Cut-off Wheels

Cut-off Wheels

Cut-off Wheels

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

DRESSING STICKS<br />

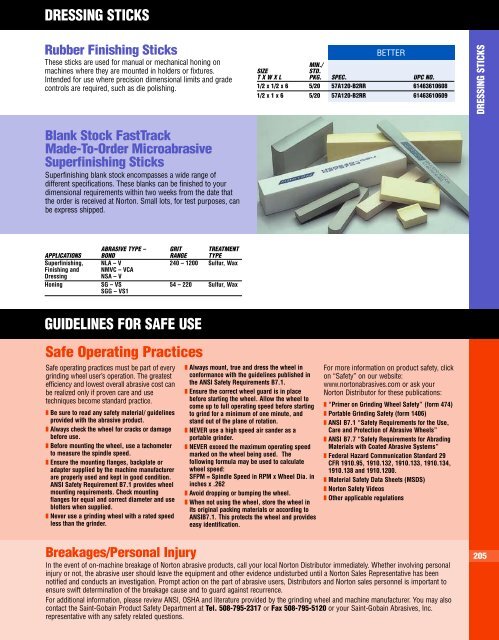

Rubber Finishing Sticks<br />

These sticks are used for manual or mechanical honing on<br />

machines where they are mounted in holders or fixtures.<br />

Intended for use where precision dimensional limits and grade<br />

controls are required, such as die polishing.<br />

BETTER<br />

MIN./<br />

SIZE<br />

STD.<br />

T X W X L PKG. SPEC. UPC NO.<br />

1/2 x 1/2 x 6 5/20 57A120-B2RR 61463610608<br />

1/2 x 1 x 6 5/20 57A120-B2RR 61463610609<br />

DRESSING STICKS<br />

Blank Stock FastTrack<br />

Made-To-Order Microabrasive<br />

Superfinishing Sticks<br />

Superfinishing blank stock encompasses a wide range of<br />

different specifications. These blanks can be finished to your<br />

dimensional requirements within two weeks from the date that<br />

the order is received at Norton. Small lots, for test purposes, can<br />

be express shipped.<br />

ABRASIVE TYPE – GRIT TREATMENT<br />

APPLICATIONS BOND RANGE TYPE<br />

Superfinishing, NLA – V 240 – 1200 Sulfur, Wax<br />

Finishing and NMVC – VCA<br />

Dressing<br />

NSA – V<br />

Honing SG – VS 54 – 220 Sulfur, Wax<br />

SGG – VS1<br />

GUIDELINES FOR SAFE USE<br />

Safe Operating Practices<br />

Safe operating practices must be part of every<br />

grinding wheel user’s operation. The greatest<br />

efficiency and lowest overall abrasive cost can<br />

be realized only if proven care and use<br />

techniques become standard practice.<br />

❚ Be sure to read any safety material/ guidelines<br />

provided with the abrasive product.<br />

❚ Always check the wheel for cracks or damage<br />

before use.<br />

❚ Before mounting the wheel, use a tachometer<br />

to measure the spindle speed.<br />

❚ Ensure the mounting flanges, backplate or<br />

adapter supplied by the machine manufacturer<br />

are properly used and kept in good condition.<br />

ANSI Safety Requirement B7.1 provides wheel<br />

mounting requirements. Check mounting<br />

flanges for equal and correct diameter and use<br />

blotters when supplied.<br />

❚ Never use a grinding wheel with a rated speed<br />

less than the grinder.<br />

❚ Always mount, true and dress the wheel in<br />

conformance with the guidelines published in<br />

the ANSI Safety Requirements B7.1.<br />

❚ Ensure the correct wheel guard is in place<br />

before starting the wheel. Allow the wheel to<br />

come up to full operating speed before starting<br />

to grind for a minimum of one minute, and<br />

stand out of the plane of rotation.<br />

❚ NEVER use a high speed air sander as a<br />

portable grinder.<br />

❚ NEVER exceed the maximum operating speed<br />

marked on the wheel being used. The<br />

following formula may be used to calculate<br />

wheel speed:<br />

SFPM = Spindle Speed in RPM x Wheel Dia. in<br />

inches x .262<br />

❚ Avoid dropping or bumping the wheel.<br />

❚ When not using the wheel, store the wheel in<br />

its original packing materials or according to<br />

ANSIB7.1. This protects the wheel and provides<br />

easy identification.<br />

For more information on product safety, click<br />

on “Safety” on our website:<br />

www.nortonabrasives.com or ask your<br />

Norton Distributor for these publications:<br />

❚ “Primer on Grinding Wheel Safety” (form 474)<br />

❚ Portable Grinding Safety (form 1406)<br />

❚ ANSI B7.1 “Safety Requirements for the Use,<br />

Care and Protection of Abrasive <strong>Wheels</strong>”<br />

❚ ANSI B7.7 “Safety Requirements for Abrading<br />

Materials with Coated Abrasive Systems”<br />

❚ Federal Hazard Communication Standard 29<br />

CFR 1910.95, 1910.132, 1910.133, 1910.134,<br />

1910.138 and 1910.1200.<br />

❚ Material Safety Data Sheets (MSDS)<br />

❚ Norton Safety Videos<br />

❚ Other applicable regulations<br />

Breakages/Personal Injury<br />

In the event of on-machine breakage of Norton abrasive products, call your local Norton Distributor immediately. Whether involving personal<br />

injury or not, the abrasive user should leave the equipment and other evidence undisturbed until a Norton Sales Representative has been<br />

notified and conducts an investigation. Prompt action on the part of abrasive users, Distributors and Norton sales personnel is important to<br />

ensure swift determination of the breakage cause and to guard against recurrence.<br />

For additional information, please review ANSI, OSHA and literature provided by the grinding wheel and machine manufacturer. You may also<br />

contact the Saint-Gobain Product Safety Department at Tel. 508-795-2317 or Fax 508-795-5120 or your Saint-Gobain Abrasives, Inc.<br />

representative with any safety related questions.<br />

205