Platinum Belt Design Manual - Jason Industrial

Platinum Belt Design Manual - Jason Industrial

Platinum Belt Design Manual - Jason Industrial

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

POWERING GLOBAL INDUSTRY<br />

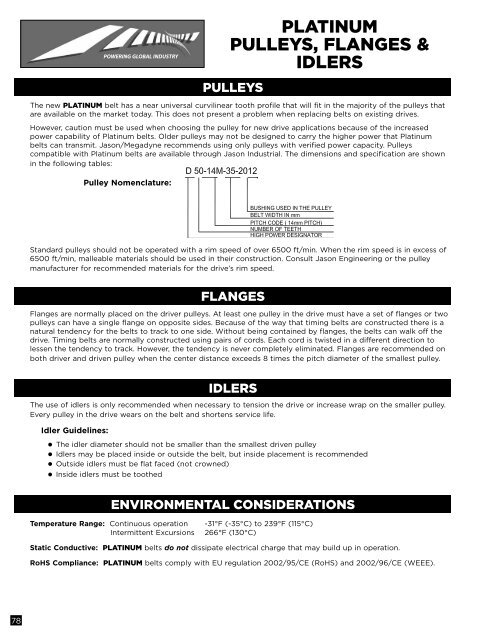

The new PLATINUM belt has a near universal curvilinear tooth profile that will fit in the majority of the pulleys that<br />

are available on the market today. This does not present a problem when replacing belts on existing drives.<br />

However, caution must be used when choosing the pulley for new drive applications because of the increased<br />

power capability of <strong>Platinum</strong> belts. Older pulleys may not be designed to carry the higher power that <strong>Platinum</strong><br />

belts can transmit. <strong>Jason</strong>/Megadyne recommends using only pulleys with verified power capacity. Pulleys<br />

compatible with <strong>Platinum</strong> belts are available through <strong>Jason</strong> <strong>Industrial</strong>. The dimensions and specification are shown<br />

in the following tables:<br />

Pulley Nomenclature:<br />

PLATINUM<br />

PULLEYS, FLANGES &<br />

IDLERS<br />

PULLEYS<br />

Standard pulleys should not be operated with a rim speed of over 6500 ft/min. When the rim speed is in excess of<br />

6500 ft/min, malleable materials should be used in their construction. Consult <strong>Jason</strong> Engineering or the pulley<br />

manufacturer for recommended materials for the drive’s rim speed.<br />

FLANGES<br />

Flanges are normally placed on the driver pulleys. At least one pulley in the drive must have a set of flanges or two<br />

pulleys can have a single flange on opposite sides. Because of the way that timing belts are constructed there is a<br />

natural tendency for the belts to track to one side. Without being contained by flanges, the belts can walk off the<br />

drive. Timing belts are normally constructed using pairs of cords. Each cord is twisted in a different direction to<br />

lessen the tendency to track. However, the tendency is never completely eliminated. Flanges are recommended on<br />

both driver and driven pulley when the center distance exceeds 8 times the pitch diameter of the smallest pulley.<br />

The use of idlers is only recommended when necessary to tension the drive or increase wrap on the smaller pulley.<br />

Every pulley in the drive wears on the belt and shortens service life.<br />

Idler Guidelines:<br />

IDLERS<br />

• The idler diameter should not be smaller than the smallest driven pulley<br />

• Idlers may be placed inside or outside the belt, but inside placement is recommended<br />

• Outside idlers must be flat faced (not crowned)<br />

• Inside idlers must be toothed<br />

ENVIRONMENTAL CONSIDERATIONS<br />

Temperature Range: Continuous operation<br />

Intermittent Excursions<br />

-31°F (-35°C) to 239°F (115°C)<br />

266°F (130°C)<br />

Static Conductive: PLATINUM belts do not dissipate electrical charge that may build up in operation.<br />

RoHS Compliance: PLATINUM belts comply with EU regulation 2002/95/CE (RoHS) and 2002/96/CE (WEEE).<br />

78