A Guide to Safe and Effective Tank Cleaning

A Guide to Safe and Effective Tank Cleaning

A Guide to Safe and Effective Tank Cleaning

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Step 2<br />

Ensure efficient delivery <strong>to</strong> the nozzle<br />

Line Strainers<br />

Line strainers are another critical component of your au<strong>to</strong>mated system.<br />

Particulates in the liquid can clog nozzles or s<strong>to</strong>p their rotation, which<br />

results in insufficient cleaning <strong>and</strong> potential product contamination.<br />

Filtering the liquid with line strainers prevents clogging <strong>and</strong> also extends<br />

the wear life of downstream equipment including nozzles <strong>and</strong> pumps.<br />

For fine straining, woven wire mesh screens provide very small openings<br />

<strong>to</strong> strain particulates down <strong>to</strong> 200 mesh (74 microns). The mesh screen<br />

should be made of stainless steel for strength <strong>and</strong> corrosion resistance.<br />

The screen is critical <strong>to</strong> the operation of the strainer, <strong>and</strong> an extra screen<br />

should be kept on h<strong>and</strong> for each strainer installed.<br />

See page 49 for strainer <strong>and</strong> mesh recommendations.<br />

<strong>Tank</strong> Wash Lances<br />

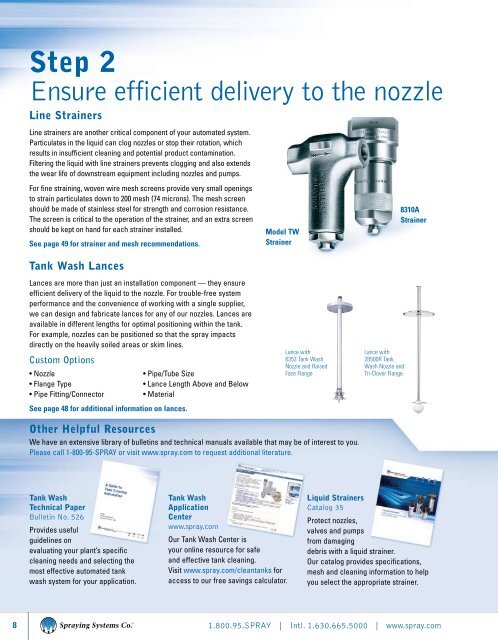

Model TW<br />

Strainer<br />

8310A<br />

Strainer<br />

Lances are more than just an installation component — they ensure<br />

efficient delivery of the liquid <strong>to</strong> the nozzle. For trouble-free system<br />

performance <strong>and</strong> the convenience of working with a single supplier,<br />

we can design <strong>and</strong> fabricate lances for any of our nozzles. Lances are<br />

available in different lengths for optimal positioning within the tank.<br />

For example, nozzles can be positioned so that the spray impacts<br />

directly on the heavily soiled areas or skim lines.<br />

Cus<strong>to</strong>m Options<br />

• Nozzle<br />

• Flange Type<br />

• Pipe Fitting/Connec<strong>to</strong>r<br />

See page 48 for additional information on lances.<br />

• Pipe/Tube Size<br />

• Lance Length Above <strong>and</strong> Below<br />

• Material<br />

Lance with<br />

6353 <strong>Tank</strong> Wash<br />

Nozzle <strong>and</strong> Raised<br />

Face Flange<br />

Lance with<br />

28500R <strong>Tank</strong><br />

Wash Nozzle <strong>and</strong><br />

Tri-Clover Flange<br />

Other Helpful Resources<br />

We have an extensive library of bulletins <strong>and</strong> technical manuals available that may be of interest <strong>to</strong> you.<br />

Please call 1-800-95-SPRAY or visit www.spray.com <strong>to</strong> request additional literature.<br />

<strong>Tank</strong> Wash<br />

Technical Paper<br />

Bulletin No. 526<br />

Provides useful<br />

guidelines on<br />

evaluating your plant’s specific<br />

cleaning needs <strong>and</strong> selecting the<br />

most effective au<strong>to</strong>mated tank<br />

wash system for your application.<br />

<strong>Tank</strong> Wash<br />

Application<br />

Center<br />

www.spray.com<br />

Our <strong>Tank</strong> Wash Center is<br />

your online resource for safe<br />

<strong>and</strong> effective tank cleaning.<br />

Visit www.spray.com/cleantanks for<br />

access <strong>to</strong> our free savings calcula<strong>to</strong>r.<br />

Liquid Strainers<br />

Catalog 35<br />

Protect nozzles,<br />

valves <strong>and</strong> pumps<br />

from damaging<br />

debris with a liquid strainer.<br />

Our catalog provides specifications,<br />

mesh <strong>and</strong> cleaning information <strong>to</strong> help<br />

you select the appropriate strainer.<br />

8 1.800.95.SPRAY | Intl. 1.630.665.5000 | www.spray.com