ER9 Pro upgrade - Intelitek

ER9 Pro upgrade - Intelitek

ER9 Pro upgrade - Intelitek

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

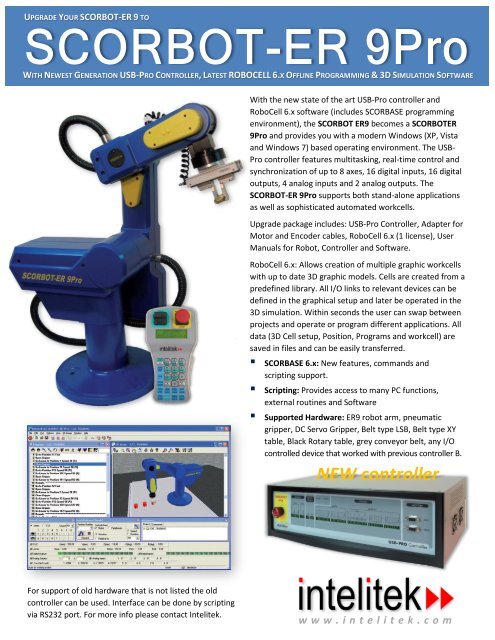

UPGRADE YOUR SCORBOT-ER 9 TO<br />

WITH NEWEST GENERATION USB-PRO CONTROLLER, LATEST ROBOCELL 6.X OFFLINE PROGRAMMING & 3D SIMULATION SOFTWARE<br />

With the new state of the art USB-<strong>Pro</strong> controller and<br />

RoboCell 6.x software (includes SCORBASE programming<br />

environment), the SCORBOT <strong>ER9</strong> becomes a SCORBOTER<br />

9<strong>Pro</strong> and provides you with a modern Windows (XP, Vista<br />

and Windows 7) based operating environment. The USB-<br />

<strong>Pro</strong> controller features multitasking, real-time control and<br />

synchronization of up to 8 axes, 16 digital inputs, 16 digital<br />

outputs, 4 analog inputs and 2 analog outputs. The<br />

SCORBOT-ER 9<strong>Pro</strong> supports both stand-alone applications<br />

as well as sophisticated automated workcells.<br />

Upgrade package includes: USB-<strong>Pro</strong> Controller, Adapter for<br />

Motor and Encoder cables, RoboCell 6.x (1 license), User<br />

Manuals for Robot, Controller and Software.<br />

RoboCell 6.x: Allows creation of multiple graphic workcells<br />

with up to date 3D graphic models. Cells are created from a<br />

predefined library. All I/O links to relevant devices can be<br />

defined in the graphical setup and later be operated in the<br />

3D simulation. Within seconds the user can swap between<br />

projects and operate or program different applications. All<br />

data (3D Cell setup, Position, <strong>Pro</strong>grams and workcell) are<br />

saved in files and can be easily transferred.<br />

• SCORBASE 6.x: New features, commands and<br />

scripting support.<br />

• Scripting: <strong>Pro</strong>vides access to many PC functions,<br />

external routines and Software<br />

• Supported Hardware: <strong>ER9</strong> robot arm, pneumatic<br />

gripper, DC Servo Gripper, Belt type LSB, Belt type XY<br />

table, Black Rotary table, grey conveyor belt, any I/O<br />

controlled device that worked with previous controller B.<br />

NEW controller<br />

For support of old hardware that is not listed the old<br />

controller can be used. Interface can be done by scripting<br />

via RS232 port. For more info please contact <strong>Intelitek</strong>.<br />

w w w . i n t e l i t e k . c o m

Cat# 100668 rev. B Specifications subject to change without prior notice<br />

Specifications<br />

USB-<strong>Pro</strong> Controller<br />

Type of control<br />

Servo axis drivers<br />

Path control<br />

Speed control<br />

Control parameters<br />

Power requirements<br />

Internal power supplies<br />

Microcontroller<br />

Communication<br />

Real-time; PID; PWM<br />

8 axes for robot and peripherals<br />

Joint; Linear; Circular<br />

10 speed settings; Travel time definitions<br />

160 parameters, many are user-accessible; Servo<br />

control; PID; speed; velocity profile; axis position<br />

error; gripper operation; impact; limit protection;<br />

homing; Cartesian calculations.<br />

110-220 VAC ±10%, 50/60Hz, 1000 W<br />

Servo: 48V Digital: 5V/12V/24V<br />

Microcontroller ARM7TDMI <strong>Pro</strong>cessor: 32-bit RISC<br />

Architecture with 256 Kbytes of Internal High-speed<br />

Flash<br />

USB type A cable connection to PC; Plug and play<br />

without rebooting; Integrated RS232 for teach<br />

pendant<br />

SCORBOT-ER 9<strong>Pro</strong> on linear slidebase tending 2 CNC and<br />

local storage (FMS workcell)<br />

Inputs 16 digital inputs: 24V max., high/low configurable; 4<br />

analog inputs: input voltage 0-10V<br />

Outputs<br />

16 digital outputs: 24V max.; 4 relays; 12 open<br />

collector, sink/source configurable; 2 analog outputs:<br />

output voltage 0-10V<br />

SCORBOT-ER 9<strong>Pro</strong> performs assembly and quality control<br />

operations.<br />

User power supply<br />

<strong>Pro</strong>gramming<br />

Position definition<br />

LED indicators<br />

Weight<br />

12 VDC (1A) and 24 VDC (2A) terminals, for connection<br />

of remote switches, sensors, etc.<br />

SCORBASE for Controller-USB PRO software, with<br />

Multitasking – Up to 100 concurrent programs; Inprogram<br />

parameter manipulation; Built in Scripting;<br />

Online Graph With PWM and position error; RoboCell:<br />

3D simulation software (optional); Teach pendant for<br />

Controller-USB PRO (optional); <strong>Pro</strong>gramming Interface<br />

XYZ coordinates; Joint coordinates (degrees); Encoder<br />

counts; Absolute and relative positions; In program<br />

position manipulation<br />

Main power, power on, communicating with PC;<br />

Motor on; Digital Inputs/Digital Outputs; Emergency<br />

7.5 kg (16.5 lbs.)<br />

RoboCell 3D graphic simulation software enables offline<br />

design and simulation of virtual robotic workcell and online<br />

graphic tracking of actual cell.<br />

Dimensions<br />

Operating temperature<br />

460x140x245 mm (18.1”x5.5”x9.6”)<br />

2° - 40°C (36° - 104°F)<br />

Safety features<br />

Gripper (not included in robot package)<br />

Certified for CE safety compliance; Emergency switch<br />

on controller front panel/Teach Pendant/remote;<br />

Input/Output short-circuit protection; Over-current<br />

protection; Communication error; impact; thermic<br />

overload<br />

SCORBOT-ER 9<strong>Pro</strong> on linear slidebase tending 2 CNC and<br />

local storage (FMS workcell)<br />

Standard Options: Pneumatic: Max. opening: 64 mm (2.5”)<br />

DC servo: Max. opening: 70 mm (2.8”)