VARIO GT 24 The variable Girder Wall Formwork System with ... - Peri

VARIO GT 24 The variable Girder Wall Formwork System with ... - Peri

VARIO GT 24 The variable Girder Wall Formwork System with ... - Peri

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

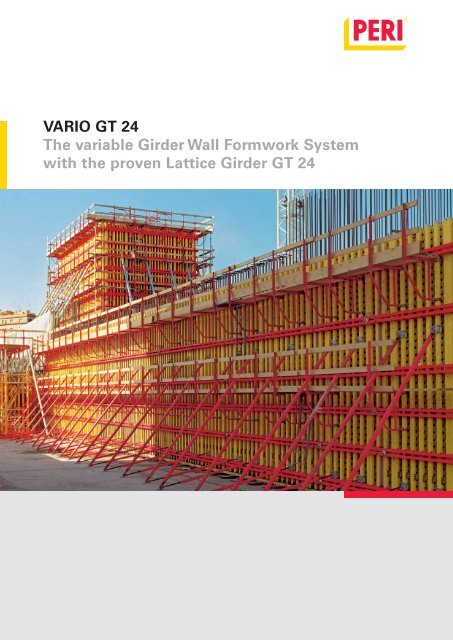

<strong>VARIO</strong> <strong>GT</strong> <strong>24</strong><br />

<strong>The</strong> <strong>variable</strong> <strong>Girder</strong> <strong>Wall</strong> <strong>Formwork</strong> <strong>System</strong><br />

<strong>with</strong> the proven Lattice <strong>Girder</strong> <strong>GT</strong> <strong>24</strong>

Content<br />

Page<br />

Edition 09/2011<br />

PERI GmbH<br />

<strong>Formwork</strong> Scaffolding Engineering<br />

P.O. Box 12 64<br />

89259 Weissenhorn<br />

Germany<br />

Tel +49 (0)7309.950-0<br />

Fax +49 (0)7309.951-0<br />

info@peri.com<br />

www.peri.com<br />

Which <strong>Wall</strong> <strong>Formwork</strong> <strong>System</strong><br />

<strong>Girder</strong> or panel formwork<br />

<strong>VARIO</strong> <strong>GT</strong> <strong>24</strong> or TRIO 1 – 3<br />

General<br />

<strong>The</strong> <strong>variable</strong> girder wall formwork system 4 –7<br />

Complicated geometries <strong>with</strong> standard<br />

system components 8 – 9<br />

<strong>The</strong> <strong>GT</strong> <strong>24</strong> lattice girder 10 – 11<br />

<strong>The</strong> standard system components of a<br />

<strong>VARIO</strong> <strong>GT</strong> <strong>24</strong> panel 12 – 13<br />

Standard Applications<br />

<strong>VARIO</strong> <strong>GT</strong> <strong>24</strong> standard panels 14 – 15<br />

Continuously adjustable panel connection 16 – 17<br />

Fillers, stopend formwork and<br />

panel width extension units 18 – 19<br />

External corners, internal corners<br />

and shafts 20 – 21<br />

Push-pull prop connector, crane splices,<br />

safety precaution 22 – 23<br />

Working and Concreting Scaffold <strong>24</strong> – 25<br />

Panel extensions 26 – 27<br />

Special applications<br />

Important Notes:<br />

Without exception, all current safety regulations<br />

must be observed in those countries where our<br />

products are used.<br />

<strong>The</strong> illustrations in this brochure are photographs<br />

of real site situations. Safety or formwork anchor<br />

details are therefore not to be taken as a definitive<br />

guide to the way the equipment is to be used.<br />

Architectural concrete 28 – 31<br />

Bridge-building 32 – 35<br />

Water retaining structures 36 – 39<br />

Single sided walls 40 – 41<br />

Components 42 – 67<br />

PERI International 68 – 69<br />

2<br />

Close attention must be paid to safety instructions<br />

and load specifications at all times. Separate structural<br />

calculations are required for any deviations<br />

from the standard design data.<br />

<strong>The</strong> information contained herein is subject to<br />

technical changes in the interests of progress.<br />

Errors and typographical mistakes reserved.

Which <strong>Wall</strong> <strong>Formwork</strong> <strong>System</strong><br />

<strong>Girder</strong> or panel formwork<br />

<strong>VARIO</strong> <strong>GT</strong> <strong>24</strong> or TRIO<br />

PERI offers a variety of systems to<br />

enable you to choose the moste<br />

conomical for your purposes.<br />

It is always worth carrying out a<br />

cost-effectiveness comparis on for<br />

larger building projects.<br />

<strong>VARIO</strong> <strong>GT</strong> <strong>24</strong> being used for housing project.<br />

TRIO formwork for industrial building.<br />

This table will help you select the<br />

right formwork system.<br />

Each site and shape of building has its own<br />

critical parameters for a comparison of costeffectiveness:<br />

<strong>VARIO</strong><br />

<strong>GT</strong> <strong>24</strong><br />

TRIO<br />

Type of layout<br />

<strong>Wall</strong> heights<br />

Concrete Pressure<br />

Tolerances<br />

(DIN 18202)<br />

Ties<br />

Concrete <strong>with</strong> special<br />

surface finish requirements<br />

Plywood<br />

Utilisation<br />

Utilisation period<br />

consistent<br />

very <strong>variable</strong><br />

consistent<br />

very <strong>variable</strong><br />

Anchor patterns<br />

Type<br />

Size<br />

Butt joint<br />

low over short construction period<br />

high over short construction period<br />

low over long construction period<br />

high over long construction period<br />

long<br />

short<br />

x<br />

x<br />

versatile<br />

30–100 kN/m 2<br />

versatile<br />

depending<br />

on design<br />

may be<br />

optimised<br />

as required<br />

x<br />

x<br />

x<br />

x<br />

x<br />

x<br />

x<br />

x<br />

x<br />

x<br />

x<br />

60 or<br />

80 kN/m 2<br />

Table 3<br />

line 6 or 7<br />

fixed,<br />

depends on<br />

size of panels<br />

only <strong>with</strong><br />

TRIO Structure<br />

x<br />

x<br />

x<br />

x x indicates the more suitable system<br />

1

Which <strong>Wall</strong> <strong>Formwork</strong> <strong>System</strong><br />

<strong>Girder</strong> or panel formwork<br />

<strong>VARIO</strong> <strong>GT</strong> <strong>24</strong> or TRIO<br />

<strong>The</strong> architecture of high-class buildings<br />

and complicated layouts often<br />

requires custom formwork.<br />

PERI <strong>VARIO</strong> <strong>GT</strong> <strong>24</strong> readily allows<br />

any configuration to be constructed<br />

using a small number of special<br />

steel walers.<br />

11,87<br />

12,83<br />

Lift shafts for a 26-storey<br />

skyscraper in Paris.<br />

<strong>The</strong> high flexural stiffness of<br />

<strong>VARIO</strong>’s <strong>GT</strong> <strong>24</strong> girders and matching<br />

steel walers can often be<br />

used to speed up shuttering, by<br />

optimising the formwork panels<br />

and minimising the number of<br />

tie points.In many cases the<br />

<strong>VARIO</strong> system yields the most<br />

cost-effective solution. It is important<br />

to work out the overall price,<br />

reflecting both materials and<br />

labour.<br />

With <strong>VARIO</strong> <strong>GT</strong> <strong>24</strong> the cost of basic<br />

assembly and dismantling of the<br />

panels, formlining and special walers<br />

has to be spread over the number of<br />

months for which the formwork is<br />

used.<br />

<strong>The</strong> lower cost of materials <strong>with</strong><br />

<strong>VARIO</strong> makes the system particularly<br />

economical where labour is cheap.<br />

Typical <strong>VARIO</strong> applications include<br />

the stairwells of multistorey buildings,<br />

dividing walls in large blocks<br />

of flats and custom formwork (see<br />

examples <strong>with</strong> girder formwork on<br />

pages 2<strong>24</strong> and 225 of the handbook).<br />

TRIO panel formwork has the advantage<br />

of versatility for frequently<br />

changing heights and layouts.<br />

2

3,60<br />

3,60<br />

<strong>VARIO</strong><br />

One-off costs spread<br />

over number of<br />

months, plus monthly<br />

hire charge/m 2<br />

One-off costs <strong>VARIO</strong><br />

consisting of cost of<br />

basic assembly and<br />

dismantling of panels<br />

53,00<br />

5,00<br />

€ 58,00<br />

€ 53,00<br />

55,-<br />

50,-<br />

Cost of materials per time formwork used, as a function of construction period<br />

and number of times used each month (2/m 2 of concrete)<br />

58,00<br />

TRIO<br />

TRIO monthly hire<br />

charge 2/m 2 : 16.50<br />

custom walers, small<br />

components, replacement<br />

formlining<br />

€ 21,50<br />

€ 31,70<br />

<strong>VARIO</strong> costs<br />

when used once a month<br />

35,-<br />

30,-<br />

31,44<br />

25,-<br />

20,-<br />

22,50<br />

15,-<br />

16,50<br />

18,15<br />

15,59<br />

TRIO costs<br />

when used once a month<br />

10,-<br />

14,52<br />

<strong>VARIO</strong> costs<br />

when used 4 times a month<br />

13,55<br />

12,53<br />

11,50<br />

10,74<br />

5,-<br />

4,10<br />

7,87<br />

5,62<br />

4,55<br />

TRIO costs<br />

when used 4 times a month<br />

0 1 2 3 4 5 6 7 8 9 10<br />

3,89<br />

3,39<br />

3,13 2,87 2,68<br />

Months<br />

<strong>The</strong> table of costs is based on the layout shown above (height 3.60 m). <strong>VARIO</strong> and TRIO were based on the same<br />

hire charge percentages. <strong>The</strong> chart shows that in terms of materials <strong>VARIO</strong> is particularly cost-effective for long<br />

construction periods. In calculating the overall price please allow for the saving in labour costs <strong>with</strong> <strong>VARIO</strong>.<br />

This amounts to about 0.1 h ≈ € 2.50 per m 2 of concrete surface area, each time the formwork is reused.<br />

3

General<br />

<strong>The</strong> <strong>variable</strong> girder wall formwork system<br />

<strong>VARIO</strong> <strong>GT</strong> <strong>24</strong>, the girder wall<br />

formwork system <strong>with</strong> the continuously<br />

adjustable slot coupling.<br />

From industrial structures to housing,<br />

bridge abutments to retaining<br />

walls, PERI <strong>VARIO</strong> shutters any<br />

layout and height up to 18 m <strong>with</strong><br />

a single unit.<br />

<strong>The</strong> <strong>GT</strong> <strong>24</strong>’s 30 cm<br />

increments make it<br />

easier to adjust to the<br />

required height.<br />

11.50 m high walls shuttered<br />

<strong>with</strong> single unit <strong>with</strong> extralong<br />

and extended <strong>GT</strong> <strong>24</strong> girders.<br />

4

Extended <strong>VARIO</strong> panels being<br />

used to shutter administration<br />

building.<br />

Simple planning, lower stock levels<br />

and fast, economical shuttering<br />

sequence.<br />

1,05<br />

1,48<br />

GB 80 GB 80<br />

<strong>VARIO</strong> <strong>GT</strong> <strong>24</strong> formwork is used to<br />

assemble exactly the right large<br />

panel for each project.<br />

<strong>The</strong> following parameters can therefore<br />

always to be freely selected:<br />

– type and size of the plywood<br />

– plywood fixings<br />

– panel widths and heights<br />

– position of any extension or<br />

reduction in height<br />

– girder length and spacing<br />

– waler position, profile and length<br />

– permissible fresh concrete<br />

pressure<br />

– vertical and horizontal tie spacing<br />

– Type of panel: straight, curved or<br />

angled<br />

1,48<br />

1,48<br />

11,50<br />

1,51<br />

1,48<br />

1,48<br />

RS 1000<br />

<strong>VARIO</strong> <strong>GT</strong> <strong>24</strong> being used in<br />

Korea to construct a settlement<br />

tank <strong>with</strong> tapered walls.<br />

RSS III<br />

1,48<br />

AV for<br />

RSS III<br />

Section of photo at the bottom of page 4.<br />

0,45<br />

5

General<br />

<strong>The</strong> <strong>variable</strong> girder wall formwork system<br />

10.7 m high walls <strong>with</strong> doubly<br />

extended <strong>VARIO</strong> formwork.<br />

<strong>The</strong> formwork is extended <strong>with</strong><br />

the <strong>VARIO</strong> extension splice <strong>24</strong>.<br />

Quickly and easily fitted through the<br />

latticework of the <strong>GT</strong> <strong>24</strong>, <strong>with</strong>out<br />

having to drill girders.<br />

<strong>The</strong> flexurally stiff connection aligns<br />

the girders (see page 26).<br />

<strong>The</strong> splice consists of just two<br />

components, which are quickly<br />

connected <strong>with</strong> three-wing nuts.<br />

6<br />

4.20 m high <strong>VARIO</strong><br />

<strong>with</strong> bulkhead fitted.

6.00 m high <strong>VARIO</strong> <strong>GT</strong> <strong>24</strong><br />

standard panels <strong>with</strong> platform.<br />

2,71<br />

0,50 2,37<br />

Soundproof sealing of the<br />

tie points costs 50% less,<br />

since the top tie point is<br />

above the concrete <strong>with</strong><br />

waler spacing of 2.37 m.<br />

<strong>VARIO</strong> panels, <strong>with</strong> concreting<br />

platform and pushpull<br />

props, are shifted as a complete<br />

unit.<br />

7

General<br />

Even complicated geometries shuttered<br />

<strong>with</strong> standard system components<br />

<strong>VARIO</strong> <strong>GT</strong> <strong>24</strong> is particularly<br />

versatile when constructing<br />

complicated layouts, such as<br />

bridge abutments.<br />

Piers and abutment walls<br />

of a motorway bridge<br />

<strong>with</strong> <strong>VARIO</strong> <strong>GT</strong> <strong>24</strong>.<br />

Complicated abutment<br />

<strong>with</strong> <strong>VARIO</strong> <strong>GT</strong> <strong>24</strong>. Easy<br />

adjustment thanks to<br />

<strong>GT</strong> <strong>24</strong> girders and steel<br />

walers.<br />

8

<strong>The</strong> stringent French safety standards<br />

for highrise construction were<br />

taken into account in planning the<br />

formwork. <strong>The</strong>y included fine wire<br />

mesh panels for all safety handrails,<br />

and end handrail swing frames for<br />

the outside climbing units, in order<br />

to maximise the protection against<br />

falling, even during climbing.<br />

Multistorey building in<br />

Paris, <strong>with</strong> <strong>VARIO</strong> <strong>GT</strong> <strong>24</strong><br />

and CB <strong>24</strong>0 climbing<br />

formwork system.<br />

11,05<br />

Even for this complicated,<br />

circular layout over 90%<br />

of the formwork consists<br />

of standard system components.<br />

<strong>VARIO</strong> <strong>GT</strong> <strong>24</strong> being used<br />

to construct a circular tank.<br />

Timber wedges between<br />

girders and steel walers<br />

produce the circular shape.<br />

9

General<br />

<strong>The</strong> <strong>GT</strong> <strong>24</strong> lattice girder<br />

Successful building contractors<br />

use this girder from PERI because<br />

it is:<br />

Light and manageable for slabs<br />

Strong enough for wall formwork<br />

Cost-effective for customized<br />

formwork solutions<br />

<strong>The</strong> formwork girder as the main<br />

component of slab and wall formworkt<br />

ends to determine whether<br />

your forms are cost effective.<br />

Rather than the initial outlay, it is<br />

the service life and handling costs<br />

that are crucial.<br />

<strong>The</strong> <strong>GT</strong> <strong>24</strong> from PERI<br />

guarantees both:<br />

– Durability<br />

– shorter shuttering times<br />

<strong>GT</strong> <strong>24</strong> Schalungsträger<br />

Einer für Alles<br />

You can find further information<br />

in the <strong>GT</strong> <strong>24</strong> brochure.<br />

Designed to last by timber<br />

specialists. <strong>The</strong> patented chord<br />

<strong>with</strong> finger joints has practically no<br />

cavities that could trap water.<br />

<strong>The</strong> latticework is well ventilated<br />

even while the girders are stacked.<br />

Comparison<br />

<strong>with</strong> <strong>GT</strong> <strong>24</strong><br />

Permissible<br />

reaction<br />

VT 20<br />

22 kN<br />

<strong>GT</strong> <strong>24</strong><br />

28 kN*<br />

Diff. %<br />

+27%<br />

Permissible<br />

bending moment<br />

5 kNm<br />

7 kNm*<br />

+40%<br />

Flexural strength<br />

429 kN/m 2<br />

800 kN/m 2<br />

+86%<br />

Weight<br />

5,9 kg/m<br />

5,9 kg/m<br />

± 0%<br />

10<br />

*can even be supported at the node

High load-bearing capacity <strong>with</strong><br />

low weight<br />

Perm. strut shear Q S<br />

= 14 kN<br />

Perm. bending moment M = 7 kNm<br />

Prin. mom. of inertia ly = 8000 cm 4<br />

6 x 8 cm chord timber<br />

For ease of screwing and nailing.<br />

To prevent splitting, the full depth of<br />

the chord is finger jointed to the struts<br />

and tied at each girder connection.<br />

PERI tables for slab and wall<br />

formwork and German Building<br />

Regulations approval Z - 9.1 - 157<br />

are available.<br />

Colour code<br />

<strong>The</strong> common lengths of the <strong>GT</strong> <strong>24</strong><br />

girder are colour coded for ease of<br />

handling in the yard and on site.<br />

Length Colour<br />

270<br />

300<br />

330<br />

360<br />

390<br />

Steel end caps <strong>with</strong> through rivet<br />

– Robust end protection<br />

– Prevents end being sawn off<br />

accidentally<br />

– Can be used to replace rubbing<br />

board on <strong>VARIO</strong> panels when<br />

required<br />

Many customers have confirmed<br />

how long the <strong>GT</strong> <strong>24</strong> lasts.<br />

Mark of conformity<br />

Year of manufacture<br />

Day of production<br />

Length in cm (rounded off)<br />

Eberhard Claus, Shuttering Manager for Max Giese<br />

GmbH in Trappenkamp: “<strong>The</strong> <strong>GT</strong> <strong>24</strong>, is virtually indestructible<br />

this is an example manufactured in 1985.”<br />

<strong>The</strong> fact that the markings are still legible is proof that<br />

<strong>The</strong> <strong>GT</strong> <strong>24</strong> really lasts!<br />

<strong>The</strong> <strong>GT</strong> <strong>24</strong> lattice girder -<br />

the one that cuts shuttering costs.<br />

11

General<br />

<strong>The</strong> standard system components<br />

of a <strong>VARIO</strong> <strong>GT</strong> <strong>24</strong> panel.<br />

<strong>The</strong> <strong>GT</strong> <strong>24</strong> formwork girder<br />

Forms the main element of the<br />

<strong>VARIO</strong> wall formwork. Available in<br />

lengths from 90 cm to 17.80 m, in<br />

30 cm increments.<br />

Cross-section<br />

80<br />

60<br />

<strong>24</strong>0<br />

296 163<br />

28<br />

296 311<br />

Steel waler SRZ / SRU<br />

Available in standard lengths and<br />

any special sizes and forms. U 100<br />

to U 140 channel and other sections.<br />

<strong>VARIO</strong> steel waler and<br />

Internal Corner Waler IRZ<br />

for corner panels.<br />

12

Plywood<br />

<strong>The</strong> right plywood for every requirement.<br />

PERI plywood is available in<br />

various sizes, thickness and grades,<br />

so that the site always has the<br />

correct formlining available.<br />

Connecting parts<br />

Hook Strap HB <strong>24</strong><br />

for connecting <strong>GT</strong> <strong>24</strong> to SRZ<br />

and SRU.<br />

Hook Strap Uni HBU<br />

for connecting <strong>GT</strong> <strong>24</strong> to SRZ<br />

and SRU.<br />

TSS Torx screw<br />

for fixing the formlining.<br />

13

Standard Applications<br />

<strong>VARIO</strong> <strong>GT</strong> <strong>24</strong> standard panels<br />

Fully pre-assembled <strong>VARIO</strong> <strong>GT</strong> <strong>24</strong><br />

standard hire panels, covered <strong>with</strong><br />

21 mm formlining. <strong>The</strong> ready-foruse<br />

wall formwork for any height<br />

and width.<br />

<strong>The</strong> standard <strong>VARIO</strong> panels are<br />

assembled from tried and tested<br />

<strong>VARIO</strong> system components.<strong>The</strong><br />

panels are supplied complete <strong>with</strong><br />

lifting eyes and rubbing board.<br />

Permissible fresh concrete pressure:<br />

60 kN/m 2 <strong>with</strong> tie spacings 55/140/55 or<br />

50 kN/m 2 <strong>with</strong> tie spacings 62.5/125/62.5<br />

according to DIN 18202, Table 3, Line 7.<br />

Top cover board for protecting<br />

against concrete splashes, and<br />

integral crane lifting point unit.<br />

<strong>VARIO</strong> <strong>GT</strong> <strong>24</strong> standard elements complete<br />

<strong>with</strong> platforms.<br />

6,00<br />

5,40<br />

2,40<br />

Height increments<br />

<strong>VARIO</strong> standard panels are available<br />

in 60 cm height increments.<br />

<strong>The</strong>se panels are simply extended<br />

for greater heights.<br />

Base panel for<br />

extension,<br />

<strong>with</strong>out top cover.<br />

2,40<br />

0,48 1,18<br />

2,99<br />

3,00<br />

0,48 1,78<br />

3,58<br />

3,60<br />

0,48 1,18 1,18<br />

4,18<br />

4,20<br />

0,48 1,18 1,18 1,18<br />

4,77<br />

4,80<br />

0,48 1,18 1,18 1,18<br />

5,36<br />

0,48 1,18 1,18 1,18 1,18<br />

5,95<br />

0,48 1,18 1,18 1,18 1,18<br />

14

Standard panels customised<br />

for 9 m highwalls of tunnel<br />

project.<br />

<strong>System</strong> width<br />

<strong>VARIO</strong> standard panels are<br />

available in 4 widths:<br />

2,50<br />

0,625 1,25 0,625<br />

<strong>VARIO</strong> standard internal corners<br />

<strong>The</strong> consistent leg length of 75 cm<br />

allows this design to be used as a<br />

left-hand or right-hand corner.<br />

1,875<br />

0,625 0,625<br />

0,625<br />

0,75<br />

1,25<br />

0,625 0,625<br />

0,75<br />

1,00<br />

<strong>VARIO</strong> standard internal corner<br />

is available in 5 heights:<br />

2.40, 3.00,3.60, 4.80 and<br />

6.00 m.<br />

15

Standard Applications<br />

Continuously adjustable panel connection<br />

<strong>The</strong> rows of slots in the PERI<br />

steel walers and couplings allow<br />

continuous tightening of panel<br />

joints of even roughly erected<br />

panels.<br />

<strong>The</strong> <strong>VARIO</strong> coupling also aligns<br />

the panels.<br />

<strong>The</strong> multifunctional <strong>VARIO</strong> coupling<br />

using wedges:<br />

– Continuously tightens until joint<br />

grout-tight<br />

– Aligns panels<br />

– Supports plywood fillers<br />

– Extends width of panels<br />

– Holds bulkheads<br />

– Stabilises internal corners<br />

– Is independently adjustable on<br />

both sides<br />

Important:<br />

To eliminate the effect of tolerances<br />

and optimise panel joint alignment,<br />

the notches in the slots of PERI<br />

steel walers and couplings must<br />

always point towards the concrete<br />

side.<br />

Standard joint<br />

<strong>The</strong> continuous adjustment available<br />

allows grout-tight panel joints.<br />

Concrete side<br />

Concrete side<br />

Steel Waler SRZ<br />

Concrete side<br />

Concrete side<br />

<strong>VARIO</strong> coupling<br />

Filler joint<br />

Any gap up to 1.25m wide can be<br />

filled.<br />

Internal corner<br />

<strong>The</strong> same <strong>VARIO</strong> coupling as for the<br />

straight joint can be used forthe<br />

internal corner.<br />

Oblique joint<br />

Any angle can be shuttered <strong>with</strong> the<br />

articulated coupling.<br />

16

Easy connection of panels <strong>with</strong><br />

PERI <strong>VARIO</strong> <strong>GT</strong> <strong>24</strong>:<br />

1. Insert coupling centrally <strong>with</strong> the<br />

notches towards the formlining,<br />

and centre <strong>with</strong>wedge 4.<br />

2. On one side, hammer the first<br />

wedge 1 into the 1st slot, andthe<br />

second wedge 2 into the 6th slot,<br />

<strong>with</strong> a gap of 4 slotsbetween<br />

them.<br />

3. To achieve a spacing of 5 cm<br />

between the two steel walers,<br />

the centering wedge 4 remains<br />

inserted until you have pulled the<br />

formlining joint grout-tight<strong>with</strong><br />

wedge 3.<br />

4. Remove the centering wedge 4<br />

and insert it in the locking position<br />

in the sixth slot. This ensures the<br />

joint can resisttension and compression,<br />

and brings the panels<br />

into tight, flush alignment.<br />

5<br />

<strong>The</strong> panel connection is finished<br />

Practical tip<br />

Whether a wedge is locking or pulling<br />

is evident from its inclination:<br />

Tip of wedge towards the panel joint<br />

= wedge pulling<br />

Tip of wedge away from panel joint<br />

= wedge locking<br />

wedge locking<br />

wedge pulling<br />

17

Standard Applications<br />

Fillers, stopend formwork<br />

and panel width extension units<br />

Infill areas<br />

Infills are shuttered <strong>with</strong> <strong>VARIO</strong><br />

<strong>GT</strong> <strong>24</strong>, using the <strong>VARIO</strong> couplings<br />

VKZ 147 and VKZ 211.<br />

Coupling VKZ<br />

Wedge K<br />

Coupling Compression<br />

Plate<br />

KDP<br />

Maximum width extensions <strong>with</strong><br />

<strong>VARIO</strong> couplings VKZ<br />

(see table for <strong>VARIO</strong> fillers)<br />

Continuously adjustable<br />

fillers <strong>with</strong> <strong>VARIO</strong> couplings.<br />

max. 0,48 m<br />

VKZ 147<br />

VKZ 211<br />

max. 1,20 m<br />

18

Stopend <strong>Formwork</strong><br />

<strong>VARIO</strong> offers two ways of forming<br />

stopends.<br />

Permissible wall thickness x [m]<br />

for stopends <strong>with</strong> VKZ<br />

1.<strong>VARIO</strong> coupling VKZ<br />

perm. tension force 50 kN<br />

<strong>VARIO</strong> coupling VKZ 99<br />

Item No. 013010<br />

x<br />

Spacer timber by site<br />

x<br />

Important:<br />

Pulling wedge must be inserted in<br />

the first hole.<br />

2. With Stopend Tie<br />

perm. tension force 30 kN<br />

Stopend Tie<br />

Item-no. 013<strong>24</strong>0<br />

Panel <strong>with</strong> extensions<br />

Complete bulkhead <strong>with</strong><br />

stopend tie.<br />

Even panel width extensions<br />

are solved using<br />

standard <strong>VARIO</strong> system<br />

components.<br />

19

Standard Applications<br />

External corners, internal corners and shafts<br />

Depending on the application,<br />

external and internal corners can<br />

be formed in various alternative<br />

ways.<br />

– With <strong>VARIO</strong> corner panel<br />

– With cross waler & shaft corner<br />

– With special walers<br />

<strong>VARIO</strong> corner panel<br />

With this solution, especially for thin<br />

walls and low utilisation, the fillers<br />

are made from standard components.<br />

External: Panel width = 2.50 m<br />

1 panel <strong>with</strong> width extension unit<br />

Internal: Panel width = 1.25/1.50 m<br />

and panel width = 1.25 m <strong>with</strong> filler.<br />

Example for filler x:<br />

d 1 = 30 cm<br />

x = 250 cm – 125 cm – 50 cm –<br />

30 cm – 2 cm formlining<br />

x = 43 cm<br />

Internal corner<br />

Detail <strong>VARIO</strong> corner<br />

External corner<br />

<strong>VARIO</strong> internal corner <strong>with</strong> filler.<br />

d 1<br />

It’s a matter of pulling tight at the<br />

correct angle. No problem <strong>with</strong> the<br />

continuous adjustment of <strong>VARIO</strong><br />

<strong>GT</strong> <strong>24</strong>.<br />

<strong>The</strong> waler on the panel width extension<br />

unit must project 2 cm to enable firm<br />

pretensioning of the corner.<br />

1,25<br />

x 0,50<br />

d 1<br />

20

Shafts<br />

Small shafts can be solved<br />

particularly cost-effectively <strong>with</strong><br />

cross walers customised for<br />

the project, and the quick<br />

release corner SSE.<br />

Detail:<br />

Safety quick release corner<br />

150<br />

150<br />

21<br />

Practical tip:<br />

Pull shaft corner tight no<br />

later than the next day.<br />

Small lift shaft <strong>with</strong> cross<br />

walers and safety quick<br />

release corner SSE.<br />

21

Standard Applications<br />

Push-pull prop connector, crane splices<br />

Connection to <strong>GT</strong> <strong>24</strong> girder <strong>with</strong><br />

girder head piece, Item no 028050.<br />

Push-pull prop connection<br />

Arrange push-pull props and kickers<br />

as shown on the diagram and in the<br />

table below. Connect to the <strong>VARIO</strong><br />

panel <strong>with</strong><br />

the girder head piece<br />

Item no 028050 or the<br />

wedge head pieceI<br />

tem no 028060. Connect to the slab<br />

<strong>with</strong> the<br />

matching base plate and PERI<br />

Anchor Bolt MMS 20x130,<br />

Item no.: 103606.<br />

<strong>The</strong> first panel must always be<br />

secured <strong>with</strong> 2 push-pull props.<br />

See table for further props.<br />

Connection to steel waler SRZ <strong>with</strong><br />

wedge head piece, Item no 028060<br />

and wedge K, Item no 0<strong>24</strong>250.<br />

picture 1<br />

h<br />

0,5 kN/m 2<br />

y<br />

FRS<br />

picture 1<br />

picture 2<br />

<strong>Formwork</strong> Height h [m]<br />

3,0 4,0 5,0 6,0 7,0 8,0 9,0 10,0 11,0 12,0<br />

max. Width of influence [m] 3,53 2,73 2,19 1,82 1,58 1,42 1,9 1,9 1,4 1,3<br />

Actual prop load F F RS1<br />

RS<br />

[kN]<br />

9,4 9,4 11,3 11,3<br />

at maximum prop spacing 9,7 9,7 9,8 9,8 9,8 9,6<br />

F RS2<br />

9,5 9,5 9,3 10,1<br />

Actual kicker load F AV<br />

[kN]<br />

2,1 2,3 2,2 2,2 2,3 2,6 2,6 2,6 2,1 1,9<br />

at maximum prop spacing<br />

x 4,3 4,3<br />

x =<br />

Dist. of base plate [m] from<br />

1<br />

5,3 5,9<br />

front face of formwork 1,2 1,6 2,0 2,4 2,9 3,5<br />

x 2<br />

2,6 2,6 2,8 3,0<br />

y = *Top connection point [m]<br />

y 1<br />

1,5 1,5 1,8 1,8<br />

1,0 1,2 1,5 1,8 2,0 2,0<br />

from top of formwork<br />

y 2<br />

4,5 4,5 6,2 6,9<br />

*If neccessary, the distances must be adapted to the existing<br />

formwork system.<br />

A maximum force of 11.3 kN is to be transfered into the building<br />

at the base of the push-pull prop for the given width of influence.<br />

Wind Loads: h < 8 m = 0,5 kN/m 2<br />

8 m h < 20 m = 0,8 kN/m 2<br />

22<br />

Permissible widths of load<br />

h<br />

0,5 kN/m 2 0,8 kN/m 2<br />

F AV<br />

60°<br />

x<br />

picture 2<br />

F AV<br />

y 1<br />

y 2<br />

FRS 1<br />

FRS 2<br />

60° 60°<br />

x 2<br />

x 1

Crane Suspension<br />

PERI <strong>VARIO</strong> offers two units for<br />

lifting panels <strong>with</strong> the crane:<br />

1. <strong>The</strong> crane splice <strong>24</strong><br />

easily fitted and removed.<br />

2. <strong>The</strong> crane lifting eye <strong>24</strong>,<br />

right/left<br />

integral lifting unit.<br />

Important:<br />

Always used two crane lifting point<br />

units for each unit to be shifted!It is<br />

essential to follow the<br />

Instructions for Use, which contain<br />

important information!<br />

Kranlasche <strong>24</strong><br />

Art.-Nr. 070760<br />

Betriebsanleitung<br />

Ausgabe 05/2007<br />

Instructions for Use<br />

of the crane splice <strong>24</strong>.<br />

Customized assembly,<br />

a <strong>VARIO</strong> <strong>GT</strong> <strong>24</strong> element<br />

ready for use.<br />

Crane Splice <strong>24</strong><br />

Safe working load of 700 kg, <strong>with</strong><br />

legs of sling at a maximum<br />

inclination of 15° to the vertical.<br />

Crane lifting eye <strong>24</strong>, right/left<br />

Safe working load of 700 kg, <strong>with</strong><br />

legs of sling at a maximum<br />

inclination of 15° to the vertical.<br />

23

Standard Applications<br />

Working and Concreting Scaffold<br />

Scaffold Bracket GB 80<br />

Scaffold components supplied by<br />

the contractors must correspond<br />

to valid safety regulations!<br />

(for Germany DIN 4420)<br />

Timber components must conform<br />

at least to S10 or MS10 classific<br />

ationaccording to DIN 4074<br />

as well as being clearly marked<br />

(BGR 169)!<br />

Cross-section of guardrail boards:<br />

3 cm x 15 cm!<br />

Secure planking and guardrails<br />

<strong>with</strong> nails or screws!<br />

A concreting platform<br />

conforming to the<br />

regulations, <strong>with</strong> PERI<br />

end handrail frame 55,<br />

Item no 065066.<br />

PERI platform bracket GB 80 for an<br />

approyimately 80 cm wide work<br />

platformPermissible Load: 150kg/m 2<br />

Max. Allowable Spacing: 1.25m<br />

<strong>24</strong><br />

Several work platform<br />

levels are required for<br />

high formwork.

<strong>VARIO</strong> platform system<br />

Pre-assembled concreting/working<br />

platforms in different widths. Complete<br />

<strong>with</strong> guardrails, end handrail<br />

frame, push-pull prop connections<br />

and crane eye. With or <strong>with</strong>out<br />

access hatch.<br />

Platform safety handrail<br />

frames 80<br />

<strong>VARIO</strong> platform<br />

100/250 <strong>with</strong> hatch<br />

<strong>VARIO</strong> platform<br />

Bulit-in crane lifitng<br />

point unit<br />

Ladder 2.40 – 2.70<br />

3,00 m<br />

Platform Brace 167<br />

Platform connector<br />

Push-pull prop<br />

<strong>VARIO</strong> platform<br />

100/250 <strong>with</strong> hatch<br />

Push-pull prop RSS III<br />

5.40 m high <strong>VARIO</strong> standard<br />

panels ready for use. With<br />

concreting platforms, ladders<br />

and push-pull props.<br />

<strong>The</strong> permissible load of the <strong>VARIO</strong><br />

platform is 1,5 kN/m 2 . <strong>The</strong> crane lifting<br />

point unit is incorporated in the<br />

platforms.<br />

25

Standard Applications<br />

Panel extensions<br />

Panels may be extended <strong>with</strong> the<br />

<strong>VARIO</strong> extension splice <strong>24</strong> for<br />

heights up to 8.00 m.<br />

<strong>The</strong> extension splice <strong>24</strong> is quickly and easily connected<br />

through the lattice work of the <strong>GT</strong> <strong>24</strong>, <strong>with</strong>out<br />

having to drill the girders.<br />

<strong>The</strong> standard method of extension<br />

is to use the <strong>VARIO</strong> extension<br />

splice <strong>24</strong>.<br />

<strong>The</strong> flexurally stiff connection aligns<br />

the girders. <strong>The</strong> splice, which consists<br />

of just two components, is connected<br />

in no time <strong>with</strong> two quick action<br />

wingnuts.<br />

Extensions up to 8.00 m<br />

8 Extension Splices <strong>24</strong> for 2.50 m<br />

wide element.<br />

Section properties for Extension<br />

Splice <strong>24</strong><br />

M perm . = 1,73 kNm<br />

Q perm. = 0<br />

or<br />

M zul. = 0<br />

Q perm. = 5 kN<br />

Extensions up to 5.00 m<br />

4 Extension Splices <strong>24</strong> for 2.50 m<br />

wide element.<br />

60 cm high timber extension made simple <strong>with</strong> the<br />

extension splice <strong>24</strong>.<br />

min 46 min 46<br />

8,00 m<br />

5,00 m<br />

26

With overlapping girders for<br />

heights up to about 9.80 m<br />

3,85<br />

3,88 4,14<br />

2,07<br />

0,13 1,18 1,22 1,18 0,16<br />

5,95<br />

5,95<br />

11,90<br />

1,18 1,18 1,18 1,18 1,22 1,18 1,18 1,18 1,18 0,78<br />

0,46<br />

1,18 1,18 1,18 1,18 1,18 1,18 1,18 0,89 0,16<br />

0,46<br />

2,10<br />

1,18 0,76<br />

0,16<br />

5,95<br />

5,95<br />

9,80<br />

With additional girders for heights<br />

up to 11.90 m.<br />

For more information on extensions,<br />

see PERI design tables or<br />

<strong>VARIO</strong> <strong>GT</strong> <strong>24</strong> assembly instructions.<br />

11.00 m high bridge abutment <strong>with</strong> butted girders<br />

and additional overlapping girders for stiffening.<br />

27

Special applications<br />

Architectural concrete<br />

Perfect concrete finishes <strong>with</strong> <strong>VARIO</strong><br />

Achieving first-class fairfaced concrete<br />

is primarily a question of<br />

theright formwork and formlining,<br />

but other factors do play an<br />

importantrole. Accuracy of formwork<br />

assembly, shuttering, release<br />

agent, concrete and its placing all<br />

significantly effect the result.<br />

Attractive looking concrete<br />

finish <strong>with</strong> rough<br />

vertical board finish.<br />

43.50 m high tower<br />

<strong>with</strong> fairfaced concrete<br />

<strong>with</strong> a board finish<br />

foran industrial plant.<br />

28

Church steeple in Feldmoching<br />

near Munich.<br />

<strong>VARIO</strong> <strong>GT</strong> <strong>24</strong> on KGF <strong>24</strong>0<br />

climbing formwork system.<br />

Exemplary fairfaced<br />

concrete <strong>with</strong> rough<br />

horizontal board finish.<br />

Consecretion Hall,<br />

Neubiberg, Germany<br />

Germany. <strong>VARIO</strong> <strong>with</strong><br />

orderly tie pattern.<br />

Formlining screwed on<br />

from the rear.<br />

Perfect fairfaced concrete <strong>with</strong> horizontal and<br />

vertical panicular pattern.<br />

29

Special applications<br />

Architectural concrete<br />

Simple yet elegant concrete finishes<br />

Fairfaced concrete formwork <strong>with</strong><br />

simple joint pattern.<br />

<strong>VARIO</strong> <strong>GT</strong> <strong>24</strong> offers a flexible choice<br />

of waler and tie spacing for a wide<br />

variety of orderly tie patterns.<br />

2.50 x 3.60 m panel<br />

<strong>with</strong> tie spacing of 1.25 x 1.18 m.<br />

2 ties horizontally<br />

3 ties vertically<br />

2.50 x 3.60 m panel<br />

<strong>with</strong> tie spacing of 0.88 x 1.78 m.<br />

3 ties horizontally<br />

2 ties vertically<br />

3,90<br />

3,60<br />

3,60<br />

2,50<br />

2,50<br />

3.00 x 3.90 m panel<br />

Fairfaced concrete <strong>with</strong> orderly<br />

pattern of joints and tie spacing of<br />

0.75 x 1.18 m. 4 ties horizontally<br />

3 ties vertically<br />

3,00<br />

30<br />

An orderly pattern of ties<br />

spaced at 0.75 x 1.18 m<br />

and smooth fairfaced<br />

concrete are the result.<br />

Grammar school centre in<br />

Kletow, Germany.

Forming boards provided by client<br />

<strong>The</strong> rough surface finish ensures<br />

the massive tunnel portals blend<br />

into the volcanic rock landscape.<br />

<strong>The</strong> unusual washboard structure<br />

was created using extra battens<br />

on the formwork skin.<br />

High-quality fairfaced concrete<br />

<strong>with</strong> vertical board finish.<br />

<strong>The</strong> panels were preassembled in<br />

PERI’s Weissenhorn factory.<br />

Portal of a tunnel structure<br />

on Hawaii. Shuttered <strong>with</strong><br />

<strong>VARIO</strong> <strong>GT</strong> <strong>24</strong> on KGF <strong>24</strong>0<br />

climbing system.<br />

German BAB 4 motorway<br />

bridge over the valley of<br />

the Triebischbach. Circular<br />

piers up to 49 m high <strong>with</strong><br />

trumpet-shaped capitals.<br />

31

… typengeprüfte Sicherheit<br />

Special applications<br />

Bridge-building<br />

<strong>VARIO</strong> on climbing scaffolds and<br />

work platforms<br />

More informations can be<br />

found in the CB brochure.<br />

Klettergerüste CB <strong>24</strong>0 und CB 160<br />

Das Baukastensystem<br />

für alle Einsatzbereiche<br />

Type-checked safety <strong>with</strong> KGF<br />

<strong>24</strong>0, KG 180 and CB <strong>24</strong>0, CB 160<br />

systems.<br />

<strong>The</strong> KGF <strong>24</strong>0 and CB <strong>24</strong>0 carriages<br />

allow the formwork to be moved<br />

75 cm on the platform <strong>with</strong>out the<br />

crane. To save time the formwork is<br />

raised together <strong>with</strong> the scaffoldin a<br />

single lift of the crane.<br />

<strong>The</strong>se two systems ensure you can<br />

work extremely safely <strong>with</strong>out any<br />

projections (such as the brackets)<br />

above the surface of the platformto<br />

trip over.<br />

To speed up erection, the staging<br />

can be prefabricated for immediate<br />

use on site after site.<br />

0,75<br />

CB <strong>24</strong>0, the triangular<br />

bracket that readily<br />

allows you to work<br />

infront of and behind<br />

the formwork.<br />

32

Klettergerüste KGF <strong>24</strong>0 und KGF 160<br />

Mit Sicherheit, wenn´s in die Höhe geht.<br />

More informations can be<br />

found in the KG brochure.<br />

1,18 0,80 1,18<br />

6,80<br />

Motorway viaduct in France.<br />

Sophisticated pier geometry<br />

<strong>with</strong> extraordinary concrete<br />

finish. Single sided shuttering<br />

<strong>with</strong> <strong>VARIO</strong> <strong>GT</strong> <strong>24</strong> and SKS<br />

climbing brackets.<br />

On ASG 160 On folding platform FB 180<br />

Faltbühne FB 180-3<br />

Das leichte und komplett vormontierte<br />

Bühnensystem für den Betonbau<br />

More informations can<br />

be found in the FB 180<br />

brochure.<br />

max. h = 5,40 m<br />

max. h = 5,40 m<br />

ASG 160 FB 180<br />

33

Special applications<br />

Bridge-building<br />

Abutments and piers<br />

Section A-A<br />

1,00<br />

GB 80<br />

5,98<br />

RSS III<br />

Bridge abutment <strong>with</strong> <strong>VARIO</strong><br />

standard panels and infillingby<br />

client.Wittstock Inter-change on<br />

the German BAB <strong>24</strong> motorway.<br />

A<br />

9,10<br />

A<br />

6,09<br />

Ground plan<br />

9,25<br />

34

Example of a bridge pier tapered<br />

towards the top.<br />

View of long side<br />

Section A-A<br />

Concreting<br />

platform GB 80<br />

5,40<br />

Push-Pull Prop<br />

RSS III<br />

Kicker<br />

RSS III<br />

3,05<br />

2,75<br />

3,05<br />

Sides of hollow piers on the banks of<br />

the river, climbed <strong>with</strong> <strong>VARIO</strong> <strong>GT</strong> <strong>24</strong> on<br />

climbing scaffold PERI KG <strong>24</strong>0. Transition<br />

to pointed ends achieved <strong>with</strong><br />

<strong>VARIO</strong> standard components and forming<br />

boards.<br />

Bridge over the Danube.<br />

BAB 8 Motorway near<br />

Leipheim.<br />

Abutment and bridge pier<br />

<strong>with</strong> <strong>VARIO</strong> <strong>GT</strong> <strong>24</strong>.<br />

Crossing structure for the<br />

suburban railway line to<br />

the new Munich Airport.<br />

35

Special applications<br />

Water retaining structures<br />

<strong>VARIO</strong> used as single sided and tied formwork<br />

When constructing locks, dams,<br />

cooling towers and walls requiring<br />

single sided shuttering, <strong>VARIO</strong><br />

<strong>GT</strong> <strong>24</strong> is always used <strong>with</strong> KG and<br />

CB, or SKS, climbing systems.<br />

Section<br />

through SKS<br />

tie-less formwork<br />

V-Strongback SKS<br />

Compression<br />

Brace SKS<br />

Bracket SKSF <strong>24</strong>0<br />

Magdeburg Rail/Road/Waterway<br />

Interchange. A number of structures<br />

will be required in the course of this<br />

transport project. <strong>The</strong> photograph<br />

shows the Rothensee Lock.<br />

It is being shuttered <strong>with</strong> <strong>VARIO</strong> <strong>GT</strong> <strong>24</strong><br />

on climbing scaffold KG and single<br />

sided climbing scaffold SKS.<br />

Complete unit:<br />

<strong>VARIO</strong> <strong>GT</strong> <strong>24</strong> on single sided<br />

climbing scaffold SKSF <strong>24</strong>0.<br />

36

Section<br />

through KGF<br />

tied formwork<br />

GB 80<br />

Power station on the river Isar at<br />

Plattling-Pielweichs.<br />

Pier formwork <strong>with</strong> <strong>VARIO</strong> <strong>GT</strong> <strong>24</strong> in<br />

combination <strong>with</strong> circular formwork<br />

GRV.<br />

Fairfaced concrete <strong>with</strong> a vertical<br />

board finish was produced.<br />

PERI <strong>VARIO</strong> <strong>GT</strong> <strong>24</strong>’s versatility and<br />

easy adaptability makes it a particularly<br />

cost-effective shuttering system<br />

in this area.<br />

Back of the weir pier.<br />

<strong>VARIO</strong> <strong>GT</strong> <strong>24</strong> is easily<br />

matched up <strong>with</strong> the<br />

sloping rear wall.<br />

4,50<br />

Bracket<br />

KGF <strong>24</strong>0<br />

Finishing platform<br />

KGF <strong>24</strong>0<br />

Front of the weir pier. <strong>VARIO</strong><br />

in combination <strong>with</strong> circular<br />

formwork system GRV on<br />

climbing scaffold KGF <strong>24</strong>0.<br />

37

Special applications<br />

Water retaining structures<br />

Circular structures <strong>with</strong> <strong>VARIO</strong> <strong>GT</strong> <strong>24</strong><br />

Separate brochures for<br />

PERI RUNDFLEX and<br />

GRV circular formwork<br />

systems.<br />

GRV Gelenkriegel Rundschalung<br />

Zum Schalen runder<br />

Bauwerke ohne Anker<br />

RUNDFLEX<br />

Die stufenlos einstellbare Rundschalung<br />

für Radien ab 1,00 m<br />

<strong>The</strong>re are two alternative methods<br />

of shuttering circular structures<br />

<strong>with</strong> <strong>VARIO</strong> <strong>GT</strong> <strong>24</strong>.<br />

<strong>The</strong> <strong>VARIO</strong> articulated coupling connects<br />

the straight steel walers in a<br />

polygonal arrangement. Its wedges<br />

allow it to be continuously adjusted<br />

in either direction to produce a clean<br />

and flush joint between panels.<br />

Timber wedges inserted between<br />

the walers and timber girders to<br />

produce the required curvature are<br />

clamped in place <strong>with</strong> hook straps.<br />

<strong>The</strong> haunched transition<br />

to the ground slab was<br />

pre-assembled <strong>with</strong> the<br />

<strong>VARIO</strong> wall formwork<br />

panels to form a single<br />

unit for lifting.<br />

Version 1<br />

Timber wedges inserted between<br />

girders <strong>GT</strong> <strong>24</strong> and steel walers SRZ.<br />

Steel Waler SRZ Special Length<br />

Timber wedge Steel waler SRZ <strong>24</strong>5<br />

38

Version 2<br />

Segment profile timbers between<br />

formlining and girders.<br />

<strong>VARIO</strong> panel <strong>with</strong> segment<br />

profile timbers on <strong>GT</strong> <strong>24</strong> girders.<br />

7.50 high circular formwork<br />

<strong>with</strong> segment profile timbers<br />

on the <strong>GT</strong> <strong>24</strong> girders.<br />

72 m high fly ash silo <strong>with</strong> a<br />

diameter of 20m for power<br />

station in Oppeln, Poland.<br />

Shuttered <strong>with</strong> circular <strong>VARIO</strong><br />

girder formwork on climbing<br />

scaffold KGF.<br />

39

Special applications<br />

Single sided walls<br />

With <strong>VARIO</strong> and brace frame SB<br />

For concreting against rock,<br />

existing walls or sheet piling,<br />

<strong>VARIO</strong> <strong>GT</strong> <strong>24</strong> <strong>with</strong> SB brace<br />

frames is used.<br />

PERI brace frames allow single<br />

sided concreting up to a maximum<br />

height of 8.75 m (see PERI charts).<br />

PERI brace frames SB-A0, A, B and<br />

C are sized for loading on a lorry or<br />

in a container.<br />

PERI brace frames can be connected<br />

to all PERI wall formwork systems<br />

(TRIO, <strong>VARIO</strong> and RUNDFLEX) <strong>with</strong><br />

standard system components.<br />

Maximum pour height of<br />

8,75 m A0, A, B or C brace<br />

frame <strong>with</strong> <strong>VARIO</strong> <strong>GT</strong> <strong>24</strong>.<br />

<strong>The</strong> PERI V-anchor bracket<br />

For easy and accurate installation of<br />

anchors when using brace frames.<br />

<strong>The</strong> V-anchor bracket and the<br />

positioning coupling allow you to<br />

fix the anchor accurately at 45°.<br />

<strong>The</strong> advantages of the anchor system<br />

<strong>with</strong> positioning coupler and V-anchor<br />

bracket are:<br />

– few components have to be<br />

stocked<br />

– no need to cut tie rods off<br />

– tie rods recoverable.<br />

<strong>The</strong> tension forces arising at the<br />

brace frame’s anchor point determine<br />

the choice of anchor system.<br />

35<br />

Anchor system easily fixed to<br />

reinforcement <strong>with</strong> wire and pliers.<br />

<strong>The</strong> positioning coupler is removed<br />

<strong>with</strong> the 70 mm single ended spanner.<br />

Example:<br />

Anchor system DW 20:<br />

Permis. tension force to DIN 18216<br />

2 x 150 kN = 300 kN<br />

40

VITAL points when using PERI<br />

brace frames:<br />

1. <strong>The</strong> structural members (eg foundations<br />

or ground slabs) must be<br />

able to take the tension and compression<br />

forces arising.<br />

Check the design of the members<br />

and position of the anchors when<br />

planning.<br />

2. <strong>The</strong> “other side” of the single<br />

sided formwork (existing walls,<br />

planking and strutting, rock, etc)<br />

must obviously be able to <strong>with</strong>stand<br />

the fresh concrete pressure acting<br />

upon it.<br />

3. DW tie rods installed for anchoring<br />

purposes must not be welded or<br />

bent. We recommend the use of<br />

PERI V-anchor brackets.<br />

Stützbock SB<br />

Für einhäuptiges<br />

Betonieren bis 8,75 m Höhe.<br />

More informations can<br />

be found in the Brace<br />

Frames brochure.<br />

SB-C<br />

<strong>The</strong> following couplers are required<br />

for connecting <strong>VARIO</strong> <strong>GT</strong> <strong>24</strong><br />

to PERI brace frames SB-A0, A, B<br />

and C:<br />

Waler connector<br />

SB-A, B, C<br />

Item no 025760<br />

Wedge K, galv.<br />

Item no 0<strong>24</strong>250<br />

8,75<br />

SB-B<br />

Example:<br />

<strong>VARIO</strong> <strong>GT</strong> <strong>24</strong> h = 8.75 m<br />

SB-A<br />

SB-A0<br />

41

<strong>VARIO</strong> <strong>GT</strong> <strong>24</strong> <strong>Girder</strong> <strong>Wall</strong> <strong>Formwork</strong><br />

Item no. Weight kg<br />

101<strong>24</strong>1<br />

101<strong>24</strong>2<br />

101<strong>24</strong>3<br />

101<strong>24</strong>4<br />

101<strong>24</strong>5<br />

101<strong>24</strong>6<br />

101<strong>24</strong>7<br />

314,000<br />

375,000<br />

480,000<br />

586,000<br />

635,000<br />

742,000<br />

791,000<br />

<strong>VARIO</strong> Standard Panels S b = 2.50 m<br />

<strong>VARIO</strong> Standard Panel S 250 x <strong>24</strong>0<br />

<strong>VARIO</strong> Standard Panel S 250 x 300<br />

<strong>VARIO</strong> Standard Panel S 250 x 360<br />

<strong>VARIO</strong> Standard Panel S 250 x 420<br />

<strong>VARIO</strong> Standard Panel S 250 x 480<br />

<strong>VARIO</strong> Standard Panel S 250 x 540<br />

<strong>VARIO</strong> Standard Panel S 250 x 600<br />

Pre-assembled panels <strong>with</strong> 21 mm plywood. With<br />

Slip Boards, Cover Board and Crane Eye <strong>24</strong>.<br />

Note<br />

Panel = 2.40 m, <strong>with</strong>out Cover Board and Crane<br />

Eye <strong>24</strong>.<br />

Technical Data<br />

Permissible fresh concrete pressure 60 kN/m 2 .<br />

Safety Instructions<br />

Load-bearing point capacity 0.7t <strong>with</strong> a crane sling<br />

angle ≤ 15°.<br />

.<br />

2500<br />

297 350 350 350 350 350 297 78<br />

.<br />

600<br />

21<br />

625 1250 625<br />

<strong>24</strong>0<br />

100<br />

540<br />

480<br />

<strong>24</strong>0<br />

459 1184<br />

2398<br />

300<br />

459 1776<br />

2990<br />

360<br />

459 1184 1184<br />

3582<br />

420<br />

459 1184 1184 1184<br />

4174<br />

459 1184<br />

1184 1184<br />

4766<br />

459 1184 1184 1184 1184<br />

5358<br />

1184 1184 1184 1184<br />

459<br />

5950<br />

101311 6,170 Protection Board 250<br />

As top covering for <strong>VARIO</strong> <strong>GT</strong> <strong>24</strong> standard panels.<br />

<strong>24</strong>8<br />

2500<br />

21<br />

42

<strong>VARIO</strong> <strong>GT</strong> <strong>24</strong> <strong>Girder</strong> <strong>Wall</strong> <strong>Formwork</strong><br />

Item no. Weight kg<br />

101<strong>24</strong>8<br />

101<strong>24</strong>9<br />

101250<br />

101251<br />

101252<br />

101253<br />

101254<br />

235,000<br />

282,000<br />

361,000<br />

440,000<br />

477,000<br />

557,000<br />

594,000<br />

<strong>VARIO</strong> Standard Panels S b = 1.875 m<br />

<strong>VARIO</strong> Standard Panel S 187,5 x <strong>24</strong>0<br />

<strong>VARIO</strong> Standard Panel S 187,5 x 300<br />

<strong>VARIO</strong> Standard Panel S 187,5 x 360<br />

<strong>VARIO</strong> Standard Panel S 187,5 x 420<br />

<strong>VARIO</strong> Standard Panel S 187,5 x 480<br />

<strong>VARIO</strong> Standard Panel S 187,5 x 540<br />

<strong>VARIO</strong> Standard Panel S 187,5 x 600<br />

Pre-assembled panels <strong>with</strong> 21 mm plywood. With<br />

Slip Boards, Cover Board and Crane Eye <strong>24</strong>.<br />

Note<br />

Panel = 2.40 m, <strong>with</strong>out Cover Board and Crane<br />

Eye <strong>24</strong>.<br />

Technical Data<br />

Permissible fresh concrete pressure 60 kN/m 2 .<br />

Safety Instructions<br />

Load-bearing point capacity 0.7t <strong>with</strong> a crane sling<br />

angle ≤ 15°.<br />

.<br />

1875<br />

319,5 360 360 360 319,5 78<br />

.<br />

600<br />

<strong>24</strong>0 21<br />

540<br />

625 625 625<br />

100<br />

480<br />

<strong>24</strong>0<br />

459 1184<br />

2398<br />

300<br />

459 1776<br />

2990<br />

360<br />

459 1184 1184<br />

3582<br />

420<br />

459 1184 1184 1184<br />

4174<br />

459 1184<br />

1184 1184<br />

4766<br />

459 1184 1184 1184 1184<br />

5358<br />

1184 1184 1184 1184<br />

459<br />

5950<br />

101318 4,470 Protection Board 187.5<br />

As top covering for <strong>VARIO</strong> <strong>GT</strong> <strong>24</strong> standard panels.<br />

<strong>24</strong>8<br />

1875<br />

21

<strong>VARIO</strong> <strong>GT</strong> <strong>24</strong> <strong>Girder</strong> <strong>Wall</strong> <strong>Formwork</strong><br />

Item no. Weight kg<br />

101255<br />

101256<br />

101257<br />

101258<br />

101259<br />

101260<br />

101261<br />

162,000<br />

208,000<br />

265,000<br />

322,000<br />

350,000<br />

407,000<br />

435,000<br />

<strong>VARIO</strong> Standard Panels S b = 1.25 m<br />

<strong>VARIO</strong> Standard Panel S 125 x <strong>24</strong>0<br />

<strong>VARIO</strong> Standard Panel S 125 x 300<br />

<strong>VARIO</strong> Standard Panel S 125 x 360<br />

<strong>VARIO</strong> Standard Panel S 125 x 420<br />

<strong>VARIO</strong> Standard Panel S 125 x 480<br />

<strong>VARIO</strong> Standard Panel S 125 x 540<br />

<strong>VARIO</strong> Standard Panel S 125 x 600<br />

Pre-assembled panels <strong>with</strong> 21 mm plywood. With<br />

Slip Boards, Cover Board and Crane Eye <strong>24</strong>.<br />

Note<br />

Panel = 2.40 m, <strong>with</strong>out Cover Board and Crane<br />

Eye <strong>24</strong>.<br />

Technical Data<br />

Permissible fresh concrete pressure 60 kN/m 2 .<br />

Safety Instructions<br />

Load-bearing point capacity 0.7t <strong>with</strong> a crane sling<br />

angle ≤ 15°.<br />

.<br />

1<strong>24</strong>8<br />

297 180 320 297 77<br />

.<br />

600<br />

21<br />

6<strong>24</strong> 6<strong>24</strong><br />

<strong>24</strong>0<br />

100<br />

540<br />

480<br />

<strong>24</strong>0<br />

459 1184<br />

2398<br />

300<br />

459 1776<br />

2990<br />

360<br />

459 1184 1184<br />

3582<br />

420<br />

459 1184 1184 1184<br />

4174<br />

459 1184<br />

1184 1184<br />

4766<br />

459 1184 1184 1184 1184<br />

5358<br />

1184 1184 1184 1184<br />

459<br />

5950<br />

101319 2,860 Protection Board 125<br />

As top covering for <strong>VARIO</strong> <strong>GT</strong> <strong>24</strong> standard panels.<br />

<strong>24</strong>8<br />

1<strong>24</strong>8<br />

21<br />

44

<strong>VARIO</strong> <strong>GT</strong> <strong>24</strong> <strong>Girder</strong> <strong>Wall</strong> <strong>Formwork</strong><br />

Item no. Weight kg<br />

101411<br />

101410<br />

101409<br />

101408<br />

101407<br />

101406<br />

101405<br />

137,000<br />

168,000<br />

213,000<br />

258,000<br />

281,000<br />

326,000<br />

349,000<br />

<strong>VARIO</strong> Standard Panels S b = 1.00 m<br />

<strong>VARIO</strong> Standard Panel S 100 x <strong>24</strong>0<br />

<strong>VARIO</strong> Standard Panel S 100 x 300<br />

<strong>VARIO</strong> Standard Panel S 100 x 360<br />

<strong>VARIO</strong> Standard Panel S 100 x 420<br />

<strong>VARIO</strong> Standard Panel S 100 x 480<br />

<strong>VARIO</strong> Standard Panel S 100 x 540<br />

<strong>VARIO</strong> Standard Panel S 100 x 600<br />

Pre-assembled panels <strong>with</strong> 21 mm plywood. With<br />

Slip Boards, Cover Board and Crane Eye <strong>24</strong>.<br />

Note<br />

Panel = 2.40 m, <strong>with</strong>out Cover Board and Crane<br />

Eye <strong>24</strong>.<br />

Technical Data<br />

Permissible fresh concrete pressure 60 kN/m 2 .<br />

Safety Instructions<br />

Load-bearing point capacity 0.7t <strong>with</strong> a crane sling<br />

angle ≤ 15°.<br />

.<br />

998<br />

297 250 297 77<br />

.<br />

600<br />

<strong>24</strong>0 21<br />

540<br />

100<br />

480<br />

<strong>24</strong>0<br />

459 1184<br />

2398<br />

300<br />

459 1776<br />

2990<br />

360<br />

459 1184 1184<br />

3582<br />

420<br />

459 1184 1184 1184<br />

4174<br />

459 1184<br />

1184 1184<br />

4766<br />

459 1184 1184 1184 1184<br />

5358<br />

1184 1184 1184 1184<br />

459<br />

5950<br />

101404 2,230 Protection Board 100<br />

As top covering for <strong>VARIO</strong> <strong>GT</strong> <strong>24</strong> standard panels.<br />

<strong>24</strong>8<br />

998<br />

21<br />

45

<strong>VARIO</strong> <strong>GT</strong> <strong>24</strong> <strong>Girder</strong> <strong>Wall</strong> <strong>Formwork</strong><br />

Item no. Weight kg<br />

101471<br />

101470<br />

101469<br />

101467<br />

101465<br />

211,000<br />

251,000<br />

325,000<br />

429,000<br />

534,000<br />

<strong>VARIO</strong> Internal Edges S 75/75<br />

<strong>VARIO</strong> Internal Edge S 75/75 x <strong>24</strong>0<br />

<strong>VARIO</strong> Internal Edge S 75/75 x 300<br />

<strong>VARIO</strong> Internal Edge S 75/75 x 360<br />

<strong>VARIO</strong> Internal Edge S 75/75 x 480<br />

<strong>VARIO</strong> Internal Edge S 75/75 x 600<br />

Pre-assembled panels <strong>with</strong> 21 mm plywood. With<br />

Slip Boards, Cover Board and Crane Eye <strong>24</strong>.<br />

Note<br />

Panel = 2.40 m, <strong>with</strong>out Cover Board and Crane<br />

Eye <strong>24</strong>.<br />

Technical Data<br />

Permissible fresh concrete pressure 60 kN/m 2 .<br />

Safety Instructions<br />

Load-bearing point capacity 0.7t <strong>with</strong> a crane sling<br />

angle ≤ 15°.<br />

.<br />

750<br />

310 301 78<br />

<strong>24</strong>0 21<br />

.<br />

600<br />

100<br />

76 262<br />

750<br />

480<br />

<strong>24</strong>0<br />

459 1184<br />

2398<br />

300<br />

459 1776<br />

2990<br />

360<br />

1184 1184<br />

459<br />

3582<br />

1184 1184 1184<br />

459<br />

4766<br />

1184 1184 1184 1184<br />

459<br />

5950<br />

101464 4,730 Protection Board IE 75/75<br />

As top covering for <strong>VARIO</strong> <strong>GT</strong> <strong>24</strong> standard panels.<br />

750<br />

400<br />

750<br />

21<br />

46

<strong>VARIO</strong> <strong>GT</strong> <strong>24</strong> <strong>Girder</strong> <strong>Wall</strong> <strong>Formwork</strong><br />

Item no. Weight kg<br />

010600<br />

010030<br />

010610<br />

010060<br />

010070<br />

010050<br />

010120<br />

19,800<br />

25,100<br />

30,400<br />

38,300<br />

40,900<br />

51,600<br />

61,500<br />

Steel Waler SRZ U100<br />

Steel Waler SRZ U-100 l = 0.95m<br />

Steel Waler SRZ U-100 l = 1.20m<br />

Steel Waler SRZ U-100 l = 1.45m<br />

Steel Waler SRZ U-100 l = 1.825m<br />

Steel Waler SRZ U-100 l = 1.95m<br />

Steel Waler SRZ U-100 l = 2,45 m<br />

Steel Waler SRZ U-100 l = 2.95m<br />

Steel waler for <strong>VARIO</strong> <strong>GT</strong> <strong>24</strong> panels and special<br />

applications.<br />

L<br />

950<br />

1200<br />

1450<br />

1825<br />

1950<br />

<strong>24</strong>50<br />

2950<br />

Note<br />

Special lengths and other profile sizes on request.<br />

Technical Data<br />

Wy = 82.4 cm³, ly = 412 cm 4<br />

L<br />

93<br />

30 170 135 205 25<br />

20<br />

53<br />

40<br />

X x 60<br />

Ø6<br />

Ø9<br />

100 60<br />

52<br />

152<br />

010080<br />

010150<br />

010090<br />

010350<br />

22,000<br />

28,000<br />

33,000<br />

0,000<br />

Steel Waler SRZ Spec. Length<br />

Steel Waler SRZ U-100 Spec. Length<br />

Steel Waler SRZ U-120 Spec. Length<br />

Steel Waler SRZ U-140 Spec. Length<br />

Additional Row of SRZ Slots<br />

Technical Data<br />

Wy = 82.4 cm³, ly = 412 cm 4<br />

. 50 52 50<br />

55 52 55<br />

60 52 60<br />

100<br />

120<br />

140<br />

U100 U120 U140<br />

710001 0,376 End Plate SRZ<br />

For Steel waler SRZ <strong>with</strong> special lengths.<br />

150 5<br />

Ø6,3 Ø9<br />

60<br />

47

<strong>VARIO</strong> <strong>GT</strong> <strong>24</strong> <strong>Girder</strong> <strong>Wall</strong> <strong>Formwork</strong><br />

Item no. Weight kg<br />

010440<br />

010420<br />

010490<br />

010500<br />

32,100<br />

58,800<br />

0,000<br />

0,000<br />

Steel Waler VSRZ<br />

Steel Waler VSRZ-<strong>24</strong> U-100 l = 1.20/12<br />

Steel Waler VSRZ-<strong>24</strong> U-100 l = 2.45/12<br />

Welding Unit for VSRZ/12<br />

Welding Unit for VSRZ<br />

Steel waler for <strong>VARIO</strong> <strong>GT</strong> <strong>24</strong> corner panels and<br />

special applications.<br />

Note<br />

Special lengths and other profile sizes on request.<br />

Technical Data<br />

Wy = 82.4 cm³, ly = 412 cm 4<br />

236<br />

236<br />

93<br />

Ø9<br />

120<br />

1200 / <strong>24</strong>50<br />

52<br />

010200 42,300 Internal Corner Waler IRZ 75/75<br />

Steel waler for <strong>VARIO</strong> <strong>GT</strong> <strong>24</strong> corner element<br />

75 x 75 cm. Allows easy striking.<br />

Note<br />

Special lengths and other profiles on request.<br />

Technical Data<br />

Wy = 82.4 cm³, ly = 412 cm 4 130<br />

10<br />

715<br />

70 301 38<br />

152<br />

236<br />

Ø9<br />

727<br />

100<br />

236<br />

38<br />

300<br />

52<br />

0<strong>24</strong><strong>24</strong>0 0,805<br />

Accessories<br />

Wedge KZ, galv.<br />

010180<br />

010270<br />

010190<br />

010400<br />

22,000<br />

28,000<br />

33,000<br />

0,000<br />

Cross Waler KRZ Spec. Length<br />

Cross Waler KRZ U-100 Spec. Length<br />

Cross Waler KRZ U-120 Spec. Length<br />

Cross Waler KRZ U-140, Spec. Length<br />

Welding Unit for KRZ<br />

Steel waler for <strong>VARIO</strong> <strong>GT</strong> <strong>24</strong> panels for narrow lift<br />

shafts.<br />

Note<br />

When ordering, state dimensions L1 and L2.<br />

Technical Data<br />

Wy = 82.4 cm³, ly = 412 cm 4<br />

93<br />

L2<br />

93<br />

236<br />

L1<br />

236<br />

52<br />

48

<strong>VARIO</strong> <strong>GT</strong> <strong>24</strong> <strong>Girder</strong> <strong>Wall</strong> <strong>Formwork</strong><br />

Item no. Weight kg<br />

103868<br />

103871<br />

103874<br />

103877<br />

103886<br />

103889<br />

103898<br />

103892<br />

103929<br />

103903<br />

103906<br />

103915<br />

103918<br />

103922<br />

103925<br />

103928<br />

103943<br />

18,100<br />

<strong>24</strong>,200<br />

30,900<br />

38,100<br />

44,700<br />

52,000<br />

58,600<br />

65,600<br />

72,000<br />

81,000<br />

92,600<br />

106,000<br />

119,000<br />

135,000<br />

146,000<br />

159,000<br />

157,000<br />

Steel Walers Universal SRU<br />

Steel Waler Universal SRU U-120 l = 0.72 m<br />

Steel Waler Universal SRU U-120 l = 0.97 m<br />

Steel Waler Universal SRU U-120 l = 1.22 m<br />

Steel Waler Universal SRU U-120 l = 1.47 m<br />

Steel Waler Universal SRU U-120 l = 1.72 m<br />

Steel Waler Universal SRU U-120 l = 1.97 m<br />

Steel Waler Universal SRU U-120 l = 2.22 m<br />

Steel Waler Universal SRU U-120 l = 2.47 m<br />

Steel Waler Universal SRU U-120 l = 2.72 m<br />

Steel Waler Universal SRU U-120 l = 2.97 m<br />

Steel Waler Universal SRU U-120 l = 3.47 m<br />

Steel Waler Universal SRU U-120 l = 3.97 m<br />

Steel Waler Universal SRU U-120 l = 4.47 m<br />

Steel Waler Universal SRU U-120 l = 4.97 m<br />

Steel Waler Universal SRU U-120 l = 5.47 m<br />

Steel Waler Universal SRU U-120 l = 5.97 m<br />

Steel Waler Universal SRU U-140 l = 4.97 m<br />

Universal steel waler profile U 120 and U 140 used<br />

as waling for girder wall formwork and for diverse<br />

special applications. With adjustable spacers.<br />

L<br />

722<br />

972<br />

1222<br />

1472<br />

1722<br />

1972<br />

2222<br />

<strong>24</strong>72<br />

2722<br />

2972<br />

3472<br />

3972<br />

4472<br />

4972<br />

5472<br />

5972<br />

4972<br />

Technical Data<br />

SRU 120 Wy = 121,4 cm³, Iy = 728 cm 4<br />

SRU 140 Wy = 172,8 cm³, Iy = 1210 cm 4<br />

L<br />

51 7 x 60<br />

37,5<br />

52,5<br />

48,5<br />

125 125 125 125<br />

198,5<br />

3 x 65<br />

19<br />

17<br />

112<br />

36 70<br />

X<br />

52<br />

120<br />

52<br />

140<br />

162<br />

172<br />

104027 7,610 Extension <strong>VARIO</strong> <strong>24</strong> U120<br />

For assembly on Steel Waler SRU.<br />

Complete <strong>with</strong><br />

4 pc. 710252 Bolt ISO 4017 M16 x 50-8.8, galv.<br />

4 pc. 1040<strong>24</strong> Nut ISO 7040 M16-8, galv.<br />

4 pc. 710880 Washer DIN 434 18, galv.<br />

Technical Data<br />

Wy = 121.4 cm³, Iy = 728 cm 4<br />

65<br />

53<br />

120<br />

52<br />

M 16<br />

236<br />

162<br />

49

<strong>VARIO</strong> <strong>GT</strong> <strong>24</strong> <strong>Girder</strong> <strong>Wall</strong> <strong>Formwork</strong><br />

Item no. Weight kg<br />

0<strong>24</strong>070 0,460 Hook Strap HB <strong>24</strong>-100/120, galv.<br />

For fixing <strong>GT</strong> <strong>24</strong> girders to Steel Waler SRZ and<br />

SRU Profile U100 - U120.<br />

M 8x70<br />

152 (U 100) 82<br />

162 (U 120)<br />

0<strong>24</strong>080 0,676 Hook Strap HB <strong>24</strong>-140/160, galv.<br />

For fixing <strong>GT</strong> <strong>24</strong> girders to Steel Waler SRZ and<br />

SRU Profile U140 - U160.<br />

M 8x70<br />

172 (U 140) 82<br />

182 (U 160)<br />

071218<br />

0<strong>24</strong>140<br />

710<strong>24</strong>0<br />

0<strong>24</strong>090<br />

0,000<br />

0,033<br />

0,050<br />

0,005<br />

Accessories Hook Straps HB<br />

Screw Change HB, incl. Screws<br />

F.H. Bolt DIN 603 M8 x 70 MU, galv.<br />

F.H. Bolt DIN 603 M8 x 100 MU, galv.<br />

Nut ISO 4032 M 8-8, galv.<br />

0<strong>24</strong>600 0,907 <strong>Girder</strong> Claw HB U100-U120, galv.<br />

For mounting the <strong>GT</strong> <strong>24</strong> edge girder on the Steel<br />

Waler SRZ and SRU Profile U100 - U120.<br />

M 8x100<br />

154<br />

152 (U 100)<br />

162 (U 120)<br />

152<br />

0<strong>24</strong>630 0,742 Fix Strap U100-120, galv.<br />

For fixing the <strong>GT</strong> <strong>24</strong> girder in the <strong>VARIO</strong> corner.<br />

M 8x100<br />

152 (U 100)<br />

162 (U 120)<br />

113<br />

0<strong>24</strong>640 0,923 Quick Str. Hook Strap <strong>24</strong>-100/140, galv.<br />

For fixing <strong>GT</strong> <strong>24</strong> girders to Steel Waler SRZ, SRU,<br />

Profile U100 - U140 outside of the girder nodes.<br />

Safety Instructions<br />

<strong>Girder</strong>s fixed in position <strong>with</strong> the Quick Strap must<br />

be specially screwed to the formlining when using<br />

crane lifting gear.<br />

99<br />

90<br />

56<br />

50