Platinum Belt Design Manual - Jason Industrial

Platinum Belt Design Manual - Jason Industrial

Platinum Belt Design Manual - Jason Industrial

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

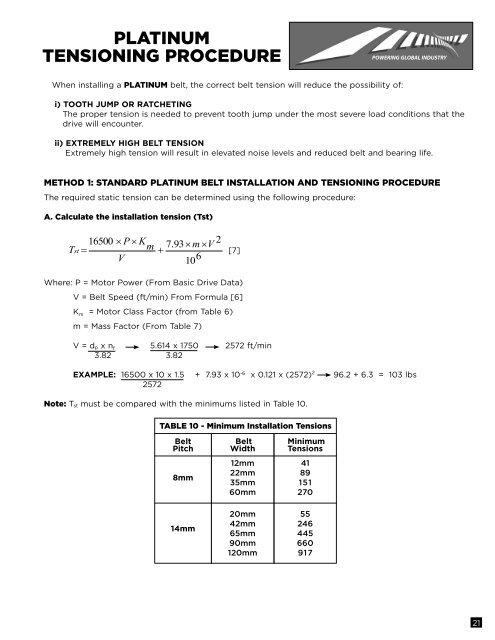

PLATINUM<br />

TENSIONING PROCEDURE<br />

POWERING GLOBAL INDUSTRY<br />

When installing a PLATINUM belt, the correct belt tension will reduce the possibility of:<br />

i) TOOTH JUMP OR RATCHETING<br />

The proper tension is needed to prevent tooth jump under the most severe load conditions that the<br />

drive will encounter.<br />

ii) EXTREMELY HIGH BELT TENSION<br />

Extremely high tension will result in elevated noise levels and reduced belt and bearing life.<br />

METHOD 1: STANDARD PLATINUM BELT INSTALLATION AND TENSIONING PROCEDURE<br />

The required static tension can be determined using the following procedure:<br />

A. Calculate the installation tension (Tst)<br />

Tst<br />

16500 P K 7.93 m V<br />

2<br />

m <br />

<br />

<br />

V<br />

10<br />

6<br />

[7]<br />

Where: P = Motor Power (From Basic Drive Data)<br />

V = <strong>Belt</strong> Speed (ft/min) From Formula [6]<br />

K m = Motor Class Factor (from Table 6)<br />

m = Mass Factor (From Table 7)<br />

V = d p x n f 5.614 x 1750 2572 ft/min<br />

3.82 3.82<br />

EXAMPLE: 16500 x 10 x 1.5 + 7.93 x 10 -6 x 0.121 x (2572) 2 96.2 + 6.3 = 103 lbs<br />

2572<br />

Note: T st must be compared with the minimums listed in Table 10.<br />

TABLE 10 - Minimum Installation Tensions<br />

<strong>Belt</strong><br />

Pitch<br />

8mm<br />

14mm<br />

<strong>Belt</strong><br />

Width<br />

12mm<br />

22mm<br />

35mm<br />

60mm<br />

20mm<br />

42mm<br />

65mm<br />

90mm<br />

120mm<br />

Minimum<br />

Tensions<br />

41<br />

89<br />

151<br />

270<br />

55<br />

246<br />

445<br />

660<br />

917<br />

21