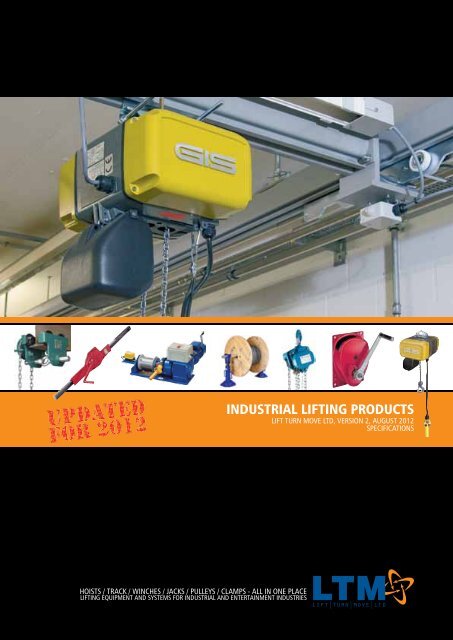

INDUSTRIAL LIFTING PRODUCTS - Lift Turn Move

INDUSTRIAL LIFTING PRODUCTS - Lift Turn Move

INDUSTRIAL LIFTING PRODUCTS - Lift Turn Move

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Hoists / Track / Winches / Jacks / Pulleys / CLAMPS - ALL IN ONE PLACE<br />

<strong>Lift</strong>ing Equipment and Systems for Industrial and Entertainment Industries<br />

<strong>INDUSTRIAL</strong> <strong>LIFTING</strong> <strong>PRODUCTS</strong><br />

<strong>Lift</strong> <strong>Turn</strong> <strong>Move</strong> Ltd, Version 2, August 2012<br />

Specifications

<strong>Lift</strong> turn move ltd<br />

2<br />

Contact Details<br />

LTM - <strong>Lift</strong> <strong>Turn</strong> <strong>Move</strong> Ltd tel: +44 (0)151 649 0467<br />

Unit 2 Stadium Court fax: +44 (0)151 649 0099<br />

Wirral International Business Park Email: sales@<strong>Lift</strong><strong>Turn</strong><strong>Move</strong>.co.uk<br />

Plantation Road<br />

www.liftturnmove.co.uk<br />

Bromborough<br />

Wirral CH62 3QG<br />

Sales Contacts:<br />

mObile Direct dial email<br />

Robert Price 07939 592 025 0151 649 1052 RobertPrice@liftturnmove.co.uk<br />

Ric Nuttall 07989 355 007 0151 649 1050 RicNuttall@liftturnmove.co.uk<br />

Peter Ashford 07774 257 409 - PeterAshford@liftturnmove.co.uk<br />

Jenny Steenson - 0151 649 1054 JennySteenson@liftturnmove.co.uk<br />

Head of industrial products:<br />

James Porter 07852 928 798 0151 649 1051 JamesPorter@liftturnmove.co.uk<br />

TECHNICAL CONTACT: ACCOUNTS CONTACT:<br />

works@liftturnmove.co.uk<br />

accounts@liftturnmove.co.uk<br />

Opening Hours: Monday - Friday 9.00am - 5.00pm the office is often open outside these times.<br />

Deliveries: We use various methods of delivery and can deliver more or less whenever you need.<br />

To stay up to date with the latest events at LTM please follow us on Facebook, Twitter and LinkedIn<br />

liftturnmove<br />

@<strong>Lift</strong><strong>Turn</strong><strong>Move</strong><br />

@<strong>Lift</strong> <strong>Turn</strong> <strong>Move</strong> Ltd<br />

LTM – <strong>Lift</strong> <strong>Turn</strong> <strong>Move</strong> Ltd<br />

<strong>Lift</strong> <strong>Turn</strong> <strong>Move</strong> Ltd (LTM) is an independent company, wholly owned and operated by the people who run the business day to day. This ensures decisions and<br />

actions are made swiftly and customer service is our top priority.<br />

LTM was set up in September 2004, with the aim of being customer focused and an enjoyable but professional place to work. We have eight sales staff, eight<br />

works staff (including two apprentices) and two staff in administration roles. All sales, technical and workshop staff hold LEEA qualifications and LEEA Team<br />

Cards and have on-going product training. Our processes are audited and checked by LEEA (<strong>Lift</strong>ing Equipment Engineers Association), of which we are full<br />

members.<br />

Markets, Clients and Products<br />

LTM operates in markets in which <strong>Lift</strong>ing, Handling, Supporting, <strong>Turn</strong>ing or Moving Loads are required. We supply an extensive range of Equipment and Solutions<br />

for use within the Engineering, Logistics, Construction, Utilities and Energy Industries. We also supply the Professional Leisure, Entertainment and Theatrical<br />

Industries.<br />

Our main clients are lifting gear re-sellers, dealers, system integrators, project installers, stage engineering companies, entertainment production companies,<br />

original equipment manufacturers and equipment rental companies.<br />

We offer Equipment and Solutions including Electric Chain Hoists, Control and Motion Control Systems, Manual <strong>Lift</strong>ing & Handling Equipment, Winches, Davits,<br />

Light Crane Systems, Jacks and Sluice Gate Jacks.<br />

Distributor Sales Policy<br />

As a <strong>Lift</strong> <strong>Turn</strong> <strong>Move</strong> (LTM) distributor of branded hoists, winches, jacks and lifting equipment, you have an opportunity to add further income and profit to<br />

your company by dealing with one of the most respected suppliers. With over 200 man years of lifting equipment experience we focus on high specification<br />

applications that require safety provided by its quality equipment range.

<strong>Lift</strong> turn move ltd<br />

LTM offers brands with a reputation for value, performance and quality engineering.<br />

• GIS Electric hoists, Track and Vacuum systems - the number one choice and a brand with instant global recognition for chain hoist applications.<br />

• Haacon - German engineering quality in Winches and Jacks<br />

• Ableforge Manufacturing Inc. - a quality Hand Chain Block and Manual Handling Equipment range<br />

3<br />

From our facilities in Bromborough we support distributors with a total package of help, advice and assistance from sales and workshop staff, marketing,<br />

promotion and training materials, spare parts and full technical support. Our staff are friendly, helpful and part of a good team of colleagues working together.<br />

In today’s tough economic climate it makes sense to explore every avenue to boost turnover and profits, and if you are interested in becoming an LTM distributor<br />

we would be happy to visit you to discuss how joining us could help you achieve your commercial ambitions.<br />

Websites, Information, and Product Documentation<br />

For further information about LTM and its products, people and services, please visit; www.liftturnmove.co.uk, and follow us on Facebook, Twitter & LinkedIn.<br />

All LTM products are supplied with comprehensive operating instructions. Also included is an EC Declaration of Conformity which confirms the certified status<br />

of the product.<br />

Additional operating manuals, spare part lists, wiring diagrams, maintenance instructions and technical drawings etc. are available on request or from our<br />

websites.<br />

Support with your marketing & promotional efforts<br />

As a commitment to our distributors, we have developed product and industry specific brochures, product charts, safety posters, flyers, interactive CD’s and<br />

websites.<br />

Please contact your sales contact for all literature, posters, images, videos, photographs, website advice and information, fonts or logos.<br />

We are happy to release the copyright of all our images for use on distributor’s websites or in your own brochures providing written consent is obtained from<br />

<strong>Lift</strong> <strong>Turn</strong> <strong>Move</strong> Ltd.<br />

Product Training & familiarization<br />

LTM continues to offer high quality equipment familiarisation and product training courses for our clients. Please consult either our web site or your normal<br />

contact at LTM if you would like to attend any of the courses that we run.<br />

Having moved premises recently we are constructing a new lifting equipment training centre in Bromborough. The school will provide a variety of courses to<br />

help employers and users operate, maintain and service GIS hoists, winches and other equipment that we offer.<br />

Experienced LTM training staff with experience of use and maintenance of lifting equipment ensure practical and thorough training in line with current legislation.<br />

As well as providing training for users, the centre will be available for companies who wish to run their own specific safety and lifting operation courses.<br />

Examples of training courses currently available include:<br />

• GIS training schools- Repair & Maintenance of electric chain hoists.<br />

• Able Forge training Schools- Repair and maintenance of manual chain hoists.<br />

• LoadGuard® Entertainment Hoist Training Schools.<br />

• Repair and Maintenance of Winches and Jacks<br />

Workshop Services<br />

We can offer repairs, routine maintenance and Thorough Inspections on all our products at our UK workshop. However our products are also available through<br />

the main stockists of our equipment throughout the UK and overseas who also undertake inspection, repairs, installation and servicing.

<strong>Lift</strong> turn move ltd<br />

4<br />

Policies…. We would like to draw your attention to some of our policies<br />

Goods Return Policy<br />

Either when incorrect goods are ordered by the distributor or the user or when goods are dispatched but later cancelled or are unwanted by the distributor or<br />

end user the following policy applies:<br />

On either of the above occasions, unless otherwise confirmed to the contrary in writing we will levy a standard handling charge. This handling charge is to cover<br />

administration costs, inspection and restocking of the returned goods.<br />

The handling charge on standard products is 15% of the net value minus any carriage costs. (Standard products are products in this brochure which are not<br />

manufactured to order).<br />

For non- standard products the handling charges is 25%<br />

Items that have been manufactured to a customer’s special requirement CANNOT be returned for credit.<br />

Returns Authorisation Number Request<br />

Before any goods are returned the distributor must contact a member of the sales team to gain a Returns Authorisation Number and form (RAN)<br />

Goods that arrive at without a RAN number and form will not be accepted and may be refused by our goods inward department, delaying any credits due.<br />

Upon the accepted return of goods, each item will be inspected and if on inspection it is noted that refurbishment is required before it can be returned into<br />

general stock the company will charge for this refurbishment. This work will be done at our standard repair charge rate and we will inform you of the faults or<br />

damage noted and the work required to reinstate the item to a saleable condition.<br />

All returned goods are to be returned by the distributor at their cost with a copy of the RAN number clearly marked on the goods and the completed form.<br />

Quality Policy Statement<br />

<strong>Lift</strong> <strong>Turn</strong> <strong>Move</strong> Ltd provides a range of products and standard of service that we hope fully meets your needs. We inspect every item and load test every hoist<br />

we sell. We are working towards ISO 9001, the internationally recognised standard of quality assurance.<br />

LTM are full members of LEEA- the <strong>Lift</strong>ing Equipment Engineers Association, our processes are audited yearly and checked by LEEA Technical Officers.<br />

Warranty Claims<br />

All equipment complies with the high standards of quality established in respect of materials and workmanship and as the sole and exclusive remedy in<br />

discharge of this warranty the company undertakes to replace free of charge within 12 months from date of dispatch from its works any components which are<br />

provided to the satisfaction of the company (whose decision shall be final and binding) to be defective in materials and workmanship.<br />

This is provided notice in writing to the company is given within 10 days of the defect occurring and provided the component which is the subject of the<br />

complaint is returned pre-paid to our works at Bromborough.<br />

In the case of defective components or parts not of the company’s manufacture the company’s liability shall be limited so such adjustment or allowance as the<br />

manufacturer shall offer.<br />

Note- <strong>Lift</strong> <strong>Turn</strong> <strong>Move</strong> Ltd will not accept responsibility for such work done or expense incurred by the buyer in connection with any repair or replacement unless<br />

the company’s prior written authorisation has been obtained.<br />

This warranty is in lieu and excludes all other conditions and warranties whatsoever whether expressed or implied and whether under common law, statue<br />

law otherwise and apart from aforesaid the company hereby expressly excludes all liability for any loss or damage whatsoever arising and howsoever caused.<br />

The buyer warrants that it will pass on, to all third parties to whom it may supply the goods, all information as to the use and safe handling of the goods, as<br />

may have been passed onto the buyer by the company.<br />

Why Use LTM<br />

We pride ourselves on fast response and delivery. The attitude of our staff makes a difference; we would not be where we are today, or where we are going to<br />

be in the future without them.<br />

We hold an extensive range of equipment including spare parts at our premises in the UK but without the understanding of the needs of demanding and rapidly<br />

moving industries by our staff we would not have the support in place that you need.<br />

All our staff hold qualifications relating to the products and services we supply; this is something we are very proud of.<br />

When to deal with LTM, you get experience, problem solving and most of all flexibility – free of charge.

Contents<br />

2-5 Introduction to <strong>Lift</strong> <strong>Turn</strong> <strong>Move</strong> Ltd & Contacts, Policies & Contents<br />

6-30 GIS Products; Electric Hoists, KB Track and Vacuum <strong>Lift</strong>ing Equipment<br />

5<br />

31-51 Ableforge Manufacturing Inc. Equipment (Manual Hoisting & Handling Equipment)<br />

52-56 Silverline Manual <strong>Lift</strong>ing Equipment & Beam Clamps<br />

57-58 Winch Information<br />

59-64 Winches - Spur Gear; Wall Mounted<br />

65 Winches - Spur Gear; Wall/Base Mounted<br />

66-71 Winches - Spur Gear; Base/Column Mounted<br />

72-75 Winches - Worm Gear; Wall mounted<br />

76-83 Winches - Harsh Environment & Special Application Winches<br />

84-87 Pulleys and Sheaves<br />

88-89 Gearbox & Braked Safety Cranks<br />

90-91 Load & Fall Arrestors<br />

92-95 Electric Winches<br />

96-100 Rack and Pinion Jacks & Steel Jacks<br />

101-103 Spindle Supports - Jacking Legs<br />

104 Cable Drum Jacks - Screw type<br />

105-113 Sluice Gate Drives & Water Industry Products<br />

114-117 Spare parts list - Silverline/Rexline Hoists<br />

118-145 Spare parts list - GIS GCH Electric Chain Hoists (V1 & V2)<br />

146-149 LoadGuard - Overview of Entertainment <strong>Lift</strong>ing Equipment & Systems<br />

150-155 Technical information (IP & FEM data), conversion table

Overview of GIS Products<br />

6<br />

<strong>Lift</strong>ing technology<br />

GIS GCH electric chain hoists (125 to 5,000 kg)<br />

• Hard working, low wear, reliable, easy to maintain<br />

• Application: stationary, movable on I-beams or combined with GIS crane system<br />

Crane technology<br />

GISKB crane system (up to 1,250 kg) - Steel or aluminium<br />

• Modular concept<br />

• Single and double bridge suspended crane for all-round goods transportation<br />

• Monorail with bends and switches for linebound transportation<br />

• Lightweight design<br />

GIS travelling cranes (up to 5,000 kg)<br />

• Designed to customer specifications<br />

• Conventional design<br />

• Especially suitable for larger spans<br />

GIS slewing pillar and wall cranes (up to 1,000 kg)<br />

• For use when ceilings have insufficient load-bearing capacity<br />

• An ideal addition to your suspended crane<br />

• Quick to plan, simple, easy to handle<br />

Vacuum lifting technology<br />

Gentle lifting with GIS vacuum equipment (up to 500 kg)<br />

• For all types of surfaces and a huge variety of products<br />

• Can be combined with electric chain hoists/wire rope hoists<br />

Benefits to you:<br />

• Quality products<br />

• Tested and proven thousands of times over<br />

• Simple design and installation<br />

• Extendable at any time

GIS gch Electric chain hoists<br />

7<br />

GIS GCH Electric Chain Hoists (125 to 5000 kg)<br />

A further evolution in chain hoist development from GIS, specialists in chain hoist manufacture since 1963. The GIS manufacturing facility in Switzerland contains<br />

some of the most modern machining centres and the hoist embodies the latest manufacturing techniques and technology.<br />

• Designed and manufactured to work in the most extreme of conditions<br />

• <strong>Lift</strong>ing capacity from 125–5000kg<br />

• Hoist body and end covers manufactured from die cast aluminium<br />

• Reliable, low wear, easy to maintain<br />

• Single or dual speeds available with many different speed options<br />

• Permanent hoist lubrication for wear resistant operation<br />

• Cast aluminium housing and end covers using the latest casting technology,<br />

maximum solidity (not plastic)<br />

• New advanced brake design providing maximum safety with minimum maintenance<br />

• Five or six pocket chain wheel giving extremely quiet running<br />

• 42V control system, electrical geared limit switches fitted as standard<br />

• Fitted with mechanical stops to prevent over travel as required in FEM standards<br />

• Ergonomic design 2 or 4 button control pendant with E stop<br />

• Available with Eye or Hook suspension, push or electric trolley on I-Beams<br />

or combined with GIS crane system

GIS GCH Electric Chain Hoist - Features<br />

8<br />

Brake<br />

• Maximum safety (construction<br />

with brake after slipping clutch)<br />

• New advanced brake design<br />

• Maintenance free<br />

Chain wheel<br />

• Made of hardened steel<br />

• 5 & 6 chain pockets, hence quiet running<br />

and improved running properties<br />

• With double bearing construction<br />

Geared limit switch (standard)<br />

• Simple adjustment<br />

• Exact positioning<br />

• <strong>Lift</strong>ing heights up to 220 m<br />

• Accuracy for repetition assured<br />

Transmission<br />

• Helical-toothed first and second gear<br />

step for quiet running<br />

• Permanent lubrication for wear<br />

resistant operation<br />

Contactor control system<br />

• Simple technology (no electronics<br />

susceptible to interference)<br />

• Reliable technique<br />

• Emergency stop as standard<br />

• 42V control system allowing highest<br />

safety of operation<br />

Hoisting chain<br />

• Calibrated especially for GIS<br />

• Zinc plated<br />

• Surface-hardened<br />

• Quality class DAT<br />

(8SS) to FEM 9.671

GIS GCH Electric Chain Hoist - Features<br />

Chain guidance<br />

• 2-part construction to optimize maintenance<br />

• Reinforced Polyoxymethylene material<br />

highly wear resistant<br />

• Safe operation-jamming excluded<br />

9<br />

Slipping clutch<br />

• Simple and precise adjustment<br />

• Maintenance free and highly resistant to wear<br />

• Ease of servicing thanks to comfortable access<br />

Motor<br />

• Design for tough working conditions<br />

• Normal, fast and super fast speed models available<br />

• With single or dual speed<br />

• Option: with temperature control system<br />

• Option: with insulation for the tropics<br />

• Special voltages available<br />

• 1-phase models - 220 or 110v supply<br />

Control switch<br />

• With built-in support wire as a standard<br />

• 2-buttons: design especially ergonomic<br />

• Emergency stop as standard<br />

• Protection: IP 65 to DIN 40050<br />

• Optional: with integrated working<br />

hours counter<br />

Housing<br />

• Cast aluminium housing with maximum solidity<br />

(no plastic material)<br />

• For extreme working conditions: cast cooling fins<br />

• Easy transformation from 1- fall to 2-fall operation:<br />

no need to dismantle

GIS GCH Electric Chain Hoist - specifications 415v - 3 phase 50hz<br />

10<br />

Type FEM Duty Classification/<strong>Lift</strong>ing Capacity <strong>Lift</strong>ing<br />

speed<br />

M3 1Bm M4 1Am M5 2m M6 3m M7 4m<br />

150 s/h 180 s/h 240 s/h 300 s/h 360 s/h<br />

25% duty 30% duty 40% duty 50% duty 60% duty<br />

Motor<br />

power<br />

3 x 400V<br />

50Hz<br />

No. Of<br />

chain<br />

falls<br />

Eye/hook<br />

suspension<br />

weight 3m lift<br />

Weight per<br />

extra metre<br />

lift<br />

(kg) (kg) (kg) (kg) (kg) (m/min) (kW) (A) (kg) (kg)<br />

GCH 250/1N 250 200 160 125 100 8 0.36 1.3 1 19 0.32<br />

GCH 250/1NF 250 200 160 125 100 8/2 0.36/0.09 2.7/3.0 1 22 0.32<br />

GCH 250/1SF 160 125 100 80 60 12.5/3 0.36/0.09 2.7/3.0 1 22 0.32<br />

GCH 250/1HF 100 80 60 50 40 20/5 0.36/0.09 2.7/3.0 1 22 0.32<br />

GCH 250/2N 500 400 320 250 200 4 0.36 1.3 2 22.5 0.64<br />

GCH 250/2NF 500 400 320 250 200 4/1 0.36/0.09 2.7/3.0 2 23 0.64<br />

GCH 250/2SF 320 250 200 160 125 6.25/1.5 0.36/0.09 2.7/3.0 2 23 0.64<br />

GCH 500/1N 500 400 320 250 200 8 0.72 2.1 1 20 0.52<br />

GCH 500/1NF 500 400 320 250 200 8/2 0.72/0.18 2.9/3.0 1 22.5 0.52<br />

GCH 500/1SF 320 250 200 160 125 12.5/3 0.72/0.18 2.9/3.0 1 22.5 0.52<br />

GCH 500/1HF 200 160 125 100 80 20/5 0.72/0.18 2.9/3.0 1 22.5 0.52<br />

GCH 500/2N 1000 800 630 500 400 4 0.72 2.1 2 22.5 1.04<br />

GCH 500/2NF 1000 800 630 500 400 4/1 0.81/0.18 2.9/3.0 2 25 1.04<br />

GCH 500/2SF 630 500 400 320 250 6.25/1.5 0.81/0.18 2.9/3.0 2 25 1.04<br />

GCH 1000/1N 1000 800 630 500 400 8 1.45 3.7 1 45 1.04<br />

GCH 1000/1NF 1000 800 630 500 400 8/2 1.45/0.36 4.0/2.8 1 46 1.04<br />

GCH 1000/1SF 500 400 320 250 200 16/4 1.45/0.36 5.8/2.6 1 48 1.04<br />

GCH 1000/2N 2000 1600 1250 1000 800 4 1.45 3.7 2 50 2.08<br />

GCH 1000/2NF 2000 1600 1250 1000 800 4/1 1.45/0.36 4.0/2.8 2 51 2.08<br />

GCH 1000/2SF 1000 800 630 500 400 8/2 1.45/.036 5.8/2.6 2 53 2.08<br />

GCH 1600/1N 1600 1250 1000 800 630 8 2.44 6.0 1 63 1.75<br />

GCH 1600/1NF 1600 1250 1000 800 630 8/2 2.44/0.61 6.6/4.2 1 65 1.75<br />

GCH 1600/1SF 1000 800 630 500 400 12.5/3 2.39/0.58 6.6/4.2 1 65 1.75<br />

GCH 1600/2N 3200 2500 2000 1600 1250 4 2.44 6.0 2 73 3.5<br />

GCH 1600/2NF 3200 2500 2000 1600 1250 4/1 2.44/0.61 6.6/4.2 2 75 3.5<br />

GCH 1600/2SF 2000 1600 1250 1000 800 6.25/1.5 2.39/0.58 6.6/4.2 2 75 3.5<br />

GCH 2000/1N 2000 1600 1250 1000 800 8 3.05 7.3 1 65 2.25<br />

GCH 2000/1NF 2000 1600 1250 1000 800 8/2 3.05/0.77 8.0/4.5 1 67 2.25<br />

GCH 2000/1SF 1250 1000 800 630 500 12.5/3 2.98/0.72 8.0/4.5 1 67 2.25<br />

GCH 2000/2N 4000 3200 2500 2000 1600 4 3.05 7.3 2 76 4.5<br />

GCH 2000/2NF 4000 3200 2500 2000 1600 4/1 3.05/0.77 8.0/4.5 2 78 4.5<br />

GCH 2000/2SF 2500 2000 1600 1250 1000 6.25/1.5 2.98/0.72 8.0/4.5 2 78 4.5<br />

GCH 2500/1N 2500 2000 1600 1250 1000 6.4 3.05 7.7 1 65 2.25<br />

GCH 2500/1NF 2500 2000 1600 1250 1000 6.4/1.6 3.05/0.77 8.2/4.4 1 67 2.25<br />

GCH 2500/1SF 1600 1250 1000 800 630 10/2.5 3.05/0.77 8.2/4.4 1 67 2.25<br />

GCH 2500/2N 5000 4000 3200 2500 2000 3.2 3.05 7.7 2 76 4.5<br />

GCH 2500/2NF 5000 4000 3200 2500 2000 3.2/0.8 3.05/0.77 8.2/4.4 2 78 4.5<br />

GCH 2500/2SF 3200 2500 2000 1600 1250 5/1.25 3.05/0.77 8.2/4.4 2 78 4.5<br />

Explanation of the LTM Product Codes for GCH Range of GIS Electric Chain Hoists<br />

GCH 500 1 N E 3<br />

Hoist Series<br />

Hoist Model<br />

250, 500, 1000, 1600,<br />

2000, 2500<br />

Chain Falls<br />

1 or 2 fall<br />

Hoisting speeds<br />

N - Normal 1 Speed 8 m/min (1 fall) 4 m/min (2 fall)<br />

NL - Normal 1 Speed 4 m/min (1 fall) 2 m/min (2 fall)<br />

NF - Normal 2 Speed 8 m/min & 2 m/min (1 fall) 4 & 1 m/min (2 fall)<br />

SF - Fast 2 speed GCH250,500,1600,2000 12.5 & 3 m/min (1 fall) 6.25 & 1.5 m/min<br />

SF - Fast 2 speed GCH1000 16 & 4 m/min (1 fall) 8 & 2 m/min (2 fall)<br />

SF - Fast 2 speed GCH2500 10 & 2.5 m/min (1 fall) 5 & 1.25 m/min (2 fall)<br />

HF - Super Fast 2 speed GCH250,500 20 & 5 m/min (1 fall only)<br />

E = Eye Suspension<br />

H = Top Hook<br />

Suspension<br />

T = Trolley<br />

Suspension<br />

Height of <strong>Lift</strong> (HoL)<br />

For Example<br />

GCH500/1/N/E3 = GCH series, Model 500, 500kg SWL, 1 Fall, 1 speed 8 mpm, eye suspension, 3m HoL<br />

GCH500/2/N/E3 = GCH series, Model 500, 1,000kg SWL, 2 Fall, 1 speed 4 mpm, eye suspension, 3m HoL<br />

GCH1000/1/NF/H8 = GCH series, Model 1000, 1000kg SWL, 1 Fall, 2 speed 8 & 2 mpm, top hook suspenion, 8m HoL<br />

GCH1000/2/NF/H8 = GCH series, Model 1000, 2000kg SWL, 2 Fall, 2 speed 4 & 1 mpm, top hook suspenion, 8m HoL

GIS GCH ELECTRIC CHAIN HOIST – SPECIFICATIONS & Prices – SINGLE PHASE<br />

Type Duty Classification/<strong>Lift</strong>ing Capacity <strong>Lift</strong>ing speed Motor power 1 x 230V<br />

50Hz or<br />

1Bm<br />

150 s/h<br />

1 x 110V<br />

50 Hz<br />

25% duty<br />

No. Of<br />

chain<br />

falls<br />

Eye/hook<br />

suspension<br />

weight 3m lift<br />

Weight per<br />

extra metre<br />

lift<br />

(kg) (m/min) (kW) (A) (kg) (kg)<br />

11<br />

GCH 250/1N 1Ph 160 8 0.23 8.9 1 19 0.32<br />

GCH 250/2N 1Ph 320 4 0.23 8.9 2 22.5 0.64<br />

GCH 500/1N 1Ph 250 8 0.36 8.9 1 20 0.52<br />

GCH 500/2N 1Ph 500 4 0.36 8.9 2 22.5 1.04<br />

GCH 500/1NL 1Ph 500 4 0.36 8.9 1 20 0.52<br />

GCH 500/2NL 1Ph 1000 2 0.36 8.9 2 22.5 1.04<br />

GCH 1000/1NL 1Ph 1000 4 0.72 13.5 1 45 1.04<br />

GCH 1000/2NL 1Ph 2000 2 0.72 13.5 2 50 2.08<br />

GIS GCH HOISTs - general Options<br />

Control pendants for gch electric chain hoists & trolleys<br />

Product Code<br />

GCHCP2-1.8<br />

GCHCP4-1.8<br />

Chain containers/buckets<br />

GIS GCH Control Switch, 2 buttons c/w E-stop & 1.8 control cable<br />

GIS GCH Control Switch, 4 buttons c/w E-stop & 1.8 control cable<br />

Product Code Material To suit Type Max Chain HoL in M To suit Type Max Chain HoL in M To suit Type Max Chain HoL in M<br />

1 Fall 2 Fall 1 Fall 2 Fall 1 Fall 2 Fall<br />

9401.3010.1 Plastic GKM250/6 KS 6 3 GKM500/4KS 4 2 N/A N/A N/A<br />

9401.3011.1 Plastic GKM250/14 KS 14 7 GKM500/10KS 10 5 N/A N/A N/A<br />

9401.3012.2 Steel GKM250/20 20 10 GKM500/16KS 16 8 N/A N/A N/A<br />

9405.3044.1 Plastic GKM1000/8 KS 8 4 N/A N/A N/A N/A N/A N/A<br />

9405.3045.1 Steel GKM1000/20 20 10 GKM1600/10 10 5 GKM2000or2500/8 8 4<br />

9405.3046.1 Steel GKM1600/30 30 15 GKM2000/25 25 12.5 GKM2500/25 25 12.5<br />

Chain containers - textile type (requires bracket)<br />

Product Code Material To suit Type Length Opening Hoist Type / Capacity of chains (m)<br />

Hoist Type 250 500 1000 1600 2000/2500<br />

(cm) (cm) (m) (m) (m) (m) (m)<br />

LGCB-30 Textile GCH ALL 30 18 x 18 Cap of chains 25 25 18 9 8<br />

LGCB-45 Textile GCH ALL 45 18 x 18 Cap of chains 40 40 30 19 14<br />

LGCB-65 Textile GCH ALL 65 18 x 18 Cap of chains 50 50 40 26 19<br />

LGCB-85 Textile GCH ALL 85 18 x 18 Cap of chains 60 60 50 40 28<br />

LGCB-100 Textile GCH ALL 100 18 x 18 Cap of chains 70 70 60 47 36<br />

Chain containers - Brackets<br />

(Required for<br />

textile bags)<br />

IP65 Protection<br />

Product Code<br />

Description<br />

Product Code<br />

Description<br />

LGCB-B25/50K Chain Bag Bracket to suit GCH 250 & 500<br />

LGCB-B100K Chain Bag Bracket to suit GCH 1000<br />

LGCB-B16/20/250K Chain Bag Bracket to suit GCH 1600 & 2000 & 2500<br />

MPIP65.GCH250/500K<br />

MPIP65.GCH1000K<br />

MPIP65.GCH16/2500K<br />

Extra cost IP65 GCH250/500 Chain Hoist<br />

Extra cost IP65 GCH1000 Chain Hoist<br />

Extra cost IP65 GCH1600-2500 Chain Hoist<br />

Temperature-Control (over heat protection)<br />

This protects the hoist from being overheated, when the hoist is close to<br />

overheating. It will not allow the hoist to raise but will lower the load safely.<br />

When cooled the hoist will work as normal.<br />

MPIP65.EMF.K<br />

Extra cost IP65 EMFE50-300 - Electric Travel Trolley<br />

Weather Jackets/Covers<br />

Product Code<br />

Description<br />

Product Code<br />

Description<br />

WC-GCH 250 - 2500 Weather cover - GCH 250 to 2500<br />

WC-GCHETT Weather cover - Electric Trolley 150 to 300<br />

MP9050.60011t Klixon - 120° C 1 Speed<br />

MP9050.6001 2t Klixon - 120° C 2 Speed<br />

Note Weather covers/jackets help to protect the hoist and trolley against<br />

water, rain and dust.<br />

Note not recommended for constant damp/wet environments, but a<br />

permanent cover will always offer better protection.

GIS GCH Electric Chain Hoist - Dimensions<br />

12<br />

A2<br />

A1<br />

A4<br />

B1<br />

C2<br />

C1<br />

H1<br />

C3<br />

B3<br />

A3<br />

B2<br />

DImensions (mm) GIS GCH Electric Chain Hoist<br />

Hoist types A1 mm A2 mm A3 mm A4 mm B1 mm B2 mm B3 mm C1 mm C2 mm C3 mm H1 mm<br />

GCH 250/1 246 281 146 40 309 155 22 164 53 448 369<br />

GCH 250/2 246 281 164 40 309 155 22 164 53 448 408<br />

GCH 500/1 246 281 146 40 309 155 22 164 53 448 377<br />

GCH 500/2 246 281 164 40 309 155 22 164 53 448 417<br />

GCH 1000/1 321 367 190 52 367 180 32 214 69 615 482<br />

GCH 1000/2 321 367 224 52 367 180 32 214 69 615 556<br />

GCH 1600/1 345 424 221 75 389 180 37 230 135 696 608<br />

GCH 1600/2 345 424 263 75 389 180 37 230 135 696 690<br />

GCH 2000/1 345 424 221 75 389 180 37 230 135 696 608<br />

GCH 2000/2 345 424 263 75 389 180 37 230 135 696 690<br />

GCH 2500/1 345 424 221 75 389 180 37 230 135 696 608<br />

GCH 2500/2 345 424 263 75 389 180 37 230 135 696 690<br />

Product data is available on request to our sales office by email: sales@liftturnmove.co.uk

example of Custom hoist features from ltm<br />

Electric Chain Hoist considerations And custom solutions we offer as standard…<br />

When assessing an electric hoist application it is advisable to consider the following:<br />

• Environment<br />

Is the hoist to be used or stored outside If the answer is yes, then consideration must be given to the level of protection provided. i.e.: a cover to park<br />

the hoist under when not in use or a higher level of enclosure specification. Can the hoist be easily removed for storage when not in use<br />

• Power Supply<br />

Is there an adequate power supply available adjacent to the hoist location What is the distance between the hoist and the supply If there is then is<br />

the supply suitable, i.e.: 400v 3Ph 50hz, 110v 1ph 50hz. Please specify others if different.<br />

13<br />

In each case it is recommended that the supply cables and equipment are checked to ensure compatibility and that the installation conforms to the current UK<br />

and European standards.<br />

• Atmosphere (ATEX)<br />

There are applications when equipment is required to work in hazardous areas such as petro chemical and pharmaceutical plants. The user then has a<br />

duty to identify if there are gases and the classification or zoning of the area must be under taken by the user and suitable equipment obtained.<br />

To learn more about hoists in explosive environments please contact <strong>Lift</strong> <strong>Turn</strong> <strong>Move</strong>’s sales office and ask for the ATEX product catalogue. Tel: 0151 649 0467<br />

After considering the above, the following custom hoist features from LTM maybe of interest to you<br />

Travel Limit switches;<br />

• Proximity - we have developed limits suitable for use in the Nuclear Industry.<br />

• Mid travel limits - to stop travel in one movement direction for position. (NOTE - requires custom control panel which is available from LTM).<br />

• Two emergency limits in addition to working units<br />

• Mechanical stops (to fit on chain to stop travel movement - a simple but efficient solution)<br />

Positional Encoders; Two types are available.<br />

• Incremental<br />

• Absolute<br />

NOTE - control systems are needed for feedback from the encoders (which LTM can provide).<br />

Upper or Lower Suspension;<br />

• Upper suspension can be an eye, swivel hook or custom plate.<br />

• Locking hooks<br />

Handles;<br />

• We can add carrying handles to the chain hoist body.<br />

Load Cells ; Two options available<br />

Installed on hoists in the eye or hook suspension (internal). Load cells can be fitted to eye and hook suspension to detect pre-set under and overloads or show<br />

an actual load on a hoist, or external units supplied as load cells within shackles.<br />

NOTE - Separate monitoring system and cabling will also be required and can be provided by LTM.<br />

Control;<br />

• Portable or wall mounted control units to operate multiple chain hoist systems.<br />

• Radio control (wireless) – for single or multiple hoist systems<br />

Hoists working outside or in aggressive atmosphere;<br />

• The standard IP rating for a GIS hoist is to IP55, we can now upgrade the hoist to IP65 Class (Ingress Protection), totally protected against dust ingress<br />

and protected against low pressure water jets from any direction (i.e. Rain).<br />

To further protect your hoists, there are a number of additional protection (extra cost) features which can be fitted including:<br />

• Galvanised Chain – The biggest threat to protecting outdoor hoists is the chain. Galvanised chain is the best protection against the elements and we<br />

will be over greasing the chain to protect it further. (NOTE we fit black chain as standard in Entertainment applications, Galvanised in Industrial).<br />

• Drainage Holes – This allows any water running down the chain into the pocket wheel to pass straight through the body rather than collecting inside<br />

and causing rust/chain damage.<br />

• Release & Over Pressure Valves – This valve acts as a barrier preventing any moisture in the air being drawn into the body. When a hoist is hot from<br />

running or from being out in the sun all day and then cools down, the pressure difference built up inside the hoist will naturally draw in air. The valve<br />

equalises this pressure, whilst preventing any moisture entering similar to Gore-Tex in outdoor clothing.<br />

• Dipped Transformer – As an added precaution, we can tropical dip the transformers, this is a waxy protection that coats the sensitive transformer completely.<br />

• Weather Covers – The weather cover will protect the hoist from the worst of the elements.<br />

Further GIS Options;<br />

• Stainless steel components<br />

• Food and pharmaceutical grade hoists- stainless steel components plus special coatings in place of paint<br />

• ATEX hoists<br />

• Duo hoists<br />

• Synchron hoists<br />

Custom solutions as standard from <strong>Lift</strong> <strong>Turn</strong> <strong>Move</strong><br />

If you have any doubts or questions regarding which electric hoist to purchase or the application you are using it in please ask a member of the LTM sales<br />

team to prior to purchasing!

GIS Manual Travel Trolley – EHF Series<br />

EHF 50/150<br />

EHF 300/500<br />

EHF 50/150/300/500<br />

14<br />

Specification & Prices - ehf trolley series<br />

ISO (FEM)<br />

classification<br />

M3 (1Bm)<br />

150 s/h<br />

25% duty<br />

M4 (1Am)<br />

180 s/h<br />

30% duty<br />

M5 (2m)<br />

240 s/h<br />

40% duty<br />

M6 (3m)<br />

300 s/h<br />

50% duty<br />

M7 (4m)<br />

360 s/h<br />

60% duty<br />

Self<br />

weight<br />

Electric or<br />

manual<br />

Beam Width Range<br />

Type Capacity (kg) (kg)<br />

EHF 50 1,000 800 630 630 500 7.5 Manual 50-99mm 100-149mm 150-200mm 201-240mm<br />

EHF 150 2,000 2,000 1,600 1,600 1,250 13.5 Manual 76-139mm 140-199mm 200-259mm 260-300mm<br />

EHF 300 4,000 4,000 3,200 2,500 2,500 27.5 Manual 56-119mm 120-179mm 180-239mm 240-300mm<br />

EHF 500 5,000 4,000 3,200 3,200 2,500 27.5 Manual 56-119mm 120-179mm 180-239mm 240-300mm<br />

DImensions (mm) - ehf series<br />

Types e1 (mm) e2 (mm) f1 (mm) f2 (mm) f3 (mm) f4 (mm) f5 (mm) f6 (mm) g1(mm) g2(mm)<br />

EHF 50 215 - - - - 183 23 - 49 167<br />

EHF 150 250 - - - - 230 27 - 60 203<br />

EHF 300 311 - - - - 290 31 - 55 218<br />

Options<br />

• other flange widths<br />

• Selection of travel trolleys:<br />

GCH 250/500: EHF50<br />

GCH 1000: EHF150<br />

GCH 1600/2000: EHF300<br />

GCH 2500: EHF500<br />

EHF 500 311 - - - - 290 31 - 55 218<br />

GIS MANUAL TROLLEY GHF 500K<br />

• For use with GCH250 and GCH500<br />

Electric Chain Hoists<br />

• Can be used as a standard beam trolley<br />

• Fits beam widths from 50-240mm<br />

• Safe Working Load – Max 500kg<br />

• Designed with a small amount of parts<br />

• Easy assembling and disassembling<br />

• Light aluminium die casting design<br />

• Strong, high resistant glass fibre<br />

reinforced plastic wheels<br />

• Adjustable to all I-beam widths<br />

FEM<br />

Classification<br />

1Bm<br />

(kg)<br />

1Am<br />

(kg)<br />

2m<br />

(kg)<br />

3m<br />

(kg)<br />

4m<br />

(kg)<br />

Spindle No. 1 Max flange<br />

thickness<br />

x=24 mm Beam Width Range<br />

GHF 500 K 500 500 500 400 320 Width of flange (mm) 50-240 Min flange width 50 mm 50-99mm 100-149mm 150-200mm 201-240mm<br />

B (mm) 30 Weight 2.5 kg<br />

L (mm) 183<br />

No. of tubes * length -<br />

Torque<br />

130 - 150Nm

GIS Power (Electric) Travel Trolley – EMFE Series<br />

Specification & prices - EMFE electric trolley series<br />

ISO<br />

(FEM)<br />

classification<br />

M3 (1Bm) M4 (1Am)<br />

150 s/h 180 s/h<br />

25% duty 30% duty<br />

M5 (2m)<br />

240 s/h<br />

40% duty<br />

M6 (3m)<br />

300 s/h<br />

50% duty<br />

M7 (4m)<br />

360 s/h<br />

60% duty<br />

Travelling<br />

speed<br />

Motor power<br />

(M3)<br />

3 x 400V<br />

50Hz<br />

(M3)<br />

Weight<br />

Electric<br />

or<br />

manual<br />

To be used<br />

with hoist<br />

type<br />

Beam Width Range<br />

15<br />

Type Capacity (kg) (m/min) (kW) (A) (kg)<br />

EMFE 50/N 1,000 800 630 630 500 12 0.25 0.8 27 Electric GCH250/500 50-99mm 100-149mm 150-200mm 201-240mm<br />

EMFE 50/NF 1,000 800 630 630 500 12/4 0.15/0.045 0.65/0.75 27 Electric GCH250/500<br />

EMFE 50/SF 800 800 630 630 500 20/6 0.15/0.045 0.65/0.75 27 Electric GCH250/500<br />

EMFE 150/N 2,000 2,000 1,600 1,600 1,250 12 0.25 0.8 31 Electric GCH1000 76-139mm 140-199mm 200-259mm 260-300mm<br />

EMFE 150/NF 2,000 2,000 1,600 1,600 1,250 12/4 0.15/0.045 0.65/0.75 31 Electric GCH1000<br />

EMFE 150/SF 1,600 1,600 1,600 1,600 1,250 20/6 0.15/0.045 0.65/0.75 31 Electric GCH1000<br />

EMFE 300/N 4,000 4,000 3,200 2’500 2,500 12 0.25 0.8 50 Electric GCH600/2000 56-119mm 120-179mm 180-239mm 240-300mm<br />

EMFE 300/NF 4,000 4,000 3,200 2,500 2,500 12/4 0.15/0.045 0.65/0.75 50 Electric GCH600/2000<br />

EMFE 300/SF 3,200 3,200 3,200 2,500 2,500 20/6 0.15/0.045 0.65/0.75 50 Electric GCH600/2000<br />

EMFE 500/N 5,000 4,000 3,200 3,200 2,500 12 2x0.25 2x0.8 57 Electric GCH2500 56-119mm 120-179mm 180-239mm 240-300mm<br />

EMFE 500/NF 5,000 4,000 3,200 3,200 2,500 12/4 2x0.15/0.045 2x0.65/0.75 57 Electric GCH2500<br />

EMFE 500/SF 4,000 4,000 3,200 3,200 2,500 20/6 2x0.15/0.045 2x0.65/0.75 57 Electric GCH2500<br />

DImensions (mm) - EMFE series<br />

Types e1 (mm) e2 (mm) f1 (mm) f2 (mm) f3 (mm) f4 (mm) f5 (mm) f6 (mm)<br />

EMFE 50 215 62 209 250 241 183 23 -<br />

EMFE 150 250 43 211 253 242 230 27 -<br />

EMFE 300 311 12 217 259 249 290 31 -<br />

EMFE 500 311 12 - 259 249 290 31 249<br />

Options<br />

• other flange widths<br />

• Selection of travel trolleys:<br />

GCH 250/500: EMFE 50<br />

GCH 1000: EMFE 150<br />

GCH 1600/2000: EMFE 300<br />

GCH 2500: EMFE 500<br />

Types g1(mm) g2 (mm) h2 (mm) Flange<br />

width<br />

(mm)<br />

EMFE 50/150/300/500<br />

GCH 250/1 GCH 250/2 GCH 500/1 GCH 500/2<br />

EMFE 50 49 167 418 457 426 466 50 - 99<br />

GCH 1000/1 GCH 1000/2<br />

EMFE 150 60 203 542 616 76 - 139<br />

GCH 1600/1 GCH 1600/2 GCH 2000/1 GCH 2000/2<br />

EMFE 300 55 218 637 719 637 719 120 - 179<br />

GCH 2500/1 GCH 2500/2<br />

EMFE 500 55 218 637 719 120-179<br />

EMFE 50/150<br />

EMFE 300/500

GIS GCH Electric Chain Hoist and trolley options<br />

16<br />

Types GCH<br />

Order Code<br />

SWL<br />

1Bm /<br />

M3<br />

Chain<br />

Falls<br />

Hoist<br />

Speed<br />

Chain<br />

Size<br />

Eye (Lug) Top Hook EXTRA PRICES FOR PUSH OR ELECTRIC TROLLEY<br />

(A) Suspension (B) Suspension Beam PUSH<br />

POWER (ELECTRIC) TRAVEL<br />

Width Travel<br />

(3 mtr <strong>Lift</strong>) (3 mtr <strong>Lift</strong>) Trolley<br />

m/min<br />

Duty Factor 25% m/min (d x p) mm O/C (£) O/C (£) (mm) 12 12/4 20/4<br />

GCH250/1N- 250 1 fall 8 4x12.3 E3 POA H3 POA 50-99 POA POA POA POA<br />

GCH250/1NF- 250 1 fall 8/2 4x12.3 E3 POA H3 POA 50-99 POA POA POA POA<br />

GCH250/1SF- 160 1 fall 12.5/3 4x12.3 E3 POA H3 POA 50-99 POA POA POA POA<br />

GCH250/1HF- 100 1 fall 20/5 4x12.3 E3 POA H3 POA 50-99 POA POA POA POA<br />

GCH250/2N- 500 2 fall 4 4x12.3 E3 POA H3 POA 50-99 POA POA POA POA<br />

GCH250/2NF- 500 2 fall 4/1 4x12.3 E3 POA H3 POA 50-99 POA POA POA POA<br />

GCH250/2SF- 320 2 fall 6.25/1.5 4x12.3 E3 POA H3 POA 50-99 POA POA POA POA<br />

GCH500/1N- 500 1 fall 8 5x15.3 E3 POA H3 POA 50-99 POA POA POA POA<br />

GCH500/1NF- 500 1 fall 8/2 5x15.3 E3 POA H3 POA 50-99 POA POA POA POA<br />

GCH500/1SF- 320 1 fall 12.5/3 5x15.3 E3 POA H3 POA 50-99 POA POA POA POA<br />

GCH500/1HF- 200 1 fall 20/5 5x15.3 E3 POA H3 POA 50-99 POA POA POA POA<br />

GCH500/2N- 1000 2 fall 4 5x15.3 E3 POA H3 POA 50-99 POA POA POA POA<br />

GCH500/2NF- 1000 2 fall 4/1 5x15.3 E3 POA H3 POA 50-99 POA POA POA POA<br />

GCH500/2SF- 630 2 fall 6.25/1.5 5x15.3 E3 POA H3 POA 50-99 POA POA POA POA<br />

GCH1000/1N- 1000 1 fall 8 7x22 E3 POA H3 POA 76-139 POA POA POA POA<br />

GCH1000/1NF- 1000 1 fall 8/2 7x22 E3 POA H3 POA 76-139 POA POA POA POA<br />

GCH1000/1SF- 1000 1 fall 16/4 7x22 E3 POA H3 POA 76-139 POA POA POA POA<br />

GCH1000/2N- 2000 2 fall 4 7x22 E3 POA H3 POA 76-139 POA POA POA POA<br />

GCH1000/2NF- 2000 2 fall 4/1 7x22 E3 POA H3 POA 76-139 POA POA POA POA<br />

GCH1000/2SF- 2000 2 fall 8/2 7x22 E3 POA H3 POA 76-139 POA POA POA POA<br />

GCH1600/1N- 1600 1 fall 8 9x27 E3 POA H3 POA 56-119 POA POA POA POA<br />

GCH1600/1NF- 1600 1 fall 8/2 9x27 E3 POA H3 POA 56-119 POA POA POA POA<br />

GCH1600/1SF- 1000 1 fall 12.5/3 9x27 E3 POA H3 POA 56-199 POA POA POA POA<br />

GCH1600/2N- 3200 2 fall 4 9x27 E3 POA H3 POA 56-119 POA POA POA POA<br />

GCH1600/2NF- 3200 2 fall 4/1 9x27 E3 POA H3 POA 56-119 POA POA POA POA<br />

GCH1600/2SF- 2000 2 fall 6.25/1.5 9x27 E3 POA H3 POA 56-199 POA POA POA POA<br />

GCH2000/1N- 2000 1 fall 8 10x28 E3 POA H3 POA 56-119 POA POA POA POA<br />

GCH2000/1NF- 2000 1 fall 8/2 10x28 E3 POA H3 POA 56-119 POA POA POA POA<br />

GCH2000/1SF- 1250 1 fall 12.5/3 10x28 E3 POA H3 POA 56-199 POA POA POA POA<br />

GCH2000/2N- 4000 2 fall 4 10x28 E3 POA H3 POA 56-119 POA POA POA POA<br />

GCH2000/2NF- 4000 2 fall 4/1 10x28 E3 POA H3 POA 56-119 POA POA POA POA<br />

GCH2000/2SF- 2500 2 fall 6.25/1.5 10x28 E3 POA H3 POA 56-199 POA POA POA POA<br />

GCH2500/1N- 2500 1 fall 6.4 10x28 E3 POA H3 POA 56-119 POA POA POA POA<br />

GCH2500/1NF- 2500 1 fall 6.4/1.6 10x28 E3 POA H3 POA 56-119 POA POA POA POA<br />

GCH2500/1SF- 1600 1 fall 10/2.5 10x28 E3 POA H3 POA 56-199 POA POA POA POA<br />

GCH2500/2N- 5000 2 fall 3.2 10x28 E3 POA H3 POA 56-119 POA POA POA POA<br />

GCH2500/2NF- 5000 2 fall 3.2/0.8 10x28 E3 POA H3 POA 56-119 POA POA POA POA<br />

GCH2500/2SF- 3200 2 fall 5/1.25 10x28 E3 POA H3 POA 56-199 POA POA POA POA<br />

Models comprising basic hoist with either eye or hook suspension, overload clutch, low voltage controls, upper & lower geared limits, limit stop, IP55, & 3<br />

metre height of lift as standard. Aditional heights of lift available on request.<br />

Chain Container and 2 Button (or 4 Button) Pendant with E-stop - Extra Price.<br />

Single and dual speed hoists available<br />

Power - 3 x 380/420V. 50Hz.<br />

Control Voltage: 42v.

GIS GCH Electric Chain Hoist and trolley options<br />

EXTRA PRICES FOR PUSH OR ELECTRIC TROLLEY EXTRA PRICES FOR PUSH OR ELECTRIC TROLLEY EXTRA PRICES FOR PUSH OR ELECTRIC TROLLEY<br />

Beam<br />

Width<br />

PUSH<br />

Travel<br />

Trolley<br />

POWER (ELECTRIC) TRAVEL Beam PUSH POWER (ELECTRIC) TRAVEL Beam PUSH POWER (ELECTRIC) TRAVEL<br />

Width Travel<br />

Width Travel<br />

m/min Trolley<br />

m/min Trolley<br />

m/min<br />

(mm) 12 12/4 20/4 (mm) 12 12/4 20/4 (mm) 12 12/4 20/4<br />

100-149 POA POA POA POA 150-200 POA POA POA POA 201-240 POA POA POA POA<br />

100-149 POA POA POA POA 150-200 POA POA POA POA 201-240 POA POA POA POA<br />

100-149 POA POA POA POA 150-200 POA POA POA POA 201-240 POA POA POA POA<br />

100-149 POA POA POA POA 150-200 POA POA POA POA 201-240 POA POA POA POA<br />

Additional<br />

<strong>Lift</strong><br />

Height<br />

Extra Cost<br />

2 Button<br />

Pendant H)<br />

Cable<br />

(P/M) (I)<br />

Extra Cost<br />

4 Button<br />

Pendant H)<br />

Cable<br />

(P/M) (I)<br />

(P/M) (G) (std 1.8m) (std 1.8m) 0<br />

(£) (£) (£) (£) (£)<br />

POA POA POA POA POA<br />

POA POA POA POA POA<br />

POA POA POA POA POA<br />

POA POA POA POA POA<br />

17<br />

100-149 POA POA POA POA 150-200 POA POA POA POA 201-240 POA POA POA POA<br />

100-149 POA POA POA POA 150-200 POA POA POA POA 201-240 POA POA POA POA<br />

100-149 POA POA POA POA 150-200 POA POA POA POA 201-240 POA POA POA POA<br />

POA POA POA POA POA<br />

POA POA POA POA POA<br />

POA POA POA POA POA<br />

100-149 POA POA POA POA 150-200 POA POA POA POA 201-240 POA POA POA POA<br />

100-149 POA POA POA POA 150-200 POA POA POA POA 201-240 POA POA POA POA<br />

100-149 POA POA POA POA 150-200 POA POA POA POA 201-240 POA POA POA POA<br />

100-149 POA POA POA POA 150-200 POA POA POA POA 201-240 POA POA POA POA<br />

POA POA POA POA POA<br />

POA POA POA POA POA<br />

POA POA POA POA POA<br />

POA POA POA POA POA<br />

100-149 POA POA POA POA 150-200 POA POA POA POA 150-200 POA POA POA POA<br />

100-149 POA POA POA POA 150-200 POA POA POA POA 150-200 POA POA POA POA<br />

100-149 POA POA POA POA 150-200 POA POA POA POA 150-200 POA POA POA POA<br />

POA POA POA POA POA<br />

POA POA POA POA POA<br />

POA POA POA POA POA<br />

140-199 POA POA POA POA 200-259 POA POA POA POA 260-320 POA POA POA POA<br />

140-199 POA POA POA POA 200-259 POA POA POA POA 260-320 POA POA POA POA<br />

140-199 POA POA POA POA 200-259 POA POA POA POA 260-320 POA POA POA POA<br />

POA POA POA POA POA<br />

POA POA POA POA POA<br />

POA POA POA POA POA<br />

140-199 POA POA POA POA 200-259 POA POA POA POA 260-320 POA POA POA POA<br />

140-199 POA POA POA POA 200-259 POA POA POA POA 260-320 POA POA POA POA<br />

140-199 POA POA POA POA 200-259 POA POA POA POA 260-320 POA POA POA POA<br />

POA POA POA POA POA<br />

POA POA POA POA POA<br />

POA POA POA POA POA<br />

120-179 POA POA POA POA 180-239 POA POA POA POA 240-300 POA POA POA POA<br />

120-179 POA POA POA POA 180-239 POA POA POA POA 240-300 POA POA POA POA<br />

120-179 POA POA POA POA 180-239 POA POA POA POA 240-300 POA POA POA POA<br />

POA POA POA POA POA<br />

POA POA POA POA POA<br />

POA POA POA POA POA<br />

120-179 POA POA POA POA 180-239 POA POA POA POA 240-300 POA POA POA POA<br />

120-179 POA POA POA POA 180-239 POA POA POA POA 240-300 POA POA POA POA<br />

120-179 POA POA POA POA 180-239 POA POA POA POA 240-300 POA POA POA POA<br />

POA POA POA POA POA<br />

POA POA POA POA POA<br />

POA POA POA POA POA<br />

120-179 POA POA POA POA 180-239 POA POA POA POA 240-300 POA POA POA POA<br />

120-179 POA POA POA POA 180-239 POA POA POA POA 240-300 POA POA POA POA<br />

120-179 POA POA POA POA 180-239 POA POA POA POA 240-300 POA POA POA POA<br />

POA POA POA POA POA<br />

POA POA POA POA POA<br />

POA POA POA POA POA<br />

120-179 POA POA POA POA 180-239 POA POA POA POA 240-300 POA POA POA POA<br />

120-179 POA POA POA POA 180-239 POA POA POA POA 240-300 POA POA POA POA<br />

120-179 POA POA POA POA 180-239 POA POA POA POA 240-300 POA POA POA POA<br />

POA POA POA POA POA<br />

POA POA POA POA POA<br />

POA POA POA POA POA<br />

120-179 POA POA POA POA 180-239 POA POA POA POA 240-300 POA POA POA POA<br />

120-179 POA POA POA POA 180-239 POA POA POA POA 240-300 POA POA POA POA<br />

120-179 POA POA POA POA 180-239 POA POA POA POA 240-300 POA POA POA POA<br />

POA POA POA POA POA<br />

POA POA POA POA POA<br />

POA POA POA POA POA<br />

120-179 POA POA POA POA 180-239 POA POA POA POA 240-300 POA POA POA POA<br />

120-179 POA POA POA POA 180-239 POA POA POA POA 240-300 POA POA POA POA<br />

120-179 POA POA POA POA 180-239 POA POA POA POA 240-300 POA POA POA POA<br />

POA POA POA POA POA<br />

POA POA POA POA POA<br />

POA POA POA POA POA

GIS Chain handy & Telescopic handy<br />

18<br />

These hoists are designed to ease repetitive manual handling,<br />

the Chain Handy & Telescopic Handy work perfectly with<br />

articulated jib cranes and KB Track Crane Systems.<br />

The GIS Handy is a versatile hoisting appliance that has been<br />

designed with a bracket for easy mounting of manipulator<br />

arms, vacuum and lifting systems for repetitive handling of<br />

many types of loads.<br />

The GIS Chain Handy allows product positioning through the<br />

2 speed toggle switch and flexible hand guide control, in a<br />

comfortable and efficient way. This product has standard left<br />

and right hand operation and is available for safe lifting up<br />

to 500kg SWL.<br />

The GIS Telescopic Handy allows accurate product<br />

positioning through the 2 speed toggle switch and rigid<br />

telescopic guide system. This product has standard left and<br />

right hand operation and is available for safe lifting up to<br />

250kg. The GIS Telescopic Handy allows the controlled and<br />

perfected handling of goods. The telescopic Handy is so rigid<br />

and smooth you can even transport liquids.<br />

Four standard telescopic lifting heights are available from<br />

800mm to 2000mm, all of which can have eccentric loads.<br />

The controls for either Handy unit are mounted adjacent to<br />

the load to provide safe handling and maximum operator<br />

control. The push button station will accept a load hook or a<br />

variety of other suspension units.<br />

All Handy hoists have fast two-speed lifting, high duty<br />

factors and are fitted with an electrical limit switch and<br />

slipping clutch to prevent overloading.<br />

Telescopic<br />

handy<br />

handy<br />

standard<br />

GCHHTD<br />

fem<br />

Classification<br />

2m 3m 4m<br />

<strong>Lift</strong>ing Motor 3x220V 3x380V 5x420V Weight<br />

Switchings /h 240 300 360 speed power 50Hz 50Hz 50Hz uncompl<br />

Duty Factor % 40 50 60<br />

kg kg kg m/min. kW (2m) A (2m) A (2m) A (2m) kg<br />

GCHHK 500<br />

/NF<br />

GCHHK 500<br />

/SF<br />

GCHHK 500<br />

/HF<br />

250 250 200 8/2 0.4/0.07 51/2.8 2.9/1.6 2.8/1.6 27<br />

200 160 125 12.5/3 0.59/0.09 5.6/2.8 3.2/1.6 2.9/1.5 27<br />

125 100 80 20/5 0.59/0.09 5.6/2.8 3.2/1.6 2.7/1.5 27<br />

DImensions (mm)<br />

<strong>Lift</strong>ing<br />

Height<br />

1200 1500 2000<br />

a b c a b c a b c<br />

GCHHTD 500 1370 2570 185÷690 1370 2870 185÷690 1620 3620 185÷1100<br />

Please consult us for eccentric loading

LTM DUO Hoisting System<br />

• Different lengths and lifting centres available<br />

• Ideal for lifting long loads - steel reels, log lifting devices for the paper<br />

industry, rollers for the printing industry, coating/ dipping of baskets,<br />

raising and lowering screens in the entertainment industry<br />

• Eye/Hook or trolley suspension on hoist<br />

• Operate 2 hoists synchronously via one pendant handset<br />

• Available with radio control<br />

• Option for supply of enclosed KB Monorail or Crane Track Systems<br />

• <strong>Lift</strong>ing Capacity from 125kg to 1000kg<br />

• Available in single speed and two speed<br />

19

GIS GCHR food grade hoist<br />

20<br />

The GCHR food grade hoist is well-suited for lifting applications in food or pharmaceutical<br />

production, wash-down, environmentally-controlled and harsh corrosive processing<br />

environments. Available in standard capacities up to 1250kg, the GCHR food grade chain hoist<br />

features highly sealed IP65 bearings and covers, food grade lubrication and stainless steel hooks,<br />

chain and a special Electrophoresis KTL / ATL plated hoist body.<br />

Chain lubrication – CALOR USDA H1, this is resistant to water washout and ensures excellent<br />

lubrication for machinery over a wide range and operating temperatures of -20 to 150 degrees<br />

centigrade. This lubrication is a semi-fluid grease suitable for use in food factory applications<br />

where the risk of food contact exists.<br />

GIS GCHR<br />

• Stainless steel components - chain, single fall<br />

hook clamp, double fall hook clamp, chain guide,<br />

load hook, hook and eyebolt suspension<br />

• High alloy steel components - chain wheel<br />

• Aluminium components: casing, limit stop assembly<br />

(screws in stainless steel A2)<br />

• Colour: black, KTL plated, resistant against water,<br />

oils, scant alkalis and acids<br />

• Gear grease: food grade<br />

• Geared limit switch for highest and lowest<br />

hook position<br />

• Control pendant<br />

GCHR500<br />

<strong>Lift</strong>ing<br />

Capacity<br />

<strong>Lift</strong>ing<br />

Capacity<br />

No of Chain<br />

Falls<br />

<strong>Lift</strong>ing Speed Motor Power 3 x 400V 50Hz Weight Extra Weight <strong>Lift</strong>ing Height<br />

FEM Classification 1Am 2m Main Speed Creep Speed Complete Per Metre <strong>Lift</strong> (standard)<br />

Duty Factor 30% 40% (for 3m <strong>Lift</strong>)<br />

Type (kg) (kg) (m/min) (m/min) (kW) (A) (kg) (kg) (m)<br />

GCHR500/1N 320 250 1 8 --- 0.72 2.1 20 0.52 3<br />

GCHR500/1NF 320 250 1 8 2 0.72/0.18 2.9/3.0 22.5 0.52 3<br />

GCHR500/2N 630 500 2 4 --- 0.72 2.1 20 0.52 3<br />

GCHR500/2NF 630 500 2 4 1 0.72/0.18 2.9/3.0 22.5 0.52 3<br />

Additional Equipment Type Order Code<br />

Geared limit switch with e-stop<br />

MP9401.3018.3<br />

Additional cost top hook suspension GCHR500 MP9401.4503.3<br />

Chain bucket GKM500/6, KS 9401.3010.1<br />

Chain bucket GKM500/12, KS 9401.3011.1<br />

Chain bucket GKM500/16R 9401.4508.2<br />

GCHR1000<br />

<strong>Lift</strong>ing<br />

Capacity<br />

<strong>Lift</strong>ing<br />

Capacity<br />

No of Chain<br />

Falls<br />

<strong>Lift</strong>ing Speed Motor Power 3 x 400V 50Hz Weight Extra Weight <strong>Lift</strong>ing Height<br />

FEM Classification 1Am 2m Main Speed Creep Speed Power Complete Per Metre <strong>Lift</strong> (standard)<br />

Duty Factor 30% 40% (for 3m <strong>Lift</strong>)<br />

Type (kg) (kg) (m/min) (m/min) (kW) (A) (kg) (kg) (m)<br />

GCHR1000/1N 630 500 1 8 --- 0.91 3.1 36 1.04 3<br />

GCHR1000/1NF 630 500 1 8 2 0.91/0.23 2.8/2.6 40 1.04 3<br />

GCHR1000/2N 1250 1000 2 4 --- 0.91 3.1 38 1.04 3<br />

GCHR1000/2NF 1250 1000 2 4 1 0.91/0.23 2.8/2.6 42 1.04 3<br />

Additional Equipment Type Order Code<br />

Geared limit switch with e-stop<br />

MP9401.3018.3<br />

Additional cost hook suspension GCHR1000 MP9405.4509.3<br />

Chain Bucket GKM 1000/8KS 9405.3044.1<br />

Chain Bucket GKMR 1000/20 9405.4511.2

ATEX dust or gas proof electric chain hoist<br />

21<br />

II 3 D IP 65 T 130ºc<br />

Equipment group II<br />

Equipment category 3<br />

Zone 22 (D)<br />

Temperature =

Radio Control Electric Chain Hoists Systems<br />

22<br />

Radio remote system for hoisting applications compliant with safety standard Cat.3 CE<br />

EN-954-1 or EN 13849. Available receiver power supplies (24-48-155 and 230v AC)<br />

with a maximum of 6 output relays.<br />

• Tactile and high sensitivity keyboard<br />

• Ergonomic transmitter with one or two step pushbuttons<br />

• Automatic working channel slection<br />

• Auto ID teaching function - Simple and easy to use<br />

• Remotely programmable receiver’s outputs using the programmer module<br />

(radio remote programmer module)<br />

• Can backup or restore system’s configurations<br />

• With plugin optional pendant<br />

• Single and multi hoist control systems<br />

• As standard all LTM radio control systems are supplied with secondary<br />

wired control system

Wind Turbine Hoist (GCH Wind)<br />

With a small body and confined dimensions, standard lifting height of up to 120 metres<br />

makes this hoist ideal for wind turbines. High lifting speeds and a safety overload clutch<br />

as overload protection guarantees a safe and efficient operation.<br />

The chain guide is composed from weather resistant material to ensure long a long life<br />

in harsh environments. The tail end of chain can be guided out of the way via reinforced<br />

tube; this allows lower headroom with the tail end of the chain being diverted safely.<br />

High duty motors, specially developed for an industry leader wind turbine manufacture<br />

this makes the GCH Winch ideal for extremely high lifts up to 120 metres. The hook cone<br />

covers the lover hook block to avoid accidental hook ups.<br />

23<br />

The GCH Wind can be customised for almost any wind turbine lifting application.<br />

• GCH500/1HFS.2M<br />

• Motor with Klixon<br />

• lifting height up to 120 m<br />

• Power supply 3 x 400 V 50 Hz<br />

• Capacity 250 kg<br />

• <strong>Lift</strong>ing speed 16/4 m/min.<br />

• Geared limit switch with automatic change from<br />

fast to slow speed and external switch<br />

• Control pendant with 1.0 m cable<br />

• Low voltage 42 V<br />

• with hook cap<br />

• with connecting cable with CEE plug

OVERVIEW OF GIS KB CRANE & MONORAIL SYSTEMS<br />

24<br />

Single bridge suspended crane Double bridge suspended crane Monorail Slewing Pillar Jib crane<br />

Single bridge suspended crane<br />

• All-round goods transportation, up to 1,250 kg (optional 2,000 kg)<br />

• For normal headroom<br />

Double bridge suspended crane<br />

• All-round goods transportation, up to 1,250 kg (optional 2,000 kg)<br />

• For lower headroom<br />

Monorail with bends, switches and turntables<br />

• To link workstations, up to 1,550 kg<br />

• Flexible line routing thanks to bends<br />

• Individual lines can be connected using slide switches and turntables<br />

For use when ceilings have insufficient load-bearing capacity or<br />

as an addition to your suspended crane. To reduce machine<br />

set-up times and waiting times.<br />

Slewing pillar JIB crane<br />

Up to 1,000 kg, max. rotational field 270°, jib arm length up<br />

to 5 m. Can also be supplied as a slewing articulated crane<br />

(up to 250 kg).<br />

Slewing wall JIB crane<br />

The alternative when it is not possible to erect a pillar.<br />

Installation on an existing pillar/wall. Technical data as<br />

slewing pillar crane.<br />

Handy chain and telescope models<br />

Economic lifting of small loads. A valuable way of making<br />

work easier, in combination with a slewing or suspended<br />

crane. Can handle offset loads: control unit directly on the<br />

load hook. (see page 18)<br />

GIS switch/turntable<br />

• For accurate transitions between tracks<br />

• Variants: slide switches/turntables with internal or<br />

external conductor lines<br />

GISKB bends<br />

• To reach individual workstations with total accuracy<br />

• To make optimum use of confined spaces<br />

Locking switches<br />

• Cost-saving technology to cover partial working areas<br />

• No need for a complete crane system<br />

• Function: locking and traversing into a lateral monorail<br />

Internal conductor line<br />

• The elegant alternative to trailing cables or looped wires<br />

• Placed inside the profile (for mechanical protection)<br />

• Ideal in confined spaces<br />

Benefits to you:<br />

• Reasonably priced, thanks to series-produced<br />

standard parts and rolled profiles<br />

• Simple to install, all components can be screwed/bolted<br />

• Manual or electrical crane/trolley movement<br />

• Low noise level thanks to plastic guide rollers<br />

• Various power supplies<br />

• Guaranteed conversion/extension of existing crane systems

OVERVIEW OF GIS KB crane system<br />

Components<br />

• Four profile sizes<br />

• Connection plates on both ends<br />

• Standard profile lengths,<br />

between 1 m and 8 m<br />

• Special lengths to order<br />

Your benefits:<br />

• Excellent performance thanks to high<br />

load-carrying capacity<br />

• Simple to install, thanks to optimised design<br />

• Competitively priced, thanks to standard<br />

rolled profiles<br />

25<br />

Optimal profile size<br />

Use the table below to determine the optimal profile size,<br />

depending on the load P and the span W.<br />

Basis: Max. permissible deflection = W/400, Max stress = 180 N/M2.<br />

<strong>Lift</strong>ing gear weight: 25 kg (up to load capacity of 500 kg), 50 kg (for load capacity over 500 KG)<br />

Load<br />

capacity<br />

GIS KB I Span (mm) GIS KB II Span (mm) Load<br />

capacity<br />

Track only | NP 120 | NP 160 | NP 180 MR Track only | NP 120 | NP 160 | NP 180 MR<br />

100 kg 4,7 5,9 7,8 7,8 7,8 7,8 7,8 7,8 7,5 7,2 7,8 7,8 7,8 7,8 7,8 7,8 7,8 100 kg<br />

125 kg 4,4 5,6 6,9 6,9 125 kg<br />

160 kg 4,0 5,3 6,1 6,4 7,8 160 kg<br />

200 kg 3,7 4,9 5,6 6,0 7,5 200 kg<br />

250 kg 3,4 4,6 7,4 5,0 5,6 7,1 250 kg<br />

320 kg 3,1 4,2 6,8 4,2 5,1 6,6 7,6 320 kg<br />

400 kg 2,8 3,8 6,3 3,3 4,7 6,2 7,6 6,8 400 kg<br />

500 kg 2,5 3,5 5,5 7,5 7,5 2,9 4,3 5,7 7,1 5,8 500 kg<br />

630 kg 2,0 3,2 4,5 7,0 6,3 7,3 2,3 3,8 5,2 6,4 4,5 630 kg<br />

800 kg 2,8 6,4 3,2 4,8 5,2 7,7 7,0 3,6 800 kg<br />

1,000 kg 2,5 5,6 7,5 2,7 4,3 4,3 7,1 5,8 6,6 3,1 1,000 kg<br />

1,250 kg 2,1 4,6 6,4 7,4 2,7 3,9 3,5 6,5 4,7 5,4 2,6 1,250 kg<br />

With reinforcement<br />

Option: Aluminium track also available - see page 28<br />

Without reinforcement<br />

Single crane with bridge span W (m)<br />

Double crane with bridge span W (m)<br />

Load Capacity (kg) GISKB III GISKB IV<br />

Load Capacity (kg) GISKB III GISKB IV<br />

100 8.2 10.5<br />

125 7.8 10.2<br />

160 7.4 9.9<br />

200 7.0 9.3<br />

250 6.5 8.9<br />

320 6.0 8.2<br />

400 5.5 7.7<br />

500 5.1 7.2<br />

630 4.6 6.6<br />

800 4.1 5.9<br />

1000 3.6 5.4<br />

1250 2.9 4.9<br />

1600 2.4 4.0<br />

100 9.4 11.8<br />

125 9.1 11.6<br />

160 8.7 11.3<br />

200 8.5 11.0<br />

250 8.1 10.8<br />

320 7.6 10.1<br />

400 7.2 9.7<br />

500 6.7 9.3<br />

630 6.2 8.5<br />

800 5.7 8.0<br />

1000 5.2 7.2<br />

1250 4.7 6.7<br />

1600 4.2 6.0

OVERVIEW OF GIS KB crane & monorail systems<br />

26<br />

Suspension options<br />

Short, rigid (fig 4)<br />

• The rigid suspension can only be supplied in the short version<br />

• Reduced headroom dimension<br />

Short, pendulating, adjustable (fig 1)<br />

• Ball pins and nuts are screwed together directly<br />

• Pendulation movements max. 10°<br />

• Height adjustable by ± 7.5 mm<br />

Distanced, pendulating, adjustable (fig 2)<br />

• Distanced suspension, variable length<br />

• Height differences of ± 15 mm can be adjusted out<br />

fig 4<br />

Distanced, pendulating, adjustable, braced (fig 3)<br />

• > distance 0.5 m: bracing is mandatory<br />

• Longitudinal bracing: both ends of track<br />

• Transverse bracing: on one side, every 2nd suspension<br />

Lateral suspension<br />

• Lateral installation on wood or concrete beam<br />

fig 1<br />

fig 2 fig 3<br />

Trolleys<br />

• Components designed in galvanized steel<br />

• Use is guaranteed for longitudinal and transverse movements<br />

• Load partition is ensured by 2 trolleys<br />

• On the saddle of the double crane bridge: 4 trolleys in use<br />

• Drive: manual or electrical<br />

2 trolleys with traverse<br />

Benefits to you:<br />

• Silent running is maximised thanks to plastic guide rollers<br />

• Ideal for awkward and critical loads<br />

• Easily converted from manual to electrical operation<br />

• Gentle start-up and braking thanks to the frequency inverter<br />

Rolling apparatus<br />

Electrical drive<br />

4 trolleys with saddle<br />

(to reduce headroom)

OVERVIEW OF GIS KB crane & monorail systems - electronics & bends<br />

Electrics<br />

Types of power supply<br />

• 3 phase, 380/400V 50Hz<br />

• Or for your operating electrical supply<br />

27<br />

GISKB power supplies complete<br />

• Cable carriage, traction limit, connector, C-rail stop ...<br />

Conventional conductor line<br />

4 types of longitudinal and transverse power supply:<br />

• Trailing cable<br />

• C-rail<br />

• Conventional enclosed conductor line<br />

• Conductor line inside profile<br />

GISKB II ST internal conductor line<br />

• Flexible, universal<br />

• Attractive design<br />

• For universal use<br />

• Load: 25A with max.100 m profile length<br />

• Trolley design as for GISKB I (up to 800 kg)<br />

Trailing cable<br />

C-rail<br />

Bends<br />

• Can be supplied with angles of 30° and 45°<br />

• Radius: 1m<br />

• End plate at both ends<br />

• Suspension at 2 points<br />

• Conductor line bends can be obtained<br />

with same angles as profile bends<br />

Slide switches/turntables<br />

• Profiles are moved manually or electrically<br />

• Manual: with traction cable<br />

• Electrical: with 2-button control switch<br />

• Option: supplied with conductor lines

GIS KB Aluminium Track<br />

28<br />

Single crane with bridge span W (m)<br />

Double crane with bridge span W (m)<br />

Load Capacity (kg) GISKB ALU S GISKB ALU M GISKB ALU L<br />

Load Capacity (kg) GISKB ALU S GISKB ALU M GISKB ALU L<br />

50 4.7 6.8 7.8<br />

80 4.1 6.2 7.8<br />

100 3.8 5.8 7.8<br />

125 3.5 5.4 7.4<br />

160 3.2 5.0 6.8<br />

200 2.9 4.5 6.3<br />

250 - 4.2 5.8<br />

320 - 3.7 5.2<br />

400 - - 4.7<br />

500 - - 4.3<br />

630 - - 3.8<br />

50 5.9 7.8 7.8<br />

80 5.3 7.7 7.8<br />

100 5.0 7.3 7.8<br />

125 4.7 7.0 7.8<br />

160 4.3 6.5 7.8<br />

200 4.0 6.0 7.8<br />

250 - 5.6 7.6<br />

320 - 5.1 7.0<br />

400 - 4.7 6.4<br />

500 - - 5.9<br />

630 - - 5.3

OVERVIEW OF GIS KB crane & monorail systems<br />

29

30<br />

OVERVIEW OF GIS KB crane & monorail systems

Able forge manufacturing INC Products<br />

<strong>Lift</strong> <strong>Turn</strong> <strong>Move</strong> Ltd, Version 2, August 2012<br />

Specifications<br />

Hoists / Track / Winches / Jacks / Pulleys / CLAMPS - ALL IN ONE PLACE<br />

<strong>Lift</strong>ing Equipment and Systems for Industrial and Entertainment Industries

ABLE Brand Chain Block Model CB-II - Fitted with G80 plated Chains<br />

32<br />

Technical Benefits<br />

• Superior Grade 100 load chain –<br />

Wafios link Din standard<br />

• Forged and Heat Treated load hooks<br />

with batch traceability and stretch<br />

indicators<br />

• Double pawls supporting failsafe<br />

brake mechanism. Even if<br />

one of the two pawls becomes<br />

unserviceable, the other will still<br />

remain operative, and the brake<br />

system remains secure.<br />

• Asbestos free Brake Linings<br />

• Forged Hook Safety Latch with<br />

manufacture mark<br />

• Individually proof load tested to<br />

1.5 X WLL with individual serial<br />

number<br />

• Lightweight yet durable<br />

• Steel frame construction is rugged yet<br />

lightweight and easy to handle<br />

• Low maintenance<br />

• Enclosed housing allows outdoor use.<br />

• The load brake requires no lubrication<br />

Quality features<br />

• Wheel cover with guide slots against<br />

jamming and slipping of chain<br />

• Forged swivel hooks with latches<br />

prevent twisting of chain and reduce<br />

unintentional unhooking of the unit<br />

or the load<br />

• Chain guide and stripper ensure proper<br />

fit of chain over pocket wheel<br />

• Two-stage gear reduction with hardened<br />

gears and pinion

ABLE Brand Chain Block Model CB-II - Fitted with G80 ABLE Chains<br />

ABLE Brand Chain Block Model CB-II - Fitted with<br />

G80 ABLE Zinc Chains<br />

Description Capacity Height of <strong>Lift</strong> No. of Falls<br />

LTM Product Code (t) (m)<br />

AB/CB250/3 ABLE CB SERIES HAND CHAIN BLOCK 0.25 3 1<br />

33<br />

DImensions (mm)<br />

Product<br />

Code<br />

AB/CB-II /005/3 ABLE CB-II SERIES HAND CHAIN BLOCK 0.5 3 1<br />

AB/CB-II /005/6 ABLE CB-II SERIES HAND CHAIN BLOCK 0.5 6 1<br />

AB/CB-II /005/9 ABLE CB-II SERIES HAND CHAIN BLOCK 0.5 9 1<br />

AB/CB-II /005/12 ABLE CB-II SERIES HAND CHAIN BLOCK 0.5 12 1<br />

AB/CB-II /010/3 ABLE CB-II SERIES HAND CHAIN BLOCK 1.0 3 1<br />

AB/CB-II /010/6 ABLE CB-II SERIES HAND CHAIN BLOCK 1.0 6 1<br />

AB/CB-II /010/9 ABLE CB-II SERIES HAND CHAIN BLOCK 1.0 9 1<br />

AB/CB-II /010/12 ABLE CB-II SERIES HAND CHAIN BLOCK 1.0 12 1<br />

AB/CB-II /015/3 ABLE CB-II SERIES HAND CHAIN BLOCK 1.5 3 1<br />

AB/CB-II /015/6 ABLE CB-II SERIES HAND CHAIN BLOCK 1.5 6 1<br />

AB/CB-II /015/9 ABLE CB-II SERIES HAND CHAIN BLOCK 1.5 9 1<br />

AB/CB-II /015/12 ABLE CB-II SERIES HAND CHAIN BLOCK 1.5 12 1<br />

AB/CB-II /020/3 ABLE CB-II SERIES HAND CHAIN BLOCK 2.0 3 1<br />

AB/CB-II /020/6 ABLE CB-II SERIES HAND CHAIN BLOCK 2.0 6 1<br />

AB/CB-II /020/9 ABLE CB-II SERIES HAND CHAIN BLOCK 2.0 9 1<br />

AB/CB-II /020/12 ABLE CB-II SERIES HAND CHAIN BLOCK 2.0 12 1<br />

AB/CB-II /030/3 ABLE CB-II SERIES HAND CHAIN BLOCK 3.0 3 2<br />

AB/CB-II /030/6 ABLE CB-II SERIES HAND CHAIN BLOCK 3.0 6 2<br />

AB/CB-II /030/9 ABLE CB-II SERIES HAND CHAIN BLOCK 3.0 9 2<br />

AB/CB-II /030/12 ABLE CB-II SERIES HAND CHAIN BLOCK 3.0 12 2<br />

AB/CB-II /050/3 ABLE CB-II SERIES HAND CHAIN BLOCK 5.0 3 2<br />

AB/CB-II /050/6 ABLE CB-II SERIES HAND CHAIN BLOCK 5.0 6 2<br />

AB/CB-II /050/9 ABLE CB-II SERIES HAND CHAIN BLOCK 5.0 9 2<br />

AB/CB-II /050/12 ABLE CB-II SERIES HAND CHAIN BLOCk 5.0 12 2<br />

AB/CB-II /100/3 ABLE CB-II SERIES HAND CHAIN BLOCK 10.0 3 4<br />

AB/CB-II /100/6 ABLE CB-II SERIES HAND CHAIN BLOCK 10.0 6 4<br />

AB/CB-II /100/9 ABLE CB-II SERIES HAND CHAIN BLOCK 10.0 9 4<br />

AB/CB-II /100/12 ABLE CB-II SERIES HAND CHAIN BLOCK 10.0 12 4<br />

AB/CB-II /200/3 ABLE CB-II SERIES HAND CHAIN BLOCK 20.0 3 8<br />

AB/CB-II /200/6 ABLE CB-II SERIES HAND CHAIN BLOCK 20.0 6 8<br />

AB/CB-II /200/9 ABLE CB-II SERIES HAND CHAIN BLOCK 20.0 9 8<br />

AB/CB-II /200/12 ABLE CB-II SERIES HAND CHAIN BLOCK 20.0 12 8<br />

AB/CB-II /300/3 ABLE CB-II SERIES HAND CHAIN BLOCK 30.0 3 12<br />

AB/CB-II /300/6 ABLE CB-II SERIES HAND CHAIN BLOCK 30.0 6 12<br />

AB/CB-II /300/9 ABLE CB-II SERIES HAND CHAIN BLOCK 30.0 9 12<br />

AB/CB-II /300/12 ABLE CB-II SERIES HAND CHAIN BLOCK 30.0 12 12<br />

Capacity Pull full load Load chain<br />

dia<br />

Dimensions (mm)<br />

Weight - 3m<br />

lift<br />

Extra weight<br />

per metre<br />

lift<br />

AB/CB-II (t) (n) (mm) A B C D H (kg) (kg)<br />

AB/CB-II /005 0.5 221 6 125 111 24 134 255 8.0 1.7<br />

AB/CB-II /010 1.0 304 6 147 126 28 154 306 10.0 1.7<br />

AB/CB-II /015 1.5 343 8 183 141 34 192 368 16.0 2.3<br />

AB/CB-II /020 2.0 294 8 215 163 38 224 396 27.0 5.3<br />

AB/CB-II /030 3.0 343 8 183 141 38 192 486 24.0 3.7<br />

AB/CB-II /050 5.0 383 10 215 163 48 224 616 36.0 5.3<br />

AB/CB-II /100 10.0 392 10 360 163 64 224 700 68.0 9.7<br />

AB/CB-II /200 20.0 392 10 585 191 82 224 1000 156.0 19.4<br />

AB/CB-II /300 30.0 435 x 2 10 705 485 75 85 1200 135.0 28.4

ABLE Brand Chain Block Model CB-I<br />

34<br />

Technical Benefits<br />

Load chains are approved to DIN 5684, one of the world’s most rigid standards. This is the special heat<br />

treated load chain of ISO Grade T (900N/mm2) whose tensile strength surpasses ISO T class.<br />

• Meets requirements of EN13157<br />

• Load sheave with sealed<br />

roller bearing<br />

Double pawls (on 1.0t and above) supporting fail-safe brake mechanism<br />

Even if by any chance one of the two pawls becomes unserviceable, the other will still remain operative, and<br />

the brake system remains secure.<br />

Bottom hook with thrust bearing<br />

The thrust bearing enables the lifted load to be moved in any direction without subjecting it to stress<br />

Hooks of easier handling shape<br />

The opening of the hooks has been made wider for easier handling and working.<br />

Durable and solid enclosure<br />

The tough gear casing, reinforced with four ribs and four knock pins, provides accurate gear centering and<br />

high mechanical efficiency.<br />