Industrial Product Guide - Nabic

Industrial Product Guide - Nabic

Industrial Product Guide - Nabic

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

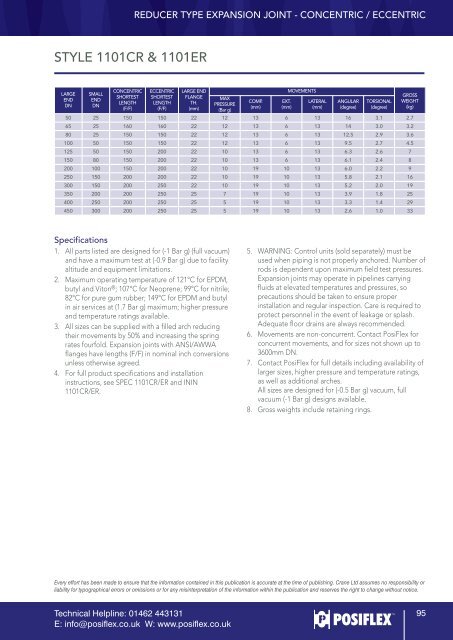

REDUCER TYPE EXPANSION JOINT - CONCENTRIC / ECCENTRIC<br />

STYLE 1101CR & 1101ER<br />

LARGE<br />

END<br />

DN<br />

SMALL<br />

END<br />

DN<br />

CONCENTRIC<br />

SHORTEST<br />

LENGTH<br />

(F/F)<br />

ECCENTRIC<br />

SHORTEST<br />

LENGTH<br />

(F/F)<br />

LARGE END<br />

FLANGE<br />

TH.<br />

(mm)<br />

MAX<br />

PRESSURE<br />

(Bar g)<br />

COMP.<br />

(mm)<br />

EXT.<br />

(mm)<br />

MOVEMENTS<br />

LATERAL<br />

(mm)<br />

ANGULAR<br />

(degree)<br />

TORSIONAL<br />

(degree)<br />

50 25 150 150 22 12 13 6 13 16 3.1 2.7<br />

65 25 160 160 22 12 13 6 13 14 3.0 3.2<br />

80 25 150 150 22 12 13 6 13 12.5 2.9 3.6<br />

100 50 150 150 22 12 13 6 13 9.5 2.7 4.5<br />

125 50 150 200 22 10 13 6 13 6.3 2.6 7<br />

150 80 150 200 22 10 13 6 13 6.1 2.4 8<br />

200 100 150 200 22 10 19 10 13 6.0 2.2 9<br />

250 150 200 200 22 10 19 10 13 5.8 2.1 16<br />

300 150 200 250 22 10 19 10 13 5.2 2.0 19<br />

350 200 200 250 25 7 19 10 13 3.9 1.8 25<br />

400 250 200 250 25 5 19 10 13 3.3 1.4 29<br />

450 300 200 250 25 5 19 10 13 2.6 1.0 33<br />

GROSS<br />

WEIGHT<br />

(kg)<br />

Specifications<br />

1. All parts listed are designed for (-1 Bar g) (full vacuum)<br />

and have a maximum test at (-0.9 Bar g) due to facility<br />

altitude and equipment limitations.<br />

2. Maximum operating temperature of 121°C for EPDM,<br />

butyl and Viton ® ; 107°C for Neoprene; 99°C for nitrile;<br />

82°C for pure gum rubber; 149°C for EPDM and butyl<br />

in air services at (1.7 Bar g) maximum; higher pressure<br />

and temperature ratings available.<br />

3. All sizes can be supplied with a filled arch reducing<br />

their movements by 50% and increasing the spring<br />

rates fourfold. Expansion joints with ANSI/AWWA<br />

flanges have lengths (F/F) in nominal inch conversions<br />

unless otherwise agreed.<br />

4. For full product specifications and installation<br />

instructions, see SPEC 1101CR/ER and ININ<br />

1101CR/ER.<br />

5. WARNING: Control units (sold separately) must be<br />

used when piping is not properly anchored. Number of<br />

rods is dependent upon maximum field test pressures.<br />

Expansion joints may operate in pipelines carrying<br />

fluids at elevated temperatures and pressures, so<br />

precautions should be taken to ensure proper<br />

installation and regular inspection. Care is required to<br />

protect personnel in the event of leakage or splash.<br />

Adequate floor drains are always recommended.<br />

6. Movements are non-concurrent. Contact PosiFlex for<br />

concurrent movements, and for sizes not shown up to<br />

3600mm DN.<br />

7. Contact PosiFlex for full details including availability of<br />

larger sizes, higher pressure and temperature ratings,<br />

as well as additional arches.<br />

All sizes are designed for (-0.5 Bar g) vacuum, full<br />

vacuum (-1 Bar g) designs available.<br />

8. Gross weights include retaining rings.<br />

Every effort has been made to ensure that the information contained in this publication is accurate at the time of publishing. Crane Ltd assumes no responsibility or<br />

liability for typographical errors or omissions or for any misinterpretation of the information within the publication and reserves the right to change without notice.<br />

Technical Helpline: 01462 443131<br />

E: info@posiflex.co.uk W: www.posiflex.co.uk<br />

95