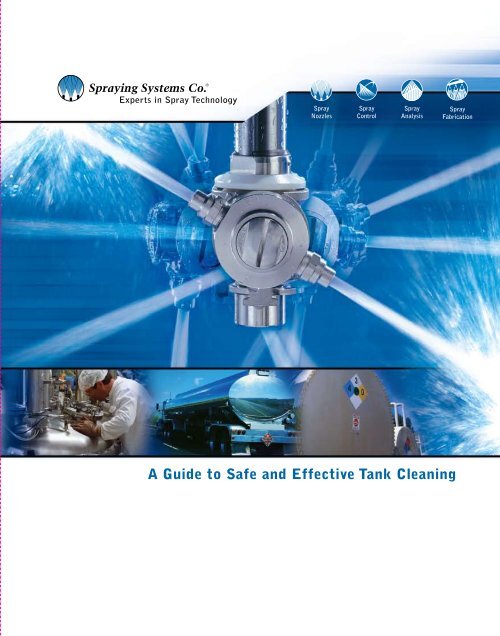

A Guide to Safe and Effective Tank Cleaning

A Guide to Safe and Effective Tank Cleaning

A Guide to Safe and Effective Tank Cleaning

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Spray<br />

Nozzles<br />

Spray<br />

Control<br />

Spray<br />

Analysis<br />

Spray<br />

Fabrication<br />

A <strong>Guide</strong> <strong>to</strong> <strong>Safe</strong> <strong>and</strong> <strong>Effective</strong> <strong>Tank</strong> <strong>Cleaning</strong>

Model Type<br />

Max. <strong>Tank</strong><br />

Diameter<br />

Flow Rate<br />

Range<br />

Pressure<br />

Range<br />

Spray<br />

Pattern<br />

Spray<br />

Coverage<br />

Mo<strong>to</strong>r Driven<br />

AA290AG<br />

AA290EP<br />

80 ft<br />

24.4 m<br />

22 - 200 gpm<br />

85 - 752 l/min<br />

50 - 250 psi<br />

3.5 - 17 bar<br />

Solid Stream<br />

AA190AGH<br />

20 - 34 ft<br />

6.0 - 10.4 m<br />

7 - 20 gpm<br />

26 - 78 l/min<br />

500 - 1000 psi<br />

35 - 70 bar<br />

Solid Stream<br />

AA190AG<br />

AA190E<br />

AA190EP<br />

AA090AG<br />

AA090E<br />

AA090EP<br />

12 - 25 ft<br />

3.7 - 7.6 m<br />

8.0 ft<br />

2.4 m<br />

Fluid Driven — Reactionary Force<br />

3.1 - 44 gpm<br />

11.8 - 170 l/min<br />

1.5 - 7.3 gpm<br />

5.7 - 28 l/min<br />

100 - 500 psi<br />

7 - 35 bar<br />

100 - 500 psi<br />

7 - 35 bar<br />

Solid Stream<br />

Solid Stream<br />

27500<br />

27500R<br />

10 - 25 ft<br />

3.0 - 7.6 m<br />

4 - 391 gpm<br />

15.3 - 1490 l/min<br />

10 - 50 psi<br />

.7 - 3.5 bar<br />

Solid Stream<br />

28500<br />

28500R<br />

18 ft<br />

5.5 m<br />

9 - 100.6 gpm<br />

34 - 384 l/min<br />

10 - 50 psi<br />

.7 - 3.5 bar<br />

Solid Stream<br />

18250A<br />

8.0 ft<br />

2.4 m<br />

10.5 - 55 gpm<br />

48 - 205 l/min<br />

10 - 60 psi<br />

1 - 4 bar<br />

Flat Fan<br />

21400A<br />

5.0 ft<br />

1.5 m<br />

5 - 22 gpm<br />

23 - 82 l/min<br />

10 - 60 psi<br />

1 - 4 bar<br />

Flat Fan<br />

30473<br />

8.0 ft<br />

2.4 m<br />

2.1 - 4.5 gpm<br />

7.8 - 18 l/min<br />

10 - 50 psi<br />

0.7 - 4 bar<br />

Flat Fan<br />

D41892<br />

6.5 ft<br />

2.0 m<br />

4.0 - 7.5 gpm<br />

15.9 - 29 l/min<br />

20 - 70 psi<br />

2 - 5 bar<br />

Flat Fan<br />

36640<br />

3.0 ft<br />

0.9 m<br />

.8 - 2.2 gpm<br />

3.4 - 7.9 l/min<br />

10 - 60 psi<br />

1 - 4 bar<br />

Flat Fan<br />

23240<br />

3.0 ft<br />

0.9 m<br />

3.5 - 22 gpm<br />

14 - 79 l/min<br />

Fluid Driven — Constant Speed Rokon<br />

20 - 200 psi<br />

1.5 - 12 bar<br />

Flat Fan<br />

D26984-SS. 316SS<br />

D26984-PVDF<br />

20 ft<br />

6.0 m<br />

3.2 - 31 gpm<br />

12 - 128 l/min<br />

30 - 230 psi<br />

2 - 16 bar<br />

Flat Fan<br />

D40159-SS, 316SS<br />

D40159-PVDF<br />

D40159-316SS<br />

20 ft<br />

6.0 m<br />

3.2 - 31 gpm<br />

12 - 128 l/min<br />

30 - 230 psi<br />

2 - 16 bar<br />

Flat Fan<br />

D41800E<br />

12 ft<br />

3.7 m<br />

2.7 - 34 gpm<br />

12 - 128 l/min<br />

29 - 230 psi<br />

2 - 16 bar<br />

Flat Fan<br />

Fixed Stationary<br />

12900<br />

22 ft<br />

6.7 m<br />

72 - 385 gpm<br />

280 - 1470 l/min<br />

20 - 50 psi<br />

1.5 - 3.5 bar<br />

Full Cone<br />

6353<br />

6353-MFP<br />

10 ft<br />

3.0 m<br />

8.9 - 80 gpm<br />

35 - 301 l/min<br />

20 - 50 psi<br />

1.5 - 3.5 bar<br />

Full Cone<br />

63225<br />

18 ft<br />

5.5 m<br />

22 - 141 gpm<br />

83 - 534 l/min<br />

15 - 30 psi<br />

1 - 2 bar<br />

Solid Stream<br />

VSM<br />

5.0 ft<br />

1.6 m<br />

2.7 - 72 gpm<br />

10.4 - 269 l/min<br />

10 - 150 psi<br />

0.7 - 10 bar<br />

Solid Stream<br />

3150<br />

3.0 ft<br />

0.9 m<br />

5.2 - 26 gpm<br />

23 - 91 l/min<br />

10 - 150 psi<br />

1 - 10 bar<br />

Full Cone<br />

15498<br />

2.0 ft<br />

0.6 m<br />

5.5 - 11.7 gpm<br />

23 - 43 l/min<br />

60 - 150 psi<br />

5 - 10 bar<br />

Full Cone<br />

2 1.800.95.SPRAY | Intl. 1.630.665.5000 | www.spray.com

Min. <strong>Tank</strong><br />

Opening Size<br />

Inlet<br />

Connection<br />

Max. Temp.<br />

Materials of<br />

Wetted Parts<br />

Page No.<br />

Mo<strong>to</strong>r Driven<br />

Table of Contents<br />

7.25", 8.25"<br />

84 , 210 mm<br />

2"<br />

200° F<br />

93° C<br />

316SS<br />

PTFE<br />

10-12<br />

Pages<br />

3.75"<br />

95 mm<br />

1"<br />

200° F<br />

93° C<br />

316SS<br />

PTFE<br />

13-19<br />

Quick Reference <strong>Guide</strong>........... 2-3<br />

3.75"<br />

95 mm<br />

1"<br />

200° F<br />

93° C<br />

316SS<br />

PTFE<br />

13-19<br />

Benefits of<br />

2.3"<br />

59 mm<br />

1"<br />

200° F<br />

93° C<br />

316SS<br />

PTFE<br />

20-21<br />

Au<strong>to</strong>mated <strong>Tank</strong> <strong>Cleaning</strong>....... 4-5<br />

Fluid Driven — Reactionary Force<br />

51 - 178 mm<br />

2.5" - 4"<br />

64 - 102 mm<br />

1/2", 3/4"<br />

1", 2", 3"<br />

3/4", 1", 1-1/2",<br />

DN20, DN25, DN40<br />

200° F<br />

93° C<br />

200° F<br />

93° C<br />

PTFE,<br />

Carbon-filled PTFE<br />

22-23<br />

PTFE 24-25<br />

Which <strong>Tank</strong> <strong>Cleaning</strong><br />

Solution is Right for<br />

Your Application.................... 6-9<br />

2-7/32"<br />

60 mm<br />

2-1/4"<br />

60 mm<br />

3/4"<br />

3/4"<br />

350° F<br />

177° C<br />

350° F<br />

177° C<br />

316SS,<br />

PTFE<br />

316SS,<br />

PTFE<br />

26-27<br />

26-28<br />

Mo<strong>to</strong>r Driven<br />

<strong>Tank</strong> Washers......................... 10-21<br />

1"<br />

25 mm<br />

1-1/2"<br />

37 mm<br />

1-1/32"<br />

26 mm<br />

1-1/32"<br />

26 mm<br />

1/4"<br />

3/8", 1/2"<br />

1/4"<br />

1/2"<br />

200° F<br />

93° C<br />

160° F<br />

70° C<br />

200° F<br />

93° C<br />

350° F<br />

177° C<br />

Fluid Driven — Constant Speed Rokon<br />

2-1/4"<br />

56 mm<br />

3/8", 1/2"<br />

160° F<br />

70° C<br />

PTFE 29<br />

POM-DELRIN ® 30<br />

316SS, HSS,<br />

PTFE<br />

316SS,<br />

PTFE<br />

303SS, 316SS<br />

PVDF, PE<br />

31<br />

32-33<br />

34-35<br />

Fluid Driven<br />

<strong>Tank</strong> Washing Nozzles<br />

Reactionary Force.............. 22-33<br />

Constant Speed................... 34-37<br />

Fixed<br />

<strong>Tank</strong> Washing Nozzles.......... 38-46<br />

2-1/4"<br />

56 mm<br />

3/8", 1/2"<br />

160° F<br />

70° C<br />

303SS, 316SS<br />

PVDF, PE<br />

34-35<br />

Au<strong>to</strong>Jet ®<br />

1-1/4"<br />

32 mm<br />

3/8",<br />

DN19<br />

302° F<br />

150° C<br />

303SS<br />

316LSS<br />

36-37<br />

<strong>Tank</strong> <strong>Cleaning</strong> Systems........... 47<br />

Fixed Stationary<br />

10"<br />

254 mm<br />

3"<br />

212° F<br />

100° C<br />

BRASS,<br />

316SS<br />

38-39<br />

Lances....................................... 48<br />

6"<br />

152 mm<br />

1-1/2"<br />

212° F<br />

100° C<br />

BRASS, 303SS,<br />

316SS<br />

38-41<br />

Strainer <strong>and</strong><br />

3.4", 3.9", 4.6"<br />

87, 100, 118 mm<br />

3/4", 1", 2"<br />

400° F<br />

204° C<br />

316L 42-43<br />

Mesh Information.....................49<br />

2"<br />

51 mm<br />

1/2", 3/4"<br />

200° F<br />

93° C<br />

NYLON 44<br />

New Product Overview............50<br />

2"<br />

51 mm<br />

1"<br />

212° F<br />

100° C<br />

BRASS, 303SS,<br />

316SS<br />

45<br />

2"<br />

51 mm<br />

1"<br />

212° F<br />

100° C<br />

BRASS, 303SS,<br />

316SS<br />

46<br />

1.800.95.SPRAY | Intl. 1.630.665.5000 | www.spray.com<br />

3

The Benefits of<br />

Au<strong>to</strong>mated <strong>Tank</strong> <strong>Cleaning</strong><br />

The primary objective of any tank cleaning application is <strong>to</strong> clean, maintain,<br />

<strong>and</strong> sanitize equipment at appropriate levels <strong>to</strong> prevent malfunctions or<br />

contamination that would alter the safety, identity, strength, quality<br />

or purity of the finished product.<br />

<strong>Tank</strong> cleaning can be a manual or au<strong>to</strong>mated process, however,<br />

manually cleaning the inside of tanks can be unproductive,<br />

unreliable <strong>and</strong> unsafe. Au<strong>to</strong>mated tank cleaning:<br />

• Ensures process integrity <strong>to</strong> meet regula<strong>to</strong>ry compliance<br />

• Keeps workers safely away from hazardous chemicals<br />

• Reduces cleaning cycle times <strong>and</strong> minimizes<br />

production downtime<br />

• Significantly reduces labor, water, chemical<br />

<strong>and</strong> wastewater disposal costs<br />

Au<strong>to</strong>mated tank cleaning is a process improvement that pays<br />

for itself quickly <strong>and</strong> getting started is easy when you have an<br />

experienced partner. Whether your tanks require a light rinse<br />

or high-impact wash, Spraying Systems Co. has the spray<br />

technology <strong>and</strong> the expertise <strong>to</strong> increase the efficiency<br />

of your cleaning application.<br />

Getting Started — Three Steps <strong>to</strong> Au<strong>to</strong>mation<br />

1<br />

Select<br />

the right<br />

tank cleaning nozzle<br />

2<br />

Ensure<br />

efficient delivery<br />

(<strong>Tank</strong> Wash Lance & Strainers)<br />

3<br />

Integrate<br />

all system<br />

components for<br />

optimal performance<br />

4 1.800.95.SPRAY | Intl. 1.630.665.5000 | www.spray.com

Evaluate your current<br />

tank cleaning operation<br />

If you’re cleaning your tanks manually or using a fill <strong>and</strong><br />

drain method, you may be able <strong>to</strong> reduce your production<br />

downtime <strong>and</strong> labor costs up <strong>to</strong> 90%. Some of our cus<strong>to</strong>mers<br />

save as much as $50,000 a year per tank by switching <strong>to</strong><br />

au<strong>to</strong>mated cleaning. Studies show that most costs are<br />

associated with production downtime <strong>and</strong> labor. There will<br />

be added savings from water, chemical <strong>and</strong> wastewater<br />

disposal costs.<br />

Estimated Au<strong>to</strong>mated <strong>Tank</strong> <strong>Cleaning</strong> Savings<br />

Annual<br />

Costs<br />

Manual Scrub/<br />

Washdown<br />

Fill &<br />

Drain<br />

Au<strong>to</strong>mated<br />

System<br />

Production<br />

downtime<br />

cost *<br />

$50,000<br />

$25,000<br />

$10,000<br />

Labor cost †<br />

$12,000<br />

$6,250<br />

$1,250<br />

Total cost 1<br />

$62,500<br />

$31,250<br />

$11,250<br />

* Downtime estimated at $100/hour † Labor estimated at $25/hour<br />

1 Based on an average of 250 washes/year of a 1500 gallon (5600 liters) tank.<br />

Save up <strong>to</strong> 82%<br />

with an au<strong>to</strong>mated tank wash system<br />

80% less in production downtime<br />

90% less in labor costs<br />

Savings Calcula<strong>to</strong>r Check List<br />

<strong>Tank</strong> size in diameter or gallons<br />

Number of tanks<br />

Production downtime per tank in hours<br />

Cost of production downtime per tank per hour<br />

Time for manual labor per tank in hours<br />

Labor cost per hour<br />

Washes per year per tank<br />

Estimated<br />

Annual Savings....................US $51,250<br />

It only takes a few minutes <strong>to</strong> find out if you’re a good<br />

c<strong>and</strong>idate for au<strong>to</strong>mation. Simply go <strong>to</strong> our online savings<br />

calcula<strong>to</strong>r at www.spray.com/cleantanks<br />

<strong>and</strong> provide some information about your current operation.<br />

Your potential savings will be<br />

calculated instantly online.<br />

When using the online savings calcula<strong>to</strong>r,<br />

you will need <strong>to</strong> know this check list information.<br />

1.800.95.SPRAY | Intl. 1.630.665.5000 | www.spray.com<br />

5

Step 1<br />

Select the right<br />

tank cleaning nozzle<br />

Evaluating these fac<strong>to</strong>rs will help you select the best au<strong>to</strong>mated<br />

tank cleaning nozzle <strong>to</strong> meet your cleaning objectives.<br />

Assess the residue <strong>to</strong> be cleaned<br />

Is the substance sticky or easily cleaned Can it be<br />

dissolved by the cleaning liquid What is the level of<br />

impact required <strong>to</strong> dissolve it <strong>and</strong> wash it away<br />

Determine the level of cleaning required<br />

Rinsing: Majority of residue is loosened <strong>and</strong><br />

removed with water<br />

<strong>Cleaning</strong>: Remaining residue is loosened<br />

<strong>and</strong> removed with water <strong>and</strong> cleaning agent<br />

High Impact <strong>Cleaning</strong>: Utilizes the impact of the<br />

spray <strong>to</strong> break apart difficult <strong>and</strong> stubborn residues<br />

<strong>and</strong> wash them away<br />

Sanitizing: Chemical agent is applied <strong>to</strong> all surfaces<br />

<strong>to</strong> kill micro-organisms <strong>to</strong> an acceptable level<br />

Disinfecting: Kills most bacteria with the<br />

exception of spores<br />

Sterilizing: Eliminates all forms of life<br />

Identify your cleaning solution <strong>and</strong> the required<br />

temperature of the cleaning liquid<br />

Chemical additives are typically used <strong>to</strong> remove<br />

contaminants, improve tank wettability <strong>and</strong><br />

reduce droplet formation. Heat can<br />

improve the cleaning action of many<br />

water-based detergent chemicals.<br />

Evaluate the size of your<br />

tank <strong>and</strong> the spray distance<br />

Spray distance is usually measured in<br />

terms of the tank diameter, however,<br />

it is important <strong>to</strong> consider the tank<br />

length <strong>and</strong> height. For example, if a<br />

tank is 20 ft. (6 m) in diameter <strong>and</strong><br />

40 ft. (12 m) long, use two tank<br />

washers that specify 20 ft. (6 m) or<br />

a single tank washer that can clean<br />

up <strong>to</strong> 40 ft (12 m).<br />

Determine the lowest possible flow rate<br />

required <strong>to</strong> achieve your cleaning objectives<br />

The lower the flow, the less liquid required, less effluent<br />

for disposal <strong>and</strong> less energy consumed. A general guideline<br />

is <strong>to</strong> work with a minimum of 0.2 gal/min/ft 2 (7 l/min/m 2 ).<br />

A more moderate recommendation is 0.4 gal/min/ft 2<br />

(15 l/min/m 2 ). This guideline generally applies <strong>to</strong> stationary<br />

nozzles where all the surfaces of the tank are sprayed at<br />

the same time. Nozzles that rotate usually contact part of<br />

the tank at one time, thus less flow rate is needed.<br />

Determine the level of spray impact required<br />

Hard-<strong>to</strong>-clean residues require a higher level of impact<br />

than residues that are easily rinsed. It is difficult <strong>to</strong><br />

determine the exact impact value of each tank wash nozzle.<br />

However, a general rule of thumb can help you increase<br />

the level of impact when determining the optimum cleaning<br />

requirements for your application. Increasing flow rate is<br />

more effective than increasing pressure. As the chart<br />

below shows, doubling the flow rate increases impact as<br />

much as 100%, while doubling pressure provides only<br />

40% more impact.<br />

Flow Rate Pressure Relative Impact<br />

13 gpm (50 l/min) 45 psi (3 bar) 1.0<br />

13 gpm (50 l/min) 90 psi (6 bar) 1.4<br />

26 gpm (100 l/min) 45 psi (3 bar) 2.0<br />

Impact values are based on theoretical <strong>to</strong>tal impact formula:<br />

Impact = .0526 x flow rate x √pressure<br />

6 1.800.95.SPRAY | Intl. 1.630.665.5000 | www.spray.com

Identify the best spray pattern for<br />

your level of cleaning<br />

Solid stream sprays provide the greatest impact, followed<br />

by flat fan <strong>and</strong> full cone sprays. Typically, fixed spray<br />

nozzles with full cone sprays are used for gentle rinsing<br />

<strong>and</strong> washing. Fluid driven nozzles with flat fan sprays<br />

offer more impact <strong>and</strong> are commonly used for cleaning.<br />

High-pressure, mo<strong>to</strong>r driven <strong>and</strong> turbine driven nozzles<br />

use solid streams for maximum impact.<br />

Evaluate your tank design <strong>to</strong> identify<br />

spray coverage <strong>and</strong> obstructions<br />

<strong>Cleaning</strong> coverage provided by various spray angles ranges<br />

from 65 <strong>to</strong> 360 degrees. Multiple nozzles may be required if<br />

a spray cannot reach a part of the tank due <strong>to</strong> internal<br />

obstructions such as a mixer or agita<strong>to</strong>r.<br />

Types of <strong>Tank</strong> <strong>Cleaning</strong> Nozzles<br />

High-pressure (mo<strong>to</strong>r driven)<br />

Two <strong>to</strong> four nozzles rotate on a<br />

mo<strong>to</strong>r driven gear hub<br />

• Solid stream, high impact nozzles<br />

clean stubborn residue<br />

• High impact reduces the water<br />

required for effective cleaning<br />

• Lightweight, portable<br />

• Recommended for cleaning<br />

medium <strong>to</strong> large tanks<br />

• Liquid pressure <strong>and</strong> rotational speeds<br />

are independently controlled<br />

Fluid driven (reactionary force)<br />

Rotational velocity increases as pressure increases<br />

• Good impact <strong>and</strong> coverage, less fluid consumption<br />

• Wide variety of materials available<br />

• Sanitary design features<br />

• Recommended for rinsing<br />

<strong>and</strong> cleaning small tanks<br />

Fluid driven (constant speed)<br />

Rotates at constant speed as<br />

pressure fluctuates<br />

• Slow rotational speed improves<br />

impact <strong>and</strong> throw<br />

Determine the duration of the cleaning cycle<br />

Most cleaning cycles last from 10 <strong>to</strong> 30 minutes <strong>and</strong><br />

include three <strong>to</strong> four stages: pre-rinse, which should<br />

remove 90% of the soil; cleaning; post-rinse <strong>and</strong> sanitizing.<br />

• Low liquid consumption<br />

• Recommended for cleaning<br />

<strong>and</strong> sanitizing small tanks<br />

Select a nozzle material <strong>and</strong> connection type<br />

appropriate for your application<br />

For most applications, stainless steel nozzles are<br />

used for their durability <strong>and</strong> ability <strong>to</strong> withst<strong>and</strong> high<br />

temperatures. For corrosive applications, nozzles made<br />

of polytetrafluoroethylene (PTFE) or polyvinylidene fluoride<br />

(PVDF) are preferred. For sanitary applications, st<strong>and</strong>ards<br />

may require special consideration for nozzle design,<br />

mounting specifications <strong>and</strong> materials of construction.<br />

Fixed (stationary)<br />

Multiple orifice assemblies stay<br />

in position while spraying<br />

• Simple design, no moving parts<br />

• Wide range of spray coverage<br />

• No mounting limitations<br />

• Recommended for rinsing small tanks<br />

1.800.95.SPRAY | Intl. 1.630.665.5000 | www.spray.com<br />

7

Step 2<br />

Ensure efficient delivery <strong>to</strong> the nozzle<br />

Line Strainers<br />

Line strainers are another critical component of your au<strong>to</strong>mated system.<br />

Particulates in the liquid can clog nozzles or s<strong>to</strong>p their rotation, which<br />

results in insufficient cleaning <strong>and</strong> potential product contamination.<br />

Filtering the liquid with line strainers prevents clogging <strong>and</strong> also extends<br />

the wear life of downstream equipment including nozzles <strong>and</strong> pumps.<br />

For fine straining, woven wire mesh screens provide very small openings<br />

<strong>to</strong> strain particulates down <strong>to</strong> 200 mesh (74 microns). The mesh screen<br />

should be made of stainless steel for strength <strong>and</strong> corrosion resistance.<br />

The screen is critical <strong>to</strong> the operation of the strainer, <strong>and</strong> an extra screen<br />

should be kept on h<strong>and</strong> for each strainer installed.<br />

See page 49 for strainer <strong>and</strong> mesh recommendations.<br />

<strong>Tank</strong> Wash Lances<br />

Model TW<br />

Strainer<br />

8310A<br />

Strainer<br />

Lances are more than just an installation component — they ensure<br />

efficient delivery of the liquid <strong>to</strong> the nozzle. For trouble-free system<br />

performance <strong>and</strong> the convenience of working with a single supplier,<br />

we can design <strong>and</strong> fabricate lances for any of our nozzles. Lances are<br />

available in different lengths for optimal positioning within the tank.<br />

For example, nozzles can be positioned so that the spray impacts<br />

directly on the heavily soiled areas or skim lines.<br />

Cus<strong>to</strong>m Options<br />

• Nozzle<br />

• Flange Type<br />

• Pipe Fitting/Connec<strong>to</strong>r<br />

See page 48 for additional information on lances.<br />

• Pipe/Tube Size<br />

• Lance Length Above <strong>and</strong> Below<br />

• Material<br />

Lance with<br />

6353 <strong>Tank</strong> Wash<br />

Nozzle <strong>and</strong> Raised<br />

Face Flange<br />

Lance with<br />

28500R <strong>Tank</strong><br />

Wash Nozzle <strong>and</strong><br />

Tri-Clover Flange<br />

Other Helpful Resources<br />

We have an extensive library of bulletins <strong>and</strong> technical manuals available that may be of interest <strong>to</strong> you.<br />

Please call 1-800-95-SPRAY or visit www.spray.com <strong>to</strong> request additional literature.<br />

<strong>Tank</strong> Wash<br />

Technical Paper<br />

Bulletin No. 526<br />

Provides useful<br />

guidelines on<br />

evaluating your plant’s specific<br />

cleaning needs <strong>and</strong> selecting the<br />

most effective au<strong>to</strong>mated tank<br />

wash system for your application.<br />

<strong>Tank</strong> Wash<br />

Application<br />

Center<br />

www.spray.com<br />

Our <strong>Tank</strong> Wash Center is<br />

your online resource for safe<br />

<strong>and</strong> effective tank cleaning.<br />

Visit www.spray.com/cleantanks for<br />

access <strong>to</strong> our free savings calcula<strong>to</strong>r.<br />

Liquid Strainers<br />

Catalog 35<br />

Protect nozzles,<br />

valves <strong>and</strong> pumps<br />

from damaging<br />

debris with a liquid strainer.<br />

Our catalog provides specifications,<br />

mesh <strong>and</strong> cleaning information <strong>to</strong> help<br />

you select the appropriate strainer.<br />

8 1.800.95.SPRAY | Intl. 1.630.665.5000 | www.spray.com

Step 3<br />

Integrate all system components<br />

Even the best tank cleaning nozzle can only perform effectively when all components — including nozzles,<br />

pumps, mo<strong>to</strong>rs, valves <strong>and</strong> strainers — are carefully integrated in<strong>to</strong> an efficient system.<br />

In addition <strong>to</strong> our broad line of tank cleaning nozzles, Spraying Systems Co. engineers complete<br />

<strong>Tank</strong> <strong>Cleaning</strong> Systems, cus<strong>to</strong>m lances, line strainers <strong>and</strong> other accessories.<br />

Our sales engineers have helped solve hundreds of application problems — from clean-in-place<br />

systems for milk filling machines <strong>to</strong> washing heavily-soiled mixing vats at an au<strong>to</strong>motive manufacturer.<br />

With sales offices located throughout the world, an au<strong>to</strong>mated solution <strong>to</strong> your tank cleaning<br />

operation is easily available.<br />

Au<strong>to</strong>Jet ® <strong>Tank</strong> <strong>Cleaning</strong> Systems<br />

Au<strong>to</strong>Jet <strong>Tank</strong> <strong>Cleaning</strong> Systems include pump/mo<strong>to</strong>r<br />

sets sized for best performance, inlet/outlet valves<br />

with pressure gauges <strong>and</strong> inlet strainers. Cycle timing<br />

control <strong>and</strong> chemical injection are optional features<br />

that enhance cleaning efficiency, effectiveness<br />

<strong>and</strong> consistency. The systems are easy<br />

<strong>to</strong> install, operate <strong>and</strong> maintain.<br />

See page 47 for complete<br />

features <strong>and</strong> specifications.<br />

From<br />

Industrial Spray<br />

Products Catalog<br />

Catalog 70<br />

Our full-productline<br />

catalog is the<br />

industry’s most comprehensive<br />

resource for spray nozzles<br />

<strong>and</strong> accessories.<br />

Application<br />

Drawings<br />

Detailed examples of<br />

successful tank wash installations.<br />

Contact your local sales representative<br />

for additional information.<br />

Optimizing System<br />

Performance<br />

with Precision<br />

Spray Control<br />

Bulletin No. AT103B<br />

Provides an overview of the<br />

benefits of au<strong>to</strong>mated spray systems.<br />

Application examples show how <strong>to</strong><br />

reduce overspray, improve product<br />

quality, increase throughput <strong>and</strong><br />

improve regula<strong>to</strong>ry compliance.<br />

1.800.95.SPRAY | Intl. 1.630.665.5000 | www.spray.com<br />

9

Mo<strong>to</strong>r Driven<br />

<strong>Tank</strong> Washers 80'<br />

(24.4 m)<br />

Max. <strong>Tank</strong> Diameter<br />

Mo<strong>to</strong>r Driven<br />

<strong>Tank</strong> Washers<br />

Features <strong>and</strong> Benefits<br />

• Versatile cleaning of large tanks, vats <strong>and</strong> vessels<br />

up <strong>to</strong> 80' (24.4 m) in diameter<br />

• Choose either air (AG) or explosion-proof (EP)<br />

electric mo<strong>to</strong>rs<br />

• Mo<strong>to</strong>r positioned outside of tank for longer life <strong>and</strong> fewer<br />

failures due <strong>to</strong> exposure <strong>to</strong> harmful cleaning solutions<br />

• Easily cus<strong>to</strong>mized <strong>to</strong> meet unique requirements –<br />

change flow rates through nozzle selection or<br />

adjustments <strong>to</strong> inlet pressure<br />

• Long-life construction features corrosion-resistant<br />

316SS <strong>and</strong> PTFE fluoropolymer resin seals<br />

• Choice of two or four nozzle hub<br />

• Easily mounted – choose from 3', 4' or 6' (.9, 1.2 or 1.8 m)<br />

shaft lengths<br />

• Optimum impact provided by 55430 series solid stream<br />

nozzles: nozzles feature stabilizer vanes that can be<br />

removed for maintenance purposes<br />

AA290EP<br />

Explosion Proof<br />

Mo<strong>to</strong>r (EP)<br />

10" Flange comes<br />

st<strong>and</strong>ard with<br />

4-nozzle hub<br />

Air Mo<strong>to</strong>r (AG)<br />

8" Flange comes<br />

st<strong>and</strong>ard with<br />

2-nozzle hub<br />

Specifications<br />

Max. tank dia.: 80' (24.4 m)<br />

Flow rate range:<br />

Pressure range:<br />

Max.<br />

operating temp.:<br />

22 <strong>to</strong> 400 gpm (85 <strong>to</strong> 1504 l/min)<br />

50 <strong>to</strong> 250 psi (3.5 <strong>to</strong> 17 bar)<br />

200°F (93°C)<br />

AA290AG<br />

2- or 4-nozzle hub<br />

Min. tank<br />

opening size:<br />

Spray coverage: 360°<br />

Inlet connection:<br />

Flanges:<br />

7.25" (184 mm) for two-nozzle hub<br />

8.25" (210 mm) for four-nozzle hub<br />

2" NPT or BSPT (F)<br />

8" (203 mm) flange for two-nozzle hub<br />

10" (254 mm) for four-nozzle hub<br />

Lubrica<strong>to</strong>r assembly is included with the air<br />

(AG) model only. Regular lubrication of the air<br />

supply line will significantly increase the life<br />

of the air mo<strong>to</strong>r.<br />

10 1.800.95.SPRAY | Intl. 1.630.665.5000 | www.spray.com

Mo<strong>to</strong>r Driven<br />

<strong>Tank</strong> Washers 80'<br />

(24.4 m)<br />

Max. <strong>Tank</strong> Diameter<br />

Performance Data<br />

Total Flow of Two Nozzles (Equal Capacity) gpm or l/min Liquid Inlet Pressure*<br />

(Double flow rates when using four nozzles.)<br />

Nozzle No. 50 psi (3.5 bar) 100 psi (7 bar) 150 psi (10 bar) 200 psi (15 bar) 250 psi (17 bar)<br />

55430-H3/4U-00100 22 (85) 32 (121) 39 (144) 45 (177) 50 (188)<br />

55430-H3/4U-00200 45 (171) 63 (241) 77 (288) 89 (353) 100 (376)<br />

55430-H3/4U-00250 56 (213) 79 (301) 97 (360) 112 (441) 125 (470)<br />

55430-H3/4U-00350 78 (298) 111 (422) 136 (505) 157 (618) 175 (658)<br />

55430-H3/4U-00400 89 (341) 126 (482) 155 (577) 179 (706) 200 (752)<br />

*Note: Liquid inlet pressure measured near inlet connection of tank washing machine.<br />

Cycle Time Data –<br />

Air Mo<strong>to</strong>r (AG)<br />

Dimensions <strong>and</strong> Weights –<br />

Air Mo<strong>to</strong>r (AG)<br />

Air<br />

Pressure<br />

psi (bar)<br />

Air<br />

Consumption<br />

scfm (l/sec)<br />

Approx. Speed<br />

(rpm)<br />

50 psi<br />

(3.4 bar)<br />

250 psi<br />

(17.2 bar)<br />

Approx. Time<br />

for One Complete<br />

Cycle (min.)<br />

50 psi<br />

(3.4 bar)<br />

250 psi<br />

(17.2 bar)<br />

Model No.<br />

Extension<br />

Length<br />

AA290AG_F3 3' (0.9 m)<br />

Overall<br />

Length<br />

60-7/8"<br />

(1.5 m)<br />

Weight<br />

with 8"<br />

Flange<br />

56 lbs<br />

(25.5 kg)<br />

Weight<br />

with 10"<br />

Flange<br />

63 lbs<br />

(28.7 kg)<br />

12 (0.83) 4.7 (2.2) 6 2 11 32<br />

14 (0.97) 5.4 (2.5) 8 4 7 17<br />

16 (1.10) 6.3 (3.0) 10 8 6 8<br />

18 (1.24) 7.1 (3.4) – 9 – 7<br />

AA290AG_F4 4' (1.2 m)<br />

AA290AG_F6 6' (1.8 m)<br />

72-7/8"<br />

(1.8 m)<br />

96-7/8"<br />

(2.5 m)<br />

60 lbs<br />

(27.3 kg)<br />

69 lbs<br />

(31.4 kg)<br />

67 lbs<br />

(30.5 kg)<br />

76 lbs<br />

(34.6 kg)<br />

Cycle Time Data –<br />

Explosion-Proof Mo<strong>to</strong>r (EP)<br />

Dimensions <strong>and</strong> Weights –<br />

Explosion-Proof Mo<strong>to</strong>r (EP)<br />

Approx.<br />

Speed (rpm)<br />

4<br />

Supply<br />

120 VAC<br />

60 Hz<br />

Approx. Time for One<br />

Complete Cycle (min.)<br />

16<br />

Model No.<br />

AA290E_F-EP3<br />

Extension<br />

Length<br />

3'<br />

(0.9 m)<br />

Overall<br />

Length<br />

61-3/4"<br />

(1.6 m)<br />

Weight<br />

with 8"<br />

Flange<br />

66 lbs<br />

(30.1 kg)<br />

Weight<br />

with 10"<br />

Flange<br />

73 lbs<br />

(33.2 kg)<br />

AA290E_F-EP4<br />

4'<br />

(1.2 m)<br />

73-3/4"<br />

(1.8 m)<br />

70 lbs<br />

(31.9 kg)<br />

77 lbs<br />

(35.0 kg)<br />

AA290E_F-EP6<br />

6'<br />

(1.8 m)<br />

97-3/4"<br />

(2.5 m)<br />

79 lbs<br />

(36.0 kg)<br />

86 lbs<br />

(39.1 kg)<br />

Spray Head <strong>Tank</strong> Diameter<br />

Opening with Two Nozzles<br />

7.25" (184 mm)<br />

Opening<br />

1.6"<br />

(40 mm)<br />

Spray Head <strong>Tank</strong> Diameter<br />

Opening with Four Nozzles<br />

8.25" (210 mm)<br />

Opening<br />

1.96"<br />

(50 mm)<br />

Typical Applications<br />

• Mixing Batch Process <strong>Tank</strong>s<br />

The AA290AG <strong>Tank</strong> Washer adds<br />

liquid <strong>to</strong> a batch in a reac<strong>to</strong>r vessel<br />

<strong>and</strong> then rinses the vessel when the<br />

reaction is finished<br />

• Paint <strong>Tank</strong> <strong>Cleaning</strong><br />

• Fermentation <strong>Tank</strong> <strong>Cleaning</strong><br />

• <strong>Cleaning</strong> Flour Silos<br />

1.800.95.SPRAY | Intl. 1.630.665.5000 | www.spray.com<br />

11

Mo<strong>to</strong>r Driven<br />

<strong>Tank</strong> Washers 80'<br />

(24.4 m)<br />

Max. <strong>Tank</strong> Diameter<br />

Accessories<br />

Strainers<br />

To prevent clogging, we recommend using a 100<br />

minimum mesh with one of our heavy-duty strainers.<br />

See page 49 for specific strainer recommendations.<br />

Flange Specifications<br />

Flange<br />

Size<br />

Flange<br />

O.D.<br />

Bolt<br />

Circle<br />

Diameter<br />

No. of<br />

Flange<br />

Holes<br />

Bolt Hole<br />

Diameter<br />

Thickness<br />

8" flange 13.5" 11.75" 8 0.875" 3/8"<br />

10" flange 16" 14.25" 12 1.00" 3/8"<br />

Request Catalog 35<br />

for more information on our complete line of strainers.<br />

O.D.<br />

Bolt Hole<br />

Dia.<br />

O.D.<br />

Bolt Hole<br />

Dia.<br />

Spray Coverage<br />

Type of<br />

Coverage<br />

360°<br />

Bolt<br />

Circle<br />

Dia.<br />

Bolt<br />

Circle<br />

Dia.<br />

8" flange 10" flange<br />

Ordering Information<br />

AA290AG<br />

<strong>Tank</strong> Washer<br />

Nozzle No.<br />

AA290AG 8F – 3 – 2 + 55430-H 3/4 U – 316SS – 00100<br />

I I I I I I I I I<br />

<strong>Tank</strong><br />

Washer<br />

Type<br />

8"<br />

Flange<br />

Extension<br />

Length<br />

2 Nozzle<br />

Hub<br />

Option<br />

Nozzle<br />

Type<br />

Prefix<br />

Nozzle<br />

Inlet<br />

Conn.<br />

Nozzle<br />

Type<br />

Material<br />

Code<br />

Capacity<br />

Size<br />

AA290E-EP<br />

<strong>Tank</strong> Washer<br />

Nozzle No.<br />

AA290E 10F – EP – 3 – 4 + 55430-H 3/4 U – 316SS – 00100<br />

I I I I I I I I I I<br />

<strong>Tank</strong><br />

Washer<br />

Type<br />

10"<br />

Flange<br />

Explosion-proof<br />

Mo<strong>to</strong>r<br />

Extension<br />

Length<br />

4 Nozzle<br />

Hub<br />

Option<br />

Nozzle<br />

Type<br />

Prefix<br />

Nozzle<br />

Inlet<br />

Conn.<br />

Nozzle<br />

Type<br />

Material<br />

Code<br />

Capacity<br />

Size<br />

12 1.800.95.SPRAY | Intl. 1.630.665.5000 | www.spray.com

Mo<strong>to</strong>r Driven<br />

<strong>Tank</strong> Washers 34'<br />

(10.4 m)<br />

Max. <strong>Tank</strong> Diameter<br />

Mo<strong>to</strong>r Driven<br />

<strong>Tank</strong> Washers<br />

Features <strong>and</strong> Benefits<br />

• Cleans medium <strong>to</strong> large tanks up <strong>to</strong> 34' (10.4 m)<br />

in diameter<br />

• Choose air (AG), high-pressure air (AGH), electric (E)<br />

or explosion-proof electric (EP) mo<strong>to</strong>rs<br />

• Select from St<strong>and</strong>ard Three-prong Mounting Flange, 150#<br />

Raised Face Flange or Sanitary Tri-Clamp Flange. See page<br />

16 for more information<br />

• Mo<strong>to</strong>r positioned outside of tank for longer life <strong>and</strong> fewer<br />

failures due <strong>to</strong> exposure <strong>to</strong> harmful cleaning solutions<br />

• Powerful cleaning performance with high-impact solid<br />

stream MEG spray nozzles<br />

• Reduces costs by using minimal liquid consumption<br />

• Lightweight <strong>and</strong> portable – allows for maximum use <strong>and</strong><br />

quick payback<br />

• Long-life construction features corrosion-resistant 316SS<br />

<strong>and</strong> PTFE fluoropolymer resin seals<br />

• Easily mounted – choose from 3', 4' or 6' (.9, 1.2 or 1.8 m)<br />

shaft lengths<br />

• Variable speed air mo<strong>to</strong>r means increased productivity<br />

through flexible wash cycle time<br />

• Thoroughly cleans all interior tank surfaces as the spray<br />

turret rotates in a spherical pattern<br />

AA190EP<br />

Spray Head <strong>Tank</strong> Diameter Opening<br />

with Two Nozzles<br />

3.75" (95 mm)<br />

Opening<br />

3.6" (85 mm)<br />

AA190AG<br />

Specifications<br />

Max. tank dia.: 34' (10.4 m)<br />

Flow rate range: 3.1 <strong>to</strong> 44 gpm (11.8 <strong>to</strong> 170 l/min)<br />

.85"<br />

(21 mm)<br />

1.3"<br />

(33 mm)<br />

3.0" (76 mm)<br />

Pressure range:<br />

Max. operating temp.:<br />

100 <strong>to</strong> 500 psi (7 <strong>to</strong> 35 bar)<br />

up <strong>to</strong> 1000 psi (70 bar) with<br />

AA190AGH<br />

200°F (93°C)<br />

Min. tank opening size: 3.75" (95 mm)<br />

Spray coverage: 360°<br />

Inlet connection:<br />

1" NPT or BSPT (F)<br />

Typical Applications<br />

• <strong>Cleaning</strong> Mixing <strong>Tank</strong>s<br />

• <strong>Cleaning</strong> Fermentation <strong>Tank</strong>s<br />

• <strong>Cleaning</strong> Paint <strong>Tank</strong>s<br />

• <strong>Cleaning</strong> Slurry <strong>Tank</strong>s<br />

1.800.95.SPRAY | Intl. 1.630.665.5000 | www.spray.com<br />

13

Mo<strong>to</strong>r Driven<br />

<strong>Tank</strong> Washers 34'<br />

(10.4 m)<br />

Max. <strong>Tank</strong> Diameter<br />

Performance Data – AA190 (AG, E <strong>and</strong> EP) <strong>Tank</strong> Washer<br />

Total Flow of Two Nozzles (Equal Capacity) gpm or l/min Liquid Inlet Pressure*<br />

Nozzle No. 100 psi (7 bar) 200 psi (15 bar) 300 psi (20 bar) 400 psi (30 bar) 500 psi (35 bar)<br />

1/4MEG-0010 3.1 (11.8) 4.4 (17.3) 5.4 (20) 6.3 (24) 7.0 (26)<br />

1/4MEG-0015 4.7 (17.9) 6.6 (26) 8.1 (30) 9.4 (37) 10.5 (40)<br />

1/4MEG-0020 6.2 (24) 8.8 (35) 10.8 (40) 12.4 (49) 13.9 (53)<br />

1/4MEG-0025 7.7 (29) 10.9 (43) 13.3 (50) 15.4 (61) 17.2 (66)<br />

1/4MEG-0030 9.1 (35) 12.9 (51) 15.8 (59) 18.2 (72) 20 (78)<br />

1/4MEG-0035 10.5 (40) 14.8 (59) 18.1 (68) 21 (83) 23 (90)<br />

1/4MEG-0040 11.8 (45) 16.7 (66) 20 (76) 24 (93) 26 (101)<br />

1/4MEG-0050 14.2 (54) 20 (79) 25 (92) 28 (112) 32 (121)<br />

1/4MEG-0060 16.4 (63) 23 (92) 28 (102) 33 (129) 37 (140)<br />

1/4MEG-0070 18.3 (70) 26 (102) 32 (118) 37 (144) 41 (156)<br />

1/4MEG-0080 19.9 (76) 28 (111) 34 (128) 40 (157) 44 (170)<br />

*Note: Flow rates tabulated above include pressure drop through unit.<br />

Pressure drop through the unit in shaded area should be evaluated when sizing pumps.<br />

Consult a Spraying Systems Co. representative for specific information.<br />

Performance Data – AA190 (AGH) <strong>Tank</strong> Washer<br />

Total Flow of Two Nozzles (Equal Capacity) gpm or l/min Liquid Inlet Pressure*<br />

Nozzle No. 500 psi (35 bar) 600 psi (40 bar) 700 psi (50 bar) 800 psi (55 bar) 900 psi (60 bar) 1000 psi (70 bar)<br />

1/4MEG-0010 7.0 (26) 7.6 (29) 8.2 (32) 8.8 (34) 9.3 (35) 9.8 (38)<br />

1/4MEG-0015 10.5 (40) 11.5 (43) 12.4 (48) 13.3 (50) 14.1 (52) 14.9 (57)<br />

1/4MEG-0020 13.9 (53) 15.2 (57) 16.4 (63) 17.5 (66) 18.6 (69) 19.6 (75)<br />

1/4MEG-0025 17.2 (66) 18.8 (70) 20 (78) – – –<br />

1/4MEG-0030 20 (78) – – – – –<br />

*Note: Flow rates tabulated above include pressure drop through unit.<br />

Cycle Time Data – Air Mo<strong>to</strong>r (AG)<br />

Air Pressure Air Consumption Approx. Speed (rpm) Approx. Time for One Complete Cycle (min.)<br />

psi (bar) scfm (l/min) 50 psi (3.45 bar) 500 psi (34.48 bar) 50 psi (3.45 bar) 500 psi (34.48 bar)<br />

6 (0.41) 3.74 (105.8) 4 1 8.8 35<br />

8 (0.55) 4.72 (133.6) 7 4 5.0 8.8<br />

10 (0.69) 5.84 (65.3) 10 8 3.5 4.4<br />

Cycle Time Data –<br />

Electric Mo<strong>to</strong>r (E <strong>and</strong> EP)<br />

Accessories<br />

Strainers<br />

Spray Coverage<br />

360°<br />

Mo<strong>to</strong>r<br />

Type<br />

Electric<br />

Explosion-<br />

Proof<br />

AC<br />

Frequency<br />

Speed<br />

(rpm)<br />

Current<br />

(amps)<br />

Power<br />

(watts)<br />

Approx. Time for<br />

One Complete<br />

Cycle (min.)<br />

50 Hz. 3.1 .39 41 11<br />

60 Hz. 3.8 .33 34 9<br />

50 Hz. 0.8 0.3 33 44<br />

60 Hz. 1.0 0.3 28 35<br />

To prevent clogging, we<br />

recommend using a 100<br />

minimum mesh with one<br />

of our heavy-duty strainers.<br />

See page 49 for specific<br />

strainer recommendations.<br />

Request Catalog 35<br />

for more information on our<br />

complete line of strainers.<br />

Type of<br />

Coverage<br />

14 1.800.95.SPRAY | Intl. 1.630.665.5000 | www.spray.com

Mo<strong>to</strong>r Driven<br />

<strong>Tank</strong> Washers 34'<br />

(10.4 m)<br />

Max. <strong>Tank</strong> Diameter<br />

Impact <strong>and</strong> Coverage Data<br />

The following charts show the decrease in impact as<br />

distance is increased from the orifice of the AA190 <strong>Tank</strong><br />

Washer. A comparison of the five charts illustrates the<br />

increase in impact as pressure increases.<br />

In generating extra impact, increasing flow rate is more<br />

effective than increasing pressure. Doubling pressure gives<br />

approximately 40 percent more impact; doubling flow will<br />

increase impact up <strong>to</strong> 100 percent.<br />

1.800.95.SPRAY | Intl. 1.630.665.5000 | www.spray.com<br />

15

Mo<strong>to</strong>r Driven<br />

<strong>Tank</strong> Washers 34'<br />

(10.4 m)<br />

Max. <strong>Tank</strong> Diameter<br />

Mounting Flange<br />

Options<br />

Sanitary Tri-Clamp<br />

Flange<br />

St<strong>and</strong>ard Three-prong<br />

Mounting Flange<br />

(as shown)<br />

150#<br />

Raised Face Flange<br />

AA190AG<br />

Ordering Information<br />

St<strong>and</strong>ard Three-prong<br />

Mounting Flange<br />

AA190 With St<strong>and</strong>ard Three-prong Flange<br />

<strong>Tank</strong> Washer<br />

Nozzle No.<br />

AA190AG – 3 + 1/4 MEG – 0010<br />

I I I I I<br />

<strong>Tank</strong> Washer<br />

Type<br />

Extension<br />

Length<br />

Inlet<br />

Conn.<br />

Nozzle<br />

Type<br />

Capacity<br />

Size<br />

Dimensions <strong>and</strong> Weights<br />

Model No.<br />

AA190AG<br />

AA190E<br />

AA190E-EP<br />

AA190AGH<br />

Extension<br />

Length<br />

Overall Length<br />

Weight<br />

3' (0.9 m) 54-1/4" (1.4 m) 14 lbs. (6.4 kg)<br />

4' (1.2 m) 66-1/4" (1.7 m) 15-1/2 lbs. (7 kg)<br />

6' (1.8 m) 90-1/4" (2.3 m) 18-1/2 lbs. (8.4 kg)<br />

3' (0.9 m) 48-7/8" (1.2 m) 14 lbs. (6.4 kg)<br />

4' (1.2 m) 60-7/8" (1.5 m) 15-1/2 lbs. (7 kg)<br />

6' (1.8 m) 84-7/8" (2.1 m) 18-1/2 lbs. (8.4 kg)<br />

3' (0.9 m) 51-7/8" (1.3 m) 14 lbs. (6.4 kg)<br />

4' (1.2 m) 63-7/8" (1.6 m) 15-1/2 lbs. (7 kg)<br />

6' (1.8 m) 87-7/8" (2.2 m) 18-1/2 lbs. (8.4 kg)<br />

3' (0.9 m) 54-1/4" (1.4 m) 14 lbs. (6.4 kg)<br />

4' (1.2 m) 66-1/4" (1.7 m) 15-1/2 lbs. (7 kg)<br />

6' (1.8 m) 90-1/4" (2.3 m) 18-1/2 lbs. (8.4 kg)<br />

16 1.800.95.SPRAY | Intl. 1.630.665.5000 | www.spray.com

Mo<strong>to</strong>r Driven<br />

<strong>Tank</strong> Washers 34'<br />

(10.4 m)<br />

Max. <strong>Tank</strong> Diameter<br />

150# Raised Face Flange<br />

Available in 3" <strong>and</strong> 4".<br />

Dimensions <strong>and</strong> Weights<br />

Ordering Information<br />

AA190 With 150# Raised Face Flange<br />

<strong>Tank</strong> Washer<br />

Nozzle No.<br />

AA190AG3 F – 3 + 1/4 MEG – 0010<br />

I I I I I I<br />

<strong>Tank</strong><br />

Washer<br />

Type<br />

150#<br />

Raised<br />

Face<br />

Flange<br />

Extension<br />

Length<br />

Inlet<br />

Conn.<br />

Nozzle<br />

Type<br />

Capacity<br />

Size<br />

Model No.<br />

AA190AG3F<br />

AA190E3F<br />

AA190AG4F<br />

AA190AE4F<br />

Extension<br />

Length<br />

Overall<br />

Length<br />

Weight<br />

3' (0.9 m) 54-1/4" (1.4 m) 24-1/2 lbs. (11.1 kg)<br />

4' (1.2 m) 66-1/4" (1.7 m) 26 lbs. (11.8 kg)<br />

6' (1.8 m) 90-1/4" (2.3 m) 29 lbs. (13.2 kg)<br />

3' (0.9 m) 48-7/8" (1.2 m) 24-1/2 lbs. (11.1 kg)<br />

4' (1.2 m) 60-7/8" (1.5 m) 26 lbs. (11.8 kg)<br />

6' (1.8 m) 84-7/8" (2.1 m) 29 lbs. (13.2 kg)<br />

3' (0.9 m) 51-7/8" (1.3 m) 29-1/2 lbs. (13.4 kg)<br />

4' (1.2 m) 63-7/8" (1.6 m) 31 lbs. (14.1 kg)<br />

6' (1.8 m) 87-7/8" (2.2 m) 34 lbs. (15.4 kg)<br />

3' (0.9 m) 54-1/4" (1.4 m) 29-1/2 lbs. (13.4 kg)<br />

4' (1.2 m) 66-1/4" (1.7 m) 31 lbs. (14.1 kg)<br />

6' (1.8 m) 90-1/4" (2.3 m) 34 lbs. (15.4 kg)<br />

Sanitary Tri-Clamp Flange<br />

Available in 3", 4" <strong>and</strong> 6".<br />

Dimensions <strong>and</strong> Weights<br />

Ordering Information<br />

AA190 With Sanitary Tri-Clamp Flange<br />

<strong>Tank</strong> Washer<br />

Nozzle No.<br />

AA190AG3 SF – 3 + 1/4 MEG – 0010<br />

I I I I I I<br />

<strong>Tank</strong><br />

Washer<br />

Type<br />

Sanitary<br />

Tri-Clamp<br />

Flange<br />

Extension<br />

Length<br />

Inlet<br />

Conn.<br />

Nozzle<br />

Type<br />

Capacity<br />

Size<br />

Note: The 3" sanitary flange has a modified hub assembly that can fit through a 2.75"<br />

opening with nozzles orientated in vertical position.<br />

Model No.<br />

AA190AG3SF<br />

AA190E3SF<br />

AA190AG4SF<br />

AA190E4SF<br />

AA190AG6SF<br />

AA190E6SF<br />

Extension<br />

Length<br />

Overall<br />

Length<br />

Weight<br />

3' (0.9 m) 54-1/4" (1.4 m) 14 lbs. (6.4 kg)<br />

4' (1.2 m) 66-1/4" (1.7 m) 15-1/2 lbs. (7 kg)<br />

6' (1.8 m) 90-1/4" (2.3 m) 18-1/2 lbs. (8.4 kg)<br />

3' (0.9 m) 48-7/8" (1.2 m) 14 lbs. (6.4 kg)<br />

4' (1.2 m) 60-7/8" (1.5 m) 15-1/2 lbs. (7 kg)<br />

6' (1.8 m) 84-7/8" (2.1 m) 18-1/2 lbs. (8.4 kg)<br />

3' (0.9 m) 54-1/4" (1.4 m) 14-1/4 lbs. (6.5 kg)<br />

4' (1.2 m) 66-1/4" (1.7 m) 15-1/2 lbs. (7 kg)<br />

6' (1.8 m) 90-1/4" (2.3 m) 18-3/4 lbs. (8.5 kg)<br />

3' (0.9 m) 48-7/8" (1.2 m) 14-1/4 lbs. (6.5 kg)<br />

4' (1.2 m) 60-7/8" (1.5 m) 15-1/2 lbs. (7 kg)<br />

6' (1.8 m) 84-7/8" (2.1 m) 18-3/4 lbs. (8.5 kg)<br />

3' (0.9 m) 54-1/4" (1.4 m) 17 lbs. (7.7 kg)<br />

4' (1.2 m) 66-1/4" (1.7 m) 18-1/2 lbs. (8.4 kg)<br />

6' (1.8 m) 90-1/4" (2.3 m) 21-1/2 lbs. (9.8 kg)<br />

3' (0.9 m) 48-7/8" (1.2 m) 17 lbs. (7.7 kg)<br />

4' (1.2 m) 60-7/8" (1.5 m) 18-1/2 lbs. (8.4 kg)<br />

6' (1.8 m) 84-7/8" (2.1 m) 21-1/2 lbs. (9.8 kg)<br />

1.800.95.SPRAY | Intl. 1.630.665.5000 | www.spray.com<br />

17

Mo<strong>to</strong>r Driven<br />

<strong>Tank</strong> Washers 34'<br />

(10.4 m)<br />

Max. <strong>Tank</strong> Diameter<br />

Accessories<br />

Features <strong>and</strong> Benefits<br />

• Adjustable accessories <strong>to</strong> achieve maximum<br />

cleaning effectiveness<br />

• Adjustable flanges allow maximum<br />

cleaning efficiencies by positioning<br />

nozzle turret <strong>to</strong> various spray depths<br />

along the length of extension<br />

Adjustable Flange<br />

• For tanks with Tri-Clamp Fitting<br />

• Choice of 2-1/2", 3", 4" or 6"<br />

Tri-Clamp Fitting<br />

Ordering Info<br />

39205 – 3 – 316SS<br />

I I I<br />

Flange<br />

Size<br />

Model<br />

No.<br />

Material<br />

Code<br />

Note: When choosing an adjustable flange, make<br />

sure the nozzle hub will fit inside tank opening. If<br />

not, some modification of the nozzle hub will be<br />

necessary. Contact your local Spraying Systems Co.<br />

representative for more information.<br />

AA190<br />

Spray Head <strong>Tank</strong> Diameter Opening<br />

with Two Nozzles<br />

3.75" (95 mm)<br />

Opening<br />

3.6" (85 mm)<br />

Adjustable<br />

Three-prong Flange<br />

• For tanks with three-prong<br />

flange connections<br />

• Use with either the AA090<br />

or AA190 <strong>Tank</strong> Washers<br />

Ordering Info<br />

22250 – 316SS<br />

I<br />

Model<br />

No.<br />

I<br />

Material<br />

Code<br />

.85"<br />

(21 mm)<br />

1.3"<br />

(33 mm)<br />

3.0" (76 mm)<br />

AA090<br />

Spray Head <strong>Tank</strong> Diameter Opening<br />

2.3" (59 mm)<br />

Opening<br />

Adjustable Flange<br />

• For tanks with 150#<br />

flange connections<br />

• Choice of 2", 3" or 4" 150#<br />

Raised Face Flange<br />

1.1"<br />

(29 mm)<br />

.84" (22 mm)<br />

Ordering Info<br />

46395 – 4 – 316SS<br />

I I I<br />

Flange<br />

Size<br />

Model<br />

No.<br />

Material<br />

Code<br />

.11"<br />

(3 mm)<br />

2.0" (51 mm)<br />

.73"<br />

(18 mm)<br />

18 1.800.95.SPRAY | Intl. 1.630.665.5000 | www.spray.com

Mo<strong>to</strong>r Driven<br />

<strong>Tank</strong> Washers 34'<br />

(10.4 m)<br />

Max. <strong>Tank</strong> Diameter<br />

Ball Swivel Adjustable Flange<br />

• Available in 4" <strong>and</strong> 6" 150 lb flanges<br />

<strong>and</strong> 4" sanitary flange<br />

• Achieve the best possible cleaning<br />

by adjusting the ball swivel <strong>and</strong><br />

changing the angle of spray head<br />

as much as 60°<br />

• Precise positioning of spray head<br />

• Helps clean around internal obstructions<br />

<strong>Tank</strong> Washer Adapter<br />

• 6-1/4" O.D.<br />

• For tanks with 2" <strong>to</strong> 4" tank<br />

inlet sizes<br />

• Install on any air or electrically driven<br />

AA090 or AA190 <strong>Tank</strong> Washers<br />

• Long operational life assured through<br />

chemical resistant CELCON ® (acetal)<br />

material with 304SS screws<br />

Ordering Info<br />

43047 – 4 – 316SS<br />

I I I<br />

Flange<br />

Size<br />

Model<br />

No.<br />

Add SF for Sanitary Flange<br />

Material<br />

Code<br />

Ordering Info<br />

45260 – CE<br />

I<br />

Model<br />

No.<br />

I<br />

Material<br />

Code<br />

Mounting Kit<br />

• Includes a 4" 316SS Raised Face<br />

Flange, stainless steel lock washers,<br />

bolts <strong>and</strong> PTFE gasket<br />

• Use <strong>to</strong> mount the st<strong>and</strong>ard AA190<br />

Three-prong Flange <strong>to</strong> a 4" 150# flange<br />

Ordering Info<br />

39204 – 4 – 316SS<br />

I I I<br />

Flange<br />

Size<br />

Model<br />

No.<br />

Material<br />

Code<br />

Dimensions <strong>and</strong> Weights<br />

Model No. Length O.D. Weight<br />

39205-2-1/2<br />

3" (76 mm) 2 lbs. (.9 kg)<br />

39205-3 3.6" (91 mm) 2.1 lbs. (.95 kg)<br />

4-3/4" (121 mm)<br />

39205-4 4.7" (119 mm) 2.5 lbs. (1.1 kg)<br />

39205-6 6.6" (168 mm) 5.3 lbs. (2.4 kg)<br />

22250 4-1/16" (103 mm) 5" (127 mm) 2.8 lbs. (1.3 kg)<br />

46395-2 4-13/16" (122 mm) 6" (152 mm) 12 lbs. (5.4 kg)<br />

46395-3 4-15/16" (125 mm) 7.5" (191 mm) 12.9 lbs. (5.9 kg)<br />

46395-4 5" (127 mm) 9" (229 mm) 17.7 lbs. (8.0 kg)<br />

43047-4<br />

9" (229 mm) 20 lbs. (9.1 kg)<br />

6-3/4" (172 mm)<br />

43047-6 11" (279 mm) 30 lbs. (13.6 kg)<br />

39204 15/16" (24 mm) 9" (229 mm) 15 lbs. (6.8 kg)<br />

45260 3-13/16" (97 mm) 6.25" (159 mm) 1 lb. (.45 kg)<br />

1.800.95.SPRAY | Intl. 1.630.665.5000 | www.spray.com<br />

19

Mo<strong>to</strong>r Driven<br />

<strong>Tank</strong> Washers 8'<br />

(2.4 m)<br />

Max. <strong>Tank</strong> Diameter<br />

Mo<strong>to</strong>r Driven<br />

<strong>Tank</strong> Washers<br />

Features <strong>and</strong> Benefits<br />

• Cleans small <strong>to</strong> medium size tanks up <strong>to</strong> 8' (2.4 m)<br />

in diameter<br />

• Provides maximum efficiency <strong>and</strong> cost reduction through<br />

high-impact cleaning with minimum liquid consumption<br />

• Choose from air (AG), electric (E) or explosion-proof<br />

electric (EP) mo<strong>to</strong>rs<br />

• Lightweight <strong>and</strong> portable – allows for maximum use<br />

<strong>and</strong> quick payback<br />

• Long-life construction features corrosion-resistant<br />

316SS <strong>and</strong> PTFE fluoropolymer resin seals<br />

• Easily mounted with choices of 1.5', 3', 4' or 6'<br />

(.5, .9, 1.2 or 1.8 m) shaft lengths<br />

• Optional adjustable flange accurately positions turret<br />

within tank<br />

1.1"<br />

(29 mm)<br />

AA090AG<br />

Spray Head <strong>Tank</strong><br />

Diameter Opening<br />

2.3" (59 mm)<br />

Opening<br />

.11"<br />

(3 mm)<br />

2.0" (51 mm)<br />

.73"<br />

(18 mm)<br />

.84" (22 mm)<br />

Lubrica<strong>to</strong>r assembly is included with the air<br />

(AG) model only. Regular lubrication of the<br />

air supply line will significantly increase the<br />

life of the air mo<strong>to</strong>r.<br />

Specifications<br />

Max. tank dia.: 8' (2.4 m)<br />

Flow rate range: 1.5 <strong>to</strong> 7.3 gpm (5.7 <strong>to</strong> 28 l/min)<br />

Pressure range: 100 <strong>to</strong> 500 psi (7 <strong>to</strong> 35 bar)<br />

Max. operating temp.: 200°F (93°C)<br />

Min. tank opening size: 2.3" (59 mm)<br />

Spray coverage: 360°<br />

Inlet connection: 1" NPT or BSPT (F)<br />

Typical Applications<br />

• Drum <strong>Cleaning</strong><br />

• Tote <strong>Cleaning</strong><br />

20 1.800.95.SPRAY | Intl. 1.630.665.5000 | www.spray.com

Mo<strong>to</strong>r Driven<br />

<strong>Tank</strong> Washers 8'<br />

(2.4 m)<br />

Max. <strong>Tank</strong> Diameter<br />

Performance Data<br />

Total Flow of Two Nozzles (Equal Capacity) gpm or l/min Liquid Inlet Pressure*<br />

Nozzle No. 100 psi (7 bar) 200 psi (15 bar) 300 psi (20 bar) 400 psi (30 bar) 500 psi (35 bar)<br />

W0005 1.5 (5.7) 2.0 (7.6) 2.4 (9.1) 2.8 (10.6) 3.2 (12.1)<br />

W0010 2.7 (10.2) 3.7 (14.0) 4.5 (17.0) 5.1 (19.3) 5.8 (22.0)<br />

W0014 3.5 (13.2) 4.7 (17.8) 5.8 (22.0) 6.6 (25.0) 7.3 (28.0)<br />

*Note: Flow rates tabulated above include pressure drop through unit.<br />

Cycle Time Data –<br />

Air Mo<strong>to</strong>r (AG)<br />

Air<br />

Pressure<br />

psi (bar)<br />

Air<br />

Consumption<br />

scfm (l/min)<br />

Approx.<br />

Speed<br />

(rpm)<br />

Approx. Time for<br />

One Complete Cycle<br />

(min.)<br />

5 (0.34) 1.4 (40) 3.2 10<br />

7 (0.48) 2.0 (57) 6 5.5<br />

10 (0.68) 3.1 (88) 8.2 4<br />

Dimensions <strong>and</strong> Weights –<br />

Air Mo<strong>to</strong>r (AG)<br />

Model No.<br />

Extension<br />

Length<br />

Overall<br />

Length<br />

Weight<br />

AA090AG-1.5 1.5' (0.5 m) 35" (0.8 m) 12-1/2 lbs. (5.7 kg)<br />

AA090AG-3 3' (0.9 m) 53" (1.3 m) 14 lbs. (6.4 kg)<br />

AA090AG-4 4' (1.2 m) 65" (1.6 m) 15-1/2 lbs. (7 kg)<br />

AA090AG-6 6' (1.8 m) 89" (2.2 m) 18-1/2 lbs. (8.4 kg)<br />

Dimensions <strong>and</strong> Weights –<br />

Explosion-Proof Mo<strong>to</strong>r (EP)<br />

Model No.<br />

Extension<br />

Length<br />

Overall Length<br />

Weight<br />

AA090E-EP-1.5 1.5' (0.5 m) 32-5/8" (0.8 m) 20 lbs. (9.1 kg)<br />

AA090E-EP-3 3' (0.9 m) 50-5/8" (1.3 m) 22 lbs. (10 kg)<br />

AA090E-EP-4 4' (1.2 m) 62-5/8" (1.6 m) 23 lbs. (10.5 kg)<br />

AA090E-EP-6 6' (1.8 m) 86-5/8" (2.2 m) 26 lbs. (11.8 kg)<br />

Cycle Time Data –<br />

Electric Mo<strong>to</strong>r (E <strong>and</strong> EP)<br />

Mo<strong>to</strong>r<br />

Type<br />

Electric<br />

Explosion-<br />

Proof<br />

Model No.<br />

AC<br />

Frequency<br />

Speed<br />

(rpm)<br />

Current<br />

(amps)<br />

Power<br />

(watts)<br />

Approx. Time for<br />

One Complete<br />

Cycle (min.)<br />

50 Hz. 3.1 0.39 41 11<br />

60 Hz. 3.8 0.33 34 9<br />

50 Hz. 0.8 0.3 33 44<br />

60 Hz. 1.0 0.3 28 35<br />

Dimensions <strong>and</strong> Weights –<br />

Electric Mo<strong>to</strong>r (E)<br />

Extension<br />

Length<br />

Overall<br />

Length<br />

Weight<br />

AA090E-1.5 1.5' (0.5 m) 29-5/8" (0.7 m) 12-1/2 lbs. (5.7 kg)<br />

AA090E-3 3' (0.9 m) 47-5/8" (1.2 m) 14 lbs. (6.4 kg)<br />

AA090E-4 4' (1.2 m) 59-5/8" (1.5 m) 15-1/2 lbs. (7 kg)<br />

AA090E-6 6' (1.8 m) 83-5/8" (2.1 m) 18-1/2 lbs. (8.4 kg)<br />

Ordering Information<br />

AA090 Mo<strong>to</strong>rized <strong>Tank</strong> Washer<br />

<strong>Tank</strong> Washer<br />

Nozzle No.<br />

AA090E – 3 + W 0005<br />

I I I I<br />

<strong>Tank</strong><br />

Washer<br />

Type<br />

Extension<br />

Length<br />

Nozzle<br />

Type<br />

Capacity<br />

Size<br />

Accessories<br />

Strainers<br />

To prevent clogging, we recommend using a 100<br />

minimum mesh with one of our heavy-duty strainers.<br />

See page 49 for specific strainer recommendations.<br />

Request Catalog 35<br />

for more information on our complete line of strainers.<br />

Adjustable Flanges<br />

See pages 18 <strong>and</strong> 19 for<br />

more information.<br />

Spray Coverage<br />

Type of<br />

Coverage<br />

360°<br />

1.800.95.SPRAY | Intl. 1.630.665.5000 | www.spray.com<br />

21

Fluid Driven<br />

Reactionary Force 25'<br />

(7.6 m)<br />

Max. <strong>Tank</strong> Diameter<br />

Fluid Driven<br />

<strong>Tank</strong> Washing Nozzles<br />

Features <strong>and</strong> Benefits<br />

• Ideal for rinsing tanks, vessels <strong>and</strong> containers up <strong>to</strong> 25'<br />

(7.6 m) in diameter<br />

• Especially suited for CIP systems – no mo<strong>to</strong>r source<br />

is needed due <strong>to</strong> the reactionary force of the cleaning liquid<br />

<strong>to</strong> rotate the spray head<br />

• Low pressure for cleaning <strong>and</strong> rinsing applications<br />

• Long-life material of construction – corrosion- <strong>and</strong><br />

chemical-resistant PTFE fluoropolymer resin<br />

27500<br />

• 27500R nozzles in 1/2" <strong>and</strong> 3/4" inlet connections are<br />

available in carbon-filled PTFE for improved thermal<br />

characteristics <strong>and</strong> higher mechanical strength over<br />

the st<strong>and</strong>ard material PTFE<br />

• Spray angles range from 180° <strong>to</strong> 360° <strong>to</strong> meet most<br />

application needs<br />

27500R<br />

• 27500R has a rotating spray head that can be easily<br />

removed from the body for inspection <strong>and</strong> maintenance<br />

• To optimize performance of the rotating spray head,<br />

use liquid free of debris<br />

Some 27500R sizes available in<br />

carbon-filled PTFE<br />

Specifications<br />

Max. tank dia.: 25' (7.6 m)<br />

Flow rate range:<br />

Pressure range:<br />

Max. operating temp.:<br />

Min. tank opening size:<br />

Spray coverage:<br />

Inlet connection 27500:<br />

4 <strong>to</strong> 391 gpm (15.3 <strong>to</strong> 1490 l/min)<br />

10 <strong>to</strong> 50 psi (.7 <strong>to</strong> 3.5 bar)<br />

200°F (93°C)<br />

2" <strong>to</strong> 7" (51 <strong>to</strong> 178 mm)<br />

depending on capacity size<br />

180° spraying up or down,<br />

270° spraying up or down<br />

<strong>and</strong> 360°<br />

1/2" <strong>to</strong> 3" NPT or BSPT<br />

Inlet connection 27500R: 1/2" <strong>to</strong> 1" NPT or BSPT<br />

Typical Applications<br />

• <strong>Cleaning</strong> Broke Chests<br />

27500 PTFE nozzles are an<br />

ideal solution for cleaning liquid<br />

<strong>and</strong> pigment material from<br />

broke chest ceilings at a pulp<br />

<strong>and</strong> paper mill.<br />

• <strong>Cleaning</strong> PCB Washers<br />

27500 nozzles are<br />

used <strong>to</strong> clean<br />

wash units in the<br />

manufacture of<br />

printed circuit boards.<br />

22 1.800.95.SPRAY | Intl. 1.630.665.5000 | www.spray.com

Fluid Driven<br />

Reactionary Force 25'<br />

(7.6 m)<br />

Max. <strong>Tank</strong> Diameter<br />

Performance Data<br />

Nozzle<br />

No.<br />

Orifice<br />

Dia.<br />

(mm)<br />

10 psi<br />

(0.7 bar)<br />

20 psi<br />

(1.5 bar)<br />

Capacity gpm (l/min)<br />

30 psi<br />

(2 bar)<br />

40 psi<br />

(3 bar)<br />

50 psi<br />

(3.5 bar)<br />

Max. <strong>Tank</strong><br />

Dia. (m)<br />

l 27500 (A thru E)-R-1/2-8-TEF 3/32" (2.4) 4.0 (15.3) 5.7 (22) 6.9 (26) 8.0 (32) 8.9 (34) 10' (3.0)<br />

l 27500 (A thru E)-R-3/4-18-TEF 3/32" (2.4) 9.0 (34) 12.7 (50) 15.6 (58) 18 (71) 20 (77) 15' (4.3)<br />

27500 (A thru E)-R-3/4-32-TEF 5/32" (4.0) 16 (61) 23 (89) 28 (103) 32 (126) 36 (136) 15' (4.3)<br />

27500 (A thru E)-R-3/4-46-TEF 15/64" (6.0) 23 (88) 33 (130) 40 (148) 46 (182) 51 (196) 15' (4.3)<br />

27500 (A thru E)-R-1-50-TEF 5/32" (4.0) 25 (95) 35 (140) 43 (161) 50 (197) 56 (215) 18' (5.5)<br />

27500 (A thru E)-R-1-70-TEF 7/32" (5.6) 35 (133) 49 (195) 61 (225) 70 (275) 78 (300) 18' (5.5)<br />

27500 (A thru E)-R-1-90-TEF 19/64" (7.5) 45 (172) 64 (250) 78 (290) 90 (355) 101 (385) 18' (5.5)<br />

27500 (A thru E)-2-100-TEF 15/64" (6.0) 50 (191) 71 (280) 87 (320) 100 (395) 112 (425) 20' (6.0)<br />

27500 (A thru E)-2-125-TEF 17/64" (6.7) 63 (240) 88 (350) 108 (400) 125 (495) 140 (530) 20' (6.0)<br />

27500 (A thru E)-2-150-TEF 5/16" (7.9) 75 (285) 106 (420) 130 (480) 150 (590) 168 (640) 20' (6.0)<br />

27500 (A thru E)-2-175-TEF 3/8" (9.5) 88 (335) 124 (490) 152 (560) 175 (690) 196 (745) 20' (6.0)<br />

27500 (A thru E)-2-200-TEF 27/64" (10.7) 100 (380) 141 (560) 173 (645) 200 (790) 224 (850) 20' (6.0)<br />

27500 (A thru E)-3-250-TEF 25/64" (9.9) 125 (475) 177 (700) 217 (805) 250 (985) 280 (1065) 25' (7.6)<br />

27500 (A thru E)-3-300-TEF 27/64" (10.7) 150 (570) 212 (840) 260 (965) 300 (1180) 335 (1280) 25' (7.6)<br />

27500 (A thru E)-3-350-TEF 31/64" (12.3) 175 (665) 247 (975) 303 (1130) 350 (1380) 391 (1490) 25' (7.6)<br />

l Models available in carbon-filled PTFE.<br />

Suggested optimum operating range – 20 <strong>to</strong> 40 psi (1.5 <strong>to</strong> 3 bar).<br />

Dimensions <strong>and</strong> Weights<br />

Z<br />

X Dia.<br />

Y<br />

Nozzle Type<br />

Inlet Dia.<br />

NPT or BSPT<br />

X Dia. Y Z Flats<br />

27500, 27500R 1/2" 1-15/16" (49.2 mm) 2-3/8" (60.3 mm) 1-1/8" (28.6 mm)<br />

27500, 27500R 3/4" 2-1/4" (57.2 mm) 2-5/8" (66.6 mm) 1-5/16" (33.3 mm)<br />

27500, 27500R 1" 2-3/4" (69.8 mm) 3" (76.2 mm) 1-5/8" (45.3 mm)<br />

27500 2" 4-7/8" (123.8 mm) 4-3/8" (111 mm) 2-3/4" (69.8 mm)<br />

27500 3" 6-7/8" (174.6 mm) 5-7/8" (149.2 mm) 3-7/8" (98.4 mm)<br />

Accessories<br />

Strainers<br />

To prevent clogging, we recommend using a 200<br />

minimum mesh with one of our heavy-duty strainers.<br />

See page 49 for specific strainer recommendations.<br />

Request Catalog 35<br />

for more information on our complete line of strainers.<br />

Ordering Information<br />

27500 <strong>Tank</strong> Washing Nozzle<br />

27500 E – R – 3/4 – 18 – TEF*<br />

I I I I I I<br />

Coverage<br />

Inlet Capacity<br />

Type<br />

Conn. Size<br />

Nozzle<br />

Type<br />

Removable<br />

Spray<br />

Head<br />

*Indicate CTEF for carbon-filled PTFE.<br />

Material<br />

Code<br />

Spray Coverage<br />

180° Up 180° Down 270° Up 270° Down 360°<br />

Type of<br />

Coverage<br />

A B C D E<br />

1.800.95.SPRAY | Intl. 1.630.665.5000 | www.spray.com<br />

23

Fluid Driven<br />

Reactionary Force 18'<br />

(5.5 m)<br />

Max. <strong>Tank</strong> Diameter<br />

Fluid Driven<br />

<strong>Tank</strong> Washing Nozzles<br />

Features <strong>and</strong> Benefits<br />

• Ideal for cleaning tanks, vessels <strong>and</strong> containers up <strong>to</strong> 18'<br />

(5.5 m) in diameter<br />

• An advantage for sanitary applications, the threadless<br />

<strong>and</strong> tapered design promotes self-draining <strong>to</strong> prevent<br />

buildup on nozzle<br />

Threadless design <strong>and</strong><br />

steel locking pin provide<br />

better seal <strong>and</strong> prevent<br />

contamination.<br />

• Secured <strong>to</strong> inlet connection with 316SS locking pin<br />

• Conforms <strong>to</strong> 3A sanitary st<strong>and</strong>ard 78-01 for spray cleaning<br />

devices <strong>to</strong> remain in place (does not apply <strong>to</strong> 180°<br />

spraying up coverage)<br />

• Constructed of PTFE fluoropolymer resin – ideal for harsh<br />

cleaning chemicals<br />

• 28500R has a rotating spray head that can be easily<br />

removed from the body for inspection <strong>and</strong> maintenance<br />

28500R<br />

Conforms <strong>to</strong> 3A<br />

st<strong>and</strong>ards for CIP<br />

• To optimize performance of the rotating spray head, use<br />

liquid free of debris<br />

28500<br />

Specifications<br />

Max. tank dia.: 18' (5.5 m)<br />

Typical Applications<br />

• Pharmaceutical Processing <strong>Tank</strong>s<br />

Flow rate range:<br />

Pressure range:<br />

Max. operating temp.:<br />

Min. tank opening size:<br />

Spray coverage:<br />

Inlet connections:<br />

9 <strong>to</strong> 100.6 gpm (34 <strong>to</strong> 384 l/min)<br />

10 <strong>to</strong> 50 psi (0.7 <strong>to</strong> 3.5 bar)<br />

200°F (93°C)<br />

2.5" <strong>to</strong> 4" (64 <strong>to</strong> 102 mm)<br />

depending on capacity size<br />

180° up or down, 270° up or down<br />

<strong>and</strong> 360°<br />

3/4", 1", 1-1/2", DN20, DN25 <strong>and</strong><br />

DN40 sanitary tubing<br />

• Food Processing<br />

A dairy manufacturer uses 28500R tank washing nozzles<br />

in their clean-in-place system for a milk filling machine.<br />

24 1.800.95.SPRAY | Intl. 1.630.665.5000 | www.spray.com

Fluid Driven<br />

Reactionary Force 18'<br />

(5.5 m)<br />

Max. <strong>Tank</strong> Diameter<br />

Performance Data<br />

Nozzle No.<br />

Orifice Dia.<br />

(mm)<br />

Capacity gpm (l/min)<br />

10 psi (0.7 bar) 20 psi (1.5 bar) 30 psi (2 bar) 40 psi (3 bar) 50 psi (3.5 bar)<br />

28500 (A thru E)-3/4-18-TEF 0.089" (2.3) 9 (34) 12.7 (50) 15.6 (58) 18 (71) 20.1 (77)<br />

28500 (A thru E)-DN20-18-TEF 0.089" (2.3) 9 (34) 12.7 (50) 15.6 (58) 18 (71) 20.1 (77)<br />

28500 (A thru E)-3/4-23-TEF 0.110" (2.8) 11.5 (44) 16.3 (64) 19.9 (74) 23 (91) 26 (99)<br />

28500 (A thru E)-DN20-23-TEF 0.110" (2.8) 11.5 (44) 16.3 (64) 19.9 (74) 23 (91) 26 (99)<br />

28500 (A thru E)-3/4-32-TEF 0.154" (3.9) 16 (61) 22.6 (89) 27.7 (103) 32 (126) 35.8 (136)<br />

28500 (A thru E)-DN20-32-TEF 0.154" (3.9) 16 (61) 22.6 (89) 27.7 (103) 32 (126) 35.8 (136)<br />

28500 (A thru E)-3/4-46-TEF 0.257" (6.5) 23 (88) 32.5 (128) 39.8 (148) 46 (181) 51.4 (196)<br />

28500 (A thru E)-DN20-46-TEF 0.257" (6.5) 23 (88) 32.5 (128) 39.8 (148) 46 (181) 51.4 (196)<br />

28500 (A thru E)-1-33-TEF 0.152" (3.9) 16.5 (63) 23 (92) 29 (106) 33 (131) 37 (141)<br />

28500 (A thru E)-DN25-33-TEF 0.152" (3.9) 16.5 (63) 23 (92) 29 (106) 33 (131) 37 (141)<br />

28500 (A thru E)-1-50-TEF 0.209" (5.3) 25 (95) 35.4 (140) 43.3 (161) 50 (197) 55.9 (213)<br />

28500 (A thru E)-DN25-50-TEF 0.209" (5.3) 25 (95) 35.4 (140) 43.3 (161) 50 (197) 55.9 (213)<br />

28500 (A thru E)-1-70-TEF 0.266" (6.8) 35 (133) 49.5 (195) 60.6 (226) 70 (276) 78.3 (298)<br />

28500 (A thru E)-DN25-70-TEF 0.266" (6.8) 35 (133) 49.5 (195) 60.6 (226) 70 (276) 78.3 (298)<br />

28500 (A thru E)-1-1/2-53-TEF 0.201" (5.1) 27 (101) 37 (148) 46 (171) 53 (209) 59 (226)<br />

28500 (A thru E)-DN40-53-TEF 0.201" (5.1) 27 (101) 37 (148) 46 (171) 53 (209) 59 (226)<br />

28500 (A thru E)-1-1/2-70-TEF 0.266" (6.8) 35 (132) 49 (185) 61 (231) 70 (265) 78 (295)<br />

28500 (A thru E)-DN40-70-TEF 0.266" (6.8) 35 (132) 49 (185) 61 (231) 70 (265) 78 (295)<br />

Dimensions <strong>and</strong> Weights<br />

X Dia.<br />

Nozzle Inlet ID Inlet Dia. X Dia. Y Z<br />

Z<br />

Y<br />

3/4" .76" 2-1/4" (57.2 mm) 2-5/8" (66.6 mm) 3/8" (9.5 mm)<br />

DN20 22.2 mm 2-1/4" (57.2 mm) 2-5/8" (66.6 mm) 3/8" (9.5 mm)<br />

1" 1.02" 2-3/4" (69.8 mm) 2-7/8" (73 mm) 1/2" (12.7 mm)<br />

DN25 28.2 mm 2-3/4" (69.8 mm) 2-7/8" (73 mm) 1/2" (12.7 mm)<br />

1-1/2" 1.52" 3-5/8" (92 mm) 3-5/8" (92 mm) 3/4" (19 mm)<br />

DN40 40.2 mm 3-5/8" (92 mm) 3-5/8" (92 mm) 3/4" (19 mm)<br />

Accessories<br />

Strainers<br />

Ordering Information<br />

28500 <strong>Tank</strong> Washing Nozzle<br />

To prevent clogging, we recommend using a 200<br />

minimum mesh with one of our heavy-duty strainers.<br />

See page 49 for specific strainer recommendations.<br />

Request Catalog 35<br />

for more information on our complete line of strainers.<br />

28500 E – R – 3/4 – 23 – TEF<br />

I I I I I I<br />

Nozzle<br />

Type<br />

Coverage<br />

Type<br />

Removable<br />

Spray<br />

Head<br />

Inlet<br />

Conn.<br />

Capacity<br />

Size<br />

Material<br />

Code<br />

Spray Coverage<br />

180° Up 180° Down 270° Up 270° Down 360°<br />

Type of<br />

Coverage<br />

A B C D E<br />

1.800.95.SPRAY | Intl. 1.630.665.5000 | www.spray.com<br />

25

Fluid Driven<br />

Reactionary Force 8'<br />

(2.4 m)<br />

Max. <strong>Tank</strong> Diameter<br />

Fluid Driven<br />

<strong>Tank</strong> Washing Nozzles<br />

Features <strong>and</strong> Benefits<br />

• <strong>Effective</strong>ly washes interior of small tanks <strong>and</strong> drums up <strong>to</strong><br />

8' (2.4 m) in diameter<br />

• Features three high-impact flat sprays mounted in a<br />

rotating spray head that is driven by the flow of the<br />

cleaning liquid<br />

• The precisely positioned orifices provide complete orbital<br />

coverage of all interior surfaces<br />

• Can be installed in either vertical or horizontal positions<br />

• Maximum wear life <strong>and</strong> corrosion resistance results from<br />

construction made of 316SS with bearing retainers<br />

constructed of RYTON ® (polyphenylene sulfide); sleeves<br />

of 50% stainless steel PTFE<br />

• To optimize performance of the rotating spray head,<br />

cleaning liquid should be single pass or free of particulate<br />

18250A<br />

Typical Applications<br />

21400A<br />