Download - Buderus

Download - Buderus

Download - Buderus

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

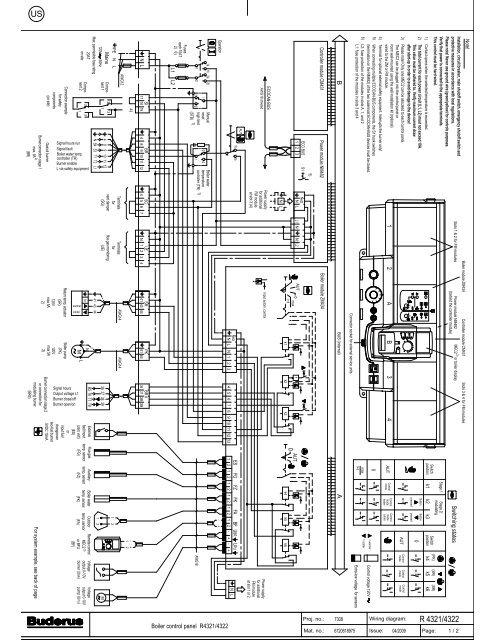

Note!<br />

1)<br />

2)<br />

3)<br />

4)<br />

5)<br />

Contact opens when the selected temperature is exceeded.<br />

The total current for each power circuit (L1, L2) must not exceed 10A.<br />

This value must be adhered to. Verify maximum current draw<br />

after start-up in order to avoid damage to the device!<br />

Please note! Only one MEC2 can be allocated to each control panel.<br />

The MEC2 can be plugged into the control panel or<br />

room wall-mounted using the wall installation kit (optional)<br />

wired to the ZM or FM module.<br />

Terminal for optional external safety equipment. Interrupts the burner only!<br />

When connecting multiple ECOCAN-BUS components, the S1 hook switches<br />

(termination on the NM482) of the two outermost ECOCAN-BUS devices must be closed.<br />

Controller module CM431<br />

Power module NM482<br />

5)<br />

ECO BUS S1<br />

1 2 3<br />

ECOCAN-BUS<br />

AWG18 shieled<br />

AUT<br />

1b<br />

1a<br />

Operation<br />

1<br />

Fuses<br />

each 10AT<br />

1a 1b<br />

1<br />

Manual<br />

reset<br />

high limit<br />

(STB)<br />

1)<br />

4<br />

Boiler water<br />

temperature<br />

controller (TR)<br />

SI<br />

N L<br />

17 18<br />

BR<br />

19<br />

4 8 9 10 11 12<br />

4)<br />

N<br />

/PE<br />

Mains<br />

120V 60Hz<br />

L<br />

Max. permissible fuse rating<br />

20AT<br />

on site<br />

4<br />

N<br />

8 9<br />

B4<br />

S3<br />

10 11<br />

T1<br />

T2<br />

Gas/oil burner<br />

12<br />

Burner connection stage 1<br />

2)<br />

max. 8A<br />

(BR)<br />

L1<br />

Netz<br />

N L<br />

N L<br />

1)<br />

SG<br />

4 5 6<br />

7<br />

Boiler module ZM434<br />

Slots 1 & 2 for FM modules<br />

Controller module CM431<br />

Slots 3 & 4 for FM modules<br />

3)<br />

Power module NM482 MEC2 or boiler display<br />

(behind the controller module)<br />

Switch<br />

position<br />

Stage 1<br />

Stage 2/<br />

modulating<br />

k1 k2 k3<br />

(PK) (SR) (SR)<br />

k4 k5 k6<br />

Button Button<br />

pressed pressed<br />

0<br />

AUT<br />

AUT<br />

Control<br />

mode<br />

Connector socket for external service units<br />

BUS (internal)<br />

0<br />

max<br />

l+ll<br />

Control voltage 120V<br />

Extra-low voltage for sensors<br />

Boiler module ZM434<br />

L1 N N L2<br />

AUT<br />

0<br />

max<br />

l+ll<br />

Netz<br />

0 AUT<br />

k 1<br />

k2<br />

k3<br />

k4 k5 k6<br />

Power supply<br />

for additional<br />

FM module<br />

at slot 1 or 2<br />

ES FG FZ FK FA BF<br />

N L<br />

N L N 1 2 3 4 5 6 7 8 9 10 11 12 13<br />

1 2 1 2 1 2 1 2 1 2<br />

+<br />

AWG18<br />

UE<br />

N 1 2<br />

3 4<br />

SR<br />

41 43<br />

PK<br />

61 63<br />

36<br />

BR II<br />

37<br />

38<br />

39<br />

- +<br />

1 2<br />

AWG14 AWG14<br />

N<br />

M L<br />

36<br />

B5<br />

37 38<br />

T6<br />

T7<br />

39<br />

T8<br />

1<br />

2<br />

1 2<br />

3)<br />

For system example, see back of page<br />

2<br />

1<br />

3<br />

2<br />

1<br />

-<br />

Signal hours<br />

Output voltage L1<br />

Burner close/off<br />

Burner open/on<br />

2a 2b<br />

2<br />

2 3<br />

1<br />

Signal hours run<br />

Signal fault<br />

Boiler water temp.<br />

controller (TR)<br />

Burner enable<br />

L via safety equipment<br />

Compo-<br />

nent 1<br />

Component<br />

2<br />

2<br />

1<br />

3<br />

Switching states<br />

M<br />

AUT<br />

AUT<br />

1 2 A<br />

B<br />

3<br />

4<br />

44<br />

41 43 44<br />

N<br />

80<br />

0<br />

max<br />

0<br />

AUT<br />

Proj. no.:<br />

Mat. no.:<br />

Wiring diagram:<br />

Issue:<br />

70<br />

90<br />

60<br />

105<br />

50<br />

= warmer<br />

= colder<br />

1<br />

warmer<br />

colder<br />

Installation, circuit breaker, main shutoff switch, emergency shutoff switch and<br />

protective measures in accordance with local regulations.<br />

Please note! Never use ground wire (green/yellow) for controls purposes.<br />

Verify that power is connected to the appropriate terminals.<br />

This control must be hard wired.<br />

6) L2: fuse protection of the modules in slots A, 1, and 2<br />

L1: fuse protection of the modules in slots 3 and 4<br />

B<br />

2)<br />

6)<br />

L1 L2<br />

A<br />

Input autom. control<br />

1<br />

2<br />

UBR UPU<br />

- + - +<br />

Voltage<br />

output 0-10V<br />

burner (UBR)<br />

M<br />

Voltage<br />

output 0-10V<br />

pump (UPU)<br />

US<br />

Boiler control panel R4321/4322<br />

7308<br />

6720618975<br />

04/2009<br />

R 4321/4322<br />

Page:<br />

1 / 2<br />

AWG12<br />

Connection example<br />

for safety<br />

components<br />

(on site)<br />

Power supply<br />

for additional<br />

FM module<br />

at slot 3 (4)<br />

Terminals<br />

for<br />

vent damper<br />

(SG)<br />

Switch<br />

position<br />

M<br />

Control<br />

mode<br />

Control<br />

mode<br />

Control<br />

mode<br />

Control<br />

mode<br />

hotter<br />

Control<br />

mode<br />

colder<br />

M<br />

Terminals<br />

for<br />

flue gas monitoring<br />

(UE)<br />

Return temp. actuator<br />

(SR)<br />

120V<br />

max 5A<br />

2)<br />

Boiler pump<br />

(PK)<br />

120V<br />

max 5A<br />

2)<br />

Burner connection stage 2<br />

or connection for<br />

modulating burner<br />

(BRII)<br />

External<br />

fault input<br />

(zero volt)<br />

(ES)<br />

or<br />

input fuel<br />

changeover<br />

two-fuel burner<br />

5VDC 10mA<br />

Flue gas<br />

temp. sensor<br />

(FG)<br />

Auxiliary<br />

temp. sensor<br />

(FZ)<br />

Boiler water<br />

temp. sensor<br />

(FK)<br />

Outdoor<br />

temp. sensor<br />

(FA)<br />

Remote control<br />

MEC2<br />

or BFU<br />

(BF)

US<br />

Legend:<br />

BF remote control MEC2 or BFU<br />

BR burner<br />

ES external fault input (dry contact)<br />

FA outdoor temperature sensor<br />

FK boiler water temperature sensor<br />

FZ auxiliary temperature sensor<br />

PK boiler pump<br />

SR return temperature actuator<br />

UPu voltage output 0-10V pump<br />

UBr voltage output 0-10V burner<br />

System example 1 System example 2<br />

FA<br />

BF<br />

FA<br />

BF<br />

AWG18<br />

AWG18<br />

ES<br />

AWG18<br />

AWG18<br />

AWG18<br />

AWG18<br />

AWG14<br />

AWG14<br />

Mains AWG14 Mains AWG14<br />

AWG14<br />

AWG18<br />

AWG18<br />

R 4321<br />

R 4321<br />

AWG18<br />

UBR<br />

FZ<br />

FK<br />

AWG18<br />

BrII<br />

BR BR<br />

BR<br />

FK<br />

BR<br />

M<br />

SR<br />

<strong>Buderus</strong><br />

Thermostream boiler or<br />

LT boiler with base line temperature<br />

<strong>Buderus</strong><br />

Thermostream boiler<br />

Example of the connection of a Thermostream boiler<br />

or LT boiler with low-end temperature<br />

control via a separate boiler circuit actuator (SR).<br />

Example for integration of Thermostream boilers.<br />

Control via boiler actuator. Terminal UPu only<br />

required for modulating boiler circuit pump.<br />

System example 3 System example 4<br />

FA<br />

BF<br />

FA<br />

BF<br />

AWG18<br />

AWG18<br />

ES<br />

AWG18<br />

AWG18<br />

AWG18<br />

AWG14<br />

PK<br />

AWG18<br />

Mains<br />

AWG14<br />

AWG18<br />

AWG14<br />

Mains AWG14 AWG14<br />

UPu<br />

AWG18<br />

AWG18<br />

R 4321<br />

R 4321<br />

FZ<br />

FK<br />

PK 1)<br />

FK<br />

AWG18<br />

BrII<br />

BR BR<br />

BR<br />

BR<br />

UBR<br />

FZ<br />

<strong>Buderus</strong><br />

LT boiler<br />

<strong>Buderus</strong> LT boiler<br />

with minimum return temperature<br />

Example of connecting a low temperature boiler.<br />

Low temperature boilers require heating circuit<br />

actuators to control the operating conditions.<br />

Example for integration of boilers with<br />

return temperature control.<br />

Control via separate boiler actuator (SR).<br />

1)<br />

A boiler circuit pump may be controlled when using low loss headers.<br />

Terminal U Pu only required for modulating boiler circuit pump (0-10V).<br />

UPu<br />

ES<br />

M SR<br />

ES<br />

PK<br />

M<br />

SR<br />

FZ<br />

Boiler control panel R4321/4322<br />

Proj. no.:<br />

Mat. no.:<br />

7308<br />

6720618975<br />

Wiring diagram:<br />

R 4321/4322<br />

Issue: 04/2009 Page: 2 / 2