automatic modular casting line type bav multi-stick ... - Azienda in fiera

automatic modular casting line type bav multi-stick ... - Azienda in fiera

automatic modular casting line type bav multi-stick ... - Azienda in fiera

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

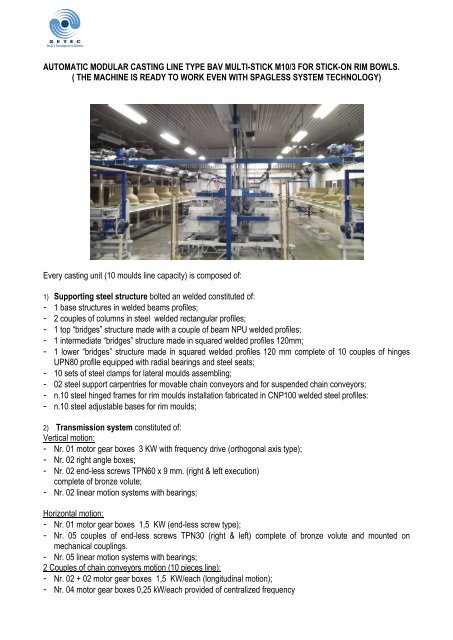

AUTOMATIC MODULAR CASTING LINE TYPE BAV MULTI-STICK M10/3 FOR STICK-ON RIM BOWLS.<br />

( THE MACHINE IS READY TO WORK EVEN WITH SPAGLESS SYSTEM TECHNOLOGY)<br />

Every <strong>cast<strong>in</strong>g</strong> unit (10 moulds <strong>l<strong>in</strong>e</strong> capacity) is composed of:<br />

1) Support<strong>in</strong>g steel structure bolted an welded constituted of:<br />

- 1 base structures <strong>in</strong> welded beams profiles;<br />

- 2 couples of columns <strong>in</strong> steel welded rectangular profiles;<br />

- 1 top “bridges” structure made with a couple of beam NPU welded profiles;<br />

- 1 <strong>in</strong>termediate “bridges” structure made <strong>in</strong> squared welded profiles 120mm;<br />

- 1 lower “bridges” structure made <strong>in</strong> squared welded profiles 120 mm complete of 10 couples of h<strong>in</strong>ges<br />

UPN80 profile equipped with radial bear<strong>in</strong>gs and steel seats;<br />

- 10 sets of steel clamps for lateral moulds assembl<strong>in</strong>g;<br />

- 02 steel support carpentries for movable cha<strong>in</strong> conveyors and for suspended cha<strong>in</strong> conveyors;<br />

- n.10 steel h<strong>in</strong>ged frames for rim moulds <strong>in</strong>stallation fabricated <strong>in</strong> CNP100 welded steel profiles:<br />

- n.10 steel adjustable bases for rim moulds;<br />

2) Transmission system constituted of:<br />

Vertical motion:<br />

- Nr. 01 motor gear boxes 3 KW with frequency drive (orthogonal axis <strong>type</strong>);<br />

- Nr. 02 right angle boxes;<br />

- Nr. 02 end-less screws TPN60 x 9 mm. (right & left execution)<br />

complete of bronze volute;<br />

- Nr. 02 <strong>l<strong>in</strong>e</strong>ar motion systems with bear<strong>in</strong>gs;<br />

Horizontal motion:<br />

- Nr. 01 motor gear boxes 1,5 KW (end-less screw <strong>type</strong>);<br />

- Nr. 05 couples of end-less screws TPN30 (right & left) complete of bronze volute and mounted on<br />

mechanical coupl<strong>in</strong>gs.<br />

- Nr. 05 <strong>l<strong>in</strong>e</strong>ar motion systems with bear<strong>in</strong>gs;<br />

2 Couples of cha<strong>in</strong> conveyors motion (10 pieces <strong>l<strong>in</strong>e</strong>):<br />

- Nr. 02 + 02 motor gear boxes 1,5 KW/each (longitud<strong>in</strong>al motion);<br />

- Nr. 04 motor gear boxes 0,25 kW/each provided of centralized frequency

controller (lateral motion for de-mould<strong>in</strong>g);<br />

3) Cast<strong>in</strong>g circuit (10 moulds <strong>l<strong>in</strong>e</strong>) constituted of:<br />

a) Bodies Section<br />

- 2 branches of PVC flanged pipe diam. 120 mm.(10 mt.) and diam. 63 mm.;<br />

- 10 clamp saddles 120mm x ¾”;<br />

- 10 ball manual valves diam. ¾” complete of hose nipples;<br />

- 2 plastic slip level tanks 30 lt. Capacity;<br />

- 2 electro-mechanical slip level controls;<br />

- 03+03 pneumatic valves complete of position magnetic sensors (2 each one);<br />

- 02 manual ball valves diam. 2”<br />

- Set of silicon rubber pipe for slip feed<strong>in</strong>g to the moulds;<br />

b) Rims section<br />

- 2 branches of PVC flanged pipe diam. 120 mm.(10 mt.) and diam. 63 mm.;<br />

- 10 clamp saddles 120mm x ¾”;<br />

- 10 ball manual valves diam. ¾” complete of hose nipples;<br />

- 2 plastic slip level tanks 30 lt. Capacity;<br />

- 2 electro-mechanical slip level controls;<br />

- 03+03 pneumatic valves complete of position magnetic sensors (2 each one);<br />

- 02 manual ball valves diam. 2”<br />

- Set of silicon rubber pipe for slip feed<strong>in</strong>g to the moulds;<br />

4) Dra<strong>in</strong>age circuit (10 moulds <strong>l<strong>in</strong>e</strong>) constituted of:<br />

a) Bodies Section<br />

- 01 air blower (low pressure) for slip dra<strong>in</strong>age complete of filter;<br />

- 2 branches of PVC flanged pipe diam. diam. 63 mm.(32 mt.);<br />

- 10 clamp saddles 63mm x ½”;<br />

- 10 ball manual valves diam. ½”complete of hose nipples;<br />

- 02 over pressure mechanical valves diam. 1” ½;<br />

- 02 pneumatic ball valves diam. 2” complete of position magnetic sensors (2 each one);<br />

- 01 pneumatic pump diam. 2” (slip recovery);<br />

b) Rims section<br />

- 01 air blower (low pressure) for slip dra<strong>in</strong>age complete of filter;<br />

- 2 branches of PVC flanged pipe diam. diam. 63 mm.(32 mt.);<br />

- 10 clamp saddles 63mm x ½”;<br />

- 10 ball manual valves diam. ½”complete of hose nipples;<br />

- 02 over pressure mechanical valves diam. 1” ½;<br />

- 02 pneumatic ball valves diam. 2” complete of position magnetic sensors (2 each one);<br />

-<br />

5) N. 10 axial fans diam. 300 mm.<br />

220/380V 50Hz. – <strong>in</strong>stalled power 150W<br />

6) Compressed air circuit (30 moulds <strong>l<strong>in</strong>e</strong>) constituted of:<br />

- 01 Centralized electro-pneumatic panel (3 <strong>cast<strong>in</strong>g</strong> units) <strong>in</strong>clud<strong>in</strong>g;<br />

- 01 air filter regulation group diam. 1” (0 – 7 bars);<br />

- 06 air pressure regulators diam. ½”; (0-7 bars);<br />

- 03 double solenoid 5/2 electric-valve ½” 24VAC (double effect pneumatic cyl<strong>in</strong>der for lower<br />

moulds slid<strong>in</strong>g);<br />

- 12 solenoid pilot electric valve 5/2 1/8” 24 VAC (pneumatic activated valves DN50 Ma<strong>in</strong> slip<br />

feed<strong>in</strong>g) complete of distributor and accessories;

- 06 double solenoid 5/2 electric-valve ½” 24VAC (double effect pneumatic cyl<strong>in</strong>ders for lockage<br />

of rims moulds metal frames);<br />

- 06 double solenoid 5/2 electric-valve ½” 24VAC (double effect pneumatic spr<strong>in</strong>gs for <strong>in</strong>dividual<br />

clos<strong>in</strong>g of rims moulds);<br />

- 06 double solenoid 5/2 electric-valve ½” 24VAC (double effect pneumatic spr<strong>in</strong>gs for <strong>in</strong>dividual<br />

clos<strong>in</strong>g of bodies moulds);<br />

- 06 double solenoid 5/2 electric-valve ½” 24VAC (double effect pneumatic cyl<strong>in</strong>ders for <strong>in</strong>dividual<br />

slop<strong>in</strong>g of rims moulds);<br />

- 03 double solenoid 5/2 electric-valve ½” 24VAC (double effect pneumatic compact press<strong>in</strong>g<br />

devices for <strong>in</strong>dividual clos<strong>in</strong>g of lateral sides moulds);<br />

- 03 on/off electric valve diam. ½” for action<strong>in</strong>g pneumatic pump for slip recovery;<br />

- Mufflers and accessories;<br />

- 06 Pneumatic guns complete of spiral pipe<strong>l<strong>in</strong>e</strong> L=32 mt.;<br />

- 60 pneumatic spr<strong>in</strong>gs (short - run) 40 mm. for bodies moulds vertical clos<strong>in</strong>g system (s<strong>in</strong>gle<br />

press<strong>in</strong>g system);<br />

- 60 pneumatic spr<strong>in</strong>gs (short - run) 40 mm. for rims moulds vertical clos<strong>in</strong>g system (s<strong>in</strong>gle<br />

press<strong>in</strong>g system);<br />

- 60 pneumatic devices (short - run) – for lateral moulds clos<strong>in</strong>g system (s<strong>in</strong>gle press<strong>in</strong>g system);<br />

- Set of accessories and plastic flexible pipe for connections;<br />

- n.30 double effect pneumatic cyl<strong>in</strong>ders (short run) for steel frames blockage dur<strong>in</strong>g <strong>cast<strong>in</strong>g</strong><br />

process (rims moulds);<br />

- n.30 double effect pneumatic cyl<strong>in</strong>ders for rim slop<strong>in</strong>g dur<strong>in</strong>g slip dra<strong>in</strong>age phase;<br />

- 09 solenoid pilot electric valve 5/2 1/8” 24 VAC (pneumatic activated valves DN50 - fast dry<strong>in</strong>g<br />

and de-water<strong>in</strong>g process) complete of distributor and accessories;<br />

-<br />

7) Pa<strong>in</strong>ted steel pipes for compressed air distribution to the <strong>cast<strong>in</strong>g</strong> moulds (fast dry<strong>in</strong>g and dewater<strong>in</strong>g<br />

process) complete of <strong>automatic</strong> three ways valves, distributors, manual valves,<br />

connections, compressed air regulation group and accessories. N.03 different circuits and pipe<strong>l<strong>in</strong>e</strong>s.<br />

8) Hydraulic safety devices aga<strong>in</strong>st suspended structures fall<strong>in</strong>g. The system is composed with 2<br />

pistons equipped of <strong>in</strong>tegrated flow control devices and out-let electric signal.<br />

9) Centralized electric control board dim. 2800 x 400 x 2000 mm. (3 <strong>cast<strong>in</strong>g</strong> units) constituted of:<br />

It should control the follow<strong>in</strong>g motors:<br />

- 03 by 3 kW/each (central <strong>cast<strong>in</strong>g</strong> unit – lift<strong>in</strong>g moulds);<br />

- 03 by 1,5 kW/each (central <strong>cast<strong>in</strong>g</strong> unit – open<strong>in</strong>g lateral moulds)<br />

- 06 by 1,5 kW/each (air blowers for slip dra<strong>in</strong>age)<br />

- 12 by 1,5 kW/each (deposit belt conveyors – longitud<strong>in</strong>al motion)<br />

- 12 by 0,25 kW/each (deposit belt conveyors – lateral motion)<br />

- 30 axial fans diam. 300 mm.<br />

- 220/380V 50Hz. – <strong>in</strong>stalled power 150W<br />

Should be controlled the follow<strong>in</strong>g equipment:<br />

- 42 solenoid electric pilot valves 5/2 diam. 24V AC;<br />

- 03 on/off electric valve diam. ½” 24VAC;<br />

- 12 pressure switches;<br />

- 12 magnetic sensors for cha<strong>in</strong> conveyor slid<strong>in</strong>g removable guides;<br />

- 18 limit switches for vertical motion control;<br />

- 06 limit switches for horizontal motion control (moulds open<strong>in</strong>g);<br />

- 24 limit switches for lateral motion of cha<strong>in</strong> conveyors;<br />

- 06 electric limit switches (conveyors for transport pieces control);

- PLC with CPU dimensioned to control the above listed equipment;<br />

- 12 electric level controls;<br />

- 60 magnetic sensors for feed-back signal of pneumatic cyl<strong>in</strong>ders (rims moulds slop<strong>in</strong>g);<br />

- 120 magnetic sensors for feed-back signal of pneumatic cyl<strong>in</strong>ders (blockage of rims moulds steel<br />

frames);<br />

- 06 magnetic sensors for feed-back signal of pneumatic cyl<strong>in</strong>der (rims moulds lower cars slid<strong>in</strong>g);<br />

- Touch screen operat<strong>in</strong>g panel 10” with synoptic panel;<br />

- Nbr. 02 Additional remote touch screen panels 10”<br />

- Software for <strong>automatic</strong> control of the follow<strong>in</strong>g work<strong>in</strong>g phases:<br />

- slip circulation for pipes clean<strong>in</strong>g;<br />

- moulds clos<strong>in</strong>g;<br />

- moulds fill<strong>in</strong>g (Slip Cast<strong>in</strong>g);<br />

- slip dra<strong>in</strong>age;<br />

- harden<strong>in</strong>g;<br />

- moulds open<strong>in</strong>g;<br />

- de-mould<strong>in</strong>g;<br />

- start/stop spag-less moulds fast de-water<strong>in</strong>g system;<br />

- pieces transport on the belt conveyors;<br />

- safeties;<br />

(Control cab<strong>in</strong>et will be provided of lamp and acoustic alarm.)<br />

General control board is realized <strong>in</strong> accord<strong>in</strong>g with CE Standard Norms.<br />

SEMI AUTOMATIC MULTI-LEVEL TRANSFER SYSTEMS MOD. TMP (Optional)<br />

It is designed to work <strong>in</strong> synchronized way with the double level cha<strong>in</strong> conveyor.<br />

It is composed of:<br />

- welded, bolted and pa<strong>in</strong>ted steel frame (base + vertical columns) realised <strong>in</strong> squared<br />

profiles and wheeled base;<br />

- convey<strong>in</strong>g movable table (LxW 1800 x 500 mm.) complete of driven cha<strong>in</strong><br />

and motorization 0,25 Kw with frequency<br />

drive;

- vertical high precision <strong>l<strong>in</strong>e</strong>ar guides complete of wheels and movable car;<br />

- motor gear box 0,75 kW. for vertical motion complete of electric brake and frequency controller for<br />

soft start/stop. An encoder device is applied to this gear box <strong>in</strong> order to manage <strong>in</strong> <strong>automatic</strong> way<br />

the <strong>multi</strong>-level deposit of the green pieces;<br />

- vertical transmission system composed of 2 cha<strong>in</strong>s, p<strong>in</strong>ions, forced expansion taper lock, steel<br />

shaft and bear<strong>in</strong>gs and protection carters;<br />

- longitud<strong>in</strong>al motion motor gear box 0,55 kW. equipped with frequency controller for soft start/stop<br />

complete of p<strong>in</strong>ion and 1,5 mt. of rack-over with shaped rail;<br />

- compact electric box with human <strong>in</strong>terface device “touch screen” assembled on adjustable<br />

movable arm;<br />

- electric power control board 800x400 mm. complete of m<strong>in</strong>i PLC;<br />

WORKING SEQUENCE DESCRIPTION:<br />

- convey<strong>in</strong>g movable table <strong>in</strong> lower stand<strong>in</strong>g position;<br />

- <strong>automatic</strong> position<strong>in</strong>g on pick-.up level;<br />

- start<strong>in</strong>g of cha<strong>in</strong> motion on transfer table;<br />

- start of cha<strong>in</strong> conveyor and transfer of casted piece on the movable table;<br />

- <strong>automatic</strong> stop of cha<strong>in</strong> motion on transfer table by means of limit switch;<br />

- lift<strong>in</strong>g of transfer table <strong>in</strong> correspondence to 2 nd level storage conveyor;<br />

- contemporary start<strong>in</strong>g of convey<strong>in</strong>g motions on the transfer table and the 2 nd level conveyor to<br />

operate drop off of casted piece.<br />

- Automatic stop of convey<strong>in</strong>g motions by means of limit switches;<br />

- Automatic return of transfer table on the pick-up position to repeat the sequence;<br />

MACHINERY TECHNICAL DESCRIPTION<br />

001 - TECHNICAL DATA<br />

-<br />

Lenght<br />

Width<br />

Height<br />

OVERALL DIMENSIONS (1 <strong>cast<strong>in</strong>g</strong> unit 10 moulds capacity):<br />

10.660 mm.<br />

7.905 mm.<br />

3.930 mm.

-<br />

Occupied surface<br />

Approx. 85 sq.m.<br />

TECHNICAL CHARACTERISTICS (1 <strong>cast<strong>in</strong>g</strong> unit 10 moulds capacity):<br />

Production capacity<br />

10 pieces/cast<br />

Nbr. Cast/day 2 (**) 4-6 (***)<br />

Casted pieces per day 20(**) 40-60(***)<br />

Nbr. of workers<br />

01/shift<br />

Installed electric power<br />

16 kW<br />

Compressed air pressure<br />

7 bars<br />

Installed moulds 10<br />

Type of production<br />

Stick-on rims Bowls<br />

(**) Increasable with a forced dry<strong>in</strong>g system mounted on the <strong>cast<strong>in</strong>g</strong> <strong>l<strong>in</strong>e</strong><br />

(***) with spagless system <strong>in</strong> 24 hours depend<strong>in</strong>g by the complexity of the casted items;<br />

-<br />

-<br />

OVERALL DIMENSIONS (3 <strong>cast<strong>in</strong>g</strong> unit 30 moulds capacity):<br />

Lenght<br />

31.980 mm.<br />

Width<br />

7.905 mm.<br />

Height<br />

3.930 mm.<br />

Occupied surface<br />

Approx. 255 sq.m.<br />

TECHNICAL CHARACTERISTICS (3 <strong>cast<strong>in</strong>g</strong> unit 30 moulds capacity):<br />

Production capacity<br />

30 pieces/cast<br />

Nbr. Cast/day 2 (**) 4-6 (***)<br />

Casted pieces per day 60(**) 120-180(***)<br />

Nbr. of workers<br />

01/shift<br />

Installed electric power<br />

16 kW<br />

Compressed air pressure<br />

7 bars<br />

Installed moulds 30<br />

Type of production<br />

Stick-on rims Bowls<br />

(**) Increasable with a forced dry<strong>in</strong>g system mounted on the <strong>cast<strong>in</strong>g</strong> <strong>l<strong>in</strong>e</strong><br />

(***) with spagless system <strong>in</strong> 24 hours depend<strong>in</strong>g by the complexity of the casted items;<br />

MAIN GUARANTEED ADVANTAGES<br />

1) Motorized open<strong>in</strong>g/clos<strong>in</strong>g of all the moulds simultaneously;<br />

2) Simultaneous de-mould<strong>in</strong>g of all the casted pieces (same harden<strong>in</strong>g level of the green products);<br />

3) Simultaneous rims <strong>stick</strong><strong>in</strong>g;<br />

4) Perfect clos<strong>in</strong>g of the moulds thanks to the s<strong>in</strong>gle press<strong>in</strong>g comb<strong>in</strong>ed system (mechanical/pneumatic);<br />

5) Possibility to cast different models and designs <strong>in</strong> the same <strong>l<strong>in</strong>e</strong>;

6) Automatic <strong>cast<strong>in</strong>g</strong>;<br />

7) Option of <strong>modular</strong> conception (10 by 10 moulds) of <strong>cast<strong>in</strong>g</strong>, dra<strong>in</strong>age, harden<strong>in</strong>g and moulds open<strong>in</strong>g;<br />

8) Longer life of moulds thanks to mechanized and controlled motions;<br />

9) Easy dry<strong>in</strong>g of all the <strong>in</strong>stalled moulds thanks to the exploded stand<strong>in</strong>g position;<br />

10) Limited deformation of the de-moulded pieces thanks to the absence of manual manipulation;<br />

11) Low physical efforts of the worker;<br />

12) Utilizable with spag-less system moulds;