the zipper loot on the left side<br />

2. To sew the right side of zipper<br />

set the zipper toot on the rigrlt<br />

side of the needle.<br />

1. To sew the left side of zipper<br />

arid place fabric under foot<br />

3. Fold the fabric about 2 cm<br />

arid attach firmly<br />

2. Place zipper foot in position<br />

preventing sewing cr1 zipper<br />

sew close to a raised edge<br />

1. ZIpper foot is designec to

— 21<br />

HEMMING Note. Hemmer foot can be purchased separately.<br />

1. Raise the foot and the needle to its highest position. Replace the foot with the<br />

2. Fold over the fabric edge by about 3mm and place it under the foot. Secure tne<br />

3. Lower the foot and sew the hem.<br />

4. Durning sewing, fold the fadric to the left a little and allow it to run into the<br />

5. Make sure that the facric does not move under the right half or the foot, The<br />

Only suitable materials can be used and some practice may be necessary to acneive<br />

best results.<br />

hemmer foot.<br />

folded edge with a few stitches. Take out the workplece and draw the hem<br />

into the hemmer foot by pulling the threads.<br />

hemmer foot.<br />

fabric must be fed into the scroll of the hemmer sutficently so that the work<br />

piece edge runs freely through the groove under the foot.<br />

—

I<br />

ThVIN NEEDLE<br />

Note: Twin needle can be purchased separately<br />

same oath as for normal sewing. Seøarate threads before last thread guide above the<br />

needle. Insert one thread into the right needle of twin needle.<br />

Insert other thread into the left needle of twiii needle.<br />

cause breaking of needle.<br />

emove regular needle and insert twin needle. Thread both threads througn me<br />

CAUTTON:Do not set stitch width wider than number 2 setting. Exceeding this will<br />

EMBROIDERY<br />

Lower feed dog and move hooped fabric slowly to form the desired effect.<br />

See Page 13 drop teed<br />

—22—

— 23 —<br />

QUILTER Note: Quilt guice can be purcnasei separately.<br />

SEAM GUIDE Note: Seam guide can be purchased separately.<br />

1. Use seam guide wnen sewing tong seam of regular distance from<br />

2. Set guide hole on bed, at right of needle fate, and adjust dis<br />

3.Run macrune with edge of material touching guide.<br />

tance from the needle to the guide for desired seam allowance.<br />

edge ci material.<br />

ISlide arm through hole on top of presser toot holder.<br />

2.Move guioe to regured stitch distance.<br />

-3

— 24 —<br />

4<br />

it<br />

(4)<br />

FIGURE (4).<br />

UNDER THE BUTTONHOLE FOOT.<br />

BU]TONHOLE <strong>SEWING</strong><br />

5. SET ZIGZAG WIDTH KNOB ON 5 THEN SEW 3-5 STITCHES AS FIGURE (3).<br />

6. SET THE STITCH LENGTH KNOB ABOUT 0.5. ZIGZAG WIDTh KNOB ON 2. NEEDLE POSITION KNOB ON<br />

4. SET STITCH LENGTh ABOUT 0.5. ZiGZAG WIDTh KNOB ABOUT 7 NEEDLE POSITION KNOB ON LEFT<br />

CENTER POSITION. THEN SEW 3-5 STITCHES AS FIGURE (1).,<br />

POSITION. THEN SEW AS FIGURE (2) UN11LL YOU REACHES ThE END OF THE MARKING.<br />

2. REMOVE THE REGULAR PRESSER FOOT AND ATTACH ThE BUTTONHOLE FOOT & PUT ThE FABRIC<br />

1.M.ARK WITH A PENCIL OR CHAU( THE EXACT LENGTH OF THE BUTTONHOLE ON THE FABRIC.<br />

7, REMOVE FABRIC FROM THE <strong>MACHINE</strong> AND OPEN ThE BUTTONHOLE WITH A BUTTONHOLE CUTTER<br />

3. SET THE STCH LENGTH KNOB ON 0’, ZIGZAG WIDTh KNOB ON 5 AND NEEDLE posrno KNOB ON<br />

RIGHT POSITION. PUSH ThE R BUTTON SEW UNTILL YOU REACHES THE END OF THE MARKING AS<br />

CR SEAM CUTTER.<br />

Before sewing fit bultonhole tool Cul outtonhole along centre ith<br />

as shown. cutter as shown.<br />

(1) (2)<br />

1r

— 25<br />

C<br />

• 3. Turn latch knob A as illustrated.<br />

2. TaKe OUt bOOOi case.<br />

o 1. Raise needle to its highest position.<br />

Open face cover and oil points<br />

MAINTENANCE (CLEANING AND OILING)<br />

indicated.<br />

Cleaning shuttle race<br />

(A Latcn knob<br />

(B) Shuttle race cover<br />

4. Take off sriuttle race cover.<br />

A 5. Take out snuttle hook.<br />

(C) Shuttle hook<br />

0 6. Clean anc oil snuttle race and hook.<br />

Nt<br />

Cleaning feed dog<br />

4. then replace in the reverse order.<br />

Open top cover and oil points indicatec.<br />

Oil points indicated on underside of bed base.<br />

—

Machine<br />

Stitch<br />

-<br />

-<br />

-<br />

- Incorrect<br />

- Needle<br />

-<br />

Tight<br />

. Needle<br />

. Nicks<br />

- Raise<br />

- ghbei<br />

*<br />

Fit<br />

-<br />

Correct<br />

Re-thread<br />

Ioosen<br />

Fit<br />

Replace<br />

-<br />

-<br />

-<br />

-<br />

CHECKING PER<strong>FOR</strong>MANCE PROBLEMS WHAT TO DO<br />

PROBLEM PROBABLE CAUSE CORRECTION<br />

Fabric not<br />

-<br />

moving<br />

-<br />

Feed dog down.<br />

not moving.<br />

length dial no positicn.<br />

Light pressure on presser loot.<br />

feed dog.<br />

etop mollon.<br />

oving dial to 1-4.<br />

Increase pressure on presser<br />

toot.<br />

Breaking Needle<br />

setting of needle. Reset needle.<br />

bent. .<br />

Pulling fabric.<br />

Incorrect use of needle, thread<br />

-<br />

new needle.<br />

Do not pull fabric.<br />

or fabric. or fabric.<br />

use of needle, thread<br />

Breaking Bobbin<br />

-<br />

Thread<br />

Improper threading.<br />

-<br />

upper thread tension.<br />

.<br />

bent.<br />

.<br />

or burrs on shuttle.<br />

-<br />

machine.<br />

upper thread tension.<br />

new needle.<br />

shuttle, or polish oil<br />

burrs completely.<br />

Machine Jamming<br />

No oil.<br />

Knocking Noise Dust and thread in shuttle.<br />

[leeds oiling<br />

Glean stmutlle.<br />

Tension too tight. -Reset.<br />

Adlust sewing loot pmessure<br />

Puckering Sewing toot pressure too strong<br />

Incorrect use of fabric, and<br />

thread, thread.<br />

Use correct fabric, needle and