Industrial Product Guide - Nabic

Industrial Product Guide - Nabic

Industrial Product Guide - Nabic

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

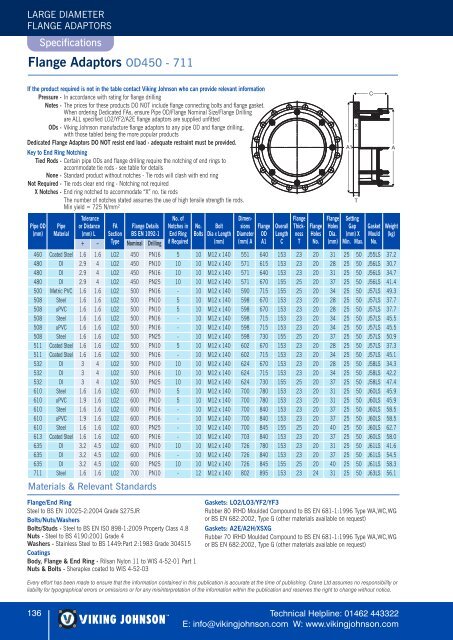

LARGE DIAMETER<br />

FLANGE ADAPTORS<br />

Specifications<br />

Flange Adaptors OD450 - 711<br />

If the product required is not in the table contact Viking Johnson who can provide relevant information<br />

Pressure - In accordance with rating for flange drilling<br />

C<br />

Notes - The prices for these products DO NOT include flange connecting bolts and flange gasket.<br />

When ordering Dedicated FAs, ensure Pipe OD/Flange Nominal Size/Flange Drilling<br />

are ALL specified LO2/YF2/A2E flange adaptors are supplied unfitted<br />

ODs - Viking Johnson manufacture flange adaptors to any pipe OD and flange drilling,<br />

X<br />

with those tabled being the more popular products<br />

Dedicated Flange Adaptors DO NOT resist end load - adequate restraint must be provided.<br />

Key to End Ring Notching<br />

A1<br />

A<br />

Tied Rods - Certain pipe ODs and flange drilling require the notching of end rings to<br />

accommodate tie rods - see table for details<br />

None - Standard product without notches - Tie rods will clash with end ring<br />

Not Required - Tie rods clear end ring - Notching not required<br />

X Notches - End ring notched to accommodate “X” no. tie rods<br />

The number of notches stated assumes the use of high tensile strength tie rods.<br />

T<br />

Min yield = 725 N/mm²<br />

Tolerance No. of Dimen- Flange Flange Setting<br />

Pipe OD Pipe or Distance FA Flange Details Notches in No. Bolt sions Flange Overall Thick- Flange Holes Gap Gasket Weight<br />

(mm) Material (mm) L Section BS EN 1092-1 End Ring Bolts Dia x Length Diameter OD Length ness Holes Dia. (mm) X Mould (kg)<br />

+ – Type Nominal Drilling if Required (mm) (mm) A A1 C T No. (mm) Min. Max. No.<br />

460 Coated Steel 1.6 1.6 LO2 450 PN16 5 10 M12 x 140 551 640 153 23 20 31 25 50 J55LS 37.2<br />

480 DI 2.9 4 LO2 450 PN10 10 10 M12 x 140 571 615 153 23 20 28 25 50 J56LS 30.7<br />

480 DI 2.9 4 LO2 450 PN16 10 10 M12 x 140 571 640 153 23 20 31 25 50 J56LS 34.7<br />

480 DI 2.9 4 LO2 450 PN25 10 10 M12 x 140 571 670 155 25 20 37 25 50 J56LS 41.4<br />

500 Metric PVC 1.6 1.6 LO2 500 PN16 - 10 M12 x 140 590 715 155 25 20 34 25 50 J57LS 49.3<br />

508 Steel 1.6 1.6 LO2 500 PN10 5 10 M12 x 140 598 670 153 23 20 28 25 50 J57LS 37.7<br />

508 uPVC 1.6 1.6 LO2 500 PN10 5 10 M12 x 140 598 670 153 23 20 28 25 50 J57LS 37.7<br />

508 Steel 1.6 1.6 LO2 500 PN16 - 10 M12 x 140 598 715 153 23 20 34 25 50 J57LS 45.5<br />

508 uPVC 1.6 1.6 LO2 500 PN16 - 10 M12 x 140 598 715 153 23 20 34 25 50 J57LS 45.5<br />

508 Steel 1.6 1.6 LO2 500 PN25 - 10 M12 x 140 598 730 155 25 20 37 25 50 J57LS 50.9<br />

511 Coated Steel 1.6 1.6 LO2 500 PN10 5 10 M12 x 140 602 670 153 23 20 28 25 50 J57LS 37.3<br />

511 Coated Steel 1.6 1.6 LO2 500 PN16 - 10 M12 x 140 602 715 153 23 20 34 25 50 J57LS 45.1<br />

532 DI 3 4 LO2 500 PN10 10 10 M12 x 140 624 670 153 23 20 28 25 50 J58LS 34.3<br />

532 DI 3 4 LO2 500 PN16 10 10 M12 x 140 624 715 153 23 20 34 25 50 J58LS 42.2<br />

532 DI 3 4 LO2 500 PN25 10 10 M12 x 140 624 730 155 25 20 37 25 50 J58LS 47.4<br />

610 Steel 1.6 1.6 LO2 600 PN10 5 10 M12 x 140 700 780 153 23 20 31 25 50 J60LS 45.9<br />

610 uPVC 1.9 1.6 LO2 600 PN10 5 10 M12 x 140 700 780 153 23 20 31 25 50 J60LS 45.9<br />

610 Steel 1.6 1.6 LO2 600 PN16 - 10 M12 x 140 700 840 153 23 20 37 25 50 J60LS 58.5<br />

610 uPVC 1.9 1.6 LO2 600 PN16 - 10 M12 x 140 700 840 153 23 20 37 25 50 J60LS 58.5<br />

610 Steel 1.6 1.6 LO2 600 PN25 - 10 M12 x 140 700 845 155 25 20 40 25 50 J60LS 62.7<br />

613 Coated Steel 1.6 1.6 LO2 600 PN16 - 10 M12 x 140 703 840 153 23 20 37 25 50 J60LS 58.0<br />

635 DI 3.2 4.5 LO2 600 PN10 10 10 M12 x 140 726 780 153 23 20 31 25 50 J61LS 41.6<br />

635 DI 3.2 4.5 LO2 600 PN16 - 10 M12 x 140 726 840 153 23 20 37 25 50 J61LS 54.5<br />

635 DI 3.2 4.5 LO2 600 PN25 10 10 M12 x 140 726 845 155 25 20 40 25 50 J61LS 58.3<br />

711 Steel 1.6 1.6 LO2 700 PN10 - 12 M12 x 140 802 895 153 23 24 31 25 50 J63LS 56.1<br />

Materials & Relevant Standards<br />

Flange/End Ring<br />

Steel to BS EN 10025-2:2004 Grade S275JR<br />

Bolts/Nuts/Washers<br />

Bolts/Studs - Steel to BS EN ISO 898-1:2009 Property Class 4.8<br />

Nuts - Steel to BS 4190:2001 Grade 4<br />

Washers - Stainless Steel to BS 1449:Part 2:1983 Grade 304S15<br />

Coatings<br />

Body, Flange & End Ring - Rilsan Nylon 11 to WIS 4-52-01 Part 1<br />

Nuts & Bolts - Sheraplex coated to WIS 4-52-03<br />

Gaskets: LO2/LO3/YF2/YF3<br />

Rubber 80 IRHD Moulded Compound to BS EN 681-1:1996 Type WA,WC,WG<br />

or BS EN 682:2002, Type G (other materials available on request)<br />

Gaskets: A2E/A2H/XSXG<br />

Rubber 70 IRHD Moulded Compound to BS EN 681-1:1996 Type WA,WC,WG<br />

or BS EN 682:2002, Type G (other materials available on request)<br />

Every effort has been made to ensure that the information contained in this publication is accurate at the time of publishing. Crane Ltd assumes no responsibility or<br />

liability for typographical errors or omissions or for any misinterpretation of the information within the publication and reserves the right to change without notice.<br />

136 Technical Helpline: 01462 443322<br />

E: info@vikingjohnson.com W: www.vikingjohnson.com