Asphalt Review - Feb/March 2013 - Australian Asphalt Pavement ...

Asphalt Review - Feb/March 2013 - Australian Asphalt Pavement ...

Asphalt Review - Feb/March 2013 - Australian Asphalt Pavement ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

need to seek controls higher in the hierarchy of controls that depend<br />

less on behaviour.<br />

Internal Traffic Management Plans (ITMP) as described below should<br />

assist to improve site safety where mobile plant and vehicles are<br />

separated from pedestrian workers as far as practical from plant and<br />

truck operating areas.<br />

Everyone who works on road construction sites needs training<br />

to understand the risk of mobile plant and trucks where the driver/<br />

operator cannot see them.<br />

Safe Work Method Statements (SWMS) could seek to control this<br />

risk by requiring workers to be more than six metres from the rear of<br />

plant but it is safer to not be behind plant or within its swing radius at<br />

any time.<br />

The US National Institute of Occupational Safety and Health (NIOSH)<br />

has produced Construction Equipment Visibility Diagrams for most of<br />

the commonly expected mobile plant and vehicles. These diagrams<br />

show the operators visibility profiles around the plant from the<br />

viewpoint of the operator. The US Work Zone Safety Clearing House<br />

also produces a “Know the Blind Spots” Poster.<br />

Internal traffic management plans (ITMP)<br />

An ITMP is used to safely coordinate the interaction between<br />

pedestrians (workers and public), construction plant, delivery<br />

trucks and incidental visitors in the work space of a road<br />

construction work zone. In the US, they are referred to as Internal<br />

Traffic Control Plans (ITCP).<br />

Similar, but less sophisticated plans, have been used previously on<br />

VicRoads major project sites combined with UHF radio communications.<br />

However, the fundamental principles are applicable to all roadwork<br />

sites (including smaller sites) for internal traffic management.<br />

Based on the US experience, the fundamental principles for setting<br />

up an effective ITMP are:<br />

• Isolate workers and other pedestrians from mobile plant and works<br />

vehicles;<br />

• Reduce the need to back up;<br />

• Limit vehicle access points to work zone;<br />

• Coordinate truck and mobile plant movements;<br />

• Provide signs within the work zone to give guidance to pedestrian<br />

workers, equipment and trucks;<br />

• Design buffer spaces to separate pedestrian workers from errant<br />

vehicles and work zone equipment; and<br />

• Inform all on-site personnel of ITMP provisions.<br />

Two examples of the isolation of pedestrians from mobile plant and<br />

other vehicles on recent VicRoads major projects are:<br />

• Leighton Contractors introduced its Pedestrian No Go Zones on the<br />

M80 Upgrade Project early in 2011. It was the first highly visible<br />

ITMP to be introduced on a VicRoads Project. Leighton was recently<br />

presented with the VicRoads Major Project Safety Innovation Award<br />

in recognition of the establishment of the Pedestrian No Go Zones,<br />

and trial of GPS Personal Warning Devices for mobile plant operators<br />

and personnel authorised to work near plant, but outside of<br />

minimum approach distances.<br />

The concept had origins in the mining industry where they are<br />

sometimes called “Red Zones”. It requires compliance with behavioural<br />

controls, just as drivers are required to do on public roads but the<br />

system does isolate plant operations from pedestrians and gives the<br />

lead plant operator authority to give permission to other vehicles to<br />

enter the zone and pass other plant.<br />

Plant is required to stop all movement and rest the booms in the<br />

case of excavators pending the safe passing by plant and vehicles<br />

authorised to pass/enter the area. If it is necessary for a pedestrian to<br />

enter or approach plant they must seek permission over the radio and<br />

machines will be stopped until they are sighted and, if necessary, given<br />

permission to come closer.<br />

All permissions and instructions must be confirmed over the<br />

radio before entering the Red Zone. Some areas are made absolute<br />

Pedestrian No Go Zones where pedestrians entry is completely<br />

prohibited. Appropriate signage is then displayed.<br />

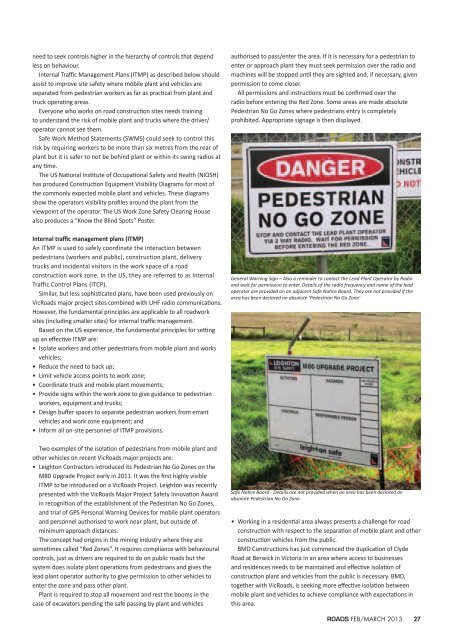

General Warning Sign – Also a reminder to contact the Lead Plant Operator by Radio<br />

and wait for permission to enter. Details of the radio frequency and name of the lead<br />

operator are provided on an adjacent Safe Notice Board. They are not provided if the<br />

area has been declared an absolute ‘Pedestrian No Go Zone’<br />

Safe Notice Board - Details are not provided when an area has been declared an<br />

absolute Pedestrian No Go Zone.<br />

• Working in a residential area always presents a challenge for road<br />

construction with respect to the separation of mobile plant and other<br />

construction vehicles from the public.<br />

BMD Constructions has just commenced the duplication of Clyde<br />

Road at Berwick in Victoria in an area where access to businesses<br />

and residences needs to be maintained and effective isolation of<br />

construction plant and vehicles from the public is necessary. BMD,<br />

together with VicRoads, is seeking more effective isolation between<br />

mobile plant and vehicles to achieve compliance with expectations in<br />

this area.<br />

ROADS FEB/MARCH <strong>2013</strong> 27