Prospekt TF-englisch.indd - Steinle Industriepumpen GmbH

Prospekt TF-englisch.indd - Steinle Industriepumpen GmbH

Prospekt TF-englisch.indd - Steinle Industriepumpen GmbH

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

© 2/2007 <strong>Steinle</strong> <strong>Industriepumpen</strong> <strong>GmbH</strong> - Series <strong>TF</strong> / Änderungen vorbehalten<br />

Filter presses<br />

with STEINLE-pump station<br />

Automatic adaption<br />

When slurry is transfered to a chamber fi lter<br />

press, fi rst the chambers get fi lled while the<br />

pressure tends to zero. Under an increasing<br />

fi lling-level the solids assemble at the fi lter<br />

cloths. This requires a pressure that continiously<br />

rises with the increasing content of<br />

solids. Under an constant fl ow quantity the<br />

pressure would rise extremly fast.<br />

The drive of the <strong>Steinle</strong> charging pump by<br />

compressed air causes a diminution of the<br />

fl ow quantity according to the increasing<br />

counter-pressure in the fi lter press. This<br />

produces a soft fi ltration curve, automatically<br />

self-regulating according to the fi lling-level of<br />

the fi lter press. This is independent from the<br />

properties of the slurry. No pressure tank nor<br />

pressure transmitter nor speed control are<br />

required. The complete pump works without<br />

electric energy.<br />

End of fi ltration process<br />

When the fi lter press is fi lled with solids so<br />

far that no more slurry can be taken up, the<br />

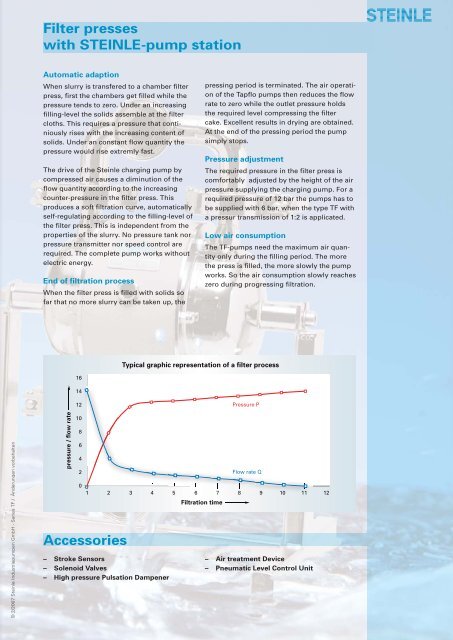

pressure / flow rate<br />

16<br />

14<br />

12<br />

10<br />

8<br />

6<br />

4<br />

2<br />

0<br />

Accessories<br />

– Stroke Sensors<br />

– Solenoid Valves<br />

– High pressure Pulsation Dampener<br />

Filtration time<br />

pressing period is terminated. The air operation<br />

of the Tapfl o pumps then reduces the fl ow<br />

rate to zero while the outlet pressure holds<br />

the required level compressing the fi lter<br />

cake. Excellent results in drying are obtained.<br />

At the end of the pressing period the pump<br />

simply stops.<br />

Pressure adjustment<br />

The required pressure in the fi lter press is<br />

comfortably adjusted by the height of the air<br />

pressure supplying the charging pump. For a<br />

required pressure of 12 bar the pumps has to<br />

be supplied with 6 bar, when the type <strong>TF</strong> with<br />

a pressur transmission of 1:2 is applicated.<br />

Low air consumption<br />

The <strong>TF</strong>-pumps need the maximum air quantity<br />

only during the fi lling period. The more<br />

the press is fi lled, the more slowly the pump<br />

works. So the air consumption slowly reaches<br />

zero during progressing fi ltration.<br />

Typical graphic representation of a filter process<br />

Pressure P<br />

Flow rate Q<br />

1 2 3 4 5 6 7 8 9 10 11 12<br />

– Air treatment Device<br />

– Pneumatic Level Control Unit