Download - O scale trains

Download - O scale trains

Download - O scale trains

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

AC<br />

IN<br />

AC<br />

IN<br />

RAIL<br />

1<br />

FROG<br />

RAIL<br />

2<br />

RECT.<br />

RECT.<br />

RECT.<br />

RECT.<br />

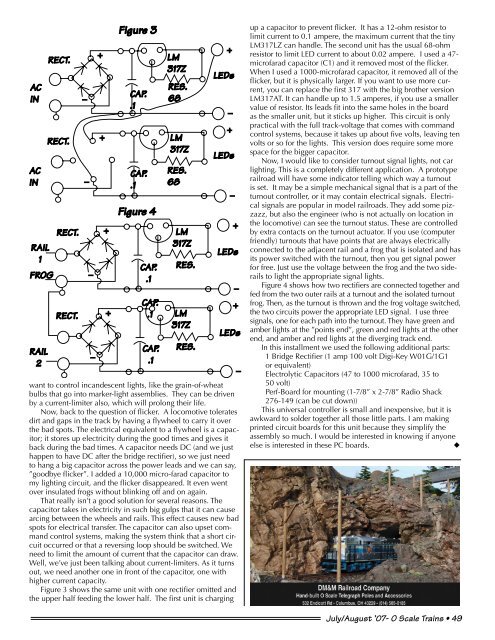

Figure 3<br />

CAP.<br />

.1<br />

CAP.<br />

.1<br />

Figure 4<br />

CAP.<br />

.1<br />

CAP.<br />

.1<br />

CAP.<br />

.1<br />

LM<br />

317Z<br />

RES.<br />

68<br />

LM<br />

317Z<br />

RES.<br />

68<br />

LM<br />

317Z<br />

RES.<br />

LM<br />

317Z<br />

RES.<br />

LEDs<br />

LEDs<br />

LEDs<br />

LEDs<br />

want to control incandescent lights, like the grain-of-wheat<br />

bulbs that go into marker-light assemblies. They can be driven<br />

by a current-limiter also, which will prolong their life.<br />

Now, back to the question of flicker. A locomotive tolerates<br />

dirt and gaps in the track by having a flywheel to carry it over<br />

the bad spots. The electrical equivalent to a flywheel is a capacitor;<br />

it stores up electricity during the good times and gives it<br />

back during the bad times. A capacitor needs DC (and we just<br />

happen to have DC after the bridge rectifier), so we just need<br />

to hang a big capacitor across the power leads and we can say,<br />

”goodbye flicker”. I added a 10,000 micro-farad capacitor to<br />

my lighting circuit, and the flicker disappeared. It even went<br />

over insulated frogs without blinking off and on again.<br />

That really isn’t a good solution for several reasons. The<br />

capacitor takes in electricity in such big gulps that it can cause<br />

arcing between the wheels and rails. This effect causes new bad<br />

spots for electrical transfer. The capacitor can also upset command<br />

control systems, making the system think that a short circuit<br />

occurred or that a reversing loop should be switched. We<br />

need to limit the amount of current that the capacitor can draw.<br />

Well, we’ve just been talking about current-limiters. As it turns<br />

out, we need another one in front of the capacitor, one with<br />

higher current capacity.<br />

Figure 3 shows the same unit with one rectifier omitted and<br />

the upper half feeding the lower half. The first unit is charging<br />

up a capacitor to prevent flicker. It has a 12-ohm resistor to<br />

limit current to 0.1 ampere, the maximum current that the tiny<br />

LM317LZ can handle. The second unit has the usual 68-ohm<br />

resistor to limit LED current to about 0.02 ampere. I used a 47-<br />

microfarad capacitor (C1) and it removed most of the flicker.<br />

When I used a 1000-microfarad capacitor, it removed all of the<br />

flicker, but it is physically larger. If you want to use more current,<br />

you can replace the first 317 with the big brother version<br />

LM317AT. It can handle up to 1.5 amperes, if you use a smaller<br />

value of resistor. Its leads fit into the same holes in the board<br />

as the smaller unit, but it sticks up higher. This circuit is only<br />

practical with the full track-voltage that comes with command<br />

control systems, because it takes up about five volts, leaving ten<br />

volts or so for the lights. This version does require some more<br />

space for the bigger capacitor.<br />

Now, I would like to consider turnout signal lights, not car<br />

lighting. This is a completely different application. A prototype<br />

railroad will have some indicator telling which way a turnout<br />

is set. It may be a simple mechanical signal that is a part of the<br />

turnout controller, or it may contain electrical signals. Electrical<br />

signals are popular in model railroads. They add some pizzazz,<br />

but also the engineer (who is not actually on location in<br />

the locomotive) can see the turnout status. These are controlled<br />

by extra contacts on the turnout actuator. If you use (computer<br />

friendly) turnouts that have points that are always electrically<br />

connected to the adjacent rail and a frog that is isolated and has<br />

its power switched with the turnout, then you get signal power<br />

for free. Just use the voltage between the frog and the two siderails<br />

to light the appropriate signal lights.<br />

Figure 4 shows how two rectifiers are connected together and<br />

fed from the two outer rails at a turnout and the isolated turnout<br />

frog. Then, as the turnout is thrown and the frog voltage switched,<br />

the two circuits power the appropriate LED signal. I use three<br />

signals, one for each path into the turnout. They have green and<br />

amber lights at the ”points end”, green and red lights at the other<br />

end, and amber and red lights at the diverging track end.<br />

In this installment we used the following additional parts:<br />

1 Bridge Rectifier (1 amp 100 volt Digi-Key W01G/1G1<br />

or equivalent)<br />

Electrolytic Capacitors (47 to 1000 microfarad, 35 to<br />

50 volt)<br />

Perf-Board for mounting (1-7/8” x 2-7/8” Radio Shack<br />

276-149 (can be cut down))<br />

This universal controller is small and inexpensive, but it is<br />

awkward to solder together all those little parts. I am making<br />

printed circuit boards for this unit because they simplify the<br />

assembly so much. I would be interested in knowing if anyone<br />

else is interested in these PC boards.<br />

u<br />

July/August ’07- O Scale Trains • 49