hm - Aug13 - cover.indd - National Hardwood Lumber Association

hm - Aug13 - cover.indd - National Hardwood Lumber Association

hm - Aug13 - cover.indd - National Hardwood Lumber Association

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

RULES<br />

CORNER<br />

SIDE BEND, IT’S NOT A WORK-OUT MOVE<br />

By Dana Spessert, NHLA Chief Inspector<br />

As NHLA Chief Inspector I have been given many opportunities to<br />

explain some of the more difficult to understand Rules. One of these<br />

Rules or in this case “Defects” is the ever annoying Side Bend.<br />

Side Bend is primarily caused by improper sawing practices with boards<br />

that have off center growth rings which allow a much greater shrinkage<br />

on one edge as opposed to the other. Another cause of Side Bend is an<br />

edger that is ripping boards in the middle to create two boards prior to<br />

drying and both pieces are subject to abnormal shrinkage patterns.<br />

When inspecting lumber remember, the grades describe a board that is<br />

to be processed in to another product and it is not intended to be used<br />

in its entirety. In other words, the NHLA Rules are for raw material<br />

inspection. Another thing to realize is that in the process of producing<br />

another product a substantial amount of material can be removed and<br />

the board may still yield the minimum required for the grade in which<br />

it was sold or purchased.<br />

When a board has Side Bend in FAS, F1F or Select and the surface measure is<br />

less than 6, it is relatively easy to turn the arc of the bow up so that both ends<br />

of the board are touching a flat surface. Measure up to the widest area between<br />

the flat surface and the edge of the board, then subtract that number from<br />

the full width of the board and that will give you the maximum width of a<br />

straight edge cutting that may be available in that piece.<br />

While this is a good measurement for narrow boards with small surface<br />

measures for the full length this does leave a substantial amount of room<br />

for interpretation in larger surface measures or lower grades where there<br />

can be multiple cuttings taken.<br />

Ideally, when faced with a board with Side Bend the inspector would<br />

take a piece of string and use that to simulate the cutting of the saw and<br />

then use that information to grade the board, but this approach would<br />

be much too time consuming as well as impractical in a production<br />

environment. I would recommend that the inspector use a string to<br />

test a few boards and get a good understanding of how much Side<br />

Bend is affecting the grade and use their best judgment in applying the<br />

knowledge gained.<br />

One of the most important things to remember when utilizing the<br />

NHLA grades is that the useable portion of the board is measured to<br />

establish the grade and not the defects.<br />

Questions about the NHLA hardwood lumbering grading Rules should<br />

be directed to Chief Inspector Dana Spessert. He can be reached by<br />

phone at 901-399-7551 or by email at d.spessert@nhla.com.<br />

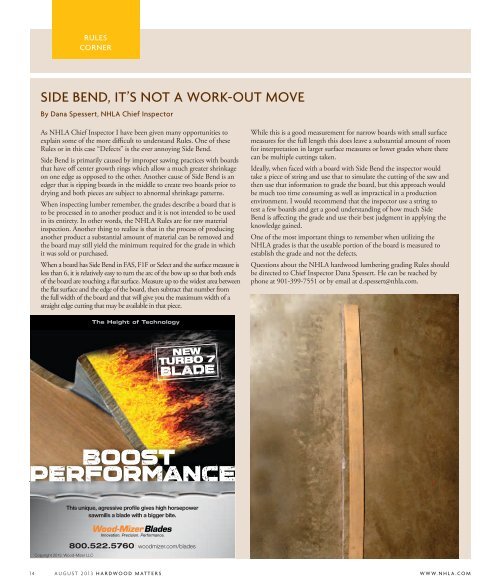

The Height of Technology<br />

NEW<br />

TURBO 7<br />

BLADE<br />

BOOST<br />

PERFORMANCE<br />

This unique, agressive profile gives high horsepower<br />

sawmills a blade with a bigger bite.<br />

Copyright 2013, Wood-Mizer LLC<br />

800.522.5760 woodmizer.com/blades<br />

14 AUGUST 2013 HARDWOOD MATTERS WWW.NHLA.COM