Platinum Belt Design Manual - Jason Industrial

Platinum Belt Design Manual - Jason Industrial

Platinum Belt Design Manual - Jason Industrial

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

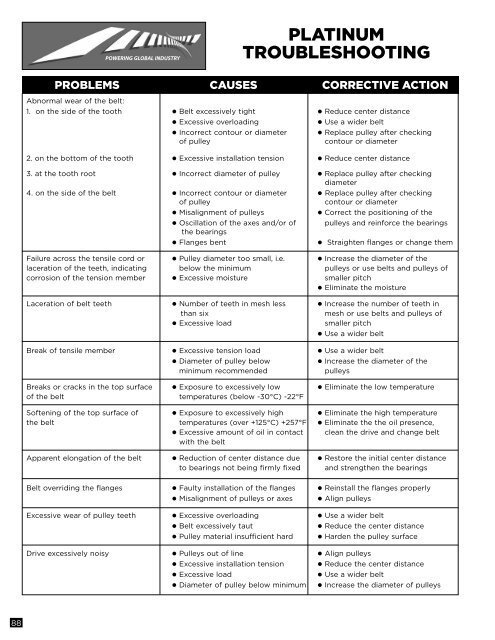

POWERING GLOBAL INDUSTRY<br />

PLATINUM<br />

TROUBLESHOOTING<br />

PROBLEMS CAUSES CORRECTIVE ACTION<br />

Abnormal wear of the belt:<br />

1. on the side of the tooth • <strong>Belt</strong> excessively tight • Reduce center distance<br />

• Excessive overloading<br />

• Use a wider belt<br />

• Incorrect contour or diameter • Replace pulley after checking<br />

of pulley<br />

contour or diameter<br />

2. on the bottom of the tooth • Excessive installation tension • Reduce center distance<br />

3. at the tooth root • Incorrect diameter of pulley • Replace pulley after checking<br />

diameter<br />

4. on the side of the belt • Incorrect contour or diameter • Replace pulley after checking<br />

of pulley<br />

contour or diameter<br />

• Misalignment of pulleys<br />

• Correct the positioning of the<br />

• Oscillation of the axes and/or of pulleys and reinforce the bearings<br />

the bearings<br />

• Flanges bent<br />

• Straighten flanges or change them<br />

Failure across the tensile cord or • Pulley diameter too small, i.e. • Increase the diameter of the<br />

laceration of the teeth, indicating below the minimum pulleys or use belts and pulleys of<br />

corrosion of the tension member • Excessive moisture smaller pitch<br />

• Eliminate the moisture<br />

Laceration of belt teeth • Number of teeth in mesh less • Increase the number of teeth in<br />

than six<br />

mesh or use belts and pulleys of<br />

• Excessive load<br />

smaller pitch<br />

• Use a wider belt<br />

Break of tensile member • Excessive tension load • Use a wider belt<br />

• Diameter of pulley below<br />

• Increase the diameter of the<br />

minimum recommended<br />

pulleys<br />

Breaks or cracks in the top surface • Exposure to excessively low • Eliminate the low temperature<br />

of the belt<br />

temperatures (below -30°C) -22°F<br />

Softening of the top surface of • Exposure to excessively high • Eliminate the high temperature<br />

the belt temperatures (over +125°C) +257°F • Eliminate the the oil presence,<br />

• Excessive amount of oil in contact clean the drive and change belt<br />

with the belt<br />

Apparent elongation of the belt • Reduction of center distance due • Restore the initial center distance<br />

to bearings not being firmly fixed and strengthen the bearings<br />

<strong>Belt</strong> overriding the flanges • Faulty installation of the flanges • Reinstall the flanges properly<br />

• Misalignment of pulleys or axes • Align pulleys<br />

Excessive wear of pulley teeth • Excessive overloading • Use a wider belt<br />

• <strong>Belt</strong> excessively taut<br />

• Reduce the center distance<br />

• Pulley material insufficient hard • Harden the pulley surface<br />

Drive excessively noisy • Pulleys out of line • Align pulleys<br />

• Excessive installation tension<br />

• Reduce the center distance<br />

• Excessive load<br />

• Use a wider belt<br />

• Diameter of pulley below minimum • Increase the diameter of pulleys<br />

88