'Sawubona' to Sandile

'Sawubona' to Sandile

'Sawubona' to Sandile

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

A world of opportunities<br />

June 2012<br />

Mee<br />

‘Sawubona’<br />

<strong>to</strong> <strong>Sandile</strong><br />

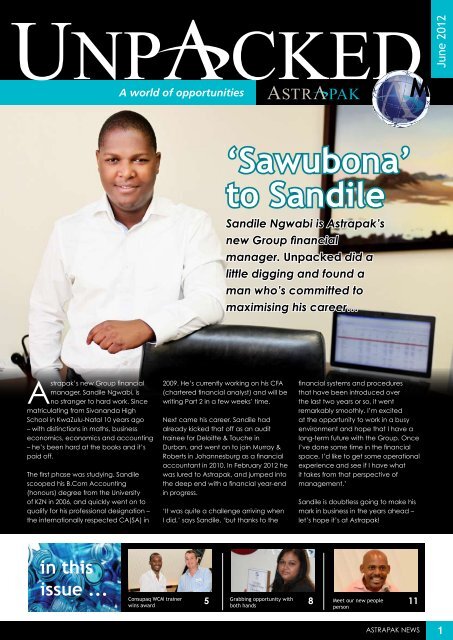

<strong>Sandile</strong> Ngwabi is Astrapak’s<br />

new Group financial<br />

manager. Unpacked did a<br />

little digging and found a<br />

man who’s committed <strong>to</strong><br />

maximising his career…<br />

Astrapak’s new Group financial<br />

manager, <strong>Sandile</strong> Ngwabi, is<br />

no stranger <strong>to</strong> hard work. Since<br />

matriculating from Sivananda High<br />

School in KwaZulu-Natal 10 years ago<br />

– with distinctions in maths, business<br />

economics, economics and accounting<br />

– he’s been hard at the books and it’s<br />

paid off.<br />

The first phase was studying. <strong>Sandile</strong><br />

scooped his B.Com Accounting<br />

(honours) degree from the University<br />

of KZN in 2006, and quickly went on <strong>to</strong><br />

qualify for his professional designation –<br />

the internationally respected CA(SA) in<br />

2009. He’s currently working on his CFA<br />

(chartered financial analyst) and will be<br />

writing Part 2 in a few weeks’ time.<br />

Next came his career. <strong>Sandile</strong> had<br />

already kicked that off as an audit<br />

trainee for Deloitte & Touche in<br />

Durban, and went on <strong>to</strong> join Murray &<br />

Roberts in Johannesburg as a financial<br />

accountant in 2010. In February 2012 he<br />

was lured <strong>to</strong> Astrapak, and jumped in<strong>to</strong><br />

the deep end with a financial year-end<br />

in progress.<br />

‘It was quite a challenge arriving when<br />

I did,’ says <strong>Sandile</strong>, ‘but thanks <strong>to</strong> the<br />

financial systems and procedures<br />

that have been introduced over<br />

the last two years or so, it went<br />

remarkably smoothly. I’m excited<br />

at the opportunity <strong>to</strong> work in a busy<br />

environment and hope that I have a<br />

long-term future with the Group. Once<br />

I’ve done some time in the financial<br />

space, I’d like <strong>to</strong> get some operational<br />

experience and see if I have what<br />

it takes from that perspective of<br />

management.’<br />

<strong>Sandile</strong> is doubtless going <strong>to</strong> make his<br />

mark in business in the years ahead –<br />

let’s hope it’s at Astrapak!<br />

in this<br />

issue ...<br />

Consupaq WCM trainer<br />

wins award<br />

5<br />

Grabbing opportunity with<br />

both hands<br />

8 Meet our new people 11<br />

person<br />

ASTRAPAK NEWS 1

Marco moves in<strong>to</strong> a new role<br />

My term as CEO concluded<br />

at the end of May but I’m<br />

pleased <strong>to</strong> say that I’ll be<br />

continuing in a consultancy role in<strong>to</strong><br />

the future.<br />

The nuts and bolts of running the Group<br />

are now firmly under Manley’s control,<br />

and I wish him well in his new position.<br />

He’s an experienced man who knows<br />

the company well and I know that<br />

he’ll bring much<br />

value and new<br />

energy <strong>to</strong> the<br />

acting chief<br />

executive<br />

position.<br />

The four<br />

years since my<br />

appointment in<br />

June 2008 seem<br />

<strong>to</strong> have gone<br />

by in a flash<br />

and probably<br />

coincided<br />

with one of<br />

the <strong>to</strong>ughest<br />

economic<br />

downturns<br />

this<br />

country<br />

– and<br />

most<br />

of the<br />

developed world – has experienced in<br />

decades.<br />

While it’s been a <strong>to</strong>ugh run and some<br />

difficult decisions had <strong>to</strong> be made, I<br />

do believe that Astrapak is in a good<br />

position <strong>to</strong> take advantage of what<br />

appears <strong>to</strong> be a very slow return <strong>to</strong> a<br />

new kind of ‘normality’ – and I put that<br />

word in inverted commas because I<br />

think normal as we knew it no longer<br />

exists. Business has changed forever.<br />

I’d like <strong>to</strong> express my gratitude <strong>to</strong> the<br />

many people I’ve worked with since<br />

becoming part of Astrapak at its<br />

inception. There’ve been some low<br />

points but they’re far outnumbered by<br />

the highs. I’ve met many people who<br />

have become loyal friends, and there<br />

are loads of memories that will be with<br />

me forever.<br />

I wish everyone a brilliant future with<br />

Astrapak and hope that your career<br />

dreams come true. I think the years<br />

ahead, while challenging at times,<br />

will prove <strong>to</strong> be good for Africa’s best<br />

plastic packaging Group.<br />

Regards<br />

Marco Baglione<br />

June 2012<br />

Astrapak Board<br />

announces<br />

senior<br />

management<br />

changes<br />

Towards the end of<br />

May the Astrapak<br />

Board announced the<br />

movement of Marco<br />

Baglione from chief executive<br />

officer <strong>to</strong> a consultancy position<br />

within the Group. This resulted in<br />

the appointment of chief financial<br />

officer Manley Diedloff as acting<br />

chief executive officer while the<br />

search for a full-time replacement<br />

is completed.<br />

Marco will make his experience<br />

and industry knowledge available<br />

<strong>to</strong> us in his new position, while<br />

Manley’s vast experience at senior<br />

and Board level will benefit the<br />

Group in this interim phase.<br />

2<br />

ASTRAPAK NEWS

Message from the CEO’s office<br />

I’m looking forward <strong>to</strong> the opportunity of<br />

serving as acting CEO <strong>to</strong> the company<br />

and people who’ve become such an<br />

integrated part of my life.<br />

After 15 years with Astrapak, I find it difficult<br />

<strong>to</strong> separate work and ‘normal’ life, but I<br />

wouldn’t have it any other way. To me,<br />

Astrapak has always stayed true <strong>to</strong> its<br />

slogan, ‘A World of Opportunities’, and I<br />

hope that I can play a small part over the<br />

next few months in steering the business<br />

in a direction that will afford the same<br />

opportunities <strong>to</strong> its employees.<br />

I’ve been asked by many <strong>to</strong> advise what<br />

the role of an acting CEO entails. On<br />

a responsibility level, it’s no different <strong>to</strong><br />

that of a permanent CEO and requires<br />

the same degree of commitment. Until<br />

such time as the Board concludes its<br />

search process and makes a permanent<br />

appointment, I will proudly steer the<br />

business <strong>to</strong> the best of my abilities.<br />

potentially those of the company<br />

and its people. It will allow me<br />

<strong>to</strong> engage more broadly with<br />

employees and other stakeholders,<br />

and I hope <strong>to</strong> be successful in the<br />

promotion of the brand and reestablishing<br />

a sense of pride in the<br />

business I treasure so much.<br />

I really appreciate the support<br />

and good wishes I’ve received<br />

from the Board, executive<br />

team and many employees<br />

and ex-employees. Please<br />

rest assured that I will<br />

remain true <strong>to</strong> Astrapak’s<br />

principles and values, and<br />

will continue <strong>to</strong> drive the<br />

business with purpose<br />

and passion.<br />

Regards<br />

I’m looking forward <strong>to</strong> the challenges<br />

and opportunities that the role will bring,<br />

and <strong>to</strong> expanding my own horizons and<br />

Manley Diedloff<br />

June 2012<br />

All about Manley<br />

Manley Diedloff joined Astrapak in 1998 as Group<br />

accountant when there were only five companies<br />

in the Group. He’s held various positions within Astrapak,<br />

including Group financial manager, Group commercial<br />

manager and business development direc<strong>to</strong>r. He was<br />

appointed <strong>to</strong> the Board in 2005, and in December 2008<br />

became Chief Financial Officer.<br />

Manley grew up in Grahams<strong>to</strong>wn. He studied accounting<br />

at the University of Stellenbosch and, once he’d<br />

completed his articles, spent some time overseas<br />

where he worked for HSBC bank as an internal audi<strong>to</strong>r.<br />

On returning <strong>to</strong> South Africa, he joined Grinaker<br />

Construction as an accountant before moving <strong>to</strong><br />

Astrapak.<br />

Manley is married <strong>to</strong> Leigh-Ann, a SuperSport presenter,<br />

and they have three children, Gabriella, Jack and Sam.<br />

Both are avid sportspeople with several marathons and a<br />

Comrades or two under their belts.<br />

ASTRAPAK NEWS 3

The financial year in review<br />

The financial year ending<br />

February 2012 has been<br />

one of the <strong>to</strong>ughest in<br />

Astrapak’s existence,<br />

one that shareholders<br />

aren’t particularly happy<br />

about and one that we<br />

as a Group don’t want <strong>to</strong><br />

repeat.<br />

While turnover was up a<br />

marginal 3.4% <strong>to</strong> R2.518 billion<br />

over the previous year, this<br />

was mainly on the back of increased<br />

selling prices – in fact, volumes through<br />

our plants were down 1.1%.<br />

Increasing production costs – primarily<br />

because of higher raw material, energy<br />

and labour charges – were one of the<br />

main reasons behind an almost 50%<br />

drop in profits. However, I’m pleased<br />

<strong>to</strong> report that costs associated with<br />

selling, administration and distribution<br />

overheads rose a marginal 0.6%, thanks<br />

<strong>to</strong> everyone who did their bit <strong>to</strong> keep<br />

these costs in check.<br />

The main reasons contributing <strong>to</strong><br />

our less-than-satisfac<strong>to</strong>ry financial<br />

performance were:<br />

• A continuing generally soft<br />

economic climate, which kept<br />

consumers under pressure and with<br />

little extra disposable income.<br />

• Decreased volumes in the market,<br />

which kept competitive activity at<br />

fever pitch, with many sacrificing<br />

price just <strong>to</strong> keep their plants<br />

running.<br />

• The industry-wide strikes in July<br />

2011, which affected almost all of<br />

Astrapak’s operations, and those<br />

of many of our cus<strong>to</strong>mers once we<br />

were back at work!<br />

• The supply of raw materials<br />

was problematic, which led <strong>to</strong><br />

s<strong>to</strong>ck-outs and, in some cases,<br />

overs<strong>to</strong>cking at higher prices.<br />

• The decision in the second half of<br />

the year <strong>to</strong> reduce the number of<br />

Flexible operations, which incurred<br />

significant one-off charges through<br />

the early termination of leases,<br />

close-down trading losses and<br />

retrenchment costs. A <strong>to</strong>tal of five<br />

operations have been reduced<br />

in size, merged with others or<br />

discontinued.<br />

• A thorough assessment of all the<br />

Group’s assets was done. The writedown<br />

of some assets affected the<br />

bot<strong>to</strong>m line.<br />

Lower profits, costs associated with<br />

the strategy <strong>to</strong> reduce the Flexibles<br />

footprint, the decision <strong>to</strong> continue with<br />

the R265.9-million capital expenditure<br />

programme and increasing inven<strong>to</strong>ry<br />

levels <strong>to</strong> cope with erratic supply – these<br />

had a real impact on our gearing,<br />

with our net debt increasing <strong>to</strong> R500.3<br />

million from R340.2 million in the previous<br />

year. This situation was aggravated by<br />

cus<strong>to</strong>mers extending payment terms,<br />

and our net working capital increased<br />

by 6.3%, which represents a 50-day net<br />

working capital cycle compared <strong>to</strong><br />

our target of 45 days. We’ll continue<br />

<strong>to</strong> focus on cash generation, prudent<br />

capital allocation, and treasury and<br />

working capital management activities<br />

<strong>to</strong> normalise these aspects over the next<br />

few months.<br />

Looking forward, there appears <strong>to</strong> be<br />

no short-term fix for the bigger issues<br />

facing us: consumers, who’re the<br />

end-users of almost every product we<br />

manufacture, will continue <strong>to</strong> be under<br />

financial pressure over the next year.<br />

Fuel prices are at their highest levels<br />

ever recorded, electricity prices are<br />

about <strong>to</strong> go through their fourth yearon-year<br />

double-digit increase, and food<br />

costs are outstripping published inflation<br />

levels.<br />

Having said that, there are reasons <strong>to</strong><br />

be optimistic.<br />

• We’ve invested heavily in new<br />

technologically advanced<br />

equipment in many operations.<br />

• There are a number of new projects<br />

that should start during this year.<br />

• We’ve reduced our operational<br />

footprint cost base.<br />

• The new equipment should see<br />

increased volumes through fewer<br />

plants at higher efficiency and with<br />

improved quality and reduced<br />

waste.<br />

• Our roll-out of World Class<br />

Manufacturing continues and<br />

real positive results are being<br />

experienced around the Group.<br />

• Transformation, training and staff<br />

development are continuing<br />

priorities as we strive <strong>to</strong> ensure<br />

that our people are suitably<br />

trained and capable of dealing<br />

with an increasingly competitive<br />

marketplace.<br />

It’s been a <strong>to</strong>ugh year and there’ll<br />

be no free rides in the one <strong>to</strong> come.<br />

But the fundamentals are in place.<br />

We need <strong>to</strong> work as a team <strong>to</strong><br />

implement our financial 2013 and<br />

res<strong>to</strong>re Astrapak as the country’s<br />

leading plastic packaging<br />

manufacturer.<br />

4<br />

ASTRAPAK NEWS

Consupaq WCM<br />

trainer wins award<br />

Trust Ndlela, World Class<br />

Manufacturing facilita<strong>to</strong>r and<br />

trainer at Consupaq, was<br />

nominated for an award at this<br />

year’s round of conferences<br />

for his exceptional talent<br />

in communicating WCM<br />

principles <strong>to</strong> all levels of<br />

employees within the business,<br />

specifically <strong>to</strong> shopfloor staff.<br />

He tells Unpacked a bit more<br />

about the challenges.<br />

As part of any World Class<br />

Manufacturing (WCM) journey,<br />

a few people are chosen<br />

<strong>to</strong> become trainers, responsible for<br />

upskilling the shopfloor team. Most of<br />

these new trainers don’t have any prior<br />

training background, so not only do<br />

they need <strong>to</strong> learn all aspects of WCM,<br />

they also have <strong>to</strong> understand how <strong>to</strong><br />

train adults.<br />

Trust Ndlela, WCM trainer and facilita<strong>to</strong>r<br />

at Consupaq, says that there’s a lot<br />

of hard work that goes in<strong>to</strong> it after<br />

hours – preparation of material is a key<br />

element. But that’s just the beginning.<br />

Trust Ndlela receives his award from KZN regional chief executive Gareth Elcox.<br />

a team, self-discipline and drive,’ says<br />

Trust, whose own learning curve was<br />

hands-on, with exposure <strong>to</strong> operations<br />

and production management skills, and<br />

the opportunity <strong>to</strong> learn at first hand<br />

how a successful business operates.<br />

Looking back at the progress Consupaq<br />

has made since implementing WCM<br />

in 2009, Trust says, ‘There’s been a<br />

cultural shift. We challenge each other<br />

<strong>to</strong> think and behave in a way that<br />

reflects our goal of being a worldclass<br />

company. The common vision<br />

environment. The business has grown<br />

and is set <strong>to</strong> grow and become even<br />

more successful.’<br />

Trust’s biggest challenge as a trainer is<br />

‘interacting with people who have little<br />

previous exposure <strong>to</strong> formal training,<br />

and expect little or no benefit from the<br />

training’. The reward? ‘Seeing the same<br />

people having grown in confidence<br />

because they’ve done what they<br />

thought wasn’t possible, which is <strong>to</strong><br />

learn something new that will indeed<br />

benefit them.’<br />

‘A good facilita<strong>to</strong>r must be an inspiring<br />

visionary. He must be able <strong>to</strong> translate<br />

and simplify the vision <strong>to</strong> all in such a<br />

way that learners understand and buy<br />

in<strong>to</strong> it.’ – Trust Ndlela<br />

Good communication skills are vital,<br />

and aspects such as body language<br />

and vocal skills can make or break a<br />

session, he says.<br />

‘The skills required from a facilita<strong>to</strong>r<br />

are good communication skills, good<br />

listening skills, the ability <strong>to</strong> work within<br />

of World Class Manufacturing has<br />

pulled our efforts <strong>to</strong>gether as opposed<br />

<strong>to</strong> previous segmented efforts. That<br />

shared vision is the fundamental<br />

driver of all our endeavours, from the<br />

fac<strong>to</strong>ry <strong>to</strong> operations and through <strong>to</strong><br />

human resources. It’s a cleaner, safer,<br />

more efficient and pleasing work<br />

He believes that the most important<br />

ingredient in being a <strong>to</strong>p trainer is<br />

passion. ‘When a trainer is excited and<br />

passionate about the WCM process, this<br />

enthusiasm comes through in everything<br />

that’s said and done, and this is a surefire<br />

way <strong>to</strong> ignite the same passion in<br />

learners.’<br />

And Trust has clearly been successful.<br />

He earned his award for his exceptional<br />

talent in communicating WCM<br />

principles <strong>to</strong> all levels of employees<br />

within the business, and specifically <strong>to</strong><br />

shopfloor staff, by adapting textbook<br />

knowledge in<strong>to</strong> a format that makes<br />

sense <strong>to</strong> them. The success of his<br />

efforts is clearly evident in the overall<br />

performance by Consupaq in WCM<br />

practices.<br />

ASTRAPAK NEWS<br />

5

Marcom goes large<br />

Marcom Plastics has grown its turnover by<br />

more than 25% per year over the last three<br />

years. This is thanks partly <strong>to</strong> the acquisition<br />

and commissioning of several new projects,<br />

but is also a credit <strong>to</strong> its sales team.<br />

On the production floor, from left: Phillip Koloko<strong>to</strong>, Jaco du Plooy, Braam Cloete and John Shabangu.<br />

Located in Rosslyn, on the northeastern<br />

periphery of Pre<strong>to</strong>ria,<br />

Marcom was established in 1994<br />

<strong>to</strong> manufacture unprinted thinwalled<br />

yoghurt containers for the dairy<br />

industry. But it was the introduction of<br />

in-mould labelling (IML) in 2005, coupled<br />

with an uncompromising commitment<br />

<strong>to</strong> outstanding cus<strong>to</strong>mer service, that<br />

ignited sales, says newly appointed<br />

general manager Gerhard van Reenen.<br />

‘IML represented a huge step forward<br />

in decoration capabilities compared<br />

<strong>to</strong> conventional printing at the time,’<br />

he explains. ‘The ability <strong>to</strong> reproduce<br />

<strong>to</strong> the highest pho<strong>to</strong>graphic quality an<br />

image of fruit on a yoghurt container<br />

was proven <strong>to</strong> be a great stimula<strong>to</strong>r for<br />

consumer demand. In fact, our large<br />

national cus<strong>to</strong>mers experienced a jump<br />

of just less than 10% in sales when they<br />

introduced IML containers, and this<br />

increased <strong>to</strong> more than 50% for many<br />

of our smaller cus<strong>to</strong>mers where the<br />

upgrade was even more marked.’<br />

Marcom has just completed a<br />

multimillion-rand expansion <strong>to</strong> cater<br />

for a huge influx of new business for<br />

Unilever, one of the world’s leading fastmoving<br />

consumer-goods companies.<br />

The conversion of an existing warehouse<br />

in<strong>to</strong> a dedicated production facility and<br />

the installation of new equipment were<br />

completed ahead of schedule, and<br />

the company is now producing huge<br />

volumes of margarine tubs and lids<br />

per day in a variety of sizes – four<br />

months before the original anticipated<br />

start date.<br />

Taking on a client of Unilever’s stature<br />

isn’t for the fainthearted, however.<br />

‘Fortunately, we have an extremely<br />

committed workforce here at Marcom,’<br />

says Gerhard. ‘Everyone has embraced<br />

the challenge and the new production<br />

facility is running well.’<br />

A corners<strong>to</strong>ne of Marcom’s success<br />

has been the way the sales team<br />

has approached its cus<strong>to</strong>mers over<br />

the years. Gerhard explains that they’ve<br />

always attempted <strong>to</strong> understand<br />

their cus<strong>to</strong>mers, the business they<br />

operate in and the challenges they<br />

face on a daily basis. ‘It’s about<br />

listening, asking the right questions<br />

and identifying opportunities where<br />

you can help improve a situation. In a<br />

number of cases we’ve secured the<br />

order not on the basis of our product<br />

price but on how we’ve managed<br />

<strong>to</strong> identify and rectify a problem in<br />

the filling process, even taking out a<br />

cus<strong>to</strong>mer’s machine and modifying it<br />

<strong>to</strong> work faster and with fewer problems.<br />

This creates a sense of faith, where the<br />

relationship changes from a supplier/<br />

cus<strong>to</strong>mer one <strong>to</strong> a partnership where<br />

each party has a vested interest in the<br />

other’s success.’<br />

Marcom’s approach <strong>to</strong> Unilever came<br />

about <strong>to</strong> counter the seasonal nature<br />

of the demand for dairy products,<br />

especially yoghurt. ‘The fact that we<br />

were already doing work for a bluechip<br />

company like Parmalat helped<br />

tremendously when we approached<br />

Unilever,’ says Gerhard. ‘But it was our<br />

ability <strong>to</strong> introduce sophisticated new<br />

multi-cavity moulds that brought our unit<br />

manufacturing cost down considerably<br />

and, <strong>to</strong>gether with great quality, that<br />

eventually secured us the business.’<br />

While acknowledging that securing<br />

the Unilever business was a feather in<br />

Marcom’s cap, Gerhard emphasises<br />

that continuing <strong>to</strong> meet very high<br />

standards is a priority. ‘It takes years <strong>to</strong><br />

build a positive reputation and a few<br />

quick mistakes <strong>to</strong> destroy it,’ he points<br />

out. ‘We’ve earned massive respect in<br />

the marketplace because of the good<br />

work we’ve done, and our priority going<br />

forward is <strong>to</strong> build on that.’<br />

One of the ways Marcom is doing<br />

this is <strong>to</strong> continue involving the entire<br />

workforce. ‘With a team-based<br />

approach, you can achieve anything,’<br />

says Gerhard.<br />

6<br />

ASTRAPAK NEWS

Proud of our people<br />

Marcom’s success is due not least <strong>to</strong><br />

the commitment of its staff, and it’s<br />

notable that almost all the people who<br />

joined at start-up in 1994 are still with the<br />

company.<br />

John Shabangu was looking for casual<br />

work when he was offered a position<br />

as a sweeper in 1994. Two years later,<br />

he was promoted <strong>to</strong> team leader<br />

and he’s subsequently moved <strong>to</strong> the<br />

mould-changing department. ‘It can<br />

be heavy and <strong>to</strong>ugh work,’ he says.<br />

‘The moulds have <strong>to</strong> be treated with<br />

the utmost care and everything has<br />

<strong>to</strong> be in perfect alignment. If I do my<br />

job properly, it enables the machine<br />

opera<strong>to</strong>r <strong>to</strong> work at peak capacity,<br />

ensuring that we meet both quality and<br />

production targets.’<br />

was a small company on a growth<br />

curve and there was no place for<br />

fancy titles or individualism.’ Jaco<br />

recalls the introduction of IML as being<br />

a real challenge. ‘We were the first<br />

company in the country <strong>to</strong> attempt <strong>to</strong><br />

apply 12 labels at once, using a system<br />

that was made up of unmatched<br />

equipment from different suppliers. In<br />

retrospect, we were probably a little<br />

crazy <strong>to</strong> even think about it, but we<br />

managed in the end thanks <strong>to</strong> input<br />

from our international technology<br />

partners Shalom Packaging.’<br />

Technical manager and 12-year<br />

veteran Jaco du Plooy started out<br />

looking after general maintenance.<br />

He’s witnessed tremendous changes<br />

over the years. ‘In the beginning we<br />

all had <strong>to</strong> do everything, because it<br />

Examples of the new margarine tubs manufactured by Marcom Plastics.<br />

Looking <strong>to</strong> the East<br />

The recently acquired Unilever business<br />

entailed commissioning a specialist<br />

Chinese engineering fac<strong>to</strong>ry <strong>to</strong> make<br />

the sophisticated moulds <strong>to</strong> Marcom’s<br />

stringent requirements. Technical<br />

manager Jaco du Plooy visited China<br />

on several occasions in order <strong>to</strong> make<br />

this happen – and it proved <strong>to</strong> be quite<br />

a cultural experience for the ‘boytjie’<br />

from Pre<strong>to</strong>ria!<br />

‘Communicating was a challenge<br />

at first but thanks <strong>to</strong> the assistance<br />

of a transla<strong>to</strong>r we soon established a<br />

method of understanding each other<br />

– some of the more technical terms<br />

proved <strong>to</strong> be problematic, though. Also,<br />

being a ‘‘meat and pota<strong>to</strong>es’’ kind of<br />

guy, the food was an initial obstacle<br />

for me. I learned not <strong>to</strong> venture very<br />

far from the establishments that were<br />

western oriented, as it was often difficult<br />

<strong>to</strong> establish exactly what some of the<br />

items on the menu were!’<br />

Nonetheless, Jaco highly recommends<br />

China as a destination. ‘It’s a<br />

fascinating place with a strong service<br />

culture, work ethic and willingness <strong>to</strong><br />

go the extra mile – nothing was <strong>to</strong>o<br />

much trouble. They’re keen <strong>to</strong> learn,<br />

eager <strong>to</strong> please and not hamstrung by<br />

hierarchy – they just want <strong>to</strong> get the job<br />

done. Once you’ve experienced the<br />

work environment, you can understand<br />

why the Chinese economy is growing at<br />

such a fast rate compared <strong>to</strong> the rest of<br />

the world.’<br />

‘The relationship changes from<br />

a supplier/cus<strong>to</strong>mer one <strong>to</strong> a<br />

partnership where each party has<br />

a vested interest in the other’s<br />

success.’<br />

ASTRAPAK NEWS 7

Grabbing opportunity<br />

with both hands<br />

A short-term transfer proved <strong>to</strong> be the catalyst for Natasha<br />

Benson <strong>to</strong> take her career in a whole new direction.<br />

Natasha Benson was employed<br />

as a personal assistant <strong>to</strong> the<br />

GM when she was temporarily<br />

seconded <strong>to</strong> the internal sales<br />

department. Her boss, Gavin Coppin,<br />

national sales manager, recalls, ‘A<br />

few years ago Plastform was in a<br />

predicament as both of the then<br />

internal salesladies resigned at the same<br />

time. Natasha stepped in and, in spite<br />

of trying times, managed <strong>to</strong> assist our<br />

cus<strong>to</strong>mers by capturing their orders and<br />

arranging deliveries on time.’<br />

The move <strong>to</strong> a cus<strong>to</strong>mer-facing role<br />

suited her personality and it wasn’t long<br />

before she was asked <strong>to</strong> take over the<br />

marketing and public-relations functions<br />

and, more recently, new product<br />

development. ‘I really enjoy dealing<br />

with people, and I think I’m quite good<br />

at it,’ says the self-assured Natasha. ‘I<br />

think I’ve found my niche in this new<br />

role but it hasn’t been easy. I’ve had <strong>to</strong><br />

study along the way <strong>to</strong> prepare myself<br />

for the demands of these important<br />

functions: first I did a PR course, and last<br />

year I completed a one-year diploma<br />

in packaging through the Institute of<br />

Packaging of South Africa.’<br />

New product development is an<br />

important part of Astrapak’s vision<br />

of becoming the country’s leading<br />

supplier of plastic packaging. Existing<br />

or potential clients normally approach<br />

the company requesting some kind of<br />

specialised packaging, and this starts<br />

off an intensive and comprehensive<br />

research process.<br />

All the relevant details of the proposed<br />

container are established, including<br />

size, special properties and machinery.<br />

A search determines if there are any<br />

existing products in the range that might<br />

meet the client’s needs. If not, a study<br />

is conducted in<strong>to</strong> potential volumes<br />

and the cost of new <strong>to</strong>oling, and cost<br />

estimates are developed. If the client is<br />

satisfied with the estimates, pro<strong>to</strong>types<br />

of the new product are made. Once<br />

the cus<strong>to</strong>mer is 100% satisfied that the<br />

concept meets his needs, he signs off<br />

and the production runs commence.<br />

‘The process from concept <strong>to</strong><br />

production can take as little as 8 <strong>to</strong> 12<br />

weeks but it can be quite a lot longer in<br />

some instances,’ says Natasha.<br />

She says that the IPSA diploma has<br />

been an important aspect in preparing<br />

her for her new role. ‘Advising clients<br />

on types of plastic and production<br />

methods can be quite intimidating,<br />

but once you’ve been through the<br />

programme, you’re well equipped <strong>to</strong><br />

deal with almost any query.’<br />

Part of the diploma’s requirements is<br />

the completion of a packaging project,<br />

where the student must develop a new<br />

product from scratch, <strong>to</strong>gether with<br />

a complete report on the need and<br />

marketing rationale, through <strong>to</strong> how it<br />

will be made and from what materials.<br />

Natasha developed a five-portion tray<br />

for instant oats named Good 2 Go!<br />

Uniquely innovative was the inclusion<br />

of disposable spoons – one for each<br />

portion – in the tray. Natasha was<br />

nominated for the Student Gold Pack<br />

National Awards and<br />

won an award for<br />

her report submission.<br />

Natasha is clearly<br />

aiming for even<br />

higher honours:<br />

she’s now<br />

embarked on<br />

a three-year<br />

marketing<br />

diploma<br />

through the<br />

Institute of<br />

Marketing<br />

Management.<br />

‘I’d certainly<br />

encourage<br />

anyone<br />

working in Astrapak <strong>to</strong> take advantage<br />

of the courses on offer,’ she says. ‘The<br />

extra commitment does take some<br />

juggling and there are times when<br />

you’re not sure how you’re going <strong>to</strong><br />

cope with the assignments, but the new<br />

knowledge is something you will have<br />

forever and it enables you <strong>to</strong> become<br />

an even more valuable asset <strong>to</strong> the<br />

company and your clients.’<br />

Says Gavin, ‘Natasha has always<br />

gone the extra mile. She’s wanted <strong>to</strong><br />

understand the whole process, <strong>to</strong> grow<br />

and learn more about packaging.<br />

In spite of a heavy work schedule,<br />

she’s done extremely well in her<br />

courses. Astrapak encourages those<br />

with the aptitude and willingness <strong>to</strong><br />

grow and develop themselves, and<br />

assists by paying for their studies. The<br />

only proviso is that they have <strong>to</strong> work<br />

for the company for two years after<br />

completion of their studies.’<br />

It’s a challenge <strong>to</strong> go back <strong>to</strong> the books but worth<br />

every moment, says Plastform’s Natasha Benson.<br />

8<br />

ASTRAPAK NEWS

Still in play:<br />

Harry Phiri<br />

After three decades in the<br />

business, Harry Phiri has seen<br />

Plastform through several ups and<br />

downs. Now, he says, ‘This industry<br />

has a great future.’<br />

When Man United fan Harry Phiri joined the company in the early 1980s,<br />

his time-clock number was 8. ‘Focus on what you’re doing and the rewards<br />

will come; employees who are diligent get recognised,’ he says.<br />

Harry Phiri is a solid guy: he’s lived<br />

in the same house for 26 years,<br />

been married <strong>to</strong> the same<br />

woman for 28 years and worked at<br />

Plastform for 32 years.<br />

But it didn’t start out all roses. When<br />

Harry first joined Plastform in 1980, he<br />

only lasted a few months: he was fired<br />

for taking the day off <strong>to</strong> commemorate<br />

the 16 June Sowe<strong>to</strong> riots. Fortunately<br />

for everyone, the following year the<br />

managing direc<strong>to</strong>r offered him his job<br />

back and Harry, now forming manager,<br />

hasn’t looked back.<br />

‘I started out as an opera<strong>to</strong>r when the<br />

business was located in Observa<strong>to</strong>ry<br />

and moved through all the departments<br />

– extrusion, forming, printing and<br />

logistics – before settling in forming.<br />

It was a dynamic little business but<br />

the company hit hard times in the<br />

’80s: increasing competition, poor<br />

manufacturing standards and virtually<br />

no quality control nearly saw the<br />

doors close permanently. World Class<br />

Manufacturing wasn’t a phrase that<br />

had even been invented back then.’<br />

He recalls being <strong>to</strong>ld by his manager<br />

at the time: ‘If the container can stand<br />

upright, send it out!’<br />

The company had already outgrown<br />

its Observa<strong>to</strong>ry premises by then, and a<br />

devastating fire that destroyed the plant<br />

proved <strong>to</strong> be a blessing in disguise,<br />

necessitating a move <strong>to</strong> larger premises<br />

in Lansdowne, where it remains <strong>to</strong>day.<br />

Harry has seen technology change<br />

over the years, from four-cavity moulds<br />

performing 8 <strong>to</strong> 10 cycles per minute <strong>to</strong><br />

20 cavity moulds completing 30 cycles<br />

now. Materials have also changed:<br />

the introduction of polyprop in the ’80s<br />

brought a huge number of headaches:<br />

it was a material that they weren’t used<br />

<strong>to</strong> dealing with, there was a lot of waste<br />

and injuries were frequent.<br />

Not only that, but machine setters<br />

retained all the knowledge <strong>to</strong> make<br />

a piece of equipment work at peak<br />

performance in their brain, and without<br />

that person’s input, a machine would<br />

frequently be idle. ‘Previously, machine<br />

opera<strong>to</strong>rs had minimal education<br />

and few responsibilities,’ Harry recalls.<br />

‘Nowadays, all new equipment requires<br />

some sort of computer literacy, and<br />

responsibilities including the writing of<br />

reports and even presentations <strong>to</strong><br />

team members.’<br />

The company went through another<br />

period of instability when Astrapak<br />

first came in<strong>to</strong> the picture but the<br />

implementation of World Class<br />

Manufacturing was the catalyst for<br />

staff at all levels <strong>to</strong> come <strong>to</strong>gether<br />

as a team, with outstanding results.<br />

Investment in new extrusion and<br />

thermoforming equipment has also<br />

contributed <strong>to</strong> staff feeling that there’s<br />

a secure future in the company.<br />

A career highlight for this father of<br />

two was his first trip overseas on an<br />

equipment fact-finding trip that <strong>to</strong>ok the<br />

team on a 14-connecting-flight journey<br />

– quite daunting for someone who’d<br />

never set foot in an aircraft before.<br />

Outside of the office Harry is a soccer<br />

fanatic: a Manchester United fan<br />

since 1977, he’s the chairperson of<br />

the Cape Town branch of the official<br />

Manchester United Supporters Club.<br />

In addition <strong>to</strong> being a rallying point for<br />

fans <strong>to</strong> watch games, the club is also<br />

active in the community, undertaking<br />

fundraising and other upliftment<br />

projects. They recently worked with<br />

the Reach for a Dream Foundation<br />

<strong>to</strong> facilitate a meeting between<br />

a terminally ill child and a visiting<br />

Manchester United player.<br />

After three decades in the business,<br />

Harry has some advice for people<br />

entering the industry: ‘Do your job <strong>to</strong> the<br />

best of your ability, and don’t be scared<br />

<strong>to</strong> take responsibility. Take advantage<br />

of the training opportunities that are<br />

offered. Don’t be discouraged by<br />

obstacles but see them as opportunities<br />

<strong>to</strong> create a new path forward.’<br />

ASTRAPAK NEWS 9

Clearing<br />

the cobwebs<br />

When Marius Murray<br />

turned up for his first<br />

4km time trial, his fellow<br />

athletes stared at him<br />

in disbelief. Eighteen<br />

months later, he’s<br />

hooked on running.<br />

Marcom Plastics’ key account<br />

manager Marius Murray <strong>to</strong>ok<br />

almost half an hour <strong>to</strong> run<br />

his first 4km time trial – not surprisingly,<br />

as he weighed 154kg at the time. But,<br />

with the support of his fellow runners at<br />

Overkruin Athletics Club in Pre<strong>to</strong>ria, he’s<br />

now clocking up at least 70km a month,<br />

in both training and races, and enjoying<br />

the benefits. These include weight loss,<br />

an improved physique and a resting<br />

heart rate that dropped by 30 beats a<br />

minute within just three months. ‘That’s a<br />

mammoth 43 300 beats a day,’ Marius<br />

says. ‘Just imagine the saving on the life<br />

span of my heart!’<br />

And the advantages of being healthy<br />

are coming through in his work life <strong>to</strong>o<br />

– he exceeded his sales target for 12<br />

months in a row in the last financial year,<br />

as well as more than doubling his client<br />

base. ‘I think running really clears the<br />

cobwebs,’ he says.<br />

Although Marius, now 40, was a regular<br />

runner and a keen golfer when he was<br />

younger, he s<strong>to</strong>pped doing sport when<br />

‘life happened’. It was only when he<br />

became fed up with feeling sluggish all<br />

the time as a result of being overweight<br />

that he <strong>to</strong>ok the advice of his brother<br />

– a keen runner with eight Comrades<br />

under his belt – and joined Overkruin<br />

Athletics Club.<br />

Within months he had run his first 5km<br />

race; 10km followed, and by May last<br />

year he was running in 21km races.<br />

‘Doing the Two Oceans half-marathon<br />

was a dream come true,’ he says. ‘To<br />

It’s thumbs-up from Marius Murray at the conclusion of his first Two Oceans earlier<br />

this year.<br />

stand among 17 000 trained hopefuls at<br />

the start was amazing.’<br />

His fellow runners at Overkruin are his<br />

support structure. ‘Having been in sales<br />

all my life, I appreciate the company of<br />

all sorts of people around me – it’s the<br />

spice of life,’ he says. ‘We support each<br />

other, joke around, and most of all share<br />

a passion for sweating hard <strong>to</strong> enjoy<br />

that first cold one after the run.’<br />

Marius wants <strong>to</strong> do a 42.2km run, but<br />

first, he says, he needs <strong>to</strong> lose another<br />

20kg. ‘Then, who knows? Maybe the<br />

Comrades….’<br />

10<br />

ASTRAPAK NEWS

Meet our new people person<br />

Mefane Makhutla is Astrapak’s new Group Human Resources executive.<br />

Unpacked asked him a few questions and discovered a person who’s<br />

passionate about people.<br />

MMefane Makhutla is man with<br />

a calling. ‘From an early age,<br />

I’d play a psychologist role,’<br />

he recalls: ‘people my age and older<br />

would always approach me for some<br />

form of advice or assistance whenever<br />

they encountered personal challenges<br />

in life.’<br />

It’s no surprise, then, that once he’d<br />

matriculated, he pursued a career in<br />

human resources management.<br />

He holds a B.Com (Hons) in HR<br />

Management from the University of<br />

Johannesburg, and has completed<br />

a Management Advancement<br />

Programme and the Executive<br />

Development Programme through<br />

Wits Business School. His career dates<br />

back <strong>to</strong> 1998, when he started working<br />

as a trainee HR consultant at Alpha<br />

(Afrisam); he then joined the National<br />

Treasury as HRD manager, followed by<br />

group employee relations specialist for<br />

Anglo-Platinum and Group HR manager<br />

for Royal Bafokeng Holdings, before<br />

being snapped up by Astrapak.<br />

‘I think our<br />

ultimate<br />

success lies<br />

with our<br />

people.’<br />

Mefane feels strongly that HR<br />

development (HRD) is a corners<strong>to</strong>ne<br />

<strong>to</strong> every organisation. ‘Through HRD,<br />

the organisation is able <strong>to</strong> re-invent<br />

itself in order <strong>to</strong> deliver on its mandate.<br />

Employees are also afforded an<br />

opportunity <strong>to</strong> realise their full potential,<br />

thus meeting their career objectives in<br />

the long term.’<br />

As Astrapak’s HR executive, an<br />

immediate challenge for Mefane is <strong>to</strong><br />

develop a Group HR strategy. ‘I think<br />

Astrapak has got the required capacity<br />

in terms of machinery, systems and<br />

technology,’ he says. ‘We now need<br />

<strong>to</strong> support all these efforts through<br />

strengthening the current human<br />

capital capacity. I think our ultimate<br />

success lies with our people. Everybody<br />

here is willing <strong>to</strong> go the extra mile in<br />

making this company a success; people<br />

are ready <strong>to</strong> embrace the change<br />

required <strong>to</strong> take Astrapak <strong>to</strong> the next<br />

level of performance. They just want <strong>to</strong><br />

be given the right <strong>to</strong>ols in order <strong>to</strong> get<br />

there.’<br />

The challenge is perfect for this man,<br />

who believes that the hurdles in life are<br />

there <strong>to</strong> prepare us ‘<strong>to</strong> tackle every<br />

situation with courage and confidence’.<br />

This extremely busy man uses his<br />

spare time <strong>to</strong> ‘read newspapers and<br />

management journals, and meet friends<br />

and other professionals as a way of<br />

creating and maintaining networks’. He<br />

admits that he does also have some<br />

genuine downtime: ‘I relax by spending<br />

some time at the gym - believe it or not!<br />

- and I sometimes go <strong>to</strong> chisa nyama<br />

<strong>to</strong> have a bit of pap and vleis on a very<br />

quiet Sunday afternoon after enjoying<br />

my moment in church.’<br />

Mefane Makhutla in full cry at the regional conference in Durban.<br />

ASTRAPAK NEWS 11

Front, from left: Tarryn van der Westhuizen, Urissa Naidoo, Dave Tyler,<br />

Anesh Mohanlall, Nils Osberg and Tyrone Nadasen. Middle, from left: Desre<br />

Arthur, Michelle Diamond, Zamani Chonco, Calvin Annandham and Yogan<br />

Ponnusamy. Back, from left: Sifiso Mkize, Veon Chetty and Collin Perumal.<br />

Gareth Elcox hands over the Employee of the Year Award<br />

<strong>to</strong> Paul Nell.<br />

Jason Page receives his award from Gareth Elcox.<br />

Winners one and all<br />

At the Astrapak regional conference in March, five worthy<br />

employees walked off with well-deserved awards.<br />

business is only as strong as its weakest<br />

A employee, and if the accolades<br />

handed out at the regional conference<br />

held in March are anything <strong>to</strong> go by,<br />

Astrapak is very strong indeed.<br />

Paul Nell, Pak 2000’s system administra<strong>to</strong>r<br />

and a key member of the Pak 2000<br />

management team, was recognised<br />

as the Pak 2000 employee of the year.<br />

His understanding and administration<br />

of the Syspro system has been faultless,<br />

and Paul has dedicated many hours of<br />

his own time <strong>to</strong> ensure that it maintains<br />

a high degree of information accuracy.<br />

His efforts have given the Pak 2000 team<br />

the edge in managing itself as a business<br />

and its feedback on critical info <strong>to</strong> our<br />

market base.<br />

Jason Page from Consupaq, who was<br />

recently appointed regional IT manager<br />

for KwaZulu-Natal, received an award for<br />

his exceptional achievement in creating<br />

and designing online <strong>to</strong>ols for the KZN<br />

region, which are now being rolled out<br />

<strong>to</strong> the entire Group.<br />

Jerrald Pillay, who was recently<br />

promoted <strong>to</strong> fac<strong>to</strong>ry manager,<br />

was awarded for his operational<br />

excellence. Jerrald has shown<br />

enormous strides in operations, WCM,<br />

supply chain and overall continued<br />

improvement. He has a dedicated,<br />

hands-on approach <strong>to</strong> problem<br />

solving and getting the job done, and<br />

inspires a good work ethic throughout<br />

the fac<strong>to</strong>ry.<br />

Zamani Chonco and Anesh<br />

Mohanlall, both from Plas<strong>to</strong>p<br />

KZN, won recognition for high levels<br />

of people and operational<br />

management growth, exceptional<br />

cost control, project management<br />

for commissioning one of the country’s<br />

first high-speed shrink-sleeving<br />

production lines in record-breaking<br />

time, displaying the highest level<br />

of commitment <strong>to</strong> their work and<br />

promoting teamwork.<br />

Trust Ndlela, WCM trainer at Consupaq,<br />

earned his award for his exceptional<br />

talent in communicating WCM<br />

principles <strong>to</strong> all levels of employees<br />

within the business. Read more about<br />

Trust on page 5.<br />

12<br />

ASTRAPAK NEWS