Installation Instructions for Series FD-RD and FDD-RD - NCA ...

Installation Instructions for Series FD-RD and FDD-RD - NCA ...

Installation Instructions for Series FD-RD and FDD-RD - NCA ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

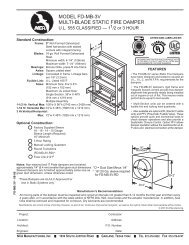

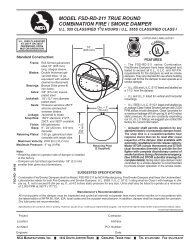

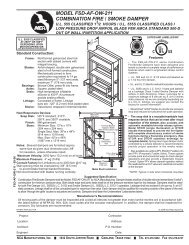

MODEL <strong>FD</strong>-<strong>RD</strong> AND <strong>FD</strong>D-<strong>RD</strong><br />

FIRE DAMPER<br />

INSTALLATION INSTRUCTIONS<br />

C<br />

CLASSIFIED<br />

U L R<br />

US<br />

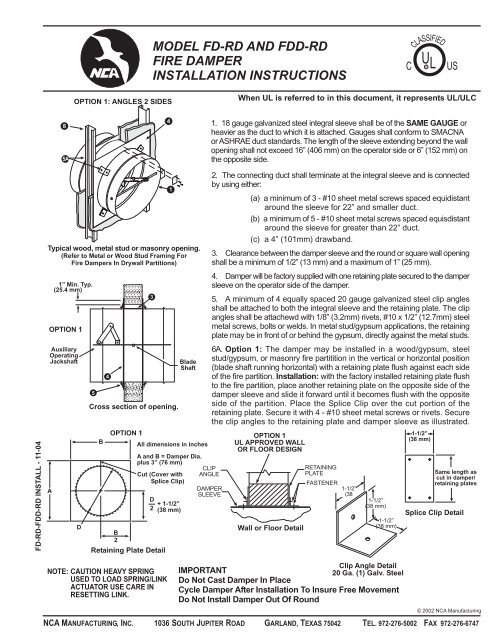

OPTION 1: ANGLES 2 SIDES<br />

When UL is referred to in this document, it represents UL/ULC<br />

8<br />

5A<br />

4<br />

1. 18 gauge galvanized steel integral sleeve shall be of the SAME GAUGE or<br />

heavier as the duct to which it is attached. Gauges shall con<strong>for</strong>m to SMACNA<br />

or ASHRAE duct st<strong>and</strong>ards. The length of the sleeve extending beyond the wall<br />

opening shall not exceed 16” (406 mm) on the operator side or 6” (152 mm) on<br />

the opposite side.<br />

<strong>FD</strong>-<strong>RD</strong>-<strong>FD</strong>D-<strong>RD</strong> INSTALL - 11-04<br />

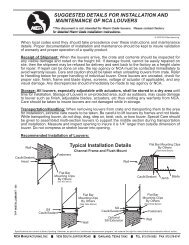

Typical wood, metal stud or masonry opening.<br />

(Refer to Metal or Wood Stud Framing For<br />

Fire Dampers In Drywall Partitions)<br />

1” Min. Typ.<br />

(25.4 mm)<br />

OPTION 1<br />

Auxiliary<br />

Operating<br />

Jackshaft<br />

A<br />

D<br />

5<br />

4<br />

Cross section of opening.<br />

B<br />

OPTION 1<br />

B<br />

2<br />

3<br />

Cut (Cover with<br />

Splice Clip)<br />

D<br />

2 + 1-1/2”<br />

(38 mm)<br />

Retaining Plate Detail<br />

Blade<br />

Shaft<br />

All dimensions in inches<br />

A <strong>and</strong> B = Damper Dia.<br />

plus 3” (76 mm)<br />

1<br />

CLIP<br />

ANGLE<br />

DAMPER<br />

SLEEVE<br />

2. The connecting duct shall terminate at the integral sleeve <strong>and</strong> is connected<br />

by using either:<br />

(a) a minimum of 3 - #10 sheet metal screws spaced equidistant<br />

around the sleeve <strong>for</strong> 22” <strong>and</strong> smaller duct.<br />

(b) a minimum of 5 - #10 sheet metal screws spaced equisdistant<br />

around the sleeve <strong>for</strong> greater than 22” duct.<br />

(c) a 4” (101mm) drawb<strong>and</strong>.<br />

3. Clearance between the damper sleeve <strong>and</strong> the round or square wall opening<br />

shall be a minimum of 1/2” (13 mm) <strong>and</strong> a maximum of 1” (25 mm).<br />

4. Damper will be factory supplied with one retaining plate secured to the damper<br />

sleeve on the operator side of the damper.<br />

5. A minimum of 4 equally spaced 20 gauge galvanized steel clip angles<br />

shall be attached to both the integral sleeve <strong>and</strong> the retaining plate. The clip<br />

angles shall be attachewd with 1/8” (3.2mm) rivets, #10 x 1/2” (12.7mm) steel<br />

metal screws, bolts or welds. In metal stud/gypsum applications, the retaining<br />

plate may be in front of or behind the gypsum, directly against the metal studs.<br />

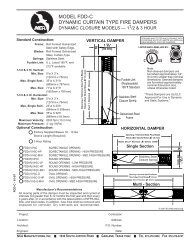

6A. Option 1: The damper may be installed in a wood/gypsum, steel<br />

stud/gypsum, or masonry fire partitition in the vertical or horizontal position<br />

(blade shaft running horizontal) with a retaining plate flush against each side<br />

of the fire partition. <strong>Installation</strong>: with the factory installed retaining plate flush<br />

to the fire partition, place another retaining plate on the opposite side of the<br />

damper sleeve <strong>and</strong> slide it <strong>for</strong>ward until it becomes flush with the opposite<br />

side of the partition. Place the Splice Clip over the cut portion of the<br />

retaining plate. Secure it with 4 - #10 sheet metal screws or rivets. Secure<br />

the clip angles to the retaining plate <strong>and</strong> damper sleeve as illustrated.<br />

OPTION 1<br />

UL APPROVED WALL<br />

OR FLOOR DESIGN<br />

Wall or Floor Detail<br />

RETAINING<br />

PLATE<br />

FASTENER<br />

1-1/2”<br />

(38<br />

1-1/2”<br />

(38 mm)<br />

1-1/2”<br />

(38 mm)<br />

1-1/2”<br />

(38 mm)<br />

Same length as<br />

cut in damper/<br />

retaining plates<br />

Splice Clip Detail<br />

NOTE: CAUTION HEAVY SPRING<br />

USED TO LOAD SPRING/LINK<br />

ACTUATOR USE CARE IN<br />

RESETTING LINK.<br />

Clip Angle Detail<br />

IMPORTANT<br />

20 Ga. (1) Galv. Steel<br />

Do Not Cast Damper In Place<br />

Cycle Damper After <strong>Installation</strong> To Insure Free Movement<br />

Do Not Install Damper Out Of Round<br />

© 2002 <strong>NCA</strong> Manufacturing<br />

<strong>NCA</strong> MANUFACTURING, INC. 1036 SOUTH JUPITER ROAD GARLAND, TEXAS 75042 TEL. 972-276-5002 FAX 972-276-6747

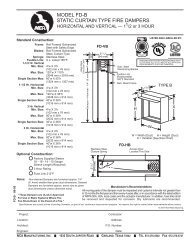

MODEL <strong>FD</strong>-<strong>RD</strong> AND <strong>FD</strong>D-<strong>RD</strong><br />

FIRE DAMPER<br />

INSTALLATION INSTRUCTIONS<br />

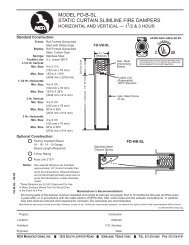

6B. Option 2: The damper may also be installed in a steel stud/gypsum,<br />

or masonry wall, in a vertical position (blade running horizontal), with a<br />

retaining plate on one side of the wall. <strong>Installation</strong>: with the factory installed<br />

retaining plate flush to the fire wall, place 8 screws (#10 sheet metal <strong>for</strong><br />

steel studs long enough to penetrate the metal stud by 1/2” minimum or<br />

#10 x 1-1/4” masonry screws) equidistant around the perimeter of the<br />

retaining plate. Screws are placed in each corner <strong>and</strong> halfway between the<br />

corners as shown.<br />

7. Electrical <strong>and</strong>/or pneumatic connections to damper actuators (if applicable)<br />

should be made in accordance with wiring <strong>and</strong> piping diagrams developed<br />

in compliance with applicable codes, ordinances <strong>and</strong> regulations.<br />

8. Refer to the installation instruction <strong>for</strong> Drywall Type Construction <strong>for</strong> the<br />

material <strong>and</strong> opening framing details.<br />

8<br />

OPTION 2: ANGLE 1 SIDE<br />

4<br />

OPTION 2<br />

Retaining Plate Detail<br />

OPTION 2<br />

STEEL STUD OR MASONRY<br />

WALL UL DESIGN<br />

Cutline on<br />

retaining<br />

plate<br />

(Cover with<br />

Splice Cap)<br />

FASTENER<br />

5<br />

RETAINING<br />

PLATE<br />

1<br />

CLIP ANGLE<br />

FASTENER<br />

DAMPER<br />

SLEEVE<br />

6B<br />

1-1/2”<br />

(38 mm)<br />

Wall Detail<br />

<strong>FD</strong>-<strong>RD</strong>-<strong>FD</strong>D-<strong>RD</strong> INSTALL - 11-04<br />

Typical masonry or metal stud opening.<br />

(Refer to Metal Stud Framing For<br />

Fire Dampers In Drywall Partitions)<br />

1” Min. Typ.<br />

(25.4 mm)<br />

OPTION 2<br />

Auxiliary<br />

Operating<br />

Jackshaft<br />

5<br />

6B<br />

4<br />

Cross section of opening.<br />

3<br />

Blade<br />

Shaft<br />

Same length as<br />

cut in damper/<br />

retaining plates<br />

Splice Clip Detail<br />

1-1/2”<br />

(38 mm)<br />

1-1/2”<br />

(38 mm)<br />

1-1/2”<br />

(38 mm)<br />

Clip Angle Detail<br />

20 Ga. (1) Galv. Steel<br />

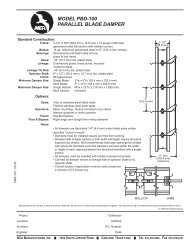

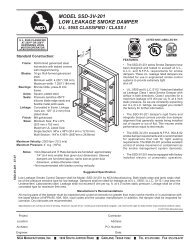

Manufacturer’s Recommendations<br />

All moving parts of the damper must be inspected <strong>and</strong> cycled at intervals not greater than every six months <strong>and</strong> in accordance with<br />

the latest edition of NFPA 90A, 92A, local codes <strong>and</strong> the actuator manufacturer. In addition, fuse links shall be removed <strong>and</strong> inspected<br />

<strong>for</strong> corrosion. Dry lubricants are recommended.<br />

This installation sheet has been reviewed <strong>and</strong> accepted by Underwriters Laboratories.<br />

When UL is referred to in this document, it represents UL/ULC. © 2002 <strong>NCA</strong> Manufacturing<br />

<strong>NCA</strong> MANUFACTURING, INC. 1036 SOUTH JUPITER ROAD GARLAND, TEXAS 75042 TEL. 972-276-5002 FAX 972-276-6747