Bicycle Tyre Range | 2009 - Continental Tyre Group AG

Bicycle Tyre Range | 2009 - Continental Tyre Group AG

Bicycle Tyre Range | 2009 - Continental Tyre Group AG

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

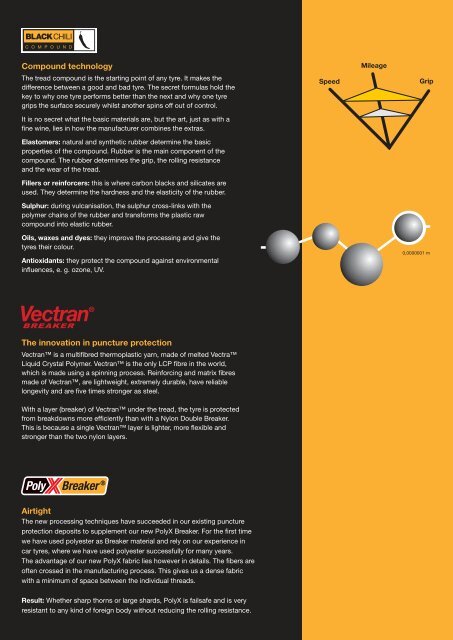

Compound technology<br />

The tread compound is the starting point of any tyre. It makes the<br />

difference between a good and bad tyre. The secret formulas hold the<br />

key to why one tyre performs better than the next and why one tyre<br />

grips the surface securely whilst another spins off out of control.<br />

It is no secret what the basic materials are, but the art, just as with a<br />

fi ne wine, lies in how the manufacturer combines the extras.<br />

Elastomers: natural and synthetic rubber determine the basic<br />

properties of the compound. Rubber is the main component of the<br />

compound. The rubber determines the grip, the rolling resistance<br />

and the wear of the tread.<br />

Fillers or reinforcers: this is where carbon blacks and silicates are<br />

used. They determine the hardness and the elasticity of the rubber.<br />

Sulphur: during vulcanisation, the sulphur cross-links with the<br />

polymer chains of the rubber and transforms the plastic raw<br />

compound into elastic rubber.<br />

Oils, waxes and dyes: they improve the processing and give the<br />

tyres their colour.<br />

Antioxidants: they protect the compound against environmental<br />

infl uences, e. g. ozone, UV.<br />

The innovation in puncture protection<br />

Vectran is a multifi bred thermoplastic yarn, made of melted Vectra<br />

Liquid Crystal Polymer. Vectran is the only LCP fi bre in the world,<br />

which is made using a spinning process. Reinforcing and matrix fi bres<br />

made of Vectran, are lightweight, extremely durable, have reliable<br />

longevity and are fi ve times stronger as steel.<br />

With a layer (breaker) of Vectran under the tread, the tyre is protected<br />

from breakdowns more effi ciently than with a Nylon Double Breaker.<br />

This is because a single Vectran layer is lighter, more fl exible and<br />

stronger than the two nylon layers.<br />

Airtight<br />

The new processing techniques have succeeded in our existing puncture<br />

protection deposits to supplement our new PolyX Breaker. For the fi rst time<br />

we have used polyester as Breaker material and rely on our experience in<br />

car tyres, where we have used polyester successfully for many years.<br />

The advantage of our new PolyX fabric lies however in details. The fi bers are<br />

often crossed in the manufacturing process. This gives us a dense fabric<br />

with a minimum of space between the individual threads.<br />

Result: Whether sharp thorns or large shards, PolyX is failsafe and is very<br />

resistant to any kind of foreign body without reducing the rolling resistance.<br />

Speed<br />

Mileage<br />

Grip<br />

0,0000001 m<br />

53