Cut-off Wheels

Cut-off Wheels

Cut-off Wheels

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

CYLINDRICAL WHEELS<br />

CENTERLESS, CYLINDRICAL & CREEPFEED<br />

Cylindrical <strong>Wheels</strong> (CONTINUED)<br />

SPEC check<br />

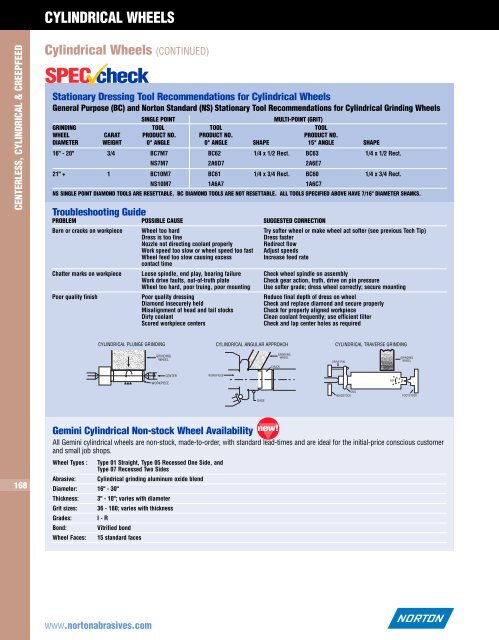

Stationary Dressing Tool Recommendations for Cylindrical <strong>Wheels</strong><br />

General Purpose (BC) and Norton Standard (NS) Stationary Tool Recommendations for Cylindrical Grinding <strong>Wheels</strong><br />

SINGLE POINT<br />

MULTI-POINT (GRIT)<br />

GRINDING TOOL TOOL TOOL<br />

WHEEL CARAT PRODUCT NO. PRODUCT NO. PRODUCT NO.<br />

DIAMETER WEIGHT 0° ANGLE 0° ANGLE SHAPE 15° ANGLE SHAPE<br />

16" - 20" 3/4 BC7M7 BC62 1/4 x 1/2 Rect. BC63 1/4 x 1/2 Rect.<br />

NS7M7 2A6D7 2A6E7<br />

21" + 1 BC10M7 BC61 1/4 x 3/4 Rect. BC60 1/4 x 3/4 Rect.<br />

NS10M7 1A6A7 1A6C7<br />

NS SINGLE POINT DIAMOND TOOLS ARE RESETTABLE. BC DIAMOND TOOLS ARE NOT RESETTABLE. ALL TOOLS SPECIFIED ABOVE HAVE 7/16" DIAMETER SHANKS.<br />

Troubleshooting Guide<br />

PROBLEM POSSIBLE CAUSE SUGGESTED CORRECTION<br />

Burn or cracks on workpiece Wheel too hard Try softer wheel or make wheel act softer (see previous Tech Tip)<br />

Dress is too fine<br />

Dress faster<br />

Nozzle not directing coolant properly Redirect flow<br />

Work speed too slow or wheel speed too fast Adjust speeds<br />

Wheel feed too slow causing excess<br />

Increase feed rate<br />

contact time<br />

Chatter marks on workpiece Loose spindle, end play, bearing failure Check wheel spindle on assembly<br />

Work drive faults, out-of-truth plate<br />

Check gear action, truth, drive on pin pressure<br />

Wheel too hard, poor truing, poor mounting Use softer grade; dress wheel correctly; secure mounting<br />

Poor quality finish Poor quality dressing Reduce final depth of dress on wheel<br />

Diamond insecurely held<br />

Check and replace diamond and secure properly<br />

Misalignment of head and tail stocks Check for properly aligned workpiece<br />

Dirty coolant<br />

Clean coolant frequently; use efficient filter<br />

Scored workpiece centers<br />

Check and lap center holes as required<br />

CYLINDRICAL PLUNGE GRINDING CYLINDRICAL ANGULAR APPROACH CYLINDRICAL TRAVERSE GRINDING<br />

GRINDING<br />

WHEEL<br />

GRINDING<br />

WHEEL<br />

DRIVE PIN<br />

GRINDING<br />

WHEEL<br />

CHUCK<br />

WORKPIECE<br />

CENTER<br />

WORKPIECE<br />

60º<br />

GAGE<br />

DOG<br />

HEADSTOCK<br />

FOOTSTOCK<br />

168<br />

Gemini Cylindrical Non-stock Wheel Availability new!<br />

All Gemini cylindrical wheels are non-stock, made-to-order, with standard lead-times and are ideal for the initial-price conscious customer<br />

and small job shops.<br />

Wheel Types : Type 01 Straight, Type 05 Recessed One Side, and<br />

Type 07 Recessed Two Sides<br />

Abrasive: Cylindrical grinding aluminum oxide blend<br />

Diameter: 16" - 30"<br />

Thickness: 3" - 10"; varies with diameter<br />

Grit sizes: 36 - 180; varies with thickness<br />

Grades: I - R<br />

Bond: Vitrified bond<br />

Wheel Faces: 15 standard faces<br />

www.nortonabrasives.com