steel - Nouvelle page 1 - Free

steel - Nouvelle page 1 - Free

steel - Nouvelle page 1 - Free

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

MMPDS-01<br />

31 January 2003<br />

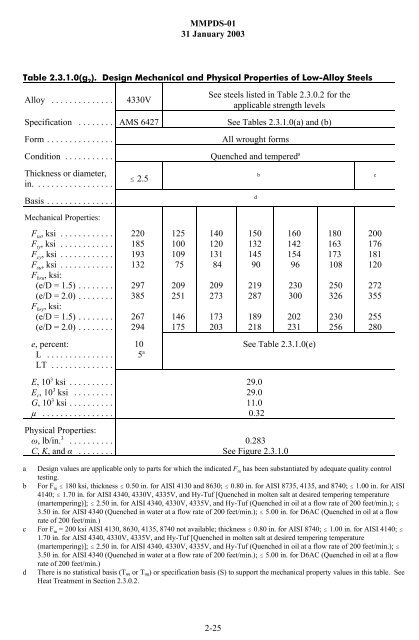

Table 2.3.1.0(g 2 ). Design Mechanical and Physical Properties of Low-Alloy Steels<br />

Alloy ..............<br />

4330V<br />

See <strong>steel</strong>s listed in Table 2.3.0.2 for the<br />

applicable strength levels<br />

Specification ........ AMS 6427 See Tables 2.3.1.0(a) and (b)<br />

Form...............<br />

Condition ...........<br />

Thickness or diameter,<br />

in. .................<br />

Basis...............<br />

# 2.5<br />

All wrought forms<br />

Quenched and tempered a<br />

d<br />

b<br />

c<br />

Mechanical Properties:<br />

F tu , ksi ............<br />

F ty , ksi ............<br />

F cy , ksi ............<br />

F su , ksi ............<br />

F bru , ksi:<br />

(e/D = 1.5)........<br />

(e/D = 2.0)........<br />

F bry , ksi:<br />

(e/D = 1.5)........<br />

(e/D = 2.0)........<br />

220<br />

185<br />

193<br />

132<br />

297<br />

385<br />

267<br />

294<br />

125<br />

100<br />

109<br />

75<br />

209<br />

251<br />

146<br />

175<br />

140<br />

120<br />

131<br />

84<br />

209<br />

273<br />

173<br />

203<br />

150<br />

132<br />

145<br />

90<br />

219<br />

287<br />

189<br />

218<br />

160<br />

142<br />

154<br />

96<br />

230<br />

300<br />

202<br />

231<br />

180<br />

163<br />

173<br />

108<br />

250<br />

326<br />

230<br />

256<br />

200<br />

176<br />

181<br />

120<br />

272<br />

355<br />

255<br />

280<br />

e, percent:<br />

L ...............<br />

LT ..............<br />

10<br />

5 a See Table 2.3.1.0(e)<br />

E, 10 3 ksi ..........<br />

E c , 10 3 ksi .........<br />

G, 10 3 ksi..........<br />

µ ................<br />

29.0<br />

29.0<br />

11.0<br />

0.32<br />

Physical Properties:<br />

ω, lb/in. 3 ..........<br />

C, K, and α ........<br />

0.283<br />

See Figure 2.3.1.0<br />

a Design values are applicable only to parts for which the indicated F tu has been substantiated by adequate quality control<br />

testing.<br />

b For F tu # 180 ksi, thickness # 0.50 in. for AISI 4130 and 8630; # 0.80 in. for AISI 8735, 4135, and 8740; # 1.00 in. for AISI<br />

4140; # 1.70 in. for AISI 4340, 4330V, 4335V, and Hy-Tuf [Quenched in molten salt at desired tempering temperature<br />

(martempering)]; # 2.50 in. for AISI 4340, 4330V, 4335V, and Hy-Tuf (Quenched in oil at a flow rate of 200 feet/min.); #<br />

3.50 in. for AISI 4340 (Quenched in water at a flow rate of 200 feet/min.); # 5.00 in. for D6AC (Quenched in oil at a flow<br />

rate of 200 feet/min.)<br />

c For F tu = 200 ksi AISI 4130, 8630, 4135, 8740 not available; thickness # 0.80 in. for AISI 8740; # 1.00 in. for AISI 4140; #<br />

1.70 in. for AISI 4340, 4330V, 4335V, and Hy-Tuf [Quenched in molten salt at desired tempering temperature<br />

(martempering)]; # 2.50 in. for AISI 4340, 4330V, 4335V, and Hy-Tuf (Quenched in oil at a flow rate of 200 feet/min.); #<br />

3.50 in. for AISI 4340 (Quenched in water at a flow rate of 200 feet/min.); # 5.00 in. for D6AC (Quenched in oil at a flow<br />

rate of 200 feet/min.)<br />

d There is no statistical basis (T 99 or T 90 ) or specification basis (S) to support the mechanical property values in this table. See<br />

Heat Treatment in Section 2.3.0.2.<br />

2-25