Sunflower - the Choice of the - AGCO Iron

Sunflower - the Choice of the - AGCO Iron

Sunflower - the Choice of the - AGCO Iron

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

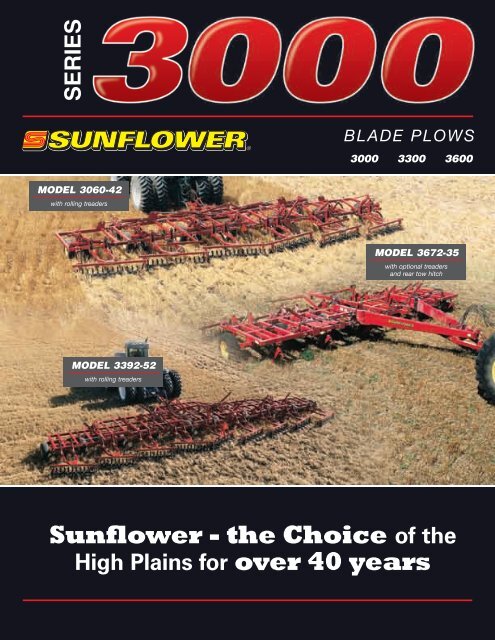

SERIES<br />

BLADE PLOWS<br />

3000 3300 3600<br />

MODEL 3060-42<br />

with rolling treaders<br />

MODEL 3672-35<br />

with optional treaders<br />

and rear tow hitch<br />

MODEL 3392-52<br />

with rolling treaders<br />

<strong>Sunflower</strong> - <strong>the</strong> <strong>Choice</strong> <strong>of</strong> <strong>the</strong><br />

High Plains for over 40 years

Fallow-King<br />

from <strong>the</strong> leader<br />

in conservation<br />

tillage.<br />

3000<br />

The Fallow-King is specially built for <strong>the</strong> wide range <strong>of</strong> soil conditions found on <strong>the</strong> Great Plains.<br />

It performs both primary and secondary tillage activities. The entire Fallow-King series features two<br />

rows <strong>of</strong> shanks and frames that flex every 7’ to hug <strong>the</strong> terrain on flat or rolling ground . . . even over<br />

terraces. <strong>Sunflower</strong>’s computer design features optimum shank placement and provides a 6” (15.24<br />

cm) overlap between <strong>the</strong> 26” (66.04 cm) sweeps. The exclusive <strong>Sunflower</strong> treader design provides<br />

unparalleled soil aeration . . . even in heavy surface residue.<br />

Walking Tandems are standard on all<br />

sections, allowing <strong>the</strong> machine to follow<br />

<strong>the</strong> ground contour precisely, maintaining a<br />

more consistent shank depth. The tandem<br />

beam pivots on a set <strong>of</strong> regreasable tapered<br />

roller bearings for smooth, long-lasting<br />

service. Zerk-equipped six-bolt hubs and<br />

heavy-duty 2” (5.08 cm) slip-in spindles<br />

feature triple-lip seals.<br />

The one piece welded hitch is attached<br />

to <strong>the</strong> middle <strong>of</strong> <strong>the</strong> right and left center<br />

frames (4 & 6 section machines) by 4 1-1/4"<br />

(3.17 cm) bolts and flex links for full<br />

flexibility without sacrificing strength. Hitch<br />

attaching points are wear protected by<br />

thrust plates to ensure long life.<br />

A rachet jack precisely levels <strong>the</strong> frame<br />

from front-to-rear on <strong>the</strong> Fallow-King. This<br />

assures level tillage in a variety <strong>of</strong> field<br />

conditions.<br />

MODEL 3040-28<br />

with rolling treaders<br />

2

Fallow-King features<br />

26" (66.04 cm) sweeps on<br />

20" (50.8 cm) centers, providing<br />

a full 6" (15.24 cm) overlap and<br />

maximum weed kill.<br />

<strong>Sunflower</strong> gauge wheels<br />

eliminate gouging and provide<br />

precision tillage on flat or<br />

rolling terrain and are standard<br />

equipment on 4 section through<br />

7 section machines.<br />

A screw-type adjustment is<br />

located at <strong>the</strong> front <strong>of</strong> <strong>the</strong> frame<br />

for operator convenience.<br />

A single setting controls <strong>the</strong><br />

operating depth <strong>of</strong> <strong>the</strong> entire<br />

machine.<br />

<strong>Sunflower</strong> mounts <strong>the</strong> rockshaft<br />

on top <strong>of</strong> <strong>the</strong> frame for superior<br />

trash clearance. Fallow-King also<br />

features a lift cylinder at EACH<br />

wheel.<br />

3000 Series Fallow-King Tillage Tools<br />

MODEL<br />

TILLAGE<br />

WIDTH<br />

NO. OF<br />

SHANKS<br />

SECTION<br />

NO. & SIZE<br />

TRANS.<br />

HEIGHT<br />

TRANS.<br />

WIDTH<br />

EST. WEIGHT<br />

(Basic Machine) **<br />

WING FOLD<br />

POSITION<br />

TIRE NO.<br />

& SIZE<br />

3030-21<br />

21'<br />

(6.40 m)<br />

13<br />

Three 7'<br />

10'-8"<br />

(3.25 m)<br />

14'-5"<br />

(4.39 m)<br />

5,944 lbs.<br />

(2,696 kg)<br />

1-1<br />

(8) 9.5L x 15, 8 ply<br />

3030-25<br />

25’<br />

(7.62 m)<br />

15<br />

Three 7'<br />

12’-4”<br />

(3.76 m)<br />

14’-5”<br />

(4.39 m)<br />

6160 lbs.<br />

(2,794 kg)<br />

1-1<br />

(8) 9.5L x 15, 8 ply<br />

3040-28<br />

28'<br />

(8.53 m)<br />

17<br />

Four 7'<br />

10'-8"<br />

(3.25 m)<br />

21'-2"<br />

(6.45 m)<br />

8,044 lbs.<br />

(3,649 kg)<br />

1-1<br />

(10) 9.5L x 15, 8 ply<br />

3040-32<br />

32'<br />

(9.75 m)<br />

19<br />

Four 7'<br />

12'-4"<br />

(3.76 m)<br />

21'-2"<br />

(6.45 m)<br />

8,274 lbs.<br />

(3,753 kg)<br />

1-1<br />

(10) 9.5L x 15, 8 ply<br />

3050-35<br />

35'<br />

(10.67 m)<br />

21<br />

Five 7'<br />

12'-8"<br />

(3.86 m)<br />

21'-3"<br />

(6.48 m)<br />

9,759 lbs.<br />

(4,427 kg)<br />

2-1<br />

(12) 9.5L x 15, 8 ply<br />

3060-42<br />

42'<br />

(12.80 m)<br />

25<br />

Six 7'<br />

13'<br />

(3.96 m)<br />

22'-8"<br />

(6.91 m)<br />

11,874 lbs.<br />

(5,386 kg)<br />

2-2<br />

(16) 9.5L x 15, 8 ply<br />

3070-49<br />

49'<br />

(14.94 m)<br />

29<br />

Seven 7'<br />

15'-6"<br />

(4.72 m)<br />

24'<br />

(7.32m)<br />

13,650 lbs.<br />

(6,192 kg)<br />

3-2<br />

(6) 9.5L x 15, 12 ply<br />

(10) 9.5L x 15, 8 ply<br />

We are continually striving to improve our machines; <strong>the</strong>refore, <strong>the</strong>se specifications are subject to change without notice.<br />

**Basic machine weight does not include machine attachments.<br />

For additional information, visit our website at www.sunflowermfg.com.<br />

3

Quality tillage<br />

in a wide variety<br />

<strong>of</strong> soil types and<br />

field conditions.<br />

<strong>Sunflower</strong>’s 3300 Blade Plow is designed with <strong>the</strong> operator in mind. This machine delivers durable,<br />

reduced-maintenance equipment by incorporating UHMW polymer technology in all high wear areas<br />

including transports, coulter pivot bushings, hinge pivot bushings and flange between <strong>the</strong> hinge ear.<br />

Metal to metal wear points have been eliminated. We’ve also added extra strength and longer life to<br />

our frame connections. The 3300 incorporates easily adjustable swivel linkages between <strong>the</strong> rockshafts<br />

at each frame for easy and fast adjustments and leveling.<br />

Frame leveling is critical to<br />

blade plow performance.<br />

<strong>Sunflower</strong> incorporated<br />

easily adjustable swivel<br />

linkages between <strong>the</strong><br />

rockshafts at each frame in<br />

<strong>the</strong> 3300. Simply remove a<br />

hold strap and start turning<br />

<strong>the</strong> link to a perfect level.<br />

The 1-1/4” thick box-braced standards<br />

add strength and stability to <strong>the</strong><br />

entire standard assembly. <strong>Sunflower</strong><br />

incorporated a slim-line design while still<br />

increasing <strong>the</strong> thickness <strong>of</strong> <strong>the</strong> upright<br />

standards by 10%. The strong, sculptured<br />

upper box-brace narrows to a streamlined<br />

shape to insure mulch disturbance is kept<br />

to a minimum.<br />

MODEL 3392-52<br />

with rolling treaders<br />

4

Previous Blade<br />

Plow Design<br />

Individual wheel adjustments<br />

are standard in necessary<br />

locations to allow <strong>the</strong> 3300<br />

Blade Plow wheels to be<br />

adjusted individually for<br />

impressions made by <strong>the</strong><br />

tractor tires without changing<br />

<strong>the</strong> swivel links.<br />

Large 22” rolling coulters with<br />

5 bolt hubs allow more room for<br />

trash flow and provide longer<br />

intervals between replacement<br />

changes. The five bolt hubs are<br />

more resistant to breakage when<br />

farming deep and/or terraced<br />

ground.<br />

New Blade<br />

Plow Design<br />

Standard Equipment<br />

• 4” x 4” x 1/4” tubular frame<br />

• 5 1/2” O.D. x 3/8” wall rockshaft<br />

• 3” x 6” x 1/4” tubular axle arms - 52’<br />

• Regular welded standards (75˚, 1-1/4” uprights)<br />

• 75˚ Plain, HFT, or HFB blades<br />

• 22” Plain coulters<br />

• Tongue jack<br />

• Single or double lip hitch clevis<br />

• UHMW - Standard on hinge bushings,<br />

coulters and rock shaft pivots<br />

• 12 ply, 12.5L x 15 tubeless tires<br />

• 15” x 10” eight bolt wheels and hubs<br />

(3372 & 3392 only)<br />

• 15” x 10” six bolt wheels and hubs<br />

Optional Equipment<br />

• Double lip hitch, 1 9/16” pin hole<br />

(5, 6 & 7 section plows)<br />

• Rear tow hitch with ball joint<br />

(5, 7 & 9 section plows)<br />

• Rear tow hitch with hitch slide and<br />

ball joint (5, 7 & 9 section plows)<br />

• Rear back stand (included with rolling<br />

treader) (7 section)<br />

• Rear back stand (included with rolling<br />

treader) (5 & 9 section)<br />

To provide extra strength and longer life to<br />

our frame connections, <strong>Sunflower</strong> has added<br />

a third hinge in <strong>the</strong> wing frames. This allows<br />

<strong>the</strong> all new 3300 Blade Plow to perform<br />

longer and deeper without <strong>the</strong> adverse side<br />

effects <strong>of</strong> worn and pulled out hinges. This<br />

feature was requested by <strong>the</strong> American<br />

farmer and now is a reality in <strong>the</strong> new 3300.<br />

3300 Series Blade Plow Specifications<br />

MODEL NUMBER<br />

NO. BLADES<br />

SIZE<br />

TILLAGE WIDTH<br />

FOLDED WIDTH*<br />

FOLDED HEIGHT*<br />

APPROX. WEIGHT**<br />

3372-40<br />

3392-52<br />

7<br />

9<br />

6'<br />

6'<br />

40'<br />

52'<br />

24'<br />

26' 5"<br />

11' 9"<br />

13' 9"<br />

12,718 lbs.<br />

15,280 lbs.<br />

We are continually striving to improve our machines; <strong>the</strong>refore, <strong>the</strong>se specifications are subject to change without notice.<br />

**Basic machine weight does not include machine attachments.<br />

For additional information, visit our website at www.sunflowermfg.com.<br />

5

Consistent, Economical<br />

weed control<br />

without <strong>the</strong> environmental<br />

concerns.<br />

3600<br />

Tillage is <strong>the</strong> low-cost method in killing weeds especially in lieu <strong>of</strong> spraying on your burndown pass.*<br />

Utilizing SUNFLOWER’s 3600 Blade Plow as your fallow maintenance tool is not only less cost per<br />

acre than chemical fallow but may be easier to time because tillage isn’t dependent on as many wea<strong>the</strong>r<br />

variables.* Plus, tillage <strong>of</strong>fers additional benefits like fracturing surface compaction, improving water/<br />

air infiltration and creating a better environment for seed germination and root growth. What does this<br />

mean to you An improvement to your bottom-line through cutting cost and enhancing yields.<br />

Unique overhead hitch and<br />

spanner beams produce<br />

positive down pressure to<br />

<strong>the</strong> frames. This design also<br />

moves <strong>the</strong> pulling point from<br />

<strong>the</strong> center <strong>of</strong> <strong>the</strong> plow to <strong>the</strong><br />

outer edges <strong>of</strong> <strong>the</strong> right and left<br />

center frames to help counter<br />

"buckling" and <strong>the</strong> "roll-over"<br />

effect common to tillage tools.<br />

UHMW hinge bushing with<br />

flanges totally eliminates daily<br />

greasing, protects against “tear<br />

out” <strong>of</strong> hinges and stops risk <strong>of</strong><br />

hinge “freeze-up”. The UHMW<br />

flange also eliminates metal<br />

to metal wear between frame<br />

connections, cushions high<br />

stress hinge areas and quiets<br />

fold operation.<br />

Easy adjustable swivel linkages<br />

between rockshafts simplify<br />

frame leveling by eliminating<br />

<strong>the</strong> need to remove bolts and<br />

linkages to make adjustments.<br />

Adjustable linkages allow an<br />

operator to fine-tune <strong>the</strong> plow<br />

to maximize results and lower<br />

<strong>the</strong> drafting requirement.<br />

The 5 point linkage<br />

between frame sections has<br />

been replaced with a simple<br />

<strong>of</strong>fset lever system that has<br />

reduced wear points by 60%.<br />

This new system requires<br />

less maintenance, less parts<br />

replacement and helps produce<br />

consistent performance from <strong>the</strong><br />

blade plow.<br />

6<br />

Each shank and each individual coulter is spaced on 60-inch<br />

centers. This allows <strong>the</strong> plow to fit 30-inch rows and stay<br />

level during row crop undercutting. Less shanks mean less<br />

residue disturbance. The SUNFLOWER 3600 Blade Plow<br />

leaves up to 95% <strong>of</strong> <strong>the</strong> crop residue it finds in <strong>the</strong> field.<br />

*University <strong>of</strong> Minnesota. For more information visit<br />

http://agecon.lib.umn.edu/mn/p98-05.html.<br />

60"

YEAR<br />

LIMITED<br />

WARRANTY<br />

Treaders have been removed.<br />

Rockshafts are now clad in UHMW,<br />

which eliminates greasing and metal<br />

to metal wear. No more re-adjusting<br />

<strong>of</strong> frames, no more greasing and less<br />

chance <strong>of</strong> down time from parts failure.<br />

Blade support standards have been<br />

increased 11% in thickness to prolong wear<br />

and provide additional strength to guard<br />

against breakage when encountering foreign<br />

objects found during field operation. These<br />

supports are still <strong>of</strong> a slim design which<br />

promotes lower drafting.<br />

A third hinge has been added to 9 and 11<br />

section models to enhance frame life by<br />

distributing bearing load over a 50% larger<br />

area. This addition decreases <strong>the</strong> amount <strong>of</strong><br />

"roll-over" associated with ground engaging<br />

farm tools. The third hinge is also protected<br />

with UHMW polymer.<br />

<strong>Sunflower</strong>’s exclusive use <strong>of</strong> UHMW Technology<br />

was initiated from need.<br />

• The need for more productive field time<br />

and less greasing maintenance time<br />

• The need for fewer replacement<br />

parts resulting in less downtime and<br />

machine expense<br />

• The need for consistent field performance<br />

through <strong>the</strong> elimination <strong>of</strong> machine wear<br />

• The need for higher valued farm<br />

equipment by an ever refining industry<br />

What is UHMW Polymer<br />

“UHMW-PE or simply UHMW stands<br />

for Ultra High Molecular Weight<br />

Polyethylene. This raw material is well<br />

known by <strong>the</strong> engineering field as one <strong>of</strong><br />

<strong>the</strong> toughest substances known to man.<br />

UHMW has an abrasion resistance<br />

10 times that <strong>of</strong> carbon steel and an<br />

amazing impact strength, in fact UHMW<br />

is used as a key ingredient in bullet pro<strong>of</strong><br />

vests and body armor.”<br />

UHMW technology has<br />

also been applied to <strong>the</strong><br />

coulter pivot area. No<br />

more greasing, no more<br />

metal to metal wear,<br />

just less cost and less<br />

mess. UHMW really is an<br />

operator’s friend.<br />

3600 Series Blade Plow Specifications<br />

WIDTH NO. OF NO. OF EST. TRANS.<br />

MODEL OF CUT BLADES TIRES WT. WIDTH<br />

3662-30 30' 6" 6 7 - 11L, 12 ply 7,787 15’ 6"<br />

3672-35 35' 6" 7 8 - 11L, 12 ply 8,742 20’ 6"<br />

3692-45 45' 6" 9 6 - 11L, 12 ply, 15 x 8 13,733 22’ 9"<br />

6 - 11L, 12 ply, 15 x 10<br />

3612-55 55' 6" 11 8 - 11L, 12 ply, 15 x 8 17,803 25’ 3"<br />

6 - 11L, 12 ply, 15 x 10<br />

For additional information, visit our<br />

website at www.sunflowermfg.com.<br />

We are continually striving to improve our machines; <strong>the</strong>refore, <strong>the</strong>se specifications are subject to<br />

change without notice.<br />

7

<strong>of</strong>fers you a choice in<br />

Treader Wheels<br />

<strong>the</strong> o<strong>the</strong>rs can’t.<br />

<strong>Sunflower</strong> <strong>of</strong>fers both Conservation and Standard Treader<br />

Wheels to match your farming operation. Hard surfaced<br />

teeth are available on <strong>the</strong> Conservation Treader Wheel.<br />

SUNFLOWER’s rolling treader is built from a durable one-piece pipe<br />

and only utilizes individual wheels outside <strong>of</strong> <strong>the</strong> bearing hangers.<br />

Tooth replacement can be made one at a time instead <strong>of</strong> replacing<br />

<strong>the</strong> whole individual wheel. Gangs are equipped with a nut at each<br />

end to facilitate any future bearing replacement. SUNFLOWER’s<br />

solid treader gang design stays tight and does not allow dust and<br />

moisture to contaminate and rust <strong>the</strong> interior gang shaft.<br />

This unique wheel<br />

features high carbon half<br />

oval teeth (8 per wheel)<br />

curved and twisted for<br />

superior soil-residue<br />

action, working and<br />

leveling <strong>the</strong> soil behind<br />

various tillage tools. The<br />

tooth’s unique digging<br />

action inverts weeds,<br />

exposing <strong>the</strong>ir roots<br />

on <strong>the</strong> surface. A mixture <strong>of</strong> small clods and<br />

residue are deposited on <strong>the</strong> surface while finer<br />

soil particles settle below, safeguarding your<br />

fields from wind and water erosion. The highcarbon<br />

teeth are specially stress-relieved for<br />

ductility and longer field life.<br />

The Conservation<br />

Treader Wheel features<br />

a flat tooth design<br />

(7 per wheel) that is<br />

curved only and cut<br />

at a 45˚ angle on <strong>the</strong><br />

soil engaging end.<br />

This less aggressive<br />

tooth destroys minimal<br />

amounts <strong>of</strong> residue,<br />

but maintains a good<br />

weed kill during tillage operations. Ideal for<br />

use in arid conditions where residue compliance<br />

is difficult to achieve. The wheel’s larger<br />

diameter, featuring less teeth with no special<br />

twist are <strong>the</strong> key ingredients in this unit’s ability<br />

to meet conservation standards. Constructed <strong>of</strong><br />

high-carbon steel, each tooth is specially stressrelieved<br />

for longer field life.<br />

Overlapping sections provide<br />

thorough tillage action with no skips<br />

or missed ground. You’ll get <strong>the</strong> full<br />

benefit <strong>of</strong> <strong>the</strong> harrow’s aggressive<br />

weed kill across <strong>the</strong> entire width <strong>of</strong><br />

your chisel or sweep plow.<br />

Adjustable spring loaded mounting<br />

brackets relieve strain on <strong>the</strong> plow frame<br />

during folding and transport.<br />

With basic tools and a few moments<br />

<strong>of</strong> time, you can adjust <strong>the</strong> treader<br />

section from 15 degrees to 20 degrees.<br />

Conservation treaders should be run at<br />

20 degrees only.<br />

Each gang is equipped with a<br />

1-1/8" square shaft and triple<br />

sealed greaseable bearings.<br />

The formed bracket protects <strong>the</strong><br />

zerk from rocks, weed wrap and<br />

premature wear.<br />

<strong>Sunflower</strong> Manufacturing<br />

P.O. Box 566 • 3154 Hallie Trail<br />

Beloit, KS 67420<br />

FOR MORE INFORMATION:<br />

1-800-748-8481 • (785) 738-2261<br />

FAX (785) 738-2406<br />

Internet - http://www.sunflowermfg.com<br />

E-mail - sales@sunflowermfg.com<br />

PRINTED IN U.S.A. BAC 37557/10/06