Valves - Gustav Wahler GmbH u. Co. KG

Valves - Gustav Wahler GmbH u. Co. KG

Valves - Gustav Wahler GmbH u. Co. KG

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

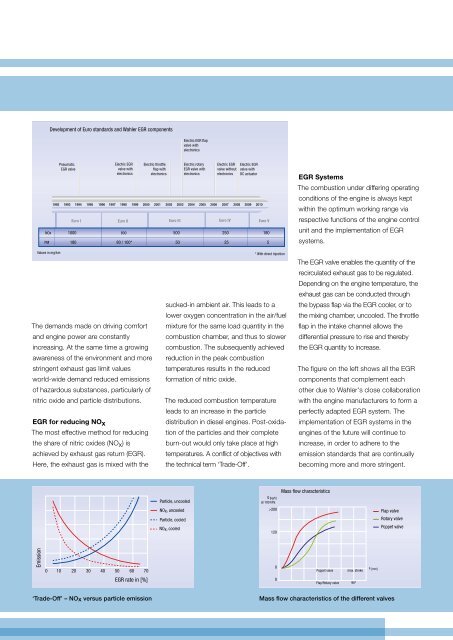

Entwicklung Development der Euro-Normen of standards und der and <strong>Wahler</strong>-AGR-Komponenten<br />

EGR components<br />

Elektrisches Electric EGR flap<br />

AGR-Klappenventil<br />

valve with<br />

mit electronics Elektronik<br />

Pneumatisches Pneumatic<br />

Electric Elektrisches EGR Electric Elektrische throttle Elektrisches Electric rotary Elektrisches Electric EGR Elektrisches Electric EGR<br />

AGR-Ventil EGR valve<br />

AGR-Ventil valve with Drosselklappe flap with AGR-Drehventil<br />

EGR valve with AGR-Ventil valve without AGR-Ventil valve with<br />

mit electronics Elektronik mit electronics Elektronik mit electronics Elektronik ohne electronics<br />

Elektronik<br />

mit DC actuator<br />

DC-Antrieb<br />

1992 1993 1994 1995 1996 1997 1998 1999 2000 2001 2002 2003 2004 2005 2006 2007 2008 2009 2010<br />

Euro I Euro II Euro III Euro IV Euro V<br />

NOx 1000<br />

800 500 250<br />

180<br />

PM<br />

180 80 / 100* 50 25<br />

5<br />

EGR Systems<br />

The combustion under differing operating<br />

conditions of the engine is always kept<br />

within the optimum working range via<br />

respective functions of the engine control<br />

unit and the implementation of EGR<br />

systems.<br />

Values Werte in mg/km<br />

The demands made on driving comfort<br />

and engine power are constantly<br />

increasing. At the same time a growing<br />

awareness of the environment and more<br />

stringent exhaust gas limit values<br />

world-wide demand reduced emissions<br />

of hazardous substances, particularly of<br />

nitric oxide and particle distributions.<br />

EGR for reducing NOx<br />

The most effective method for reducing<br />

the share of nitric oxides (NOx) is<br />

achieved by exhaust gas return (EGR).<br />

Here, the exhaust gas is mixed with the<br />

* mit * With Direkteinspritzung<br />

direct injection<br />

sucked-in ambient air. This leads to a<br />

lower oxygen concentration in the air/fuel<br />

mixture for the same load quantity in the<br />

combustion chamber, and thus to slower<br />

combustion. The subsequently achieved<br />

reduction in the peak combustion<br />

temperatures results in the reduced<br />

formation of nitric oxide.<br />

The reduced combustion temperature<br />

leads to an increase in the particle<br />

distribution in diesel engines. Post-oxidation<br />

of the particles and their complete<br />

burn-out would only take place at high<br />

temperatures. A conflict of objectives with<br />

the technical term ‘Trade-Off’.<br />

The EGR valve enables the quantity of the<br />

recirculated exhaust gas to be regulated.<br />

Depending on the engine temperature, the<br />

exhaust gas can be conducted through<br />

the bypass flap via the EGR cooler, or to<br />

the mixing chamber, uncooled. The throttle<br />

flap in the intake channel allows the<br />

differential pressure to rise and thereby<br />

the EGR quantity to increase.<br />

The figure on the left shows all the EGR<br />

components that complement each<br />

other due to <strong>Wahler</strong>'s close collaboration<br />

with the engine manufacturers to form a<br />

perfectly adapted EGR system. The<br />

implementation of EGR systems in the<br />

engines of the future will continue to<br />

increase, in order to adhere to the<br />

emission standards that are continually<br />

becoming more and more stringent.<br />

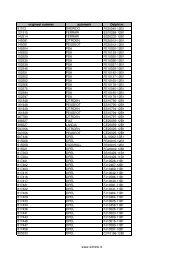

Durchsatzkennlinien<br />

Mass flow characteristics<br />

Partikel, Particle, uncooled ungekühlt<br />

Q [kg/h]<br />

bei at 100 hPa<br />

NOx, ungekühlt uncooled<br />

Partikel, Particle, cooled gekühlt<br />

NOx, gekühlt cooled<br />

>200<br />

120<br />

Klappenventil<br />

Flap valve<br />

Drehventil Rotary valve<br />

Hubventil Poppet valve<br />

Emission<br />

0<br />

10 20 30 40 50 60 70<br />

AGR-Rate EGR rate in [%]<br />

0<br />

0<br />

Hubventil Poppet valve<br />

max. Hub stroke<br />

Flap/Rotary Klappen-/Drehventil valve 90°<br />

s [mm]<br />

ϕ [ ]<br />

‘Trade-Off’ – NOx versus particle emission<br />

Mass flow characteristics of the different valves