automatic modular casting line type bav multi-stick ... - Azienda in fiera

automatic modular casting line type bav multi-stick ... - Azienda in fiera

automatic modular casting line type bav multi-stick ... - Azienda in fiera

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

-<br />

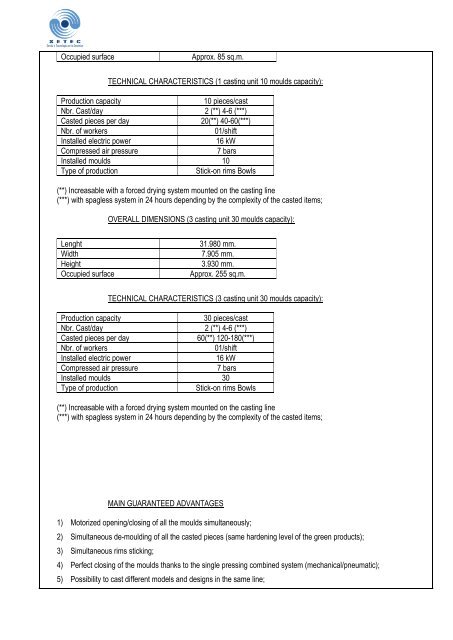

Occupied surface<br />

Approx. 85 sq.m.<br />

TECHNICAL CHARACTERISTICS (1 <strong>cast<strong>in</strong>g</strong> unit 10 moulds capacity):<br />

Production capacity<br />

10 pieces/cast<br />

Nbr. Cast/day 2 (**) 4-6 (***)<br />

Casted pieces per day 20(**) 40-60(***)<br />

Nbr. of workers<br />

01/shift<br />

Installed electric power<br />

16 kW<br />

Compressed air pressure<br />

7 bars<br />

Installed moulds 10<br />

Type of production<br />

Stick-on rims Bowls<br />

(**) Increasable with a forced dry<strong>in</strong>g system mounted on the <strong>cast<strong>in</strong>g</strong> <strong>l<strong>in</strong>e</strong><br />

(***) with spagless system <strong>in</strong> 24 hours depend<strong>in</strong>g by the complexity of the casted items;<br />

-<br />

-<br />

OVERALL DIMENSIONS (3 <strong>cast<strong>in</strong>g</strong> unit 30 moulds capacity):<br />

Lenght<br />

31.980 mm.<br />

Width<br />

7.905 mm.<br />

Height<br />

3.930 mm.<br />

Occupied surface<br />

Approx. 255 sq.m.<br />

TECHNICAL CHARACTERISTICS (3 <strong>cast<strong>in</strong>g</strong> unit 30 moulds capacity):<br />

Production capacity<br />

30 pieces/cast<br />

Nbr. Cast/day 2 (**) 4-6 (***)<br />

Casted pieces per day 60(**) 120-180(***)<br />

Nbr. of workers<br />

01/shift<br />

Installed electric power<br />

16 kW<br />

Compressed air pressure<br />

7 bars<br />

Installed moulds 30<br />

Type of production<br />

Stick-on rims Bowls<br />

(**) Increasable with a forced dry<strong>in</strong>g system mounted on the <strong>cast<strong>in</strong>g</strong> <strong>l<strong>in</strong>e</strong><br />

(***) with spagless system <strong>in</strong> 24 hours depend<strong>in</strong>g by the complexity of the casted items;<br />

MAIN GUARANTEED ADVANTAGES<br />

1) Motorized open<strong>in</strong>g/clos<strong>in</strong>g of all the moulds simultaneously;<br />

2) Simultaneous de-mould<strong>in</strong>g of all the casted pieces (same harden<strong>in</strong>g level of the green products);<br />

3) Simultaneous rims <strong>stick</strong><strong>in</strong>g;<br />

4) Perfect clos<strong>in</strong>g of the moulds thanks to the s<strong>in</strong>gle press<strong>in</strong>g comb<strong>in</strong>ed system (mechanical/pneumatic);<br />

5) Possibility to cast different models and designs <strong>in</strong> the same <strong>l<strong>in</strong>e</strong>;