Room decon - external gassing (Bioquell Clarus C) - CapellaScience

Room decon - external gassing (Bioquell Clarus C) - CapellaScience

Room decon - external gassing (Bioquell Clarus C) - CapellaScience

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

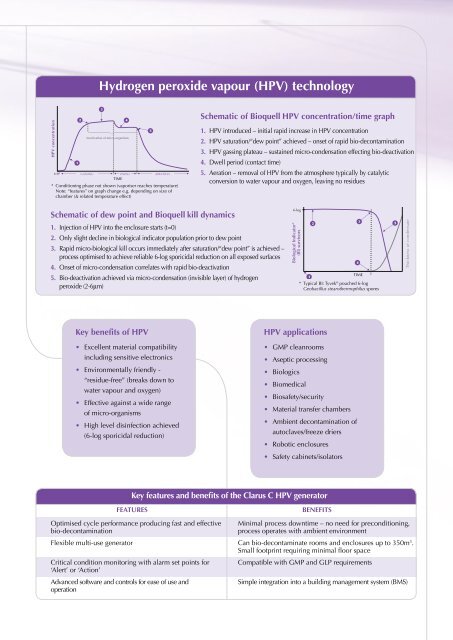

Hydrogen peroxide vapour (HPV) technology<br />

HPV concentration<br />

1<br />

2<br />

3<br />

Inactivation of micro-organisms<br />

t=0*<br />

GASSING DWELL AERATION<br />

TIME<br />

* Conditioning phase not shown (vaporiser reaches temperature)<br />

Note: “features” on graph change e.g. depending on size of<br />

chamber (& related temperature effect)<br />

4<br />

5<br />

Schematic of <strong>Bioquell</strong> HPV concentration/time graph<br />

1. HPV introduced – initial rapid increase in HPV concentration<br />

2. HPV saturation/“dew point” achieved – onset of rapid bio-<strong>decon</strong>tamination<br />

3. HPV <strong>gassing</strong> plateau – sustained micro-condensation effecting bio-deactivation<br />

4. Dwell period (contact time)<br />

5. Aeration – removal of HPV from the atmosphere typically by catalytic<br />

conversion to water vapour and oxygen, leaving no residues<br />

Schematic of dew point and <strong>Bioquell</strong> kill dynamics<br />

1. Injection of HPV into the enclosure starts (t=0)<br />

2. Only slight decline in biological indicator population prior to dew point<br />

3. Rapid micro-biological kill occurs immediately after saturation/“dew point” is achieved –<br />

process optimised to achieve reliable 6-log sporicidal reduction on all exposed surfaces<br />

4. Onset of micro-condensation correlates with rapid bio-deactivation<br />

5. Bio-deactivation achieved via micro-condensation (invisible layer) of hydrogen<br />

peroxide (2-6µm)<br />

* Typical BI: Tyvek ® pouched 6-log<br />

Geobacillus stearothermophilus spores<br />

Key benefits of HPV<br />

• Excellent material compatibility<br />

including sensitive electronics<br />

• Environmentally friendly -<br />

“residue-free” (breaks down to<br />

water vapour and oxygen)<br />

• Effective against a wide range<br />

of micro-organisms<br />

• High level disinfection achieved<br />

(6-log sporicidal reduction)<br />

HPV applications<br />

• GMP cleanrooms<br />

• Aseptic processing<br />

• Biologics<br />

• Biomedical<br />

• Biosafety/security<br />

• Material transfer chambers<br />

• Ambient <strong>decon</strong>tamination of<br />

autoclaves/freeze driers<br />

• Robotic enclosures<br />

• Safety cabinets/isolators<br />

Key features and benefits of the <strong>Clarus</strong> C HPV generator<br />

FEATURES<br />

Optimised cycle performance producing fast and effective<br />

bio-<strong>decon</strong>tamination<br />

Flexible multi-use generator<br />

Critical condition monitoring with alarm set points for<br />

‘Alert’ or ‘Action’<br />

Advanced software and controls for ease of use and<br />

operation<br />

BENEFITS<br />

Minimal process downtime – no need for preconditioning,<br />

process operates with ambient environment<br />

Can bio-<strong>decon</strong>taminate rooms and enclosures up to 350m 3 .<br />

Small footprint requiring minimal floor space<br />

Compatible with GMP and GLP requirements<br />

Simple integration into a building management system (BMS)