ex-annex to certificate of conformity - Imtex Controls

ex-annex to certificate of conformity - Imtex Controls

ex-annex to certificate of conformity - Imtex Controls

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

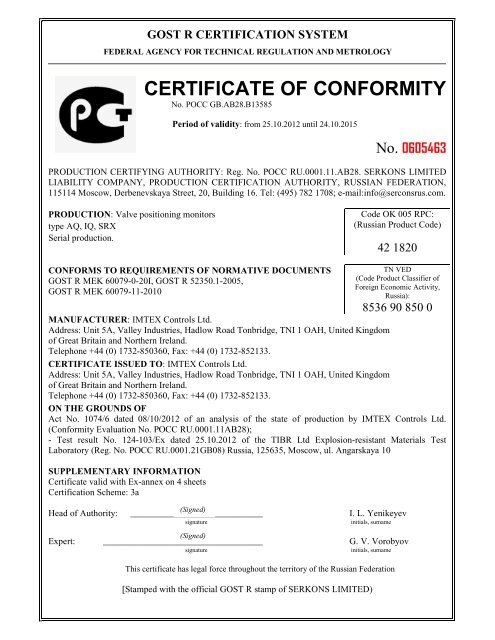

GOST R CERTIFICATION SYSTEM<br />

FEDERAL AGENCY FOR TECHNICAL REGULATION AND METROLOGY<br />

CERTIFICATE OF CONFORMITY<br />

No. POCC GB.AB28.B13585<br />

Period <strong>of</strong> validity: from 25.10.2012 until 24.10.2015<br />

No. 0605463<br />

PRODUCTION CERTIFYING AUTHORITY: Reg. No. POCC RU.0001.11.AB28. SERKONS LIMITED<br />

LIABILITY COMPANY, PRODUCTION CERTIFICATION AUTHORITY, RUSSIAN FEDERATION,<br />

115114 Moscow, Derbenevskaya Street, 20, Building 16. Tel: (495) 782 1708; e-mail:info@serconsrus.com.<br />

PRODUCTION: Valve positioning moni<strong>to</strong>rs<br />

type AQ, IQ, SRX<br />

Serial production.<br />

Code OK 005 RPC:<br />

(Russian Product Code)<br />

42 1820<br />

CONFORMS TO REQUIREMENTS OF NORMATIVE DOCUMENTS<br />

GOST R MEK 60079-0-20I, GOST R 52350.1-2005,<br />

GOST R MEK 60079-11-2010<br />

TN VED<br />

(Code Product Classifier <strong>of</strong><br />

Foreign Economic Activity,<br />

Russia):<br />

8536 90 850 0<br />

MANUFACTURER: IMTEX <strong>Controls</strong> Ltd.<br />

Address: Unit 5А, Valley Industries, Hadlow Road Tonbridge, TNI 1 OAH, United Kingdom<br />

<strong>of</strong> Great Britain and Northern Ireland.<br />

Telephone +44 (0) 1732-850360, Fax: +44 (0) 1732-852133.<br />

CERTIFICATE ISSUED TO: IMTEX <strong>Controls</strong> Ltd.<br />

Address: Unit 5А, Valley Industries, Hadlow Road Tonbridge, TNI 1 OAH, United Kingdom<br />

<strong>of</strong> Great Britain and Northern Ireland.<br />

Telephone +44 (0) 1732-850360, Fax: +44 (0) 1732-852133.<br />

ON THE GROUNDS OF<br />

Act No. 1074/6 dated 08/10/2012 <strong>of</strong> an analysis <strong>of</strong> the state <strong>of</strong> production by IMTEX <strong>Controls</strong> Ltd.<br />

(Conformity Evaluation No. РОСС RU.0001.11АВ28);<br />

- Test result No. 124-103/Ех dated 25.10.2012 <strong>of</strong> the TIBR Ltd Explosion-resistant Materials Test<br />

Labora<strong>to</strong>ry (Reg. No. РОСС RU.0001.21GB08) Russia, 125635, Moscow, ul. Angarskaya 10<br />

SUPPLEMENTARY INFORMATION<br />

Certificate valid with Ex-ann<strong>ex</strong> on 4 sheets<br />

Certification Scheme: 3a<br />

Head <strong>of</strong> Authority:<br />

(Signed)<br />

_____________________________ I. L. Yenikeyev<br />

signature<br />

initials, surname<br />

Expert:<br />

(Signed)<br />

___________________________________ G. V. Vorobyov<br />

signature<br />

initials, surname<br />

This <strong>certificate</strong> has legal force throughout the terri<strong>to</strong>ry <strong>of</strong> the Russian Federation<br />

[Stamped with the <strong>of</strong>ficial GOST R stamp <strong>of</strong> SERKONS LIMITED)

GOST R CERTIFICATION SYSTEM<br />

Compiled in <strong>conformity</strong> with Paragraph 7.10.1 <strong>of</strong> the Rules for the Certification <strong>of</strong> Electrical Equipment for Explosive Environments<br />

Sheet 1 <strong>of</strong> 4<br />

EX-ANNEX TO CERTIFICATE OF CONFORMITY<br />

No. РОСС GB.AB28.B13585<br />

PRODUCTION CERTIFICATION AUTHORITY reg. No. РОСС RU.0001.11АВ28<br />

SERKONS, Limited Liability Company<br />

Russia, 115114, Moscow Derbenevskaya Street, 20, Building 16; Telephone: (495) 782-17-08; Fax: (495) 775-76-60<br />

1 Moni<strong>to</strong>rs for the Positioning <strong>of</strong> Type AQ, IQ and SRX Valves<br />

Code OK 005 (All-Russian Production Code) 42 1820<br />

Russian Foreign Economic Activity Product Classifier Code: 8536 90 850 0<br />

The <strong>ex</strong>plosion protection designation <strong>of</strong> the valve positioning moni<strong>to</strong>rs is presented in Table 1.<br />

2 Manufacturer<br />

IMTEX <strong>Controls</strong> Ltd.<br />

Address: Unit 5, Valley Industries, Hadlow Road, Tonbridge, TNI 1 OAH, United Kingdom<br />

3 Conditions <strong>of</strong> Use<br />

3.1. Moni<strong>to</strong>rs for the positioning <strong>of</strong> type AQ, IQ and SRX valves should be used in <strong>conformity</strong><br />

with the appropriate <strong>ex</strong>plosion protection designation, with the requirements <strong>of</strong> Russian Standard<br />

GOST R 52350.14-2006, with the current Rules for the Installation <strong>of</strong> Electrical Equipment<br />

(Chapter 7.3), the Rules for the Technical Operation <strong>of</strong> Electrical Installations (Chapter 3.4), with<br />

other normative documents such as govern the use <strong>of</strong> electrical equipment in zones where there is<br />

threat <strong>of</strong> <strong>ex</strong>plosion, and with the manufacturer's operating instructions.<br />

3.2. Potentially <strong>ex</strong>plosive zones for the use <strong>of</strong> valve positioning moni<strong>to</strong>rs, categories and groups <strong>of</strong><br />

<strong>ex</strong>plosive gas and steam/air mixtures are in accordance with Russian Standard GOST R 52350.10-<br />

2005 and GOST R 52350.14-2006 and with the Rules for the Installation <strong>of</strong> Electrical Equipment<br />

(Chapter 7.3.)<br />

3.3. Equipment <strong>to</strong> be linked in<strong>to</strong> Exia type AQ and SRX valve positioning moni<strong>to</strong>r circuits should<br />

have intrinsically safe electric circuits that conform <strong>to</strong> GOST R (Electrical Correlation Method)<br />

60079.11-2010, with their intrinsically safe parameters (level <strong>of</strong> intrinsic safety in an electric<br />

circuit and electrical equipment subgroup) should conform <strong>to</strong> the conditions <strong>of</strong> use.<br />

3.4. Valve position moni<strong>to</strong>rs that have <strong>ex</strong>plosion protection Exd in view should be operated with<br />

cable inputs and termina<strong>to</strong>rs that ensure the appropriate viewability and level <strong>of</strong> hazard protection<br />

degree <strong>of</strong> housing protection in <strong>conformity</strong> with GOST 14254-96.<br />

3.5. The introduction <strong>of</strong> any alterations in<strong>to</strong> the construction <strong>of</strong> type AQ, IQ and SRX valve<br />

moni<strong>to</strong>rs that impact upon their means <strong>of</strong> hazard protection must be approved by the appropriate<br />

test organisation.<br />

Head <strong>of</strong> Authority:<br />

(Signed)<br />

_____________________________ I. L. Yenikeyev<br />

signature<br />

initials, surname<br />

Expert:<br />

(Signed)<br />

___________________________________ G. V. Vorobyov<br />

signature<br />

initials, surname<br />

This <strong>certificate</strong> has legal force throughout the terri<strong>to</strong>ry <strong>of</strong> the Russian Federation

[Stamped with the <strong>of</strong>ficial GOST R stamp <strong>of</strong> SERKONS LIMITED)<br />

GOST R CERTIFICATION SYSTEM<br />

Compiled in <strong>conformity</strong> with Paragraph 7.10.1 <strong>of</strong> the Rules for the Certification <strong>of</strong> Electrical Equipment for Explosive Environments<br />

Sheet 2 <strong>of</strong> 4<br />

EX-ANNEX TO CERTIFICATE OF CONFORMITY<br />

No. РОСС GB.AB28.B13585<br />

PRODUCTION CERTIFICATION AUTHORITY reg. No. РОСС RU.0001.11АВ28<br />

SERKONS, Limited Liability Company<br />

Russia, 115114, Moscow Derbenevskaya Street, 20, Building 16; Telephone: (495) 782-17-08; Fax: (495) 775-76-60<br />

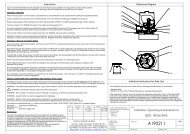

4 Composition, performance and specifications <strong>of</strong> the part<br />

AQ<br />

IQ<br />

This Certificate <strong>of</strong> Conformity applies <strong>to</strong> type AQ, IQ and SRX valve moni<strong>to</strong>rs.<br />

TYPE<br />

AMBIENT AIR<br />

TEMPERATURE (°C)<br />

From -25 <strong>to</strong> +72<br />

From -40 / -55 <strong>to</strong> +60<br />

From -40 / -55 <strong>to</strong> +80<br />

Table 1.<br />

EXPLOSION PROTECTION<br />

DESIGNATION<br />

0Ex ia IIC T6<br />

1Ex d IIC T6<br />

SRX From -40 / -55 <strong>to</strong> +60<br />

0EX ia IC T6<br />

1Ex d IIB T6<br />

5. Purpose and Scope <strong>of</strong> Application<br />

Type AQ, IQ and SRX valve moni<strong>to</strong>rs are designed <strong>to</strong> transform the mechanical motion <strong>of</strong> a valve<br />

in<strong>to</strong> an electric signal and feedback the valve position <strong>to</strong> the mechanism control systems.<br />

These type AQ, IQ and SRX valve moni<strong>to</strong>rs come under Group II <strong>ex</strong>plosion-protected equipment<br />

in accordance with GOST R MEK 60079-0-2011, and are designed for use in hazardous zones in<br />

<strong>conformity</strong> with the appropriate <strong>ex</strong>plosion protection designation.<br />

6. Basic Technical Data<br />

6.1. Explosive mixtures according <strong>to</strong> GOST R 52350.14-2006........................... Categories NA, IV, PS<br />

Groups T1... T3<br />

6.2. Type <strong>of</strong> <strong>ex</strong>plosion protection .............................................................<strong>ex</strong>plosion-resistant casing "d"<br />

intrinsically safe electric circuit <strong>of</strong> level "ia"<br />

6.3. Explosion Protection Designation................................................................................ See Table 1.<br />

6.4. Degree <strong>of</strong> protection from <strong>ex</strong>ternal fac<strong>to</strong>rs as per GOST 14254-96 no less than....................... IP67<br />

6.5. Electric parameters<br />

Supply voltage (V)<br />

AQ – alternating current........................................................................................................15÷28<br />

IQ – alternating current .......................................................................................................30÷125<br />

Head <strong>of</strong> Authority:<br />

(Signed)<br />

_____________________________ I. L. Yenikeyev<br />

signature<br />

initials, surname<br />

Expert:<br />

(Signed)<br />

___________________________________ G. V. Vorobyov<br />

signature<br />

initials, surname<br />

This <strong>certificate</strong> has legal force throughout the terri<strong>to</strong>ry <strong>of</strong> the Russian Federation

[Stamped with the <strong>of</strong>ficial GOST R stamp <strong>of</strong> SERKONS LIMITED)<br />

GOST R CERTIFICATION SYSTEM<br />

Compiled in <strong>conformity</strong> with Paragraph 7.10.1 <strong>of</strong> the Rules for the Certification <strong>of</strong> Electrical Equipment for Explosive Environments<br />

Sheet 3 <strong>of</strong> 4<br />

EX-ANNEX TO CERTIFICATE OF CONFORMITY<br />

No. РОСС GB.AB28.B13585<br />

PRODUCTION CERTIFICATION AUTHORITY reg. No. РОСС RU.0001.11АВ28<br />

SERKONS, Limited Liability Company<br />

Russia, 115114, Moscow Derbenevskaya Street, 20, Building 16; Telephone: (495) 782-17-08; Fax: (495) 775-76-60<br />

IQ – alternating current................................................................................................. 125÷250<br />

SRX – direct current .........................................................................................................10÷30<br />

6.6. Electric shock protection as per GOST 12.2.007.0-75....................................................................Class III<br />

6.7. Ambient temperature, ( o С).......................................................................................................... cf. Table 1<br />

6.8. Dimensions and mass...............................................................cf. manufacturer's technical documentation<br />

Description <strong>of</strong> structural elements and means <strong>of</strong> <strong>ex</strong>plosion protection<br />

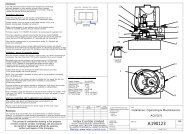

7.1. The positioning moni<strong>to</strong>r consists <strong>of</strong> a casing inside which, depending on the type and<br />

construction, are fitted mechanical switches, inductive gauges, reed switches and transmitters.<br />

The valve positioning moni<strong>to</strong>r is manufactured in a casing with "d" <strong>ex</strong>plosion protection. The casing<br />

may be manufactured from stainless steel or from aluminium. The casing is closed by means <strong>of</strong> a<br />

threaded dome-shaped cover and has two threaded holes for the connection <strong>of</strong> cable inputs. The<br />

cover is secured <strong>to</strong> the main body with four M5 x 0.8 stainless steel bolts.<br />

Installed inside the casing are an indica<strong>to</strong>r, a Klemm brake, certified switches and gauges. The<br />

indica<strong>to</strong>r is installed in the upper portion <strong>of</strong> the casing and <strong>of</strong>fers a visual indication <strong>of</strong> the position <strong>of</strong><br />

the shaft. Connection <strong>of</strong> the leads is effected through the Klemm brake that is mounted in the casing.<br />

The valve positioning moni<strong>to</strong>rs has a degree <strong>of</strong> protection conforming <strong>to</strong> IP67 as per GOST14254-96.<br />

7.2. Explosion protection <strong>of</strong> the AQ and SRX valve positioning moni<strong>to</strong>r is by means <strong>of</strong> an<br />

intrinsically safe electric circuit <strong>of</strong> level "ia" that is maintained by the following means.<br />

7.2.1. The electric load on active and passive elements in intrinsically safe circuits and <strong>ex</strong>plosion<br />

protection elements must not <strong>ex</strong>ceed 2/3 <strong>of</strong> nominal readings.<br />

7.2.2. Leakage paths, electrical clearances and dielectric strength and the electrical parameters <strong>of</strong><br />

contact joints meet the requirements <strong>of</strong> GOST R MEK 60079-11-2010.<br />

7.2.3. The electrical parameters <strong>of</strong> intrinsically safe circuits meet the requirements for this sub-set <strong>of</strong><br />

electrical equipment. Capacitance and inductance do not <strong>ex</strong>ceed the regulated requirements <strong>of</strong><br />

GOST R MEK 60079-11-2010.<br />

7.3. Explosion protection <strong>of</strong> the AQ and SRX valve positioning moni<strong>to</strong>r is by means <strong>of</strong> an<br />

intrinsically safe <strong>ex</strong>plosion-resistant casing "d" that is maintained by the following means.<br />

7.3.1. Electrical parts are fitted inside an <strong>ex</strong>plosion-resistant sleeve which will withstand the<br />

pressure from an <strong>ex</strong>plosion and inhibit its transmission in<strong>to</strong> the surrounding medium.<br />

7.3.2. The assembly <strong>of</strong> individual parts is by means <strong>of</strong> sealing gaskets.<br />

Head <strong>of</strong> Authority:<br />

(Signed)<br />

_____________________________ I. L. Yenikeyev<br />

signature<br />

initials, surname<br />

Expert:<br />

(Signed)<br />

___________________________________ G. V. Vorobyov<br />

signature<br />

initials, surname<br />

This <strong>certificate</strong> has legal force throughout the terri<strong>to</strong>ry <strong>of</strong> the Russian Federation

[Stamped with the <strong>of</strong>ficial GOST R stamp <strong>of</strong> SERKONS LIMITED)<br />

GOST R CERTIFICATION SYSTEM<br />

Compiled in <strong>conformity</strong> with Paragraph 7.10.1 <strong>of</strong> the Rules for the Certification <strong>of</strong> Electrical Equipment for Explosive Environments<br />

Sheet 4 <strong>of</strong> 4<br />

EX-ANNEX TO CERTIFICATE OF CONFORMITY<br />

No. РОСС GB.AB28.B13585<br />

PRODUCTION CERTIFICATION AUTHORITY reg. No. РОСС RU.0001.11АВ28<br />

SERKONS, Limited Liability Company<br />

Russia, 115114, Moscow Derbenevskaya Street, 20, Building 16; Telephone: (495) 782-17-08; Fax: (495) 775-76-60<br />

7.4. The material used for the casing and the individual parts <strong>of</strong> the valve position moni<strong>to</strong>r, the<br />

strength <strong>of</strong> the sleeve, and the temperature characteristics <strong>of</strong> the materials used, conform <strong>to</strong> the<br />

requirements <strong>of</strong> GOST R 52350.1-2005.<br />

8 Testing Data<br />

The maximum temperature <strong>to</strong> which the valve positioner elements are heated under stipulated<br />

operation conditions does not <strong>ex</strong>ceed the value that correspond <strong>to</strong> temperature class T6 as per<br />

GOST R MEK 6009-0-2011.<br />

The results <strong>of</strong> design verification, testing and compliance <strong>of</strong> <strong>ex</strong>plosion protection parameters<br />

with the requirements <strong>of</strong> GOST R MEK 60079-0-2011, GOST R 52350.1-2005 and GOST R<br />

MEK 60079-11-2010 are listed in test report issued by the TIBR Explosion-resistant Materials<br />

Test Labora<strong>to</strong>ry under No. 124-103/Ex.<br />

The operating instructions for valve positioning moni<strong>to</strong>rs contain the necessary directions<br />

concerning fitting conditions and safe operation.<br />

9 Explosion-resistant labelling<br />

Given the type and level <strong>of</strong> protection, the manufacturer's <strong>ex</strong>plosion-pro<strong>of</strong> markings, the results<br />

<strong>of</strong> inspections and tests carried out in accordance with the requirements <strong>of</strong> GOST R MEK<br />

60079-0-2011, GOST R 52350.1-2005 and GOST R MEK 60079-11-2010, type AQ, IQ and<br />

SRX valve positioning moni<strong>to</strong>rs are assigned the designation <strong>of</strong> <strong>ex</strong>plosion-resistant, as shown in<br />

Table 1.<br />

10 List <strong>of</strong> documents containing details <strong>of</strong> <strong>ex</strong>plosion protection<br />

An Operation and Installation Handbook .................................................................. (no number)<br />

Drawings ...................................................... А190179, А190209, А190210, А190211, А190220<br />

А190223, А190224, А190225, А190226, А190227<br />

А190235, А190236, А190238, А190247<br />

A190120-RUS, A190121-RUS, A190122-RUS, A190123-RUS<br />

TIBR Explosion-resistant Materials Test Labora<strong>to</strong>ry Test Report.........................No. 124-103/Ex<br />

Head <strong>of</strong> Authority:<br />

(Signed)<br />

_____________________________ I. L. Yenikeyev<br />

signature<br />

initials, surname<br />

Expert:<br />

(Signed)<br />

___________________________________ G. V. Vorobyov<br />

signature<br />

initials, surname<br />

This <strong>certificate</strong> has legal force throughout the terri<strong>to</strong>ry <strong>of</strong> the Russian Federation<br />

[Stamped with the <strong>of</strong>ficial GOST R stamp <strong>of</strong> SERKONS LIMITED)