Cut-off Wheels

Cut-off Wheels

Cut-off Wheels

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

CENTERLESS AND FEED WHEELS<br />

CENTERLESS, CYLINDRICAL & CREEPFEED<br />

SPEC check<br />

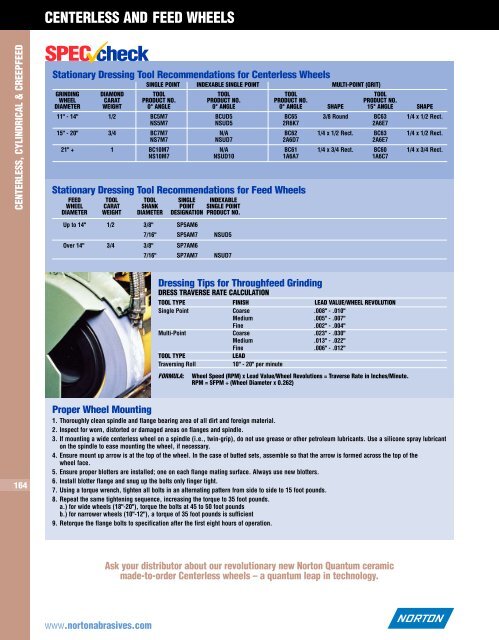

Stationary Dressing Tool Recommendations for Centerless <strong>Wheels</strong><br />

SINGLE POINT INDEXABLE SINGLE POINT MULTI-POINT (GRIT)<br />

GRINDING DIAMOND TOOL TOOL TOOL TOOL<br />

WHEEL CARAT PRODUCT NO. PRODUCT NO. PRODUCT NO. PRODUCT NO.<br />

DIAMETER WEIGHT 0° ANGLE 0° ANGLE 0° ANGLE SHAPE 15° ANGLE SHAPE<br />

11" - 14" 1/2 BC5M7 BCUD5 BC65 3/8 Round BC63 1/4 x 1/2 Rect.<br />

NS5M7 NSUD5 2R6K7 2A6E7<br />

15" - 20" 3/4 BC7M7 N/A BC62 1/4 x 1/2 Rect. BC63 1/4 x 1/2 Rect.<br />

NS7M7 NSUD7 2A6D7 2A6E7<br />

21" + 1 BC10M7 N/A BC61 1/4 x 3/4 Rect. BC60 1/4 x 3/4 Rect.<br />

NS10M7 NSUD10 1A6A7 1A6C7<br />

Stationary Dressing Tool Recommendations for Feed <strong>Wheels</strong><br />

FEED TOOL TOOL SINGLE INDEXABLE<br />

WHEEL CARAT SHANK POINT SINGLE POINT<br />

DIAMETER WEIGHT DIAMETER DESIGNATION PRODUCT NO.<br />

Up to 14" 1/2 3/8" SP5AM6<br />

7/16" SP5AM7 NSUD5<br />

Over 14" 3/4 3/8" SP7AM6<br />

7/16" SP7AM7 NSUD7<br />

Dressing Tips for Throughfeed Grinding<br />

DRESS TRAVERSE RATE CALCULATION<br />

TOOL TYPE FINISH LEAD VALUE/WHEEL REVOLUTION<br />

Single Point Coarse .008" - .010"<br />

Medium .005" - .007"<br />

Fine .002" - .004"<br />

Multi-Point Coarse .023" - .030"<br />

Medium .013" - .022"<br />

Fine .006" - .012"<br />

TOOL TYPE<br />

LEAD<br />

Traversing Roll<br />

10" - 20" per minute<br />

FORMULA:<br />

Wheel Speed (RPM) x Lead Value/Wheel Revolutions = Traverse Rate in Inches/Minute.<br />

RPM = SFPM ÷ (Wheel Diameter x 0.262)<br />

164<br />

Proper Wheel Mounting<br />

1. Thoroughly clean spindle and flange bearing area of all dirt and foreign material.<br />

2. Inspect for worn, distorted or damaged areas on flanges and spindle.<br />

3. If mounting a wide centerless wheel on a spindle (i.e., twin-grip), do not use grease or other petroleum lubricants. Use a silicone spray lubricant<br />

on the spindle to ease mounting the wheel, if necessary.<br />

4. Ensure mount up arrow is at the top of the wheel. In the case of butted sets, assemble so that the arrow is formed across the top of the<br />

wheel face.<br />

5. Ensure proper blotters are installed; one on each flange mating surface. Always use new blotters.<br />

6. Install blotter flange and snug up the bolts only finger tight.<br />

7. Using a torque wrench, tighten all bolts in an alternating pattern from side to side to 15 foot pounds.<br />

8. Repeat the same tightening sequence, increasing the torque to 35 foot pounds.<br />

a.) for wide wheels (18"-20"), torque the bolts at 45 to 50 foot pounds<br />

b.) for narrower wheels (10"-12"), a torque of 35 foot pounds is sufficient<br />

9. Retorque the flange bolts to specification after the first eight hours of operation.<br />

Ask your distributor about our revolutionary new Norton Quantum ceramic<br />

made-to-order Centerless wheels – a quantum leap in technology.<br />

www.nortonabrasives.com