Adhesive-Free Lamination Technique using a Plasma Surface ...

Adhesive-Free Lamination Technique using a Plasma Surface ...

Adhesive-Free Lamination Technique using a Plasma Surface ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

3. Results and discussion<br />

The AS of each combination of the films is shown in<br />

table 2. All combinations of untreated films were not<br />

stuck only by the heat-press. While the AS values of the<br />

treated films did not exceed the industrial required values,<br />

they showed hopeful high values.<br />

Fig. 3 shows the treatment time dependence of the AS<br />

of PET/LDPE treated in reactor a). Since this result was<br />

one of the previous study results and PET was pulled in<br />

the 180º peel test, these AS values were bigger than that<br />

of table 2. As shown in Fig. 3, we obtained no clear dependence<br />

of the AS on the treatment time. Thus, we tried<br />

to use the reactor b) which was able to treat the films for a<br />

quite short time.<br />

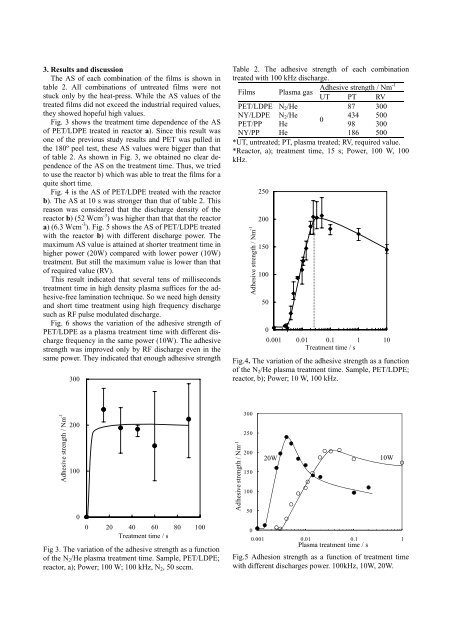

Fig. 4 is the AS of PET/LDPE treated with the reactor<br />

b). The AS at 10 s was stronger than that of table 2. This<br />

reason was considered that the discharge density of the<br />

reactor b) (52 Wcm -3 ) was higher than that that the reactor<br />

a) (6.3 Wcm -3 ). Fig. 5 shows the AS of PET/LDPE treated<br />

with the reactor b) with different discharge power. The<br />

maximum AS value is attained at shorter treatment time in<br />

higher power (20W) compared with lower power (10W)<br />

treatment. But still the maximum value is lower than that<br />

of required value (RV).<br />

This result indicated that several tens of milliseconds<br />

treatment time in high density plasma suffices for the adhesive-free<br />

lamination technique. So we need high density<br />

and short time treatment <strong>using</strong> high frequency discharge<br />

such as RF pulse modulated discharge.<br />

Fig. 6 shows the variation of the adhesive strength of<br />

PET/LDPE as a plasma treatment time with different discharge<br />

frequency in the same power (10W). The adhesive<br />

strength was improved only by RF discharge even in the<br />

same power. They indicated that enough adhesive strength<br />

300<br />

Table 2. The adhesive strength of each combination<br />

treated with 100 kHz discharge.<br />

<strong>Adhesive</strong> strength / Nm -1<br />

Films <strong>Plasma</strong> gas<br />

UT PT RV<br />

PET/LDPE N 2 /He<br />

87 300<br />

NY/LDPE N 2 /He 434 500<br />

0<br />

PET/PP He 98 300<br />

NY/PP He 186 500<br />

*UT, untreated; PT, plasma treated; RV, required value.<br />

*Reactor, a); treatment time, 15 s; Power, 100 W, 100<br />

kHz.<br />

<strong>Adhesive</strong> strength / Nm -1<br />

250<br />

200<br />

150<br />

100<br />

50<br />

0<br />

0.001 0.01 0.1 1 10<br />

Treatment time / s<br />

Fig.4. The variation of the adhesive strength as a function<br />

of the N 2 /He plasma treatment time. Sample, PET/LDPE;<br />

reactor, b); Power; 10 W, 100 kHz.<br />

<strong>Adhesive</strong> strength / Nm -1<br />

200<br />

100<br />

0<br />

0 20 40 60 80 100<br />

Treatment time / s<br />

Fig 3. The variation of the adhesive strength as a function<br />

of the N 2 /He plasma treatment time. Sample, PET/LDPE;<br />

reactor, a); Power; 100 W; 100 kHz, N 2 , 50 sccm.<br />

<strong>Adhesive</strong> strength / Nm -1<br />

300<br />

250<br />

200<br />

150<br />

100<br />

50<br />

0<br />

20W<br />

10W<br />

0.001 0.01 0.1 1<br />

<strong>Plasma</strong> treatment time / s<br />

Fig.5 Adhesion strength as a function of treatment time<br />

with different discharges power. 100kHz, 10W, 20W.