Download - O scale trains

Download - O scale trains

Download - O scale trains

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

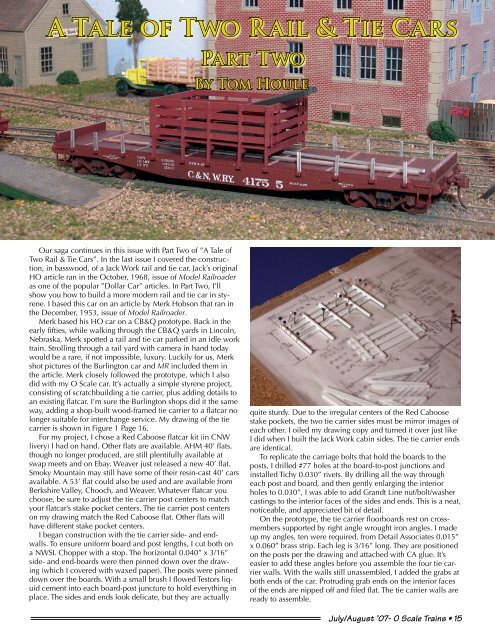

A Tale of Two Rail & Tie Cars<br />

Part Two<br />

By Tom Houle<br />

Our saga continues in this issue with Part Two of ”A Tale of<br />

Two Rail & Tie Cars”. In the last issue I covered the construction,<br />

in basswood, of a Jack Work rail and tie car. Jack’s original<br />

HO article ran in the October, 1968, issue of Model Railroader<br />

as one of the popular ”Dollar Car” articles. In Part Two, I’ll<br />

show you how to build a more modern rail and tie car in styrene.<br />

I based this car on an article by Merk Hobson that ran in<br />

the December, 1953, issue of Model Railroader.<br />

Merk based his HO car on a CB&Q prototype. Back in the<br />

early fifties, while walking through the CB&Q yards in Lincoln,<br />

Nebraska, Merk spotted a rail and tie car parked in an idle work<br />

train. Strolling through a rail yard with camera in hand today<br />

would be a rare, if not impossible, luxury. Luckily for us, Merk<br />

shot pictures of the Burlington car and MR included them in<br />

the article. Merk closely followed the prototype, which I also<br />

did with my O Scale car. It’s actually a simple styrene project,<br />

consisting of scratchbuilding a tie carrier, plus adding details to<br />

an existing flatcar. I’m sure the Burlington shops did it the same<br />

way, adding a shop-built wood-framed tie carrier to a flatcar no<br />

longer suitable for interchange service. My drawing of the tie<br />

carrier is shown in Figure 1 Page 16.<br />

For my project, I chose a Red Caboose flatcar kit (in CNW<br />

livery) I had on hand. Other flats are available. AHM 40’ flats,<br />

though no longer produced, are still plentifully available at<br />

swap meets and on Ebay. Weaver just released a new 40’ flat.<br />

Smoky Mountain may still have some of their resin-cast 40’ cars<br />

available. A 53’ flat could also be used and are available from<br />

Berkshire Valley, Chooch, and Weaver. Whatever flatcar you<br />

choose, be sure to adjust the tie carrier post centers to match<br />

your flatcar’s stake pocket centers. The tie carrier post centers<br />

on my drawing match the Red Caboose flat. Other flats will<br />

have different stake pocket centers.<br />

I began construction with the tie carrier side- and endwalls.<br />

To ensure uniform board and post lengths, I cut both on<br />

a NWSL Chopper with a stop. The horizontal 0.040” x 3/16”<br />

side- and end-boards were then pinned down over the drawing<br />

(which I covered with waxed paper). The posts were pinned<br />

down over the boards. With a small brush I flowed Testors liquid<br />

cement into each board-post juncture to hold everything in<br />

place. The sides and ends look delicate, but they are actually<br />

quite sturdy. Due to the irregular centers of the Red Caboose<br />

stake pockets, the two tie carrier sides must be mirror images of<br />

each other. I oiled my drawing copy and turned it over just like<br />

I did when I built the Jack Work cabin sides. The tie carrier ends<br />

are identical.<br />

To replicate the carriage bolts that hold the boards to the<br />

posts, I drilled #77 holes at the board-to-post junctions and<br />

installed Tichy 0.030” rivets. By drilling all the way through<br />

each post and board, and then gently enlarging the interior<br />

holes to 0.030”, I was able to add Grandt Line nut/bolt/washer<br />

castings to the interior faces of the sides and ends. This is a neat,<br />

noticeable, and appreciated bit of detail.<br />

On the prototype, the tie carrier floorboards rest on crossmembers<br />

supported by right angle wrought iron angles. I made<br />

up my angles, ten were required, from Detail Associates 0.015”<br />

x 0.060” brass strip. Each leg is 3/16” long. They are positioned<br />

on the posts per the drawing and attached with CA glue. It’s<br />

easier to add these angles before you assemble the four tie carrier<br />

walls. With the walls still unassembled, I added the grabs at<br />

both ends of the car. Protruding grab ends on the interior faces<br />

of the ends are nipped off and filed flat. The tie carrier walls are<br />

ready to assemble.<br />

July/August ’07- O Scale Trains • 15